Key technology of automatic loading and unloading system for dual-pipe directional drilling rig and its application in soft–fragmentized coal seam

-

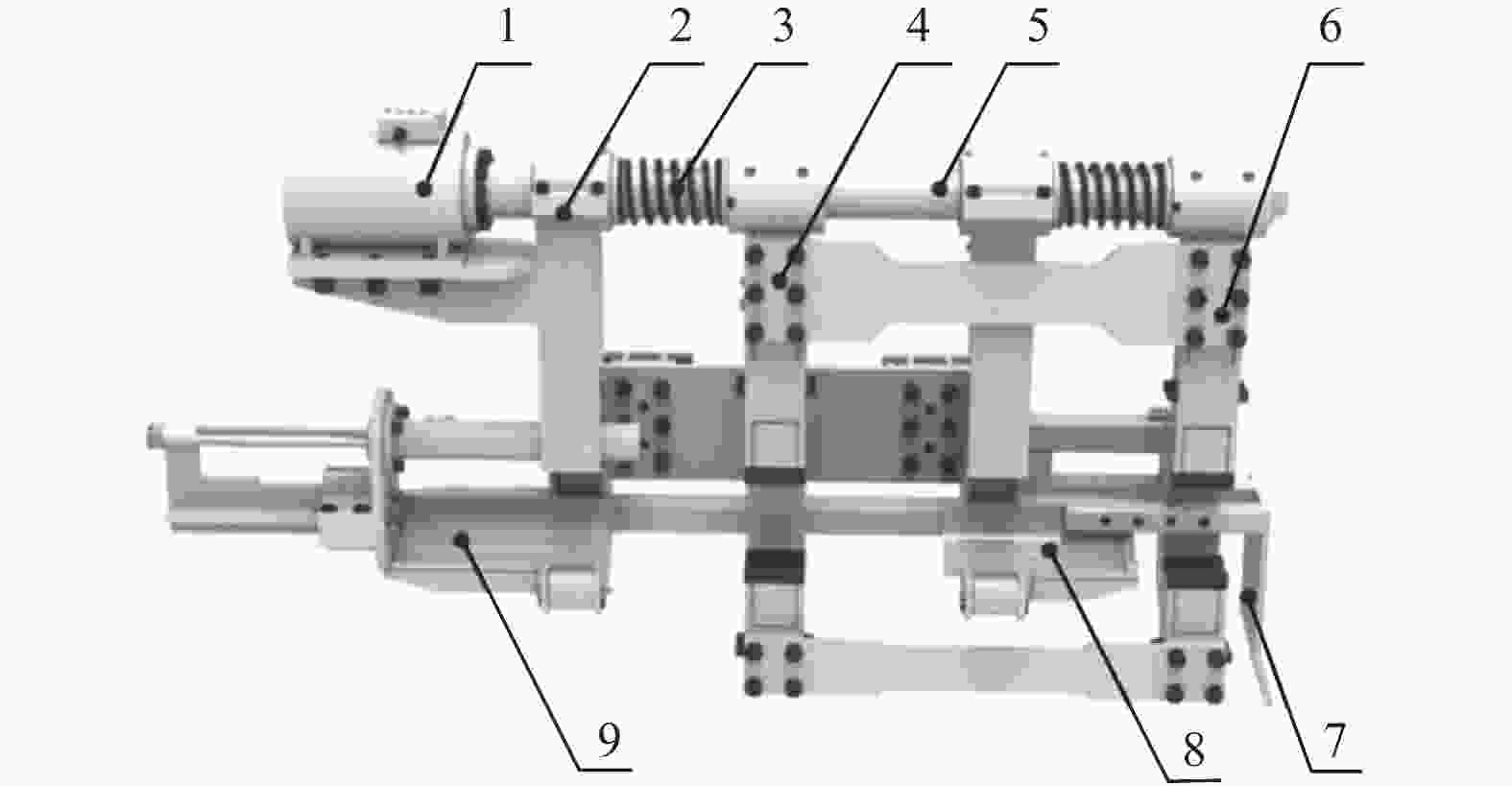

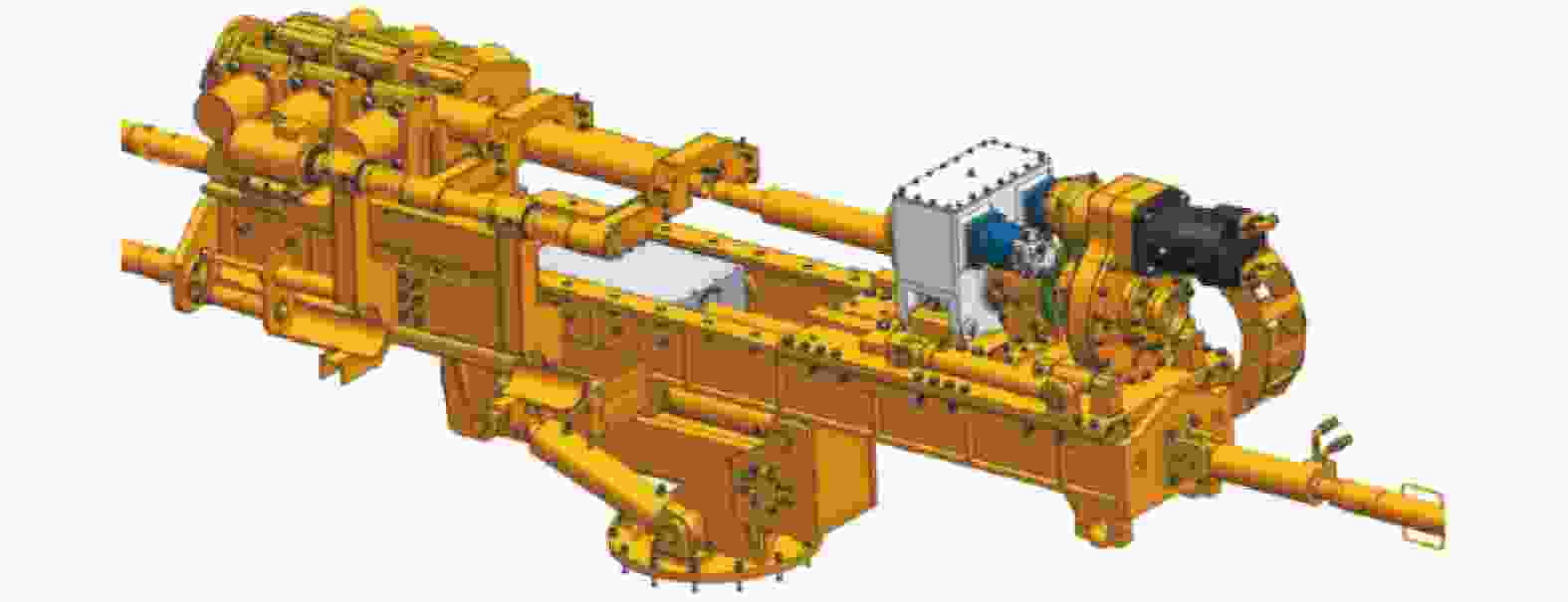

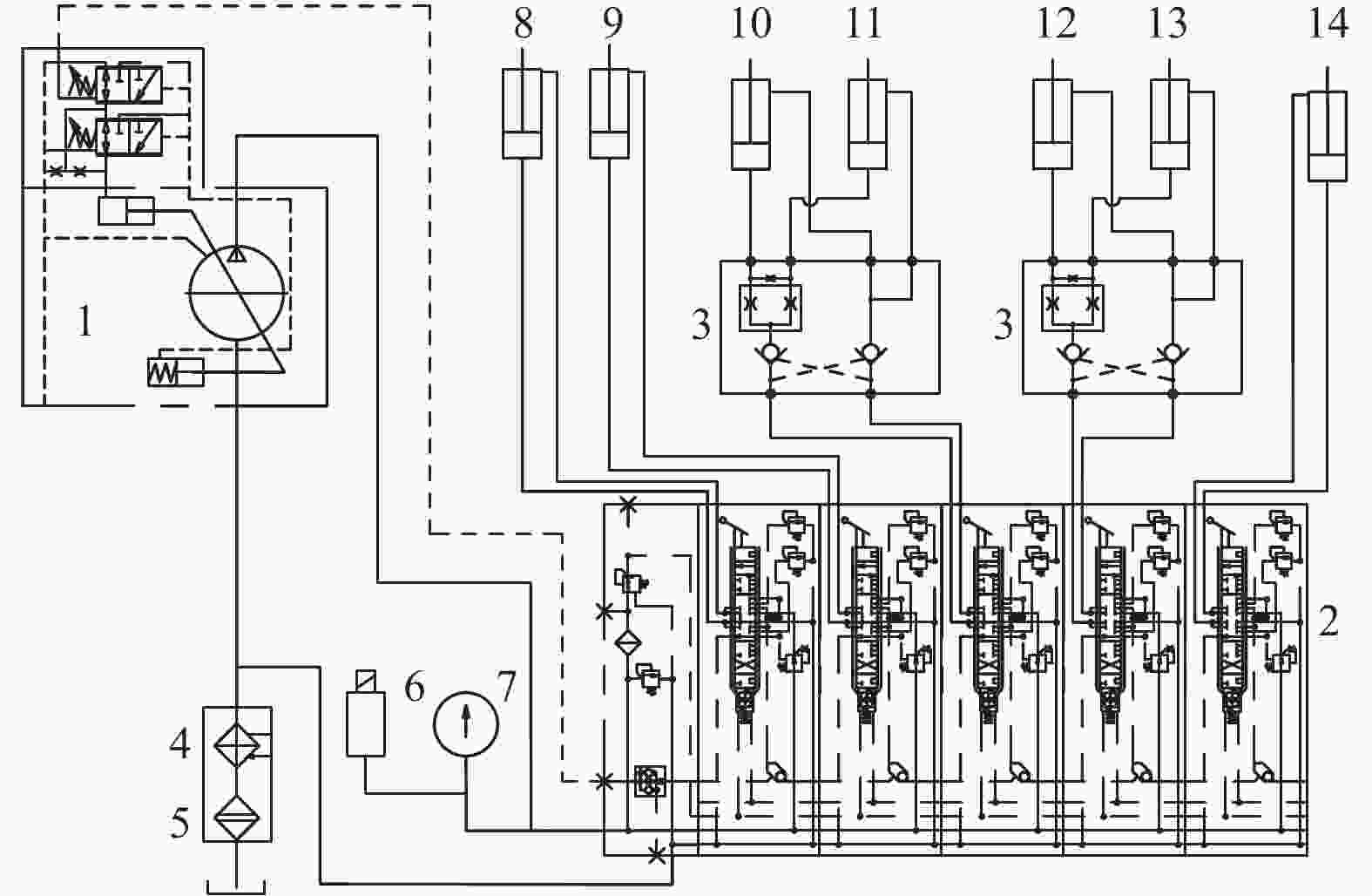

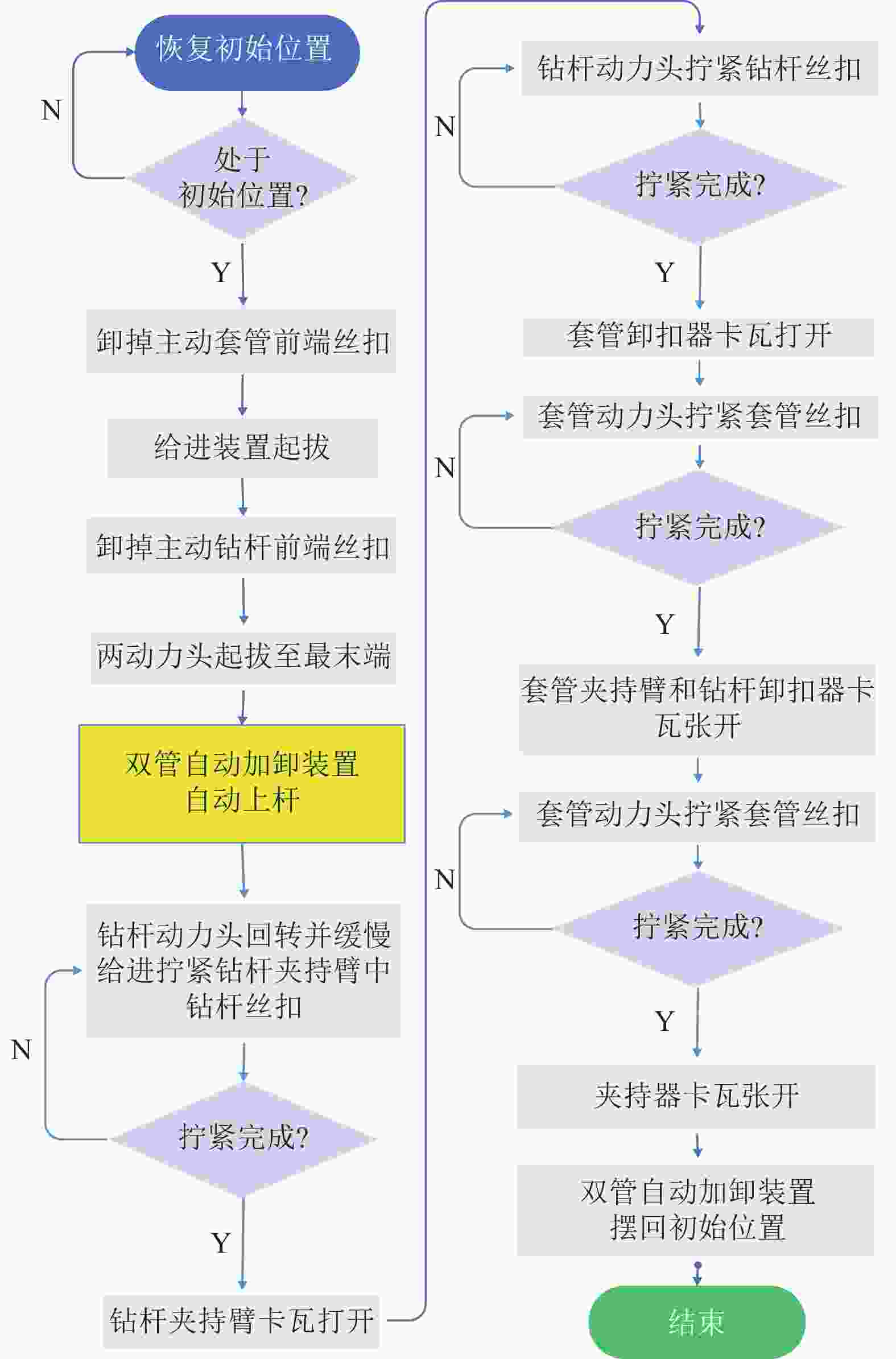

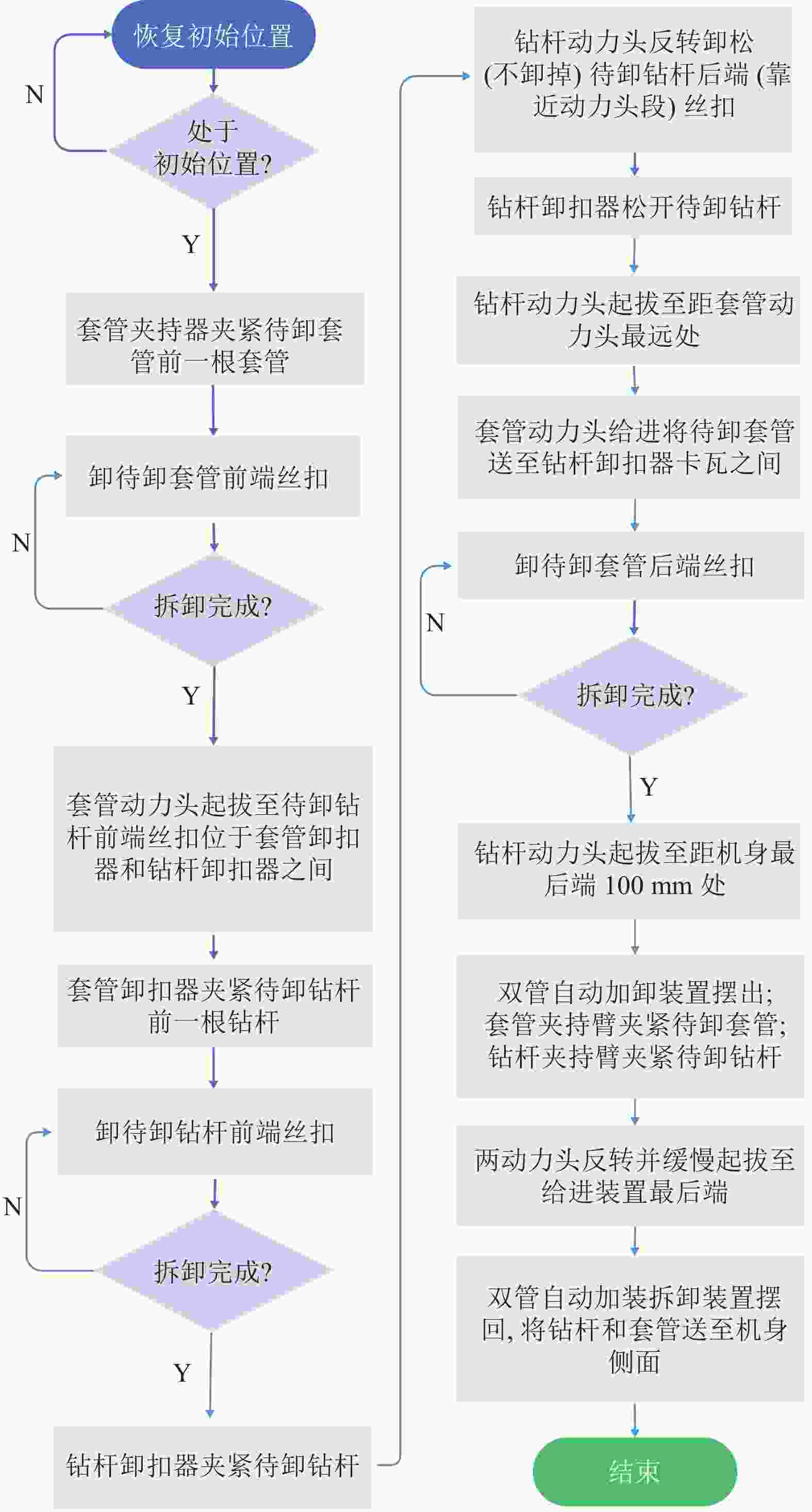

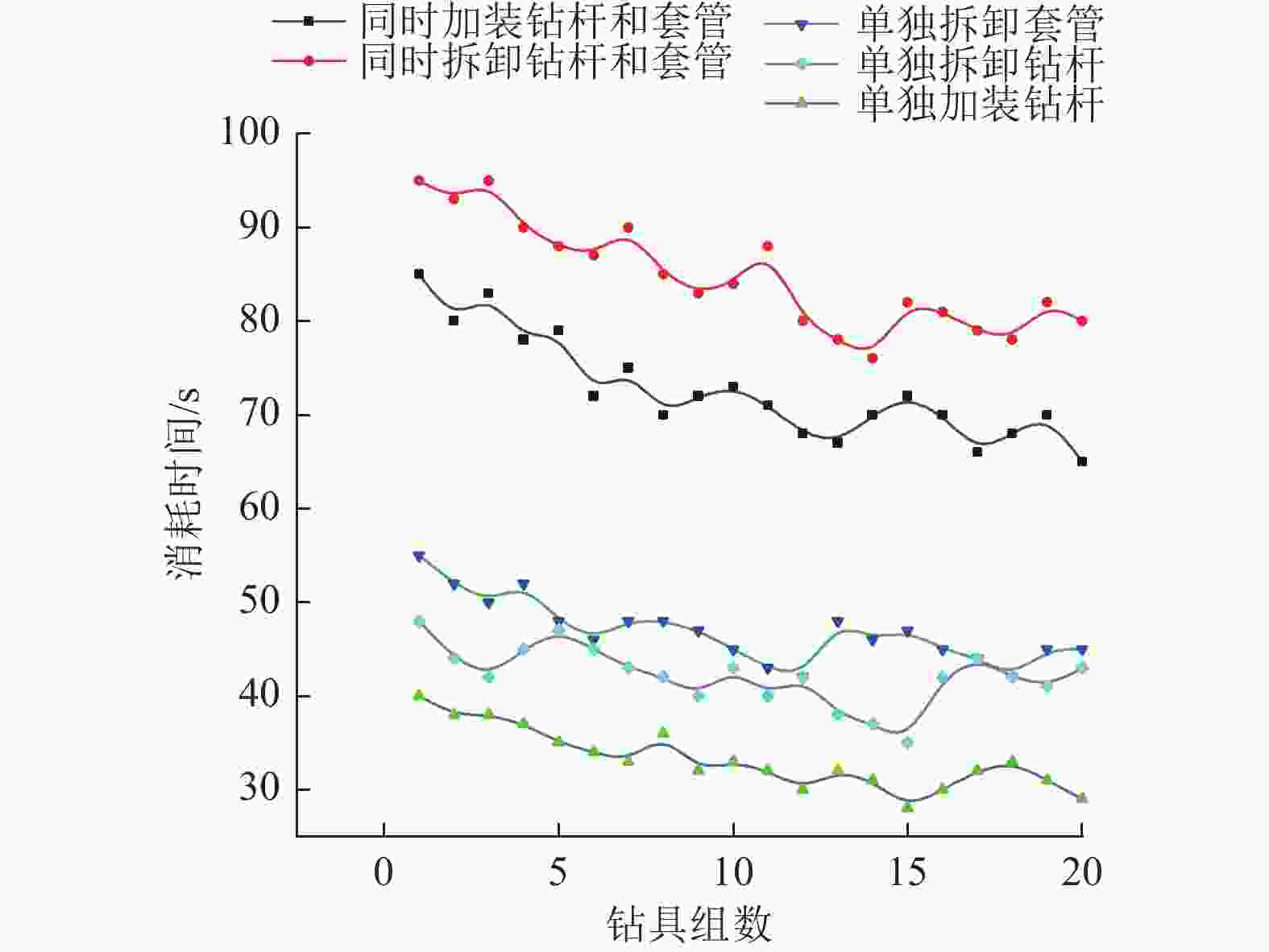

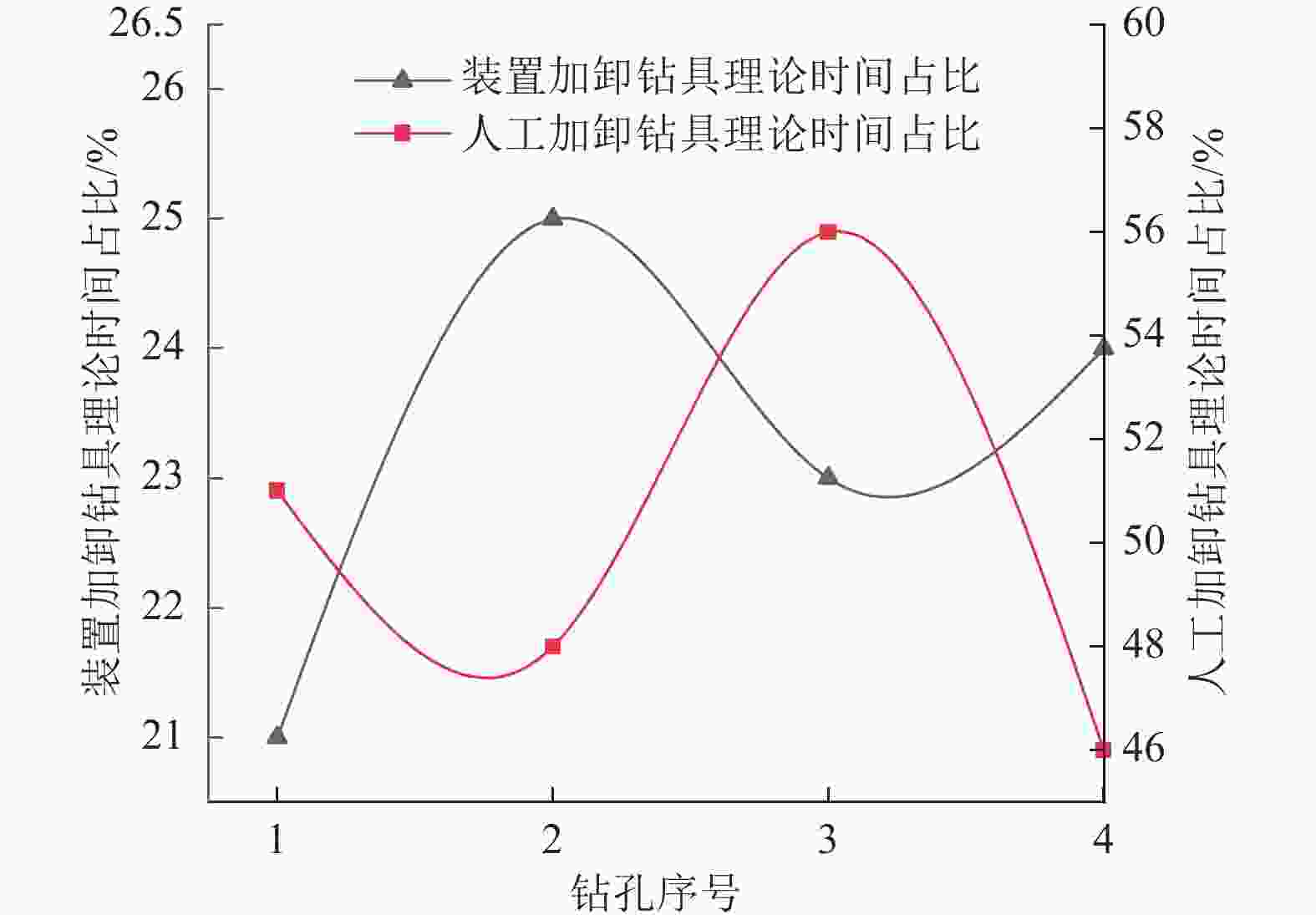

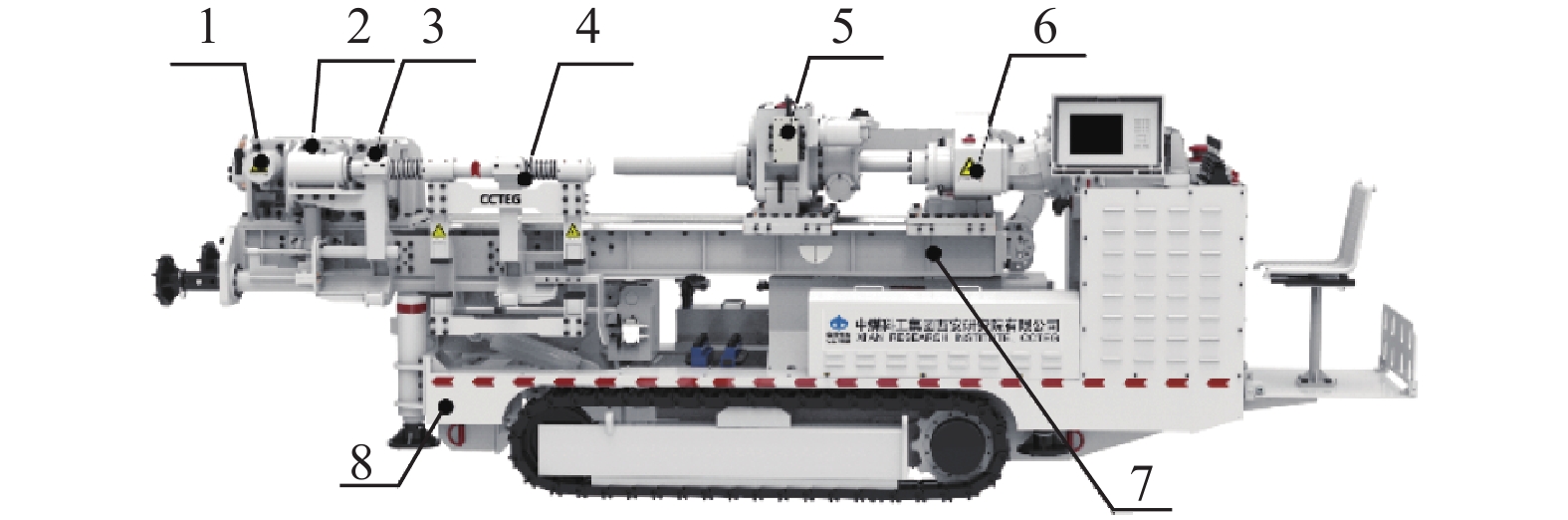

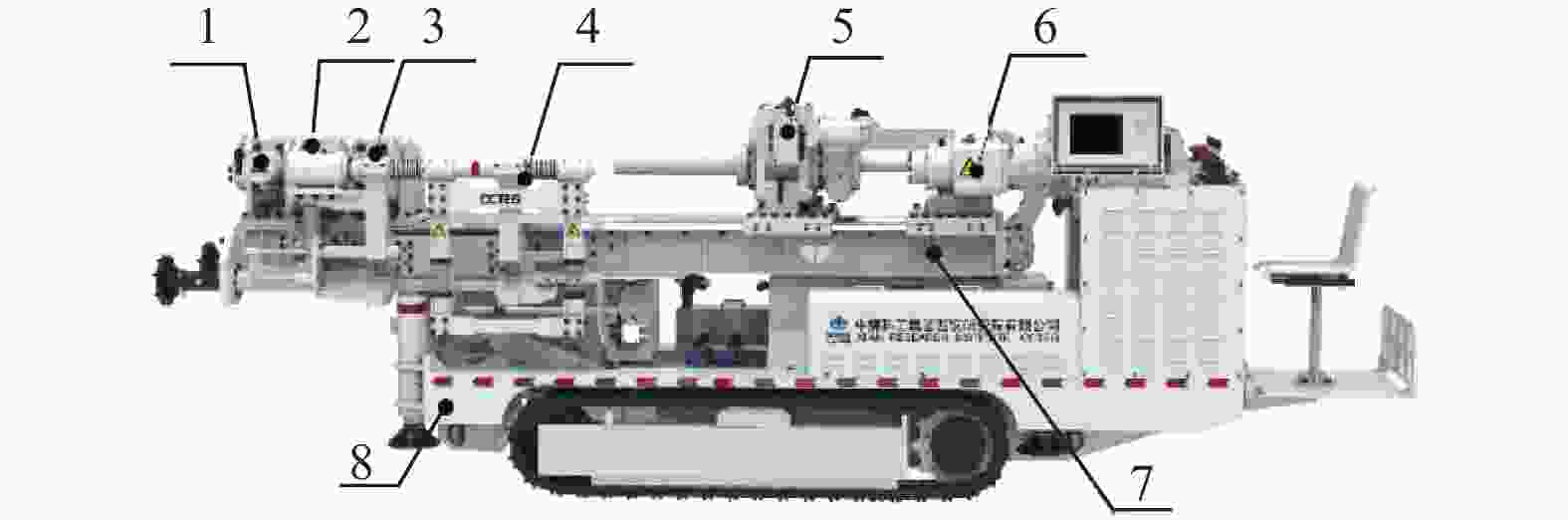

摘要: 为提高双管定向钻进钻孔施工时钻具加装和拆卸的自动化水平,提高装卸效率,开发一种双管自动加卸装置,实现不同工况下钻具的全自动装卸,解决双管定向钻进过程中钻杆和套管的同时加装和拆卸的技术难题,完成装置结构和控制系统的设计,运用末端柔顺技术,限制施工过程中装置承受的载荷,明确控制程序关键边界条件,制定不同工况下钻具自动装卸施工工艺流程。在安徽淮北矿业祁南煤矿展开工业性试验,试验顺利完成4个钻孔的施工,共进尺1170 m。试验过程中双管自动加卸装置运行平稳,能够满足不同工况下钻具组合的加装和拆卸需求。将原本需要2~3人密切配合才能完成的钻具组合自动装卸工作,变为依靠程序控制自动完成,钻杆和套管同时装卸和单独装卸平均效率较人工装卸分别提高了350%和110%,保证了双管定向钻进综合施工效率,减少了作业工人数量,降低了工人劳动强度,保障了施工安全。试验结果表明:双管自动加卸装置运行稳定可靠,施工工艺流程合理,装置各项性能满足双管定向钻进需求。研究成果为双管定向钻孔施工钻具的自动装卸提供了技术和装备支撑,为双管定向钻进技术在煤层气开采相关领域的推广应用奠定了基础。Abstract: To improve the automatic level and efficiency of loading and unloading of drilling rigs during the construction of dual-pipe directional drilling, an automatic loading and unloading device of dual pipe was developed to realize the fully automatic loading and unloading of drilling rigs under different working conditions and to solve the technical problems of loading and unloading the drill pipes and casing simultaneously during the dual-pipe directional drilling. Meanwhile, the device structure and control system was designed to restrict the load applied to the device during construction with the end-compliant technique. Besides, the key boundary conditions of the control program were clarified, and the process of automatic loading and unloading of drilling rigs under different working conditions was developed. The industrial test was carried out in Qinan Coal Mine of Huaibei Mining Holdings Co., Ltd. in Anhui, with 4 boreholes in a total footage of 1 170 m drilled. During the test, the automatic loading and unloading device of dual-pipe operated smoothly and was able to meet the loading and unloading requirements of drilling rigs under different working conditions. By applying this device, the automatic loading and unloading of drilling rigs, which originally requires the close cooperation of 2‒3 people, could be done automatically by program control, and the average efficiency of simultaneous and separate loading and unloading of drill pipe and casing increased by 350% and 110% respectively. In addition, the comprehensive construction efficiency of dual-pipe directional drilling was assured, with the number of workers reduced, the labor intensity of workers lowered and the construction safety ensured. The test results show that the automatic loading and unloading device of dual-pipe operates stably and reliably with reasonable construction process and the performances of the device meets the needs of dual-pipe directional drilling. The research results provide technical and equipment support for the automatic loading and unloading of dual-pipe directional drilling rigs and lay the foundation for the popularization and application of dual-pipe directional drilling technology in the relevant fields of CBM mining.

-

表 1 夹持臂参数

Table 1 Parameters of hold-down champs

主要性能 赋值 复位弹簧刚度K/(N·mm−1) 22 弹簧设计压缩量l1 /mm 45.0 弹簧许用压缩量l2 /mm 87.5 卡瓦摩擦因数μ 0.3 夹持油缸缸径D /mm 25 夹持油缸压力p/MPa 12 表 2 控制程序关键边界条件

Table 2 Key boundary conditions of control program

判断条件 系统压力/MPa 新装钻杆与主动钻杆间丝扣完全连接 ≥5 新装套管与主动套管间丝扣完全连接 钻杆丝扣顺利拆卸 <5 套管丝扣顺利拆卸 夹持器内钻具拧紧 ≥25 表 3 不同工况下人工装卸单组钻具所用时间统计

Table 3 Statistics of time for manual loading and unloading of a drilling rig under various working conditions

工况 工人数量 平均时长/s 钻杆套管同时加装 3 331.7 钻杆套管同时拆卸 3 282.4 单独加装钻杆 1 70.2 单独拆卸钻杆 1 60.5 单独拆卸套管 1 52.3 -

[1] 胡省三,成玉琪. 21世纪前期我国煤炭科技重点发展领域探讨[J]. 煤炭学报,2005,30(1):1−7.. doi: 10.3321/j.issn:0253-9993.2005.01.001HU Shengsan,CHENG Yuqi. Discussions on key development fields of China’s coal science and technology at early stage of 21st century[J]. Journal of China Coal Society,2005,30(1):1−7.. doi: 10.3321/j.issn:0253-9993.2005.01.001 [2] 刘春. 松软煤层瓦斯抽采钻孔塌孔失效特性及控制技术基础[D]. 徐州: 中国矿业大学, 2014.LIU Chun. Study on mechanism and controlling of borehole collapse in soft coal seam[D]. Xuzhou: China University of Mining and Technology, 2014. [3] 陈科,陈毅雯,刘志伟,何伟,杨发荣,唐磊. 中低渗高阶煤煤岩毛管压力数学表征[J]. 地质与勘探,2021,57(6):1401−1408.CHEN Ke,CHEN Yiwen,LIU Zhiwei,HE Wei,et al. Mathematical characterization of capillary pressure of middle-low-permeability of rock in high-rank coal seam[J]. Geology and Exploration,2021,57(6):1401−1408. [4] 林柏泉,李庆钊,杨威,等. 基于千米钻机的“三软”煤层瓦斯治理技术及应用[J]. 煤炭学报,2011,36(12):1968−1973.. doi: 10.13225/j.cnki.jccs.2011.12.006LIN Baiquan,LI Qingzhao,YANG Wei,et al. Gas control technology and applications for the three–soft coal seam based on VLD–1000 drilling systems[J]. Journal of China Coal Society,2011,36(12):1968−1973.. doi: 10.13225/j.cnki.jccs.2011.12.006 [5] 张世阔,曹思华. 复杂地质条件下矿井安全高效开采地质保障技术[J]. 煤矿安全,2010,41(4):70−73.ZHANG Shikuo,CAO Sihua. Geological guarantee technology about safety and efficient mining of coal mine under complex geological conditions[J]. Safety in Coal Mines,2010,41(4):70−73. [6] 李泉新,石智军,田宏亮,等. 我国煤矿区钻探技术装备研究进展[J]. 煤田地质与勘探,2019,47(2):1−6.LI Quanxin,SHI Zhijun,TIAN Hongliang,et al. Progress in the research on drilling technology and equipment in coal mining areas of China[J]. Coal Geology & Exploration,2019,47(2):1−6. [7] 姚宁平,王毅,姚亚峰,等. 我国煤矿井下复杂地质条件下钻探技术与装备进展[J]. 煤田地质与勘探,2020,48(2):1−7.. doi: 10.3969/j.issn.1001-1986.2020.02.001YAO Ningping,WANG Yi,YAO Yafeng,et al. Progress of drilling technologies and equipments for complicated geological conditions in underground coal mines in China[J]. Coal Geology & Exploration,2020,48(2):1−7.. doi: 10.3969/j.issn.1001-1986.2020.02.001 [8] 姚亚峰,姚宁平,彭涛. 松软煤层套管钻机夹持机构设计与分析[J]. 煤炭科学技术,2013,41(6):73−76.. doi: 10.13199/j.cst.2013.06.79.yaoyf.023YAO Yafeng,YAO Ningping,PENG Tao. Design and analysis on clamping mechanism of soft seam casing drilling rig[J]. Coal Science and Technology,2013,41(6):73−76.. doi: 10.13199/j.cst.2013.06.79.yaoyf.023 [9] 聂超,王毅,姚亚峰,等. 碎软煤层气动双管定向钻进排粉特性分析及应用[J]. 煤田地质与勘探,2022,50(5):159−166.. doi: 10.12363/issn.1001-1986.21.12.0789NIE Chao,WANG Yi,YAO Yafeng,et al. Powder discharge characteristics of pneumatic double pipe directional drilling in broken soft coal seams and its application[J]. Coal Geology & Exploration,2022,50(5):159−166.. doi: 10.12363/issn.1001-1986.21.12.0789 [10] 姚亚峰,姚宁平,沙翠翠,等. 煤矿井下双动力头定向钻机关键技术研究[J]. 煤矿机械,2020,41(11):30−32.. doi: 10.13436/j.mkjx.202011010YAO Yafeng,YAO Ningping,SHA Cuicui,et al. Research on key technologies of directional drilling rig with double power heads in underground coal mine[J]. Coal Mine Machinery,2020,41(11):30−32.. doi: 10.13436/j.mkjx.202011010 [11] 董洪波,范强,李坤,等. ZDY4500LFK全自动钻机开发与应用[J]. 煤田地质与勘探,2022,50(1):66−71.. doi: 10.12363/issn.1001-1986.21.12.0855DONG Hongbo,FAN Qiang,LI Kun,et al. Development and application of ZDY4500LFK full automatic drilling rig[J]. Coal Geology & Exploration,2022,50(1):66−71.. doi: 10.12363/issn.1001-1986.21.12.0855 [12] 王天龙,马斌,董洪波. 煤矿用自动化钻机远程监测系统研制[J]. 煤田地质与勘探,2022,50(1):80−85.. doi: 10.12363/issn.1001-1986.21.12.0723WANG Tianlong,MA Bin,DONG Hongbo. Development of a remote monitoring system for coal mine automatic drilling rigs[J]. Coal Geology & Exploration,2022,50(1):80−85.. doi: 10.12363/issn.1001-1986.21.12.0723 [13] 方鹏,姚克,王龙鹏,等. ZDY25000LDK智能化定向钻进装备关键技术研究[J]. 煤田地质与勘探,2022,50(1):72−79.. doi: 10.12363/issn.1001-1986.21.10.0597FANG Peng,YAO Ke,WANG Longpeng,et al. Research on key technologies of the ZDY25000LDK intelligent directional drilling equipment[J]. Coal Geology & Exploration,2022,50(1):72−79.. doi: 10.12363/issn.1001-1986.21.10.0597 [14] 姚亚峰,李晓鹏,张刚,等. 煤矿坑道钻机自动加卸钻杆装置的研发[J]. 煤矿机械,2017,38(6):91−93.. doi: 10.13436/j.mkjx.201706036YAO Yafeng,LI Xiaopeng,ZHANG Gang,et al. Development of automatic loading drill rods device on coal mine tunnel drill rig[J]. Coal Mine Machinery,2017,38(6):91−93.. doi: 10.13436/j.mkjx.201706036 [15] 梁春苗. 煤矿用钻孔机器人自动加杆识别与钻臂定位误差补偿研究[D]. 北京: 煤炭科学研究总院, 2022.LIANG Chunmiao. Study on recognition of automatic drill pipe-adding and positioning error compensation of drilling boom for the drilling robot in coal mine[D]. Beijing: China Coal Research Institute, 2022. [16] 马斌,彭光宇. 基于单目视觉的钻杆位姿识别技术研究[J]. 煤田地质与勘探,2022,50(10):171−178.. doi: 10.12363/issn.1001-1986.22.01.0036MA Bin,PENG Guangyu. Research on drill pipe pose recognition technology based on monocular vision[J]. Coal Geology & Exploration,2022,50(10):171−178.. doi: 10.12363/issn.1001-1986.22.01.0036 [17] CHEN Hang,XIN Dezhong. Research on the four–stage drill pipe automatic conveying system[J]. Journal of Physics:Conference Series,2021,2095:012043. [18] LIU Zhijian, CHEN Yunlong, RUAN Hailong. Study on dynamics of hydraulic control system for automatic loading and unloading of drill pipe of geological drilling rig[J]. Shock and Vibration, 2022, 2022. [19] 姚亚峰, 李坤, 姚宁平, 等. 一种双管自动加卸装置及煤矿双动力头钻机: CN201811424801. 5[P]. 2019-04-12. [20] 徐瑞,洪建俊,张杰. 双管定向钻进技术在祁南矿313工作面的应用[J]. 煤矿安全,2021,52(7):121−124.XU Rui,HONG Jianjun,ZHANG Jie. Application of double pipe directional drilling technology in 313 face of Qinan Mine[J]. Safety in Coal Mines,2021,52(7):121−124. [21] 王力. 井下碎软煤层双管双动空气定向钻进工艺研究[J]. 煤田地质与勘探,2022,50(7):166−172.. doi: 10.12363/issn.1001-1986.22.02.0072WANG Li. Techniques of double–pipe and double–acting directional drilling with air in broken and soft coal seams in underground coal mines[J]. Coal Geology & Exploration,2022,50(7):166−172.. doi: 10.12363/issn.1001-1986.22.02.0072 -

下载:

下载: