Experimental research on mechanical properties of “jacked pipe-frozen soil” composite structure in freeze-sealing pipe roof tunnel

-

摘要:

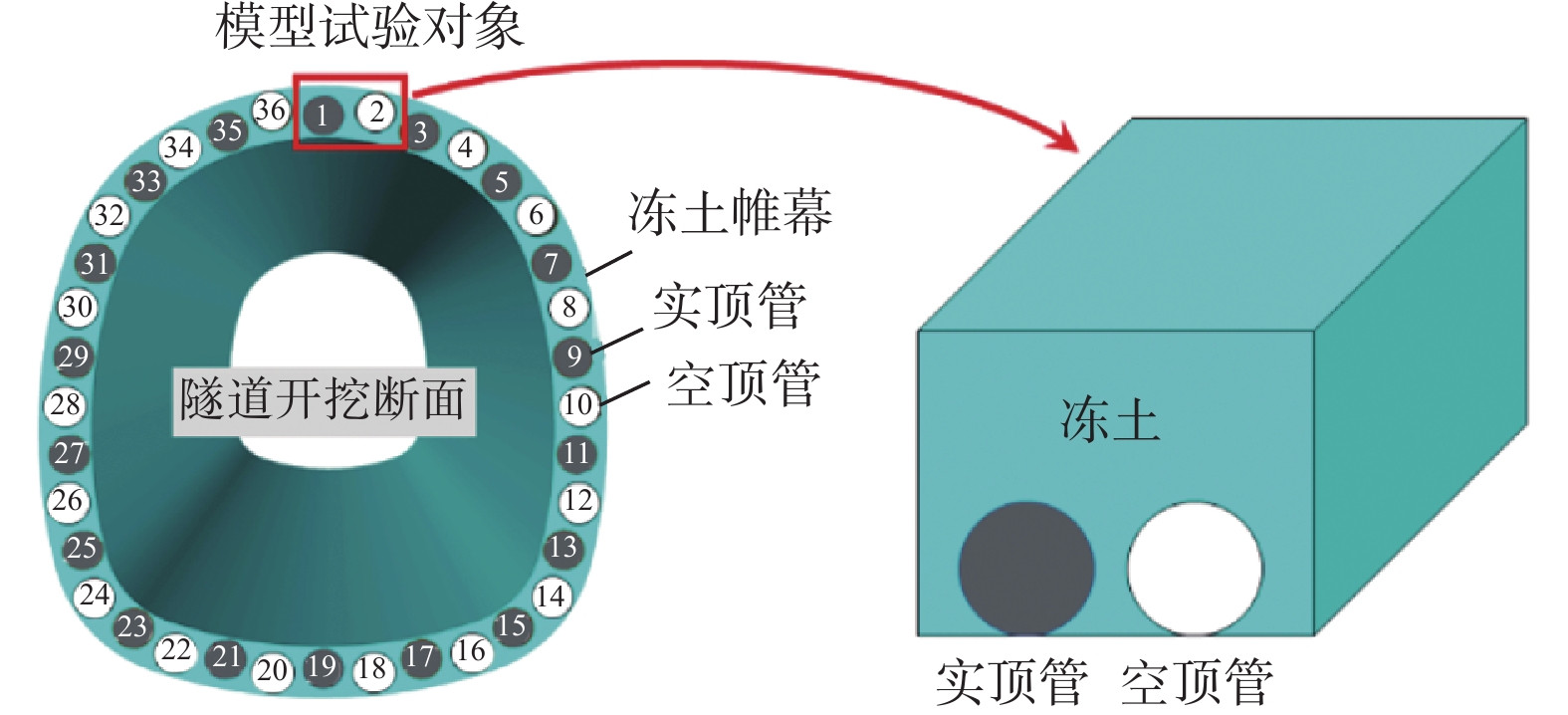

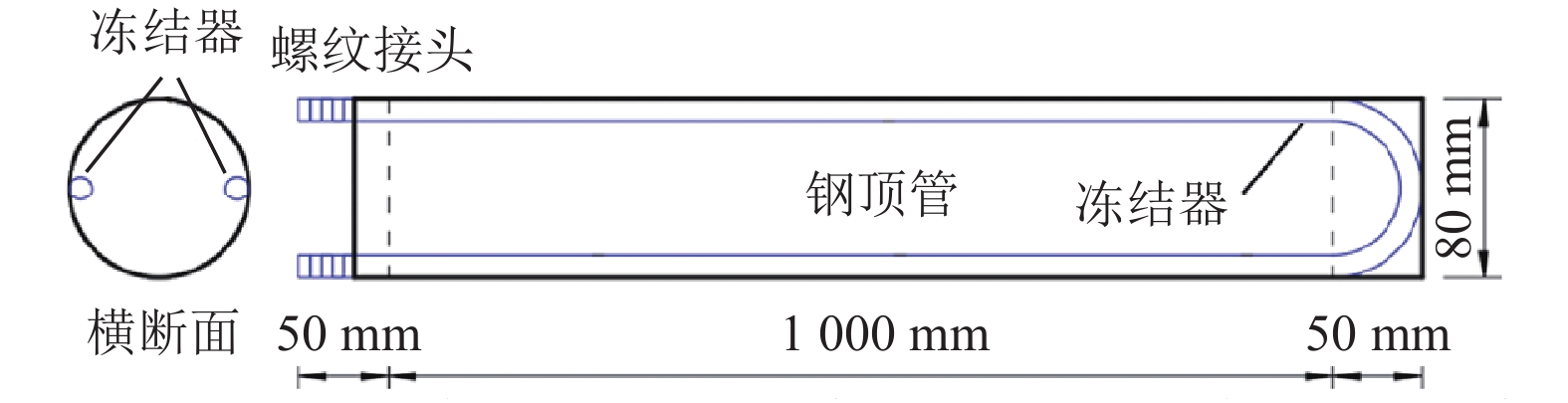

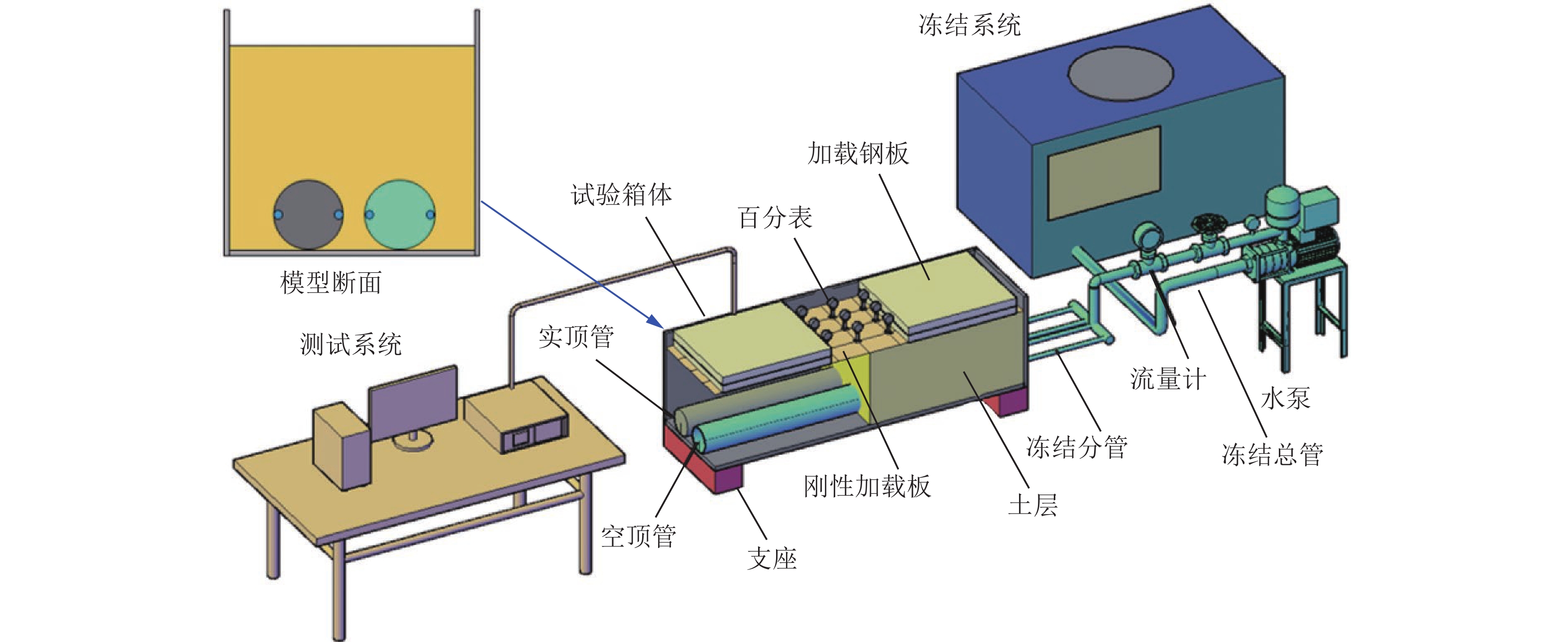

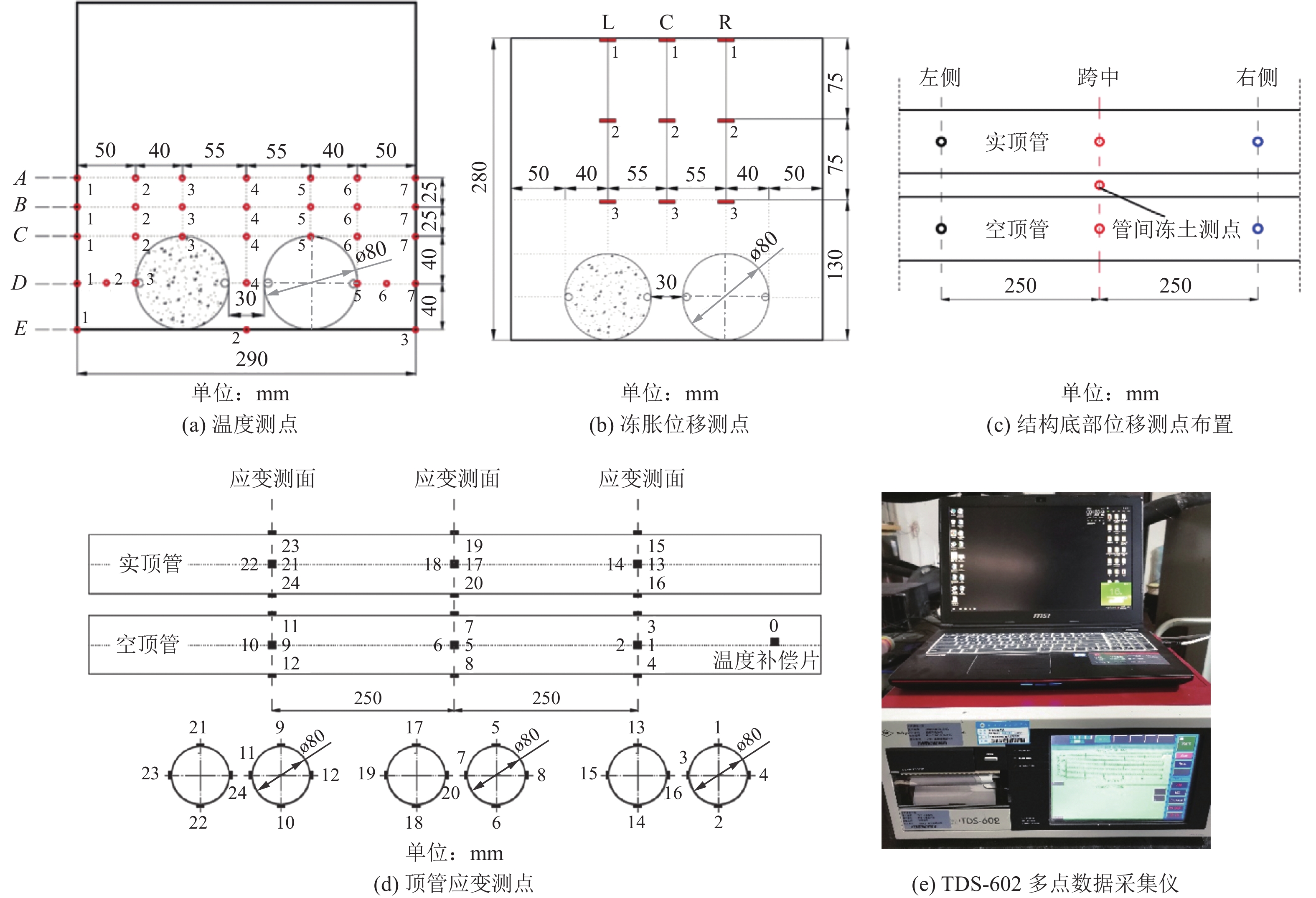

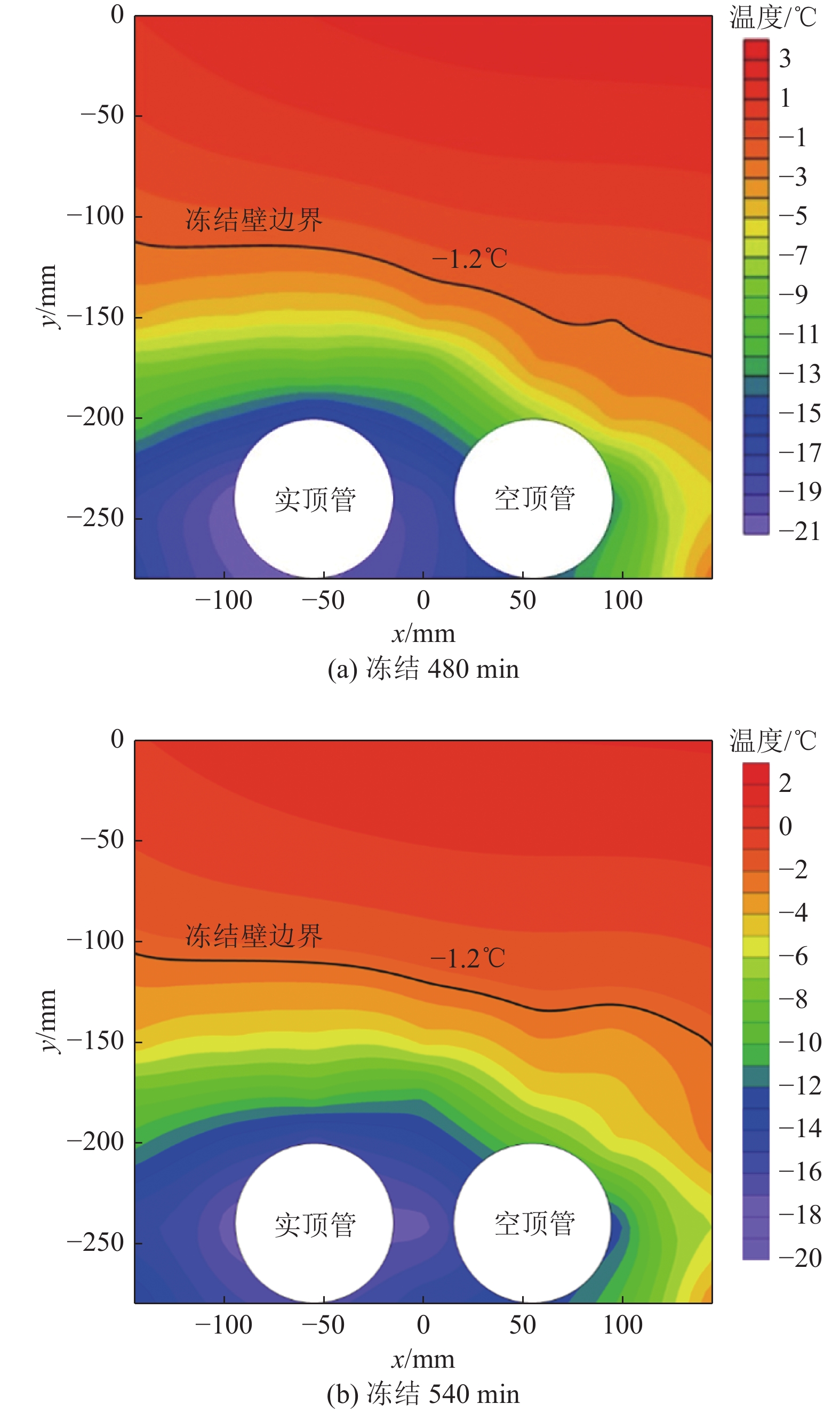

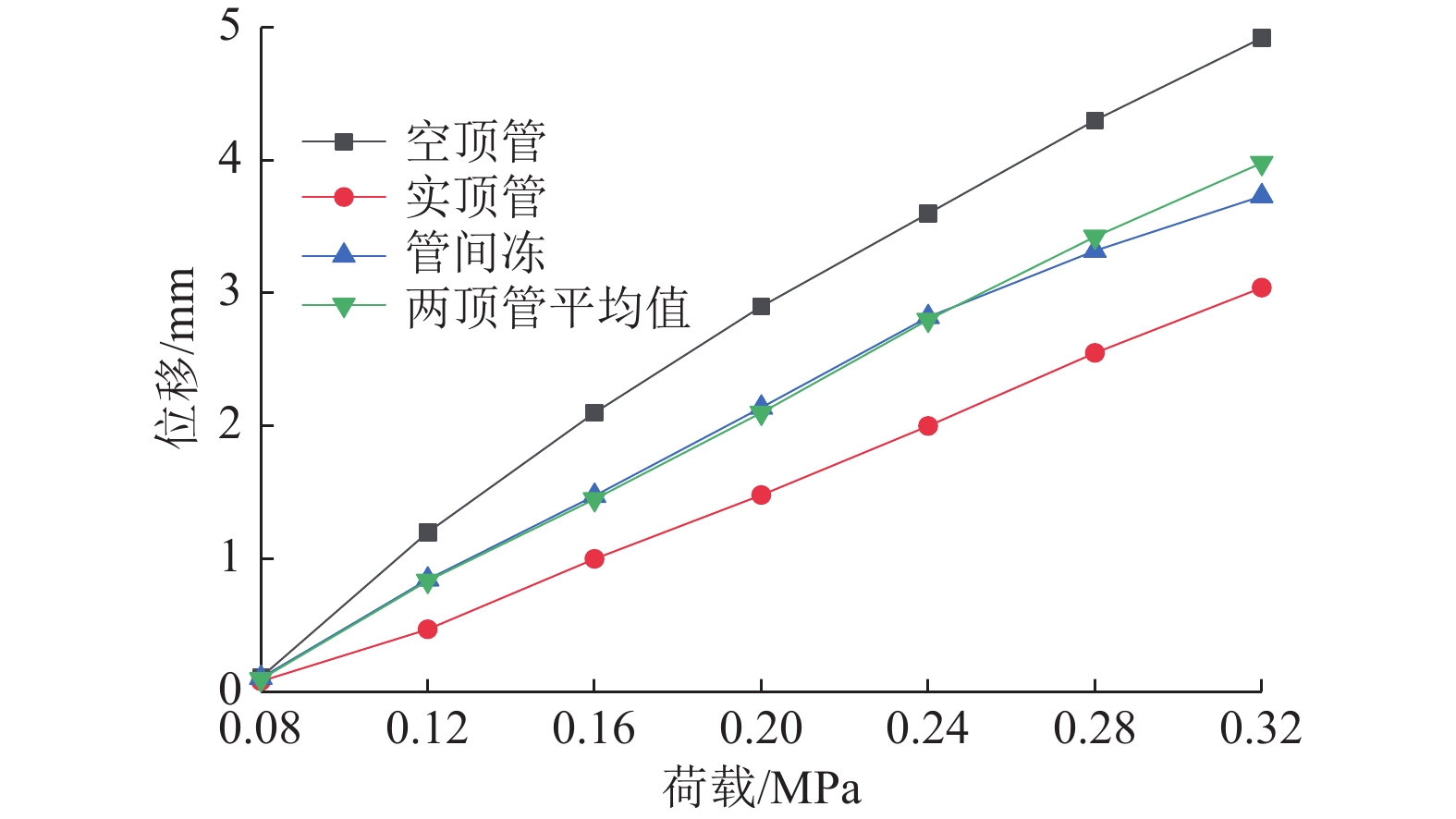

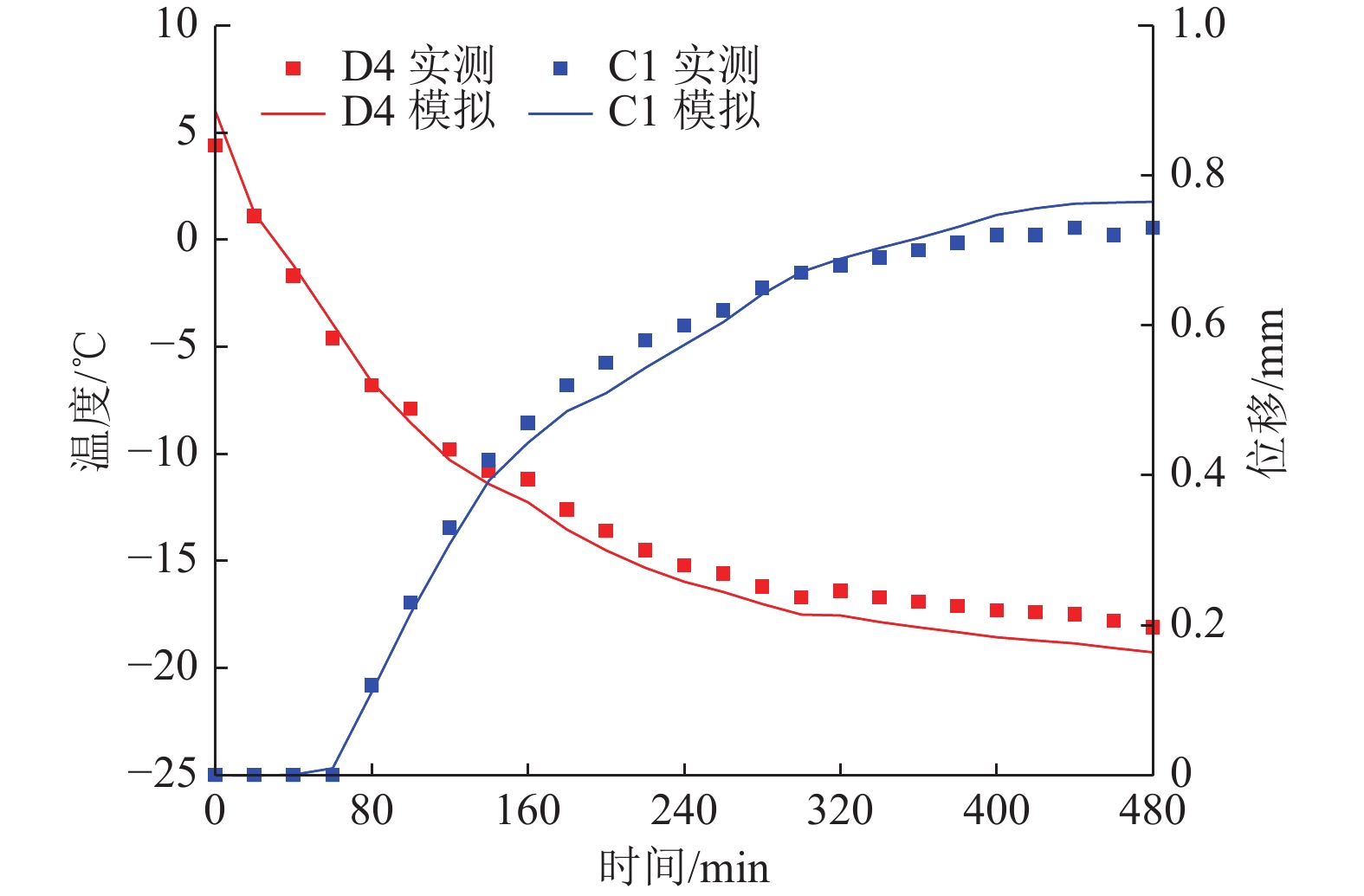

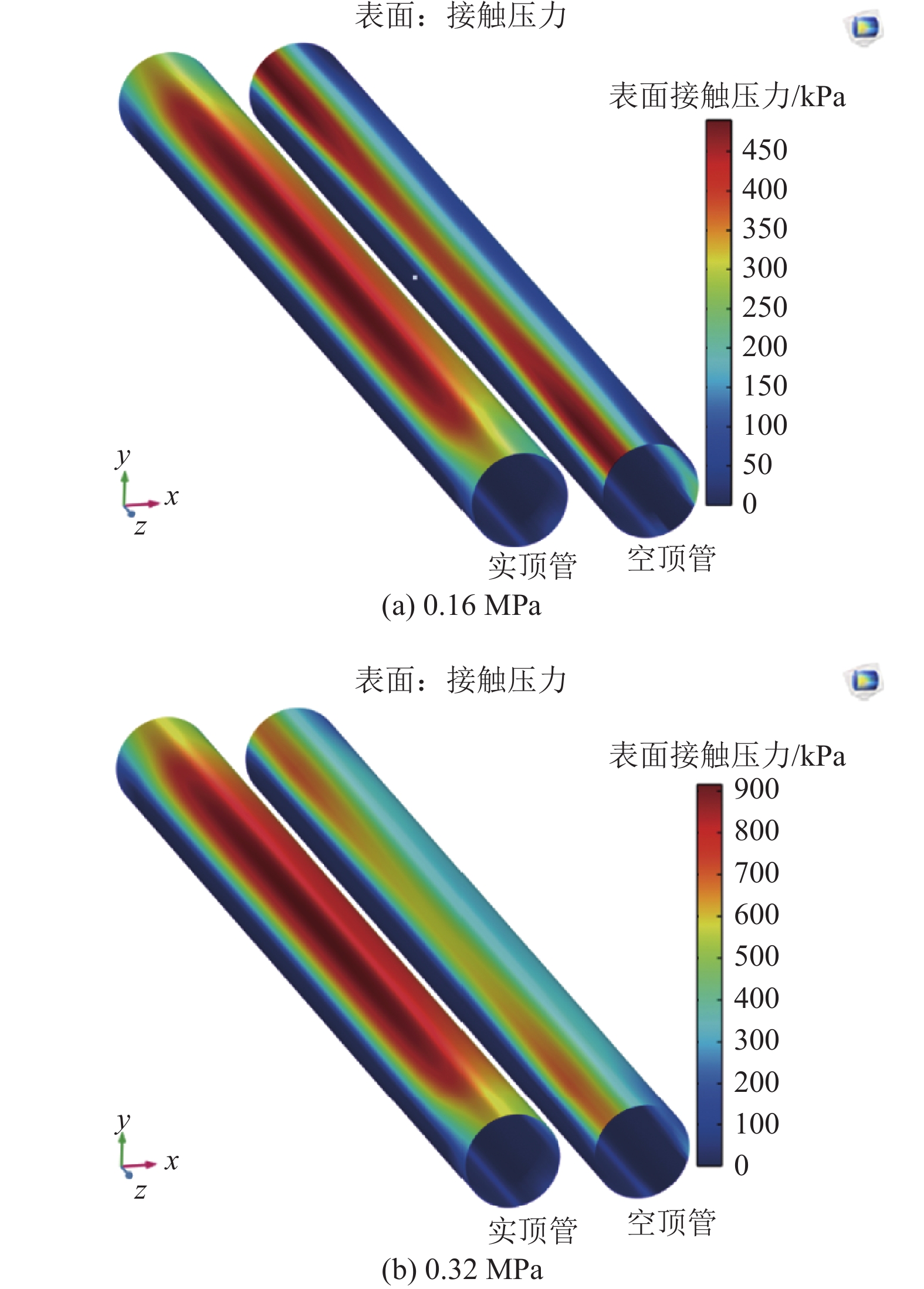

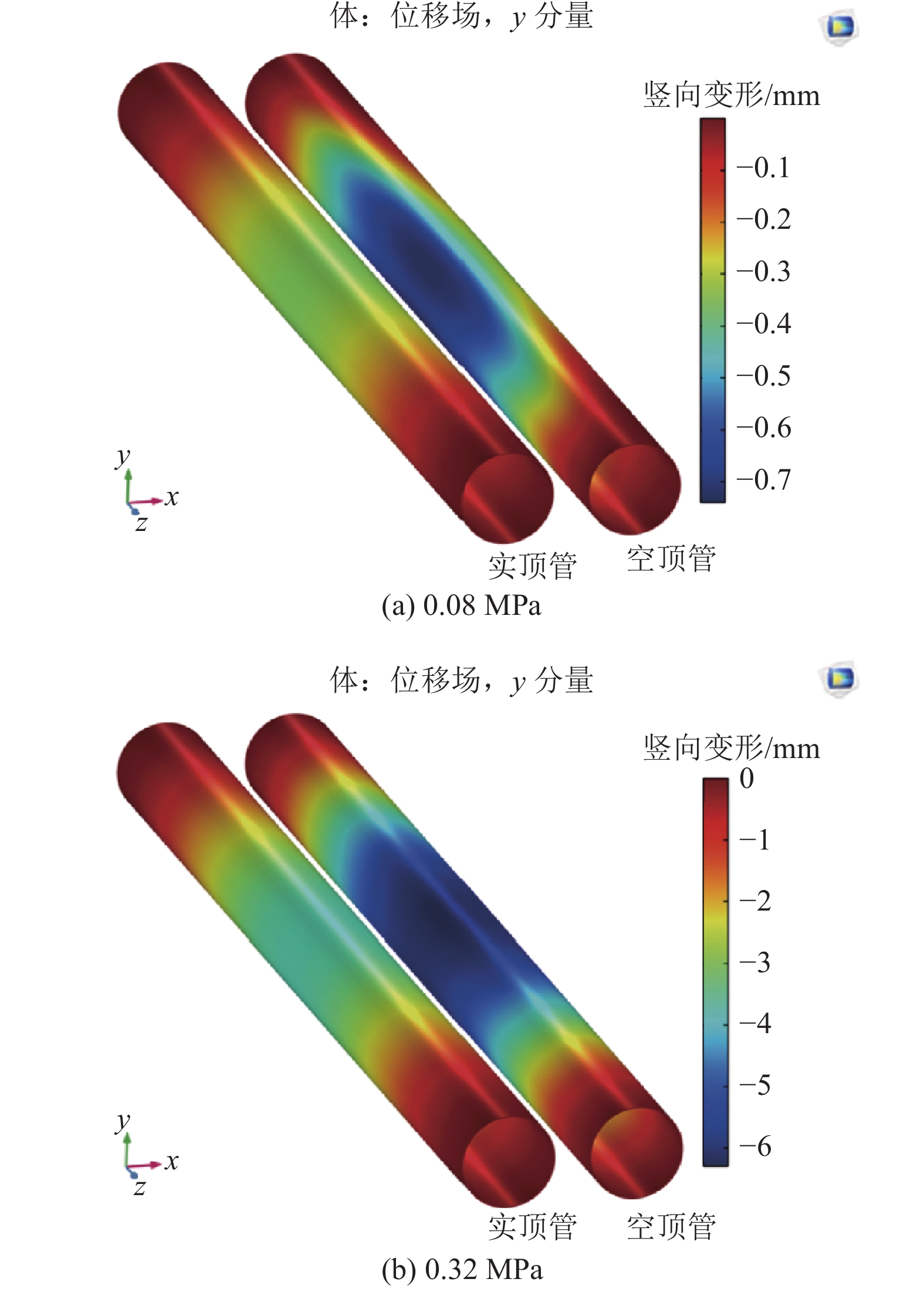

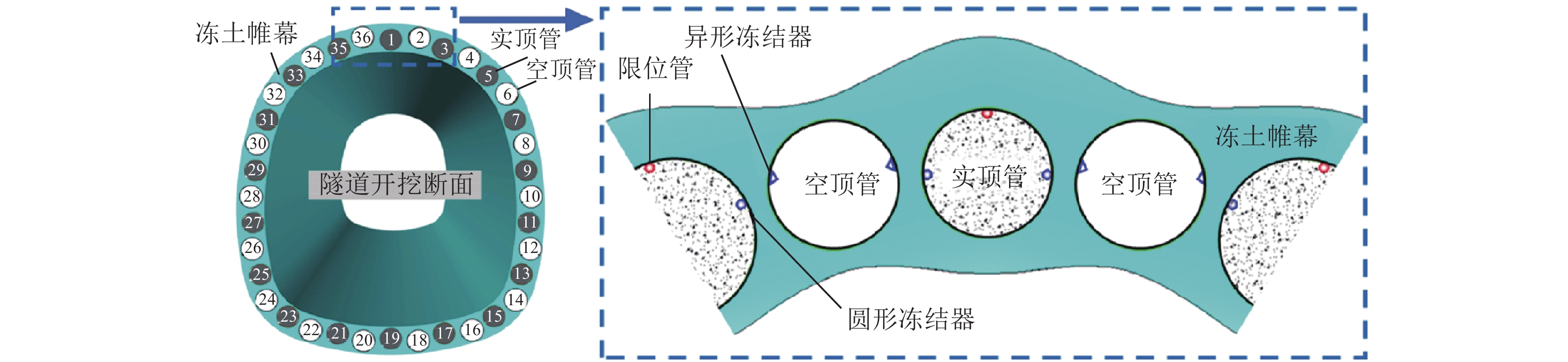

拱北隧道暗挖段作为港珠澳大桥珠海连接线的重点工程,首次运用管幕冻结法进行施工。该法综合管幕法和人工地层冻结法的优势,可在隧道断面形成“顶管−冻土帷幕”复合支护体系,有效实现“承载”与“顶管间止水”的双重目标,确保隧道开挖时的稳定与安全。为获得“顶管−冻土”复合结构的温度、变形与力学特性,基于相似理论自主研发构建一套相似模型试验系统并开展试验研究,同时利用有限元软件COMSOL Multiphysics建立数值计算模型进行模拟验证。结果表明:复合结构的冻结温度场因空、实顶管及其内部冻结器的布置形式呈现不均匀分布特征,冻土形成速率在冻结后期明显变缓;土体竖向冻胀变形在60~160 min内急剧增大,且冻胀量随深度增加而增大,整体规律与温度场分布密切相关;土体冻结产生的冻胀力对顶管水平受力影响较大,空顶管相对刚度较小而产生较大水平变形;在加载阶段,顶管受力与变形均以竖向为主。因空、实顶管刚度差异和冻土厚度不均匀的共同影响,空顶管竖向变形包含了“弯曲”与“压扁”并具有非线性特征,其跨中截面底部竖向位移峰值约为实顶管的1.6倍;加载至0.28 MPa时,管间冻土首先发生破坏,进而导致顶管间封水功能失效,实际施工中应重点监测空顶管的变形规律、管间冻土帷幕的温度变化及其完整性。研究成果可为管幕冻结法的施工与监测提供参考,也可为热力耦合数值计算模型提供验证依据。

Abstract:As the key project of Zhuhai Connecting Line of Hong Kong‒Zhuhai‒Macao Bridge, the underground excavation section of Gongbei Tunnel has applied the freeze-sealing pipe roof method for the first time. Combining the advantages of the pipe roof method and the artificial ground freezing method, this method could form a “jacked pipe-frozen soil curtain” composite support system on the tunnel section, so as to effectively achieve the dual goals of “bearing” and “water-stopping between pipes”, thereby ensuring that stability and safety during tunnel excavation. To obtain the temperature, deformation and mechanical properties of the “jacked pipe-frozen soil” composite structure, a set of scaled model test system was independently developed based on the similarity theory and the experimental research was carried out. At the same time, a numerical calculation model was established using the finite element software COMSOL Multiphysics for simulation verification. According to the results, the freezing temperature field of the composite structure is characterized by uneven distribution due to the arrangement of hollow pipe, solid pipe and their internal freezers, and the formation rate of frozen soil slows down significantly in the later stage of freezing. Besides, the vertical frost heaving deformation increases sharply within 60‒160 min, the frost heaving amount increases with the depth, and the overall law of frost heaving is closely related to the distribution of the freezing temperature field. The frost heaving force caused by soil freezing has a great influence on the horizontal force of the pipe, so that the hollow pipe with relative low stiffness may be subjected to larger horizontal deformation. In the loading stage, the jacked pipe is mainly applied with force and deformed in the vertical direction. Due to the joint influence of the stiffness difference between the two pipes and the uneven thickness of frozen soil, the vertical deformation of the hollow pipe, including “bending” and “flattening”, has nonlinear characteristics, and the peak value of the vertical displacement at the bottom of the midspan section is about 1.6 times that of the solid pipe. When the load reaches 0.28 MPa, the frozen soil between pipes will be damaged at first, which leads to the failure of water sealing between pipes. In actual construction, the deformation law of hollow pipe, as well as the temperature change and integrity of the frozen soil curtain between adjacent pipes, is the key for monitoring. The research results can provide reference for the construction and monitoring of the freeze-sealing pipe roof method and verification basis for the thermodynamic coupling numerical calculation model.

-

-

表 1 相似准则

Table 1 Similarity criteria

相似准则 π1 π2 π3 π4 π5 π6 表达式 $\dfrac{ { {E_{\rm{t}}}{D^2} } }{P}$ $\dfrac{ {c{D^2} } }{P}$ $\dfrac{ { {\gamma _{\rm{t}}}{D^3} } }{P}$ $\dfrac{ {\sigma {D^2} } }{P}$ $\dfrac{ { {a_{\rm{t}}} } }{ { {a_{\rm{g}}} } }$ $\dfrac{ { {C_{\rm{t} } }t{D^2} } }{ {a_{\rm{g} }^2} }$ 相似准则 π7 π8 π9 π10 π11 π12 表达式 $\dfrac{ { {E_{\rm{g}}}{D^2} } }{P}$ $\dfrac{ { {\gamma _{\rm{g}}}{D^3} } }{P}$ $\dfrac{ { {E_{\rm{h}}}{D^2} } }{P}$ $\dfrac{ { {\gamma _{\rm{h}}}{D^3} } }{P}$ $\dfrac{d}{D}$ $\dfrac{ { {t_{\rm{d} } } } }{t}$ 表 2 主要相似比常数

Table 2 Main similarity ratio constant

几何 位移 温度 时间 应力 容重 荷载 弹性模量 1/20 1/20 1 1/400 1 20 1 1 表 3 顶管设计参数

Table 3 Design parameters of jacked pipe

模型类型 顶管弹性模量/MPa 顶管内径/mm 壁厚/mm 冻结器内径/mm 实顶管内填充 原型 20 000 1600 20 159 C30细石混凝土 模型 20 000 80 1 8 C30细石混凝土 表 4 粉质黏土与混凝土热物理试验参数

Table 4 Thermophysical parameters of silty clay and concrete

材料 密度/

(kg·m−3)比热容/

(J·kg−1·K−1)导热系数/

(W·m−1·K−1)含水率/

%冰点/

℃立方体抗压

强度/MPa弹性模量/

MPa泊松比 干密度 湿密度 未冻 已冻 未冻 已冻 粉质黏土 1 590 2 010 1 572 1 481 1.28 1.82 26 −1.2 混凝土 2 450 920 1.55 32 25×103 0.22 表 5 粉质黏土力学性能试验数据

Table 5 Mechanical property data of silty clay

材料 温度/℃ 单轴抗压强度/MPa 弹性模量/MPa 内摩擦角/(°) 黏聚力/MPa 抗折强度/MPa 粉质黏土 −5 1.22 30 6.4 0.85 0.41 −10 2.20 61 7.1 1.77 0.82 −15 3.60 107 4.5 2.58 1.16 -

[1] 程桦. 深厚冲积层冻结法凿井理论与技术[M]. 北京: 科学出版社, 2016. [2] 张松,岳祖润,卢相忠,等. 冻结法施工中冻结管断裂的影响及其处理方法[J]. 城市轨道交通研究,2020,23(12):99−102. DOI: 10.16037/j.1007-869x.2020.12.020 ZHANG Song,YUE Zurun,LU Xiangzhong,et al. Impact and treatment method of freeze pipe fracture in AGF project[J]. Urban Mass Transit,2020,23(12):99−102. DOI: 10.16037/j.1007-869x.2020.12.020

[3] 李方政,崔兵兵,张世银. 盾构进洞加固PVC冻结管力学性能试验研究[J]. 地下空间与工程学报,2016,12(5):1179−1184. LI Fangzheng,CUI Bingbing,ZHANG Shiyin. Experimental research on the mechanical properties of PVC freezing pipe for shield arriving construction[J]. Chinese Journal of Underground Space and Engineering,2016,12(5):1179−1184.

[4] 周晓敏. 冻结管在冻结壁变形段内的受力计算[J]. 煤炭学报,1996,21(1):30−34. DOI: 10.3321/j.issn:0253-9993.1996.01.006 ZHOU Xiaomin. Stressing of freeze pipe in the deformed section of ice wall[J]. Journal of China Coal Society,1996,21(1):30−34. DOI: 10.3321/j.issn:0253-9993.1996.01.006

[5] 杨维好,黄家会. 冻结管受力分析与试验研究[J]. 冰川冻土,1999,21(1):33−38. YANG Weihao,HUANG Jiahui. Theoretical analyses and experimental research on stresses in freezing pipes[J]. Journal of Glaciology and Geocryology,1999,21(1):33−38.

[6] 李晓芳,蔡海兵. 内衬冻结管的低温力学性能试验与安全性判定[J]. 低温建筑技术,2017,39(11):100−103. DOI: 10.13905/j.cnki.dwjz.2017.11.026 LI Xiaofang,CAI Haibing. Mechanical performance test at low temperature and security judgement of lining frozen tubes[J]. Low Temperature Architecture Technology,2017,39(11):100−103. DOI: 10.13905/j.cnki.dwjz.2017.11.026

[7] 上田保司,生頼孝博. 鋼管補強による凍土梁の曲げ強度特性の改良[J]. 土木学会論文報告集,2001,12:81−90. UEDA Y,OHRAI T. Improvement of bending strength of frozen soil beam reinforced by steel pipe[J]. Proceedings of the Japan Society of Civil Engineers,2001,12:81−90.

[8] 森内浩史, 上田保司, 生頼孝博. 鋼管変形に対する凍土の追随性把握実験[C]//土木学会第58回年次学術講演会. 日本, 2003: 753–754. MORIUCHI K, UEDA Y, OHRAI T. Study on the fitting ability of frozen soil and steel pipes[C]//Proceeding of the 58 Annual Conference of the Japan Society of Civil Engineering. Japan2003: 753–754.

[9] 夏慧民,牛富俊. 冻结管对人工冻结构件加筋作用的试验研究及数值模拟[J]. 冰川冻土,2002,24(2):155−159. DOI: 10.3969/j.issn.1000-0240.2002.02.008 XIA Huimin,NIU Fujun. Experimental study and numerical simulation of the reinforcement of embedded freezing pipes on artificial frozen components[J]. Journal of Glaciology and Geocryology,2002,24(2):155−159. DOI: 10.3969/j.issn.1000-0240.2002.02.008

[10] 李志军,曲月霞,沈照伟,等. DUT–1非冻结合成模型冰的弯曲强度[J]. 冰川冻土,2001,23(2):170−175. DOI: 10.3969/j.issn.1000-0240.2001.02.010 LI Zhijun,QU Yuexia,SHEN Zhaowei,et al. Flexural strength of DUT−1 synthetic model ice[J]. Journal of Glaciology and Geocryology,2001,23(2):170−175. DOI: 10.3969/j.issn.1000-0240.2001.02.010

[11] 盛应平. 软土地层地铁车站浅埋冻结暗挖法施工方案分析[J]. 城市轨道交通研究,2019,22(6):138−142. SHENG Yingping. Analysis on metro station construction with shallow–buried frozen excavation method in soft soil stratum[J]. Urban Mass Transit,2019,22(6):138−142.

[12] 刘健鹏,杨平,何文龙,等. 盾构下穿敏感性建筑的管棚+水平冻结接收技术[J]. 铁道科学与工程学报,2017,14(10):2194−2202. DOI: 10.3969/j.issn.1672-7029.2017.10.022 LIU Jianpeng,YANG Ping,HE Wenlong,et al. Shield receiving technology of pipe–roof grouting and horizontal freezing entrancing beneath sensitive buildings[J]. Journal of Railway Science and Engineering,2017,14(10):2194−2202. DOI: 10.3969/j.issn.1672-7029.2017.10.022

[13] 周顺华. 软弱地层浅埋暗挖施工中管棚法的棚架原理[J]. 岩石力学与工程学报,2005,24(14):2565−2570. DOI: 10.3321/j.issn:1000-6915.2005.14.026 ZHOU Shunhua. Principles of pipe roof applied to shallow–buried tunnels in soft ground[J]. Chinese Journal of Rock Mechanics and Engineering,2005,24(14):2565−2570. DOI: 10.3321/j.issn:1000-6915.2005.14.026

[14] 张川,杨春满,左永江. 松软地层水平管棚工艺参数的研究[J]. 煤炭学报,2000,25(6):607−609. DOI: 10.3321/j.issn:0253-9993.2000.06.011 ZHANG Chuan,YANG Chunman,ZUO Yongjiang. Study on the art parameters of horizontal barrel vault advanced support in the soft rock[J]. Journal of China Coal Society,2000,25(6):607−609. DOI: 10.3321/j.issn:0253-9993.2000.06.011

[15] 张洁,史培新,潘建立. 拱北隧道管幕冷冻施工中的冻胀控制技术研究[J]. 隧道建设(中英文),2018,38(5):809−817. ZHANG Jie,SHI Peixin,PAN Jianli. Study of ground frost heave control technology used in Gongbei tunnel constructed by pipe roof and ground freezing method[J]. Tunnel Construction,2018,38(5):809−817.

[16] DUAN Yin,RONG Chuanxin,CHENG Hua,et al. Experimental and numerical investigation on improved design for profiled freezing–tube of FSPR[J]. Processes,2020,8(8):992. DOI: 10.3390/pr8080992

[17] 张冬梅,逄健,任辉,等. 港珠澳大桥拱北隧道施工变形规律分析[J]. 岩土工程学报,2020,42(9):1632−1641. ZHANG Dongmei,PANG Jian,REN Hui,et al. Observed deformation behavior of Gongbei tunnel of Hong Kong−Zhuhai–Macao Bridge during construction[J]. Chinese Journal of Geotechnical Engineering,2020,42(9):1632−1641.

[18] ZHANG Peng,MA Baosong,ZENG Cong,et al. Key techniques for the largest curved pipe jacking roof to date:A case study of Gongbei tunnel[J]. Tunnelling and Underground Space Technology,2016,59:134−145. DOI: 10.1016/j.tust.2016.07.001

[19] KANG Yongshui,LIU Quansheng,CHENG Yong,et al. Combined freeze–sealing and New Tubular Roof construction methods for seaside urban tunnel in soft ground[J]. Tunnelling and Underground Space Technology,2016,58(9):1−10.

[20] 任辉,胡向东,陈锦,等. 异形加强冻结管在管幕冻结法中的冻结效果及使用方法研究[J]. 隧道建设,2015,35(11):1169−1175. REN Hui,HU Xiangdong,CHEN Jin,et al. Study on freezing effect and operation of profiled enhancing freezing−tube in freeze–sealing pipe roof[J]. Tunnel Construction,2015,35(11):1169−1175.

[21] 胡向东,任辉,陈锦,等. 管幕冻结法积极冻结方案模型试验研究[J]. 现代隧道技术,2014,51(5):92−98. HU Xiangdong,REN Hui,CHEN Jin,et al. Model test study of the active freezing scheme for the combined pipe–roof and freezing method[J]. Modern Tunnelling Technology,2014,51(5):92−98.

[22] HU Xiangdong,SHE Siyuan. Study of freezing scheme in freeze–sealing pipe roof method based on numerical simulation of temperature field[J]. American Society of Civil Engineers,2012:1798−1805.

[23] 李志宏,王文州,胡向东. 施工热扰动对管幕冻结止水帷幕影响研究[J]. 土木工程学报,2015,48(增刊2):374−379. LI Zhihong,WANG Wenzhou,HU Xiangdong. Research on influence of construction thermal disturbance on the freezing–sealing pipe roof[J]. China Civil Engineering Journal,2015,48(Sup.2):374−379.

[24] 张军,胡向东,任辉. 拱北隧道管幕冻结施工中限位管的冻结效果控制研究[J]. 隧道建设,2015,35(11):1157−1163. ZHANG Jun,HU Xiangdong,REN Hui. Case study on control of freezing effect by installing limiting tubes in freezing–sealing pipe roof in Gongbei tunnel[J]. Tunnel Construction,2015,35(11):1157−1163.

[25] 张鹏,马保松,曾聪,等. 基于管土接触特性的顶进力计算模型分析[J]. 岩土工程学报,2017,39(2):244−249. DOI: 10.11779/CJGE201702007 ZHANG Peng,MA Baosong,ZENG Cong,et al. Numerical model for jacking force based on pipe–soil contact characteristics[J]. Chinese Journal of Geotechnical Engineering,2017,39(2):244−249. DOI: 10.11779/CJGE201702007

[26] LIU Jiguo,MA Baosong,CHENG Yong. Design of the Gongbei tunnel using a very large cross–section pipe–roof and soil freezing method[J]. Tunnelling and Underground Space Technology,2018,72(2):28−40.

[27] 刘稳,荣传新,段寅,等. 基于灰色关联度的管幕冻结隧道开挖断面变形影响因素分析[J]. 安徽建筑大学学报,2020,28(6):30−38. LIU Wen,RONG Chuanxin,DUAN Yin,et al. Analysis of factors influencing deformation of excavation section of freeze–sealing pipe roof method for tunnel based on gray correlation degree[J]. Journal of Anhui Jianzhu University,2020,28(6):30−38.

[28] 潘伟强. 软土地区管幕群顶管施工地面沉降监测与分析[J]. 岩土工程学报,2019,41(增刊1):201−204. PAN Weiqiang. Monitoring and analysis of ground settlement during pipe roof construction of pipe–jacking groups in soft soil areas[J]. Chinese Journal of Geotechnical Engineering,2019,41(Sup.1):201−204.

[29] 段寅,荣传新,程桦,等. 不同顶管组合方式的管幕冻结温度场模型试验[J]. 冰川冻土,2020,42(2):479−490. DOI: 10.7522/j.issn.1000-0240.2020.0048 DUAN Yin,RONG Chuanxin,CHENG Hua,et al. Model test of freezing temperature field of the freeze–sealing pipe roof method under different pipe arrangements[J]. Journal of Glaciology and Geocryology,2020,42(2):479−490. DOI: 10.7522/j.issn.1000-0240.2020.0048

[30] 龙伟,荣传新,段寅,等. 拱北隧道管幕冻结法温度场数值计算[J]. 煤田地质与勘探,2020,48(3):160−168. DOI: 10.3969/j.issn.1001-1986.2020.03.023 LONG Wei,RONG Chuanxin,DUAN Yin,et al. Numerical calculation of temperature field of freeze–sealing pipe roof method in Gongbei tunnel[J]. Coal Geology & Exploration,2020,48(3):160−168. DOI: 10.3969/j.issn.1001-1986.2020.03.023

[31] 崔广心. 相似理论与模型试验[M]. 徐州: 中国矿业大学出版社, 1990. [32] 国家安全生产监督管理总局. 人工冻土物理力学性能试验: MT/T 593.1—2011[S]. 北京: 煤矿专用设备标准化技术委员会, 2011. [33] 中华人民共和国水利部, 中华人民共和国建设部. 土工试验方法标准: GB/T 50123—1999[S]. 北京: 中国计划出版社, 1999. [34] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 绝热材料稳态热阻及有关特性的测定防护热板法: GB/T 10294—2008[S]. 北京: 中国标准出版社, 2008. [35] 中华人民共和国住房和城乡建设部, 中华人民共和国国家质量监督检验检疫总局. 混凝土结构试验方法标准: GB/T 50152—2012[S]. 北京: 中国建筑工业出版社, 2012. [36] 马巍,吴紫汪,张长庆. 冻土的强度与屈服准则[J]. 冰川冻土,1993,15(1):129−133. MA Wei,WU Ziwang,ZHANG Changqing. Strength and yield criteria of frozen soil[J]. Journal of Glaciology and Geocryology,1993,15(1):129−133.

[37] 马巍,朱元林,马文婷,等. 冻结粘性土的变形分析[J]. 冰川冻土,2000,22(1):43−47. DOI: 10.3969/j.issn.1000-0240.2000.01.007 MA Wei,ZHU Yuanlin,MA Wenting,et al. Analyses of deformation in frozen clayey soils[J]. Journal of Glaciology and Geocryology,2000,22(1):43−47. DOI: 10.3969/j.issn.1000-0240.2000.01.007

-

期刊类型引用(6)

1. 赵海峰,杨紫怡,梁为,钟骏兵. 深部煤层近井激光热裂机理及工艺参数优化. 煤田地质与勘探. 2024(02): 161-170 .  本站查看

本站查看

2. 文国军,黄子恒,王玉丹,史垚城,姜宇昊. 基于仿真数据驱动的激光钻进气体喷嘴结构优化. 钻探工程. 2024(03): 69-75 .  百度学术

百度学术

3. 吴波,刘林,郁东旭,王建州,王义江. 激光照射花岗岩抗拉强度及孔隙分布研究. 建井技术. 2024(04): 88-94+74 .  百度学术

百度学术

4. 王玉丹,罗耀坤,文国军,吴玲玲,官东林,姚邹. 激光钻进煤岩技术的研究进展. 煤田地质与勘探. 2021(01): 297-302 .  本站查看

本站查看

5. 葛振龙,孙强,王苗苗,赵春虎. 基于RA/AF的高温后砂岩破裂特征识别研究. 煤田地质与勘探. 2021(02): 176-183 .  本站查看

本站查看

6. 官兵,李士斌,张立刚,陈双庆. 激光破岩技术的研究现状及进展. 中国光学. 2020(02): 229-248 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: