Discussion on underground system sealing methods in in-situ pyrolysis exploitation of tar-rich coal

-

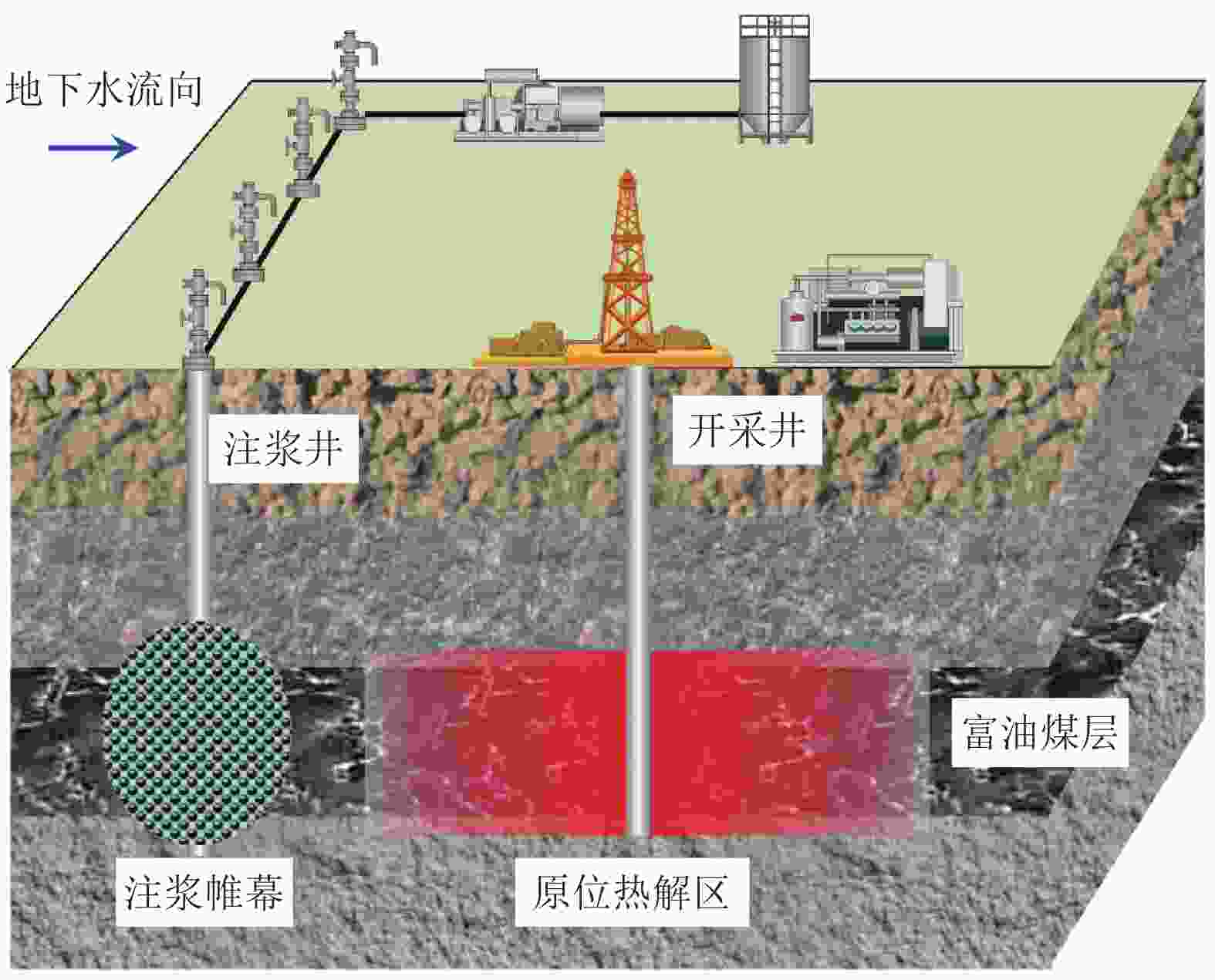

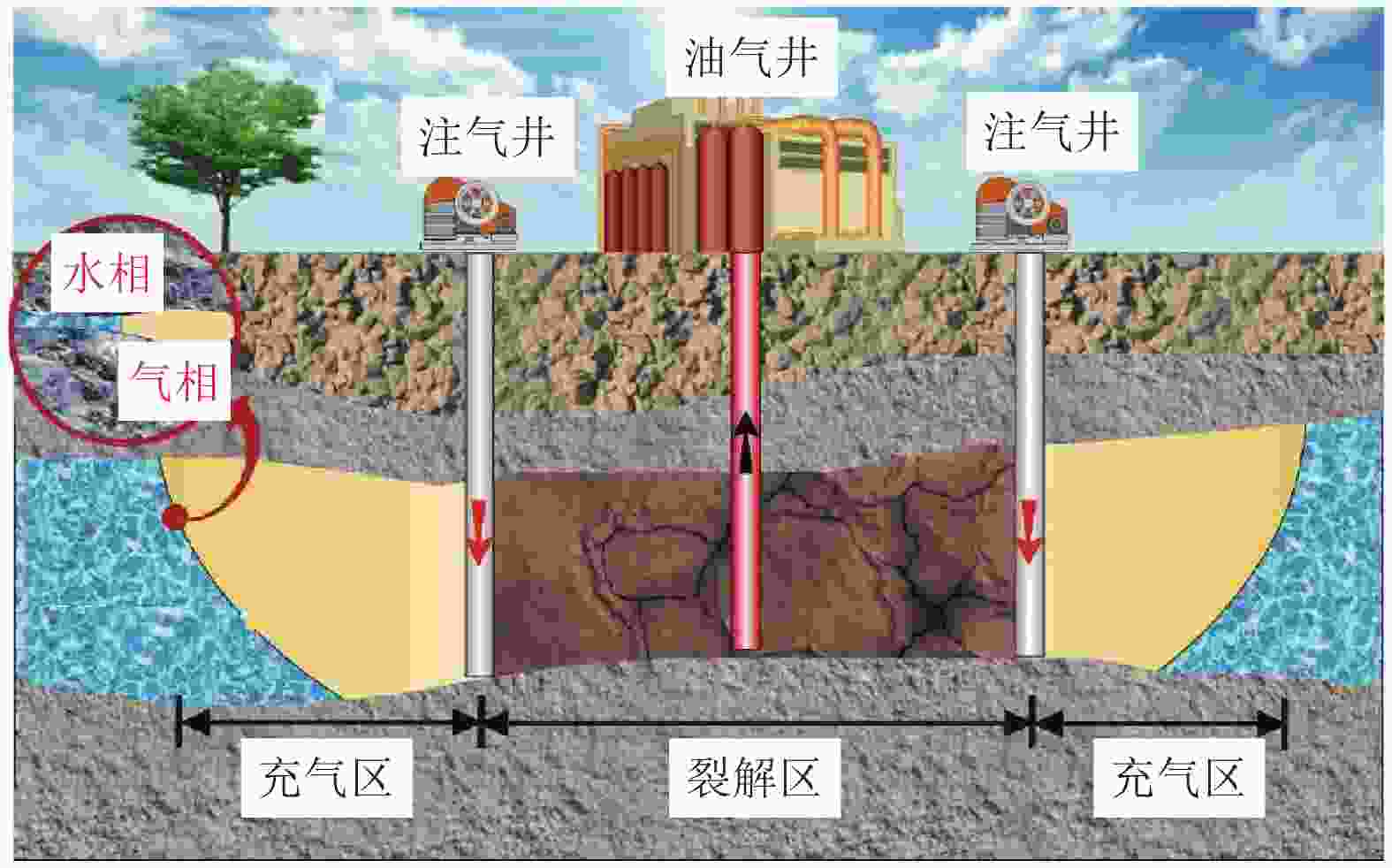

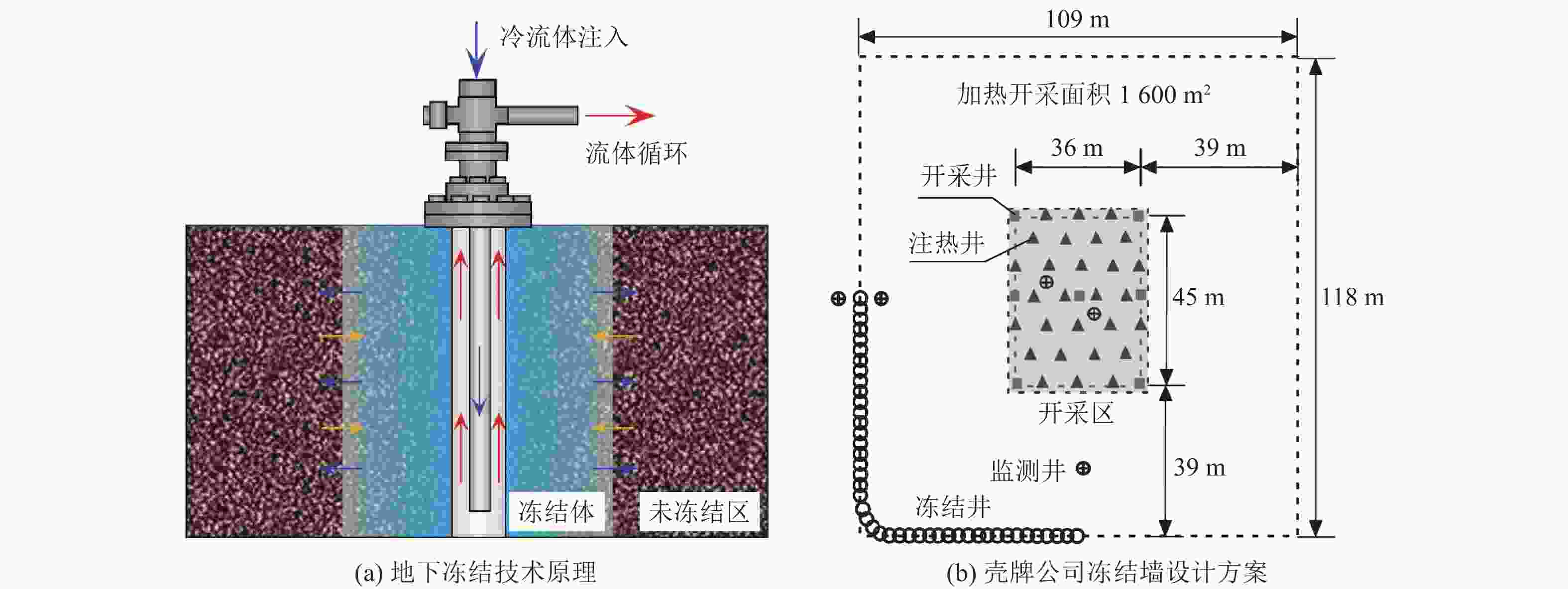

摘要: 我国富油煤资源丰富,采用地下原位热解“取油留碳”是富油煤资源绿色高效开发的主要趋势。富油煤地下原位热解开采尚处于技术研发阶段,需要围绕富油煤原位开发的关键技术开展攻关。地下体系封闭是保障富油煤原位热解开采能量高效利用和生态环保的关键技术之一,亟需研发并构建适于富油煤原位热解开发特点的地下体系封闭技术。根据目前地下体系封闭技术研究与应用现状,系统梳理总结了地下冻结、注浆帷幕、气驱止水、泡沫止水等各类地下体系封闭技术原理与优缺点,深入分析了各类技术的地层适应性。结合富油煤层埋深、层厚、区域构造等地质特点,以及热解开发工艺和规模,讨论了不同体系封闭技术在富油煤热解开发中的适用性。探讨了体系封闭技术研发的发展趋势,即创新现有技术原理、发展复合封闭技术。针对地下体系封闭技术的工程实施,围绕开发前精细设计、开发中严密监测和开发后安全恢复,提出了包括地下体系封闭设计−监测−修复和环境恢复的系统方法。通过整合富油煤原位热解、地下体系封闭、产物驱采、CO2地质封存等关键技术,提出了富油煤地下原位热解开发及CO2地质封存一体化技术构想,为我国富油煤地下原位热解开采技术研发与工业化应用提供参考。Abstract: China has abundant tar-rich coal resource, in-situ underground pyrolysis is the main trend of green and efficient development of tar-rich coal resources. However, the underground in-situ pyrolysis of tar-rich coal is still in the stage of technology research and development, and it is necessary to focus on the key technology of tar-rich coal to carry out research . Underground system sealing is one of the key technologies to ensure the efficient use of energy and ecological protection of tar-rich coal in-situ pyrolysis mining, and there is an urgent need to develop and construct underground system closure technology suitable for the characteristics of tar-rich coal in-situ pyrolysis development. Based on the current status of research and application of underground system sealing technology, the principles, advantages and disadvantages of various types of underground system sealing technologies such as underground artificial freezing, grouting curtain, water-stopping by gas flooding and foam water-stopping, etc. were systematically sorted out and summarized, and the stratigraphic adaptability of various technologies weas analyzed in depth. The applicability of different system sealing technologies in the development of tar-rich coal pyrolysis is analyzed in the context of geological characteristics such as burial depth, layer thickness and regional tectonics of tar-rich coal seam, as well as the pyrolysis development process and scale. Further, the development trend of system sealing technology is discussed, i.e., innovating of existing technical principles and development of composite sealing technology. For the engineering implementation of underground system sealing technology, a systematic approach including design-monitoring-repair and environment restoration of underground system sealing is proposed around the fine design before development, strict monitoring during development and safe restoration after development. Finally, an integrated technology concept of underground in-situ pyrolysis exploitation of tar-rich coal and CO2 geological storage was proposed by integrating the key technologies such as in-situ pyrolysis, underground system sealing, product displacement and CO2 geological storage, which provided references for the development and industrial application of in-situ pyrolysis exploitation technology of tar-rich coal in China.

-

表 1 4种地下体系封闭技术特点

Table 1 Characteristics of 4 underground system sealing methods

技术种类 适应地层 封闭范围 工程应用情况 对地层和工艺的影响 地下冻结技术 各类地层 封闭半径小于1 m 浅层 地层影响可逆 注浆帷幕技术 高渗、浅埋深地层 封闭半径小于1 m 浅层 地层影响不可逆 气驱止水封闭技术 无断层或溶洞等易发生

气体窜流的地层封闭半径可达数十米 浅层、中深层油页岩

原位开采对地层无影响,具有驱油

效果泡沫止水技术 各类地层,尤其适用于

渗透率极差较大的地层封闭半径中等,取决于

注入泡沫压力石油工程 对地层无影响,具有驱油

效果 -

[1] 樊大磊,王宗礼,李文博,等. 2021年国内外油气资源形势分析及展望[J]. 中国矿业,2022,31(1):26−31.FAN Dalei,WANG Zongli,LI Wenbo,et al. Analysis and prospects of oil and gas resource situation at home and abroad in 2021[J]. China Mining Magazine,2022,31(1):26−31. [2] 张蕾,韩智坤,舒浩,等. 陕北富油煤低温热解提油基础特性[J]. 煤炭工程,2022,54(9):124−128.ZHANG Lei,HAN Zhikun,SHU Hao,et al. Basic characteristics of tar extraction in low temperature pyrolysis of tar–rich coal from northen Shaanxi[J]. Coal Engineering,2022,54(9):124−128. [3] 王双明,师庆民,王生全,等. 富油煤的油气资源属性与绿色低碳开发[J]. 煤炭学报,2021,46(5):1365−1377.WANG Shuangming,SHI Qingmin,WANG Shengquan,et al. Resource property and exploitation concepts with green and low–carbon of tar–rich coal as coal–based oil and gas[J]. Journal of China Coal Society,2021,46(5):1365−1377. [4] 马丽,段中会,杨甫,等. “双碳”背景下煤炭原位地下热解采油意义研究[J]. 中国煤炭地质,2022,34(4):5−7.MA Li,DUAN Zhonghui,YANG Fu,et al. Study on the significance of coal in–situ underground pyrolytic oil production under carbon peaking and carbon neutrality background[J]. Coal Geology of China,2022,34(4):5−7. [5] 中国煤炭地质总局. 西北地区富油煤资源评价与开发利用研究[R]. 北京: 中国煤炭地质总局, 2021. [6] 孙友宏,郭威,邓孙华. 油页岩地下原位转化与钻采技术现状及发展趋势[J]. 钻探工程,2021,48(1):57−67.SUN Youhong,GUO Wei,DENG Sunhua. The status and development trend of in–situ conversion and drilling exploitation technology for oil shale[J]. Drilling Engineering,2021,48(1):57−67. [7] 汪友平,王益维,孟祥龙,等. 美国油页岩原位开采技术与启示[J]. 石油钻采工艺,2013,35(6):55−59.WANG Youping,WANG Yiwei,MENG Xianglong,et al. Enlightenment of American’s oil shale in−situ retorting technology[J]. Oil Drilling & Production Technology,2013,35(6):55−59. [8] 刘召. 油页岩原位开采气驱止水特征实验和数值模拟及应用研究[D]. 长春: 吉林大学, 2021.LIU Zhao. Experimental and numerical study on the characteristics of water blocking by gas flooding and application in oil shale in–situ exploitation[D]. Changchun: Jilin University, 2021. [9] SUN Youhong,LIU Zhao,LI Qiang,et al. Controlling groundwater infiltration by gas flooding for oil shale in situ pyrolysis exploitation[J]. Journal of Petroleum Science and Engineering,2019,179:444−454. [10] BRANDT A R. Converting oil shale to liquid fuels:Energy inputs and greenhouse gas emissions of the shell in situ conversion process[J]. Environmental Science & Technology,2008,42(19):7489−7495. [11] 张渺. 地下水对油页岩原位裂解注浆止水浆液扩散特性的影响研究[D]. 长春: 吉林大学, 2020.ZHANG Miao. Study on the influence of groundwater on the diffusion characteristics of slurry in the grouting for oil shale in–situ pyrolysis project[D]. Changchun: Jilin University, 2020. [12] LIU Zhao,SUN Youhong,GUO Wei,et al. Experimental study of the characteristics of gas–injection barrier in two–dimensional porous media[J]. Journal of Hydrology,2021,593:125919. [13] ZHANG Song,YUE Zurun,LU Xiangzhong,et al. Model test and numerical simulation of foundation pit constructions using the combined artificial ground freezing method[J]. Cold Regions Science and Technology,2023,205:103700. [14] 李粮纲,唐平,何维山,等. 深矿钻孔帷幕灌浆的数值模拟与应用[J]. 探矿工程(岩土钻掘工程),2010,37(12):36−40.LI Lianggang,TANG Ping,HE Weishan,et al. Numerical simulation of curtain grouting in deep borehole and the application[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2010,37(12):36−40. [15] GUO Wei,ZHANG Miao,SUN Youhong,et al. Numerical simulation and field test of grouting in Nong’an pilot project of in–situ conversion of oil shale[J]. Journal of Petroleum Science and Engineering,2020,184:106477. [16] CHEN Danqi,ZHAO Hongwei,LIU Kun,et al. The effect of emulsion and foam on anti–water coning during nitrogen foam injection in bottom–water reservoirs[J]. Journal of Petroleum Science and Engineering,2021,196:107766. [17] DAVARZANI H,ARANDA R,COLOMBANO S,et al. Experimental study of foam propagation and stability in highly permeable porous media under lateral water flow:Diverting groundwater for application to soil remediation[J]. Journal of Contaminant Hydrology,2021,243:103917. [18] 许婷,李宁,姚征,等. 陕北榆神矿区富油煤分布规律及形成控制因素[J]. 煤炭科学技术,2022,50(3):161−168.XU Ting,LI Ning,YAO Zheng,et al. Distribution and geological controls of tar–rich coals in Yushen mining area of northern Shaanxi[J]. Coal Science and Technology,2022,50(3):161−168. [19] 刘浩,候吉峰,姜永东,等. 煤与页岩渗透性对比实验研究[J]. 煤矿安全,2018,49(3):36−39.LIU Hao,HOU Jifeng,JIANG Yongdong,et al. Experimental comparison study on permeability of coal and shale[J]. Safety in Coal Mines,2018,49(3):36−39. [20] 刘向阳. 煤矿深部岩层劈裂注浆扩散机理研究[D]. 合肥: 合肥工业大学, 2021.LIU Xiangyang. The mechanism of capillary–film water migration in freezing soil and its experimental study[D]. Hefei: Hefei University of Technology, 2021. [21] LIU Zhao,SUN Youhong,GUO Wei,et al. Effects of gas injection combined with wettability alteration on boundary water inrush[J]. Journal of Natural Gas Science and Engineering,2021,90:103920. [22] 吕士东. 油页岩原位裂解止水注浆实验及数值模拟研究[D]. 长春: 吉林大学, 2017.LYU Shidong. Experimental study and numerical simulation of sealing grouting for oil shale in–situ pyrolysis[D]. Changchun: Jilin University, 2017. [23] LIU Zhao,SUN Youhong,WANG Bingge,et al. Experimental study of artificial ground freezing by natural cold gas injection[J]. Applied Sciences,2020,10(17):6055. [24] 薛香玉, 王长安, 邓磊, 等. 基于全生命周期的富油煤原位热解碳排放研究[J]. 煤炭学报, 2022: 1–11[2023-01-11]. DOI: 10.13225/j.cnki.jccs.2022.0444.XUE Xiangyu, WANG Chang’an, DENG Lei, et al. Study on carbon emissions from in–situ pyrolysis of tar–rich coal based on full life cycle analysis method[J]. Journal of China Coal Society, 2022: 1–11[2023-01-11]. DOI: 10.13225/j.cnki.jccs.2022.0444. -

下载:

下载: