Study on performance optimization of gasification slag based paste filling materials in Ningdong mining area

-

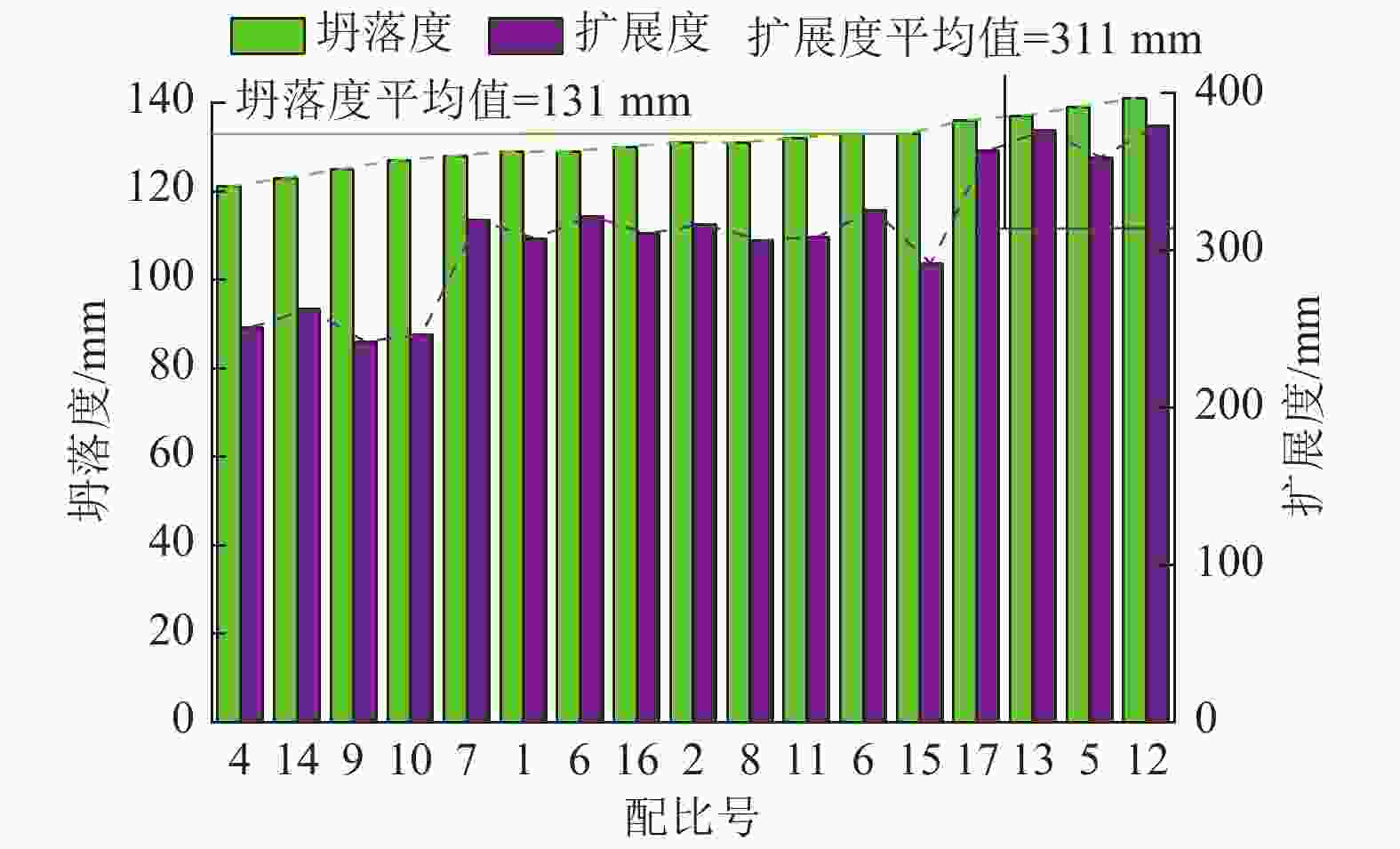

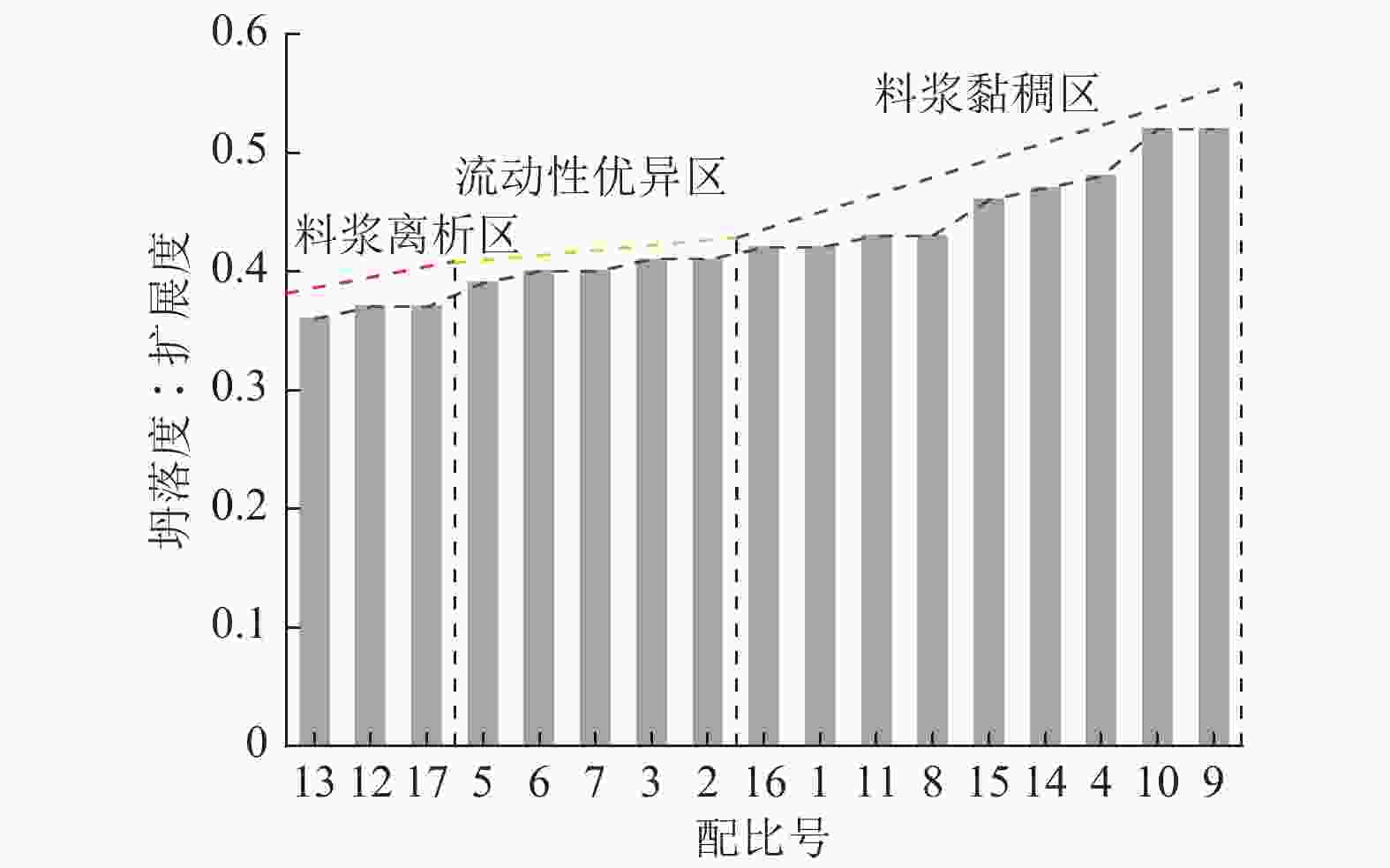

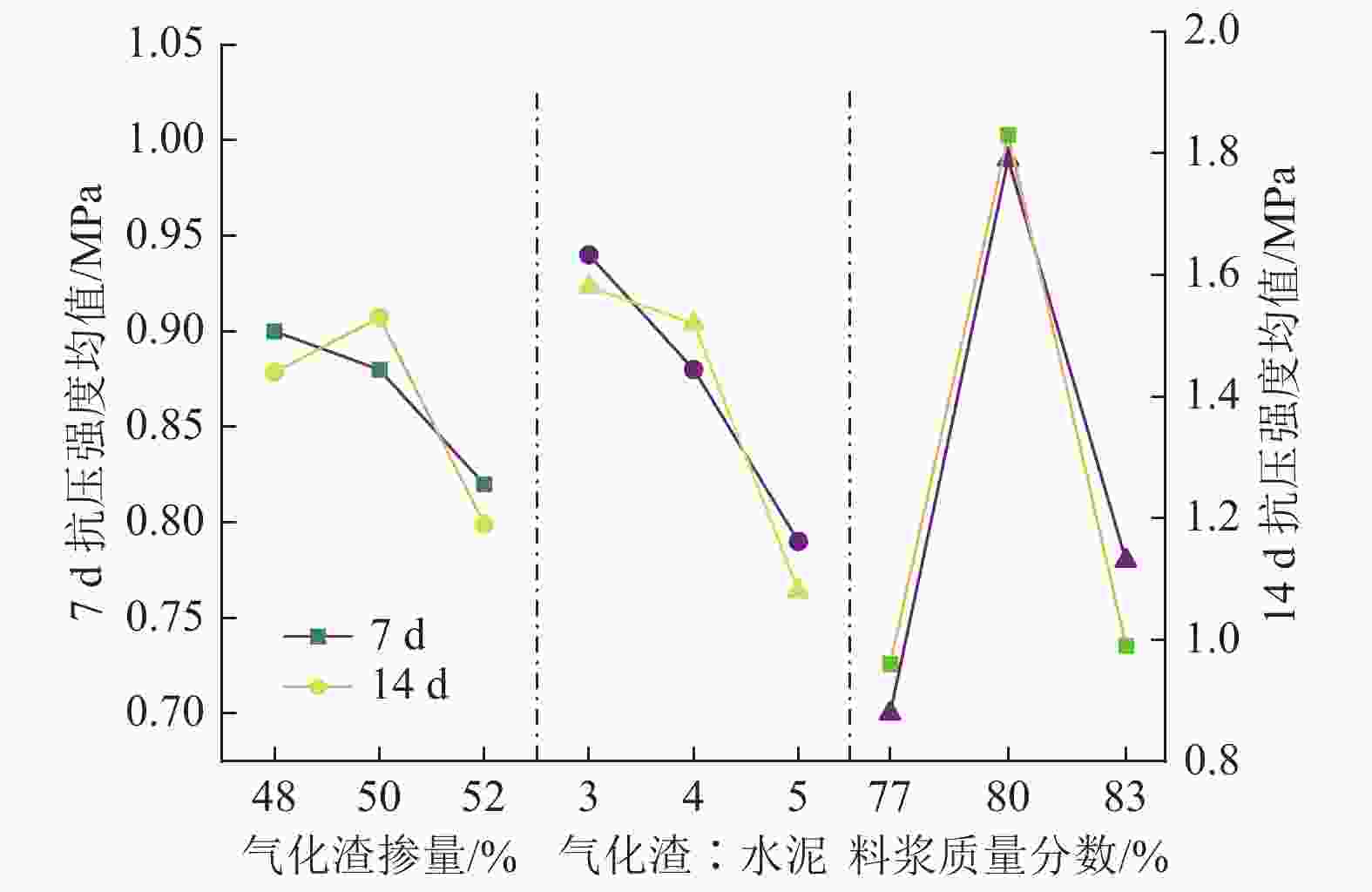

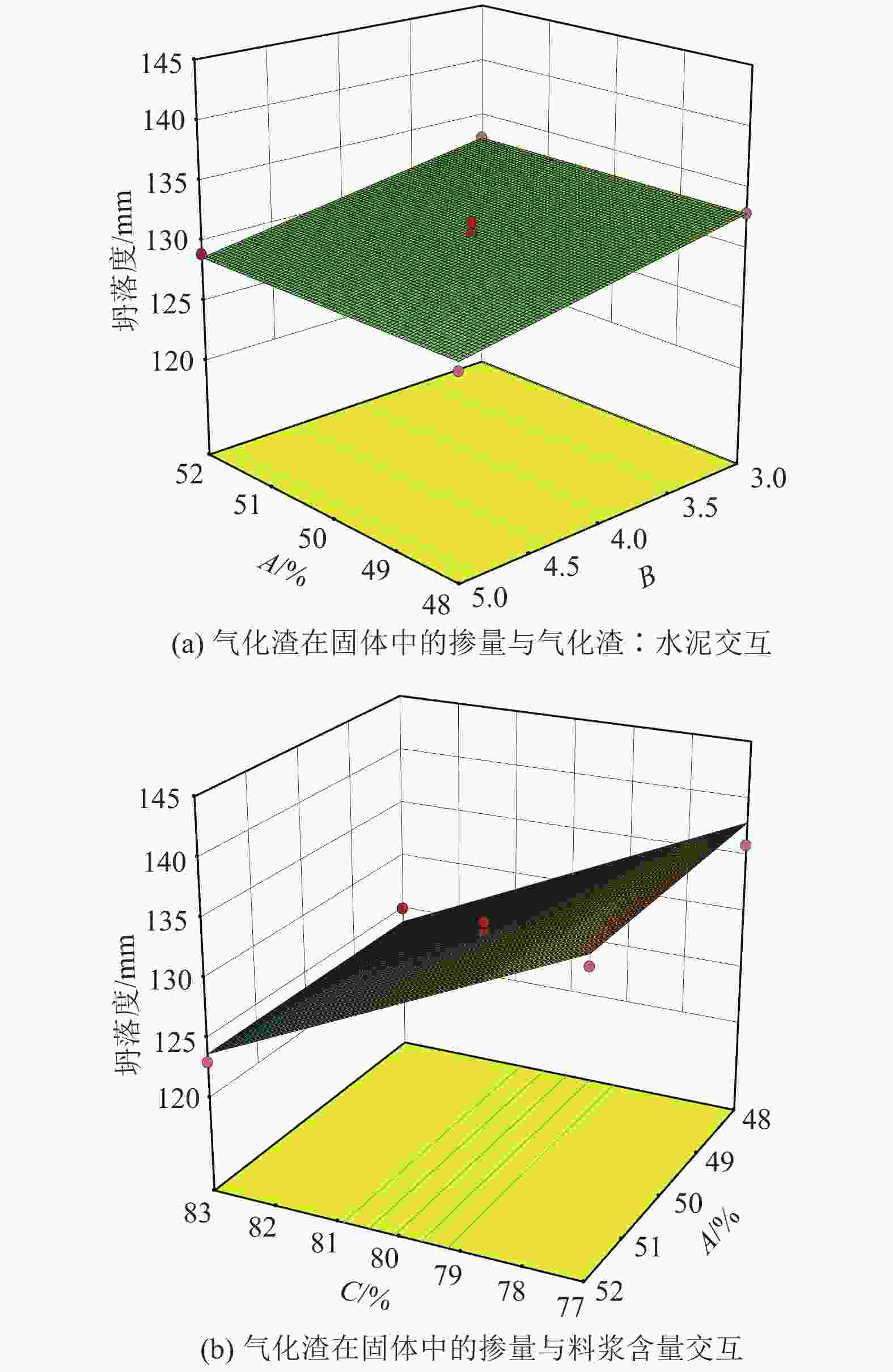

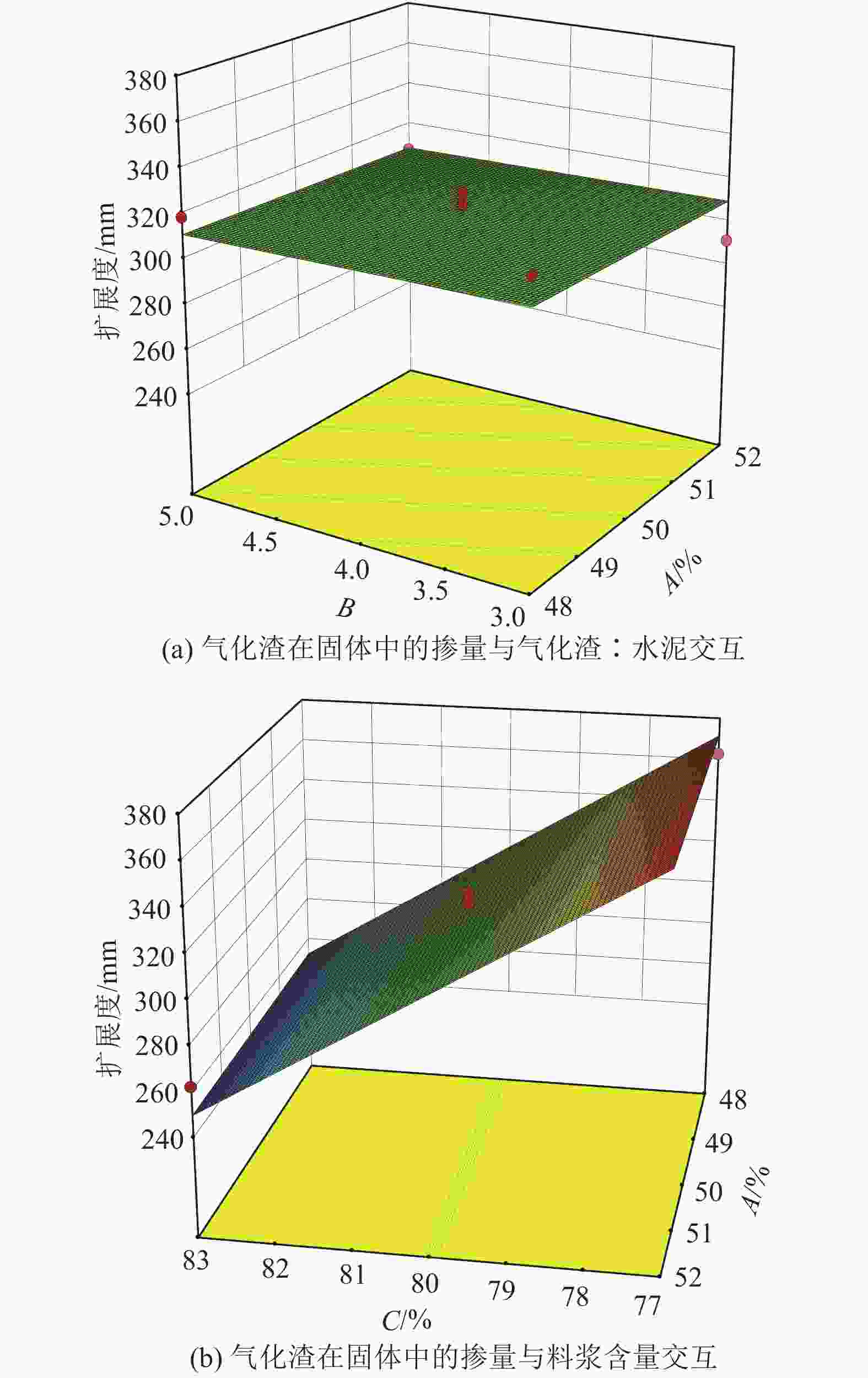

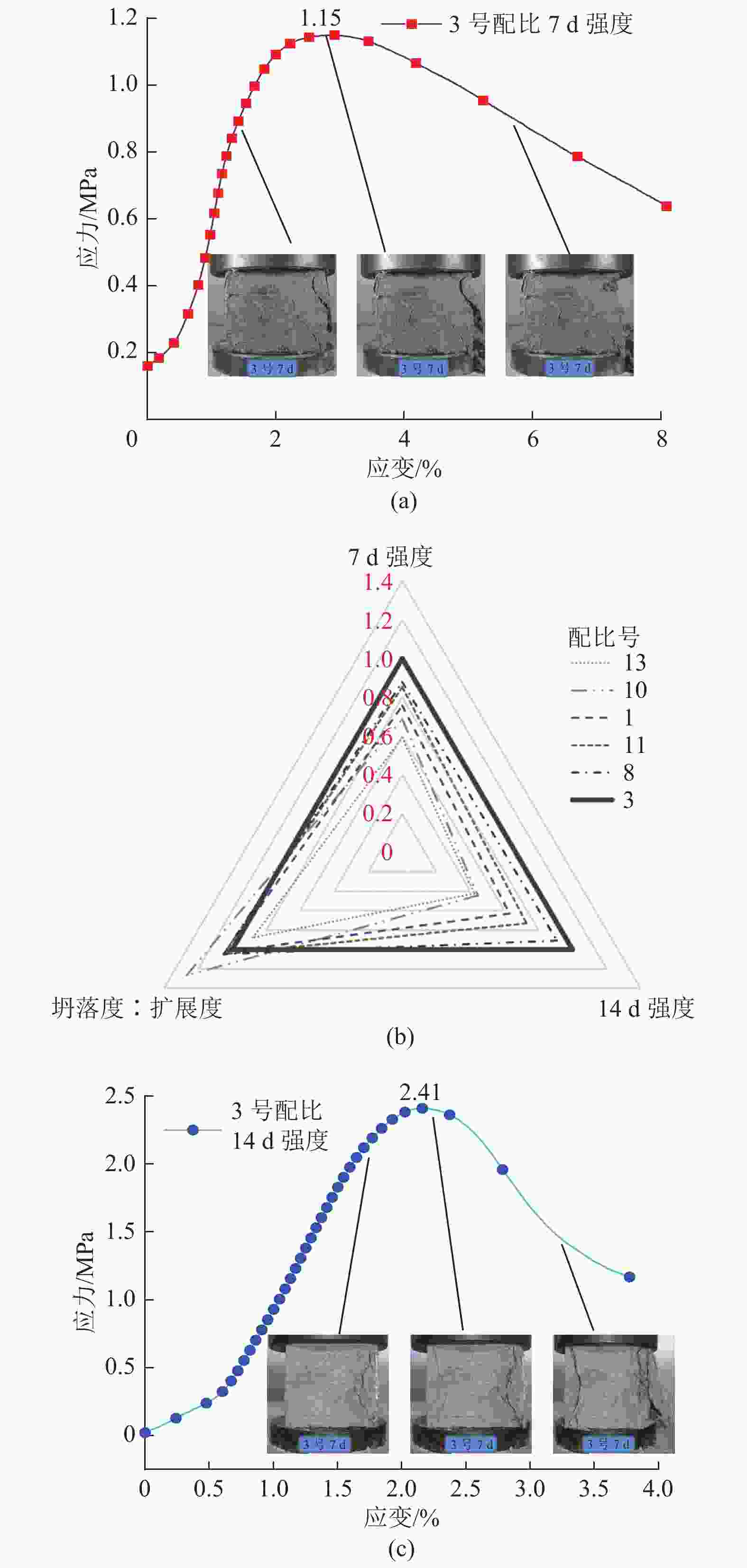

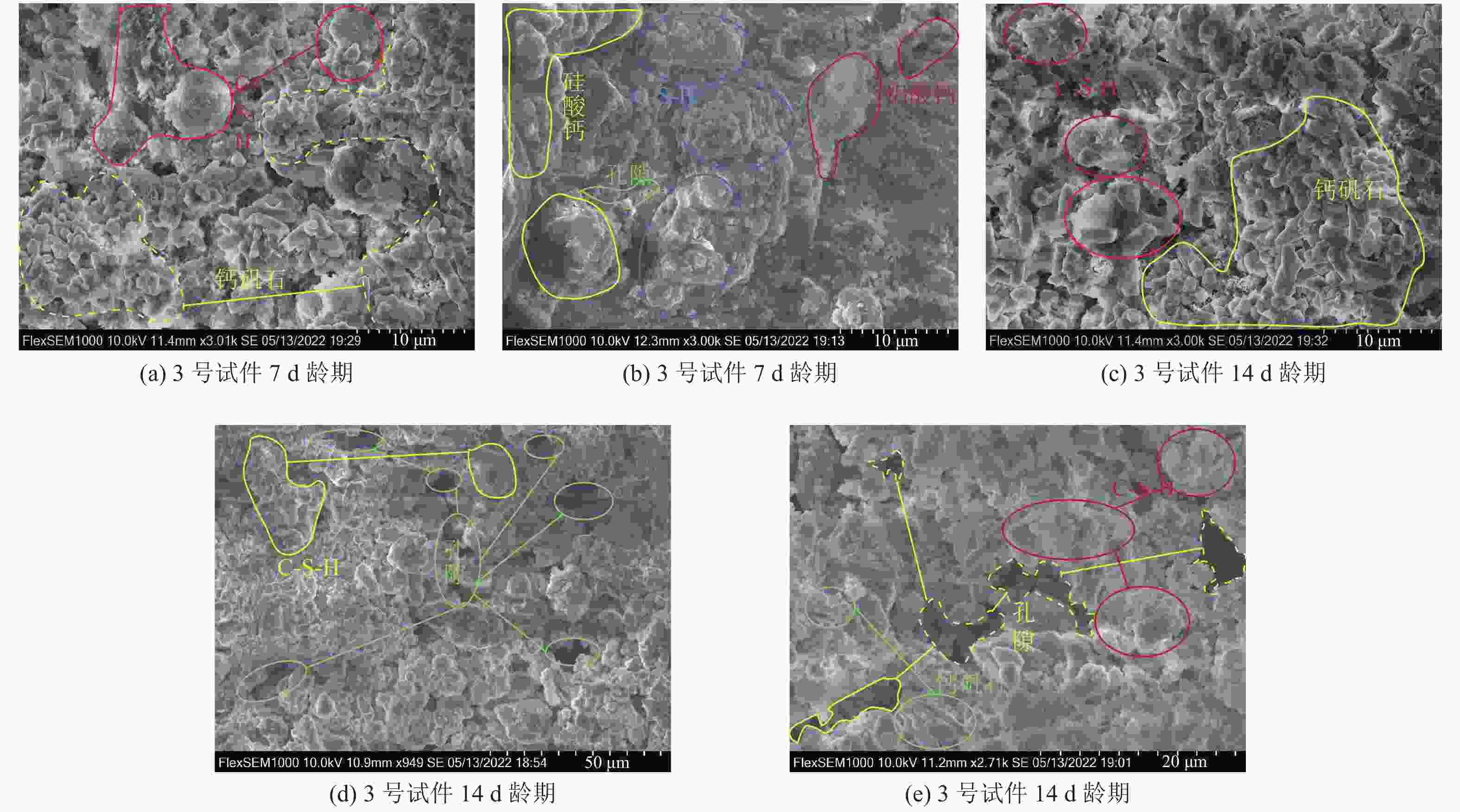

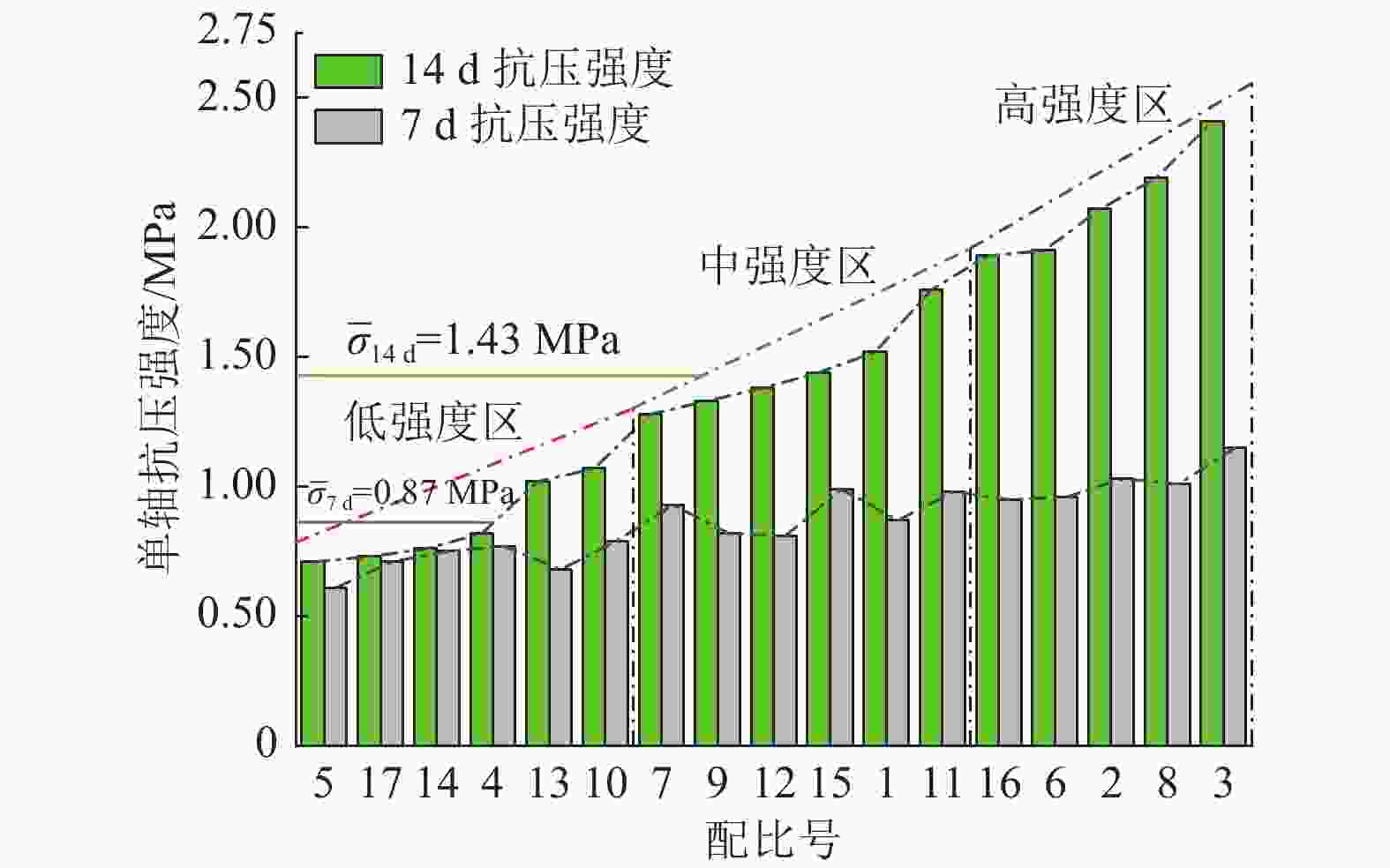

摘要: 宁东矿区作为黄河流域的9个亿吨煤基地之一,年产出煤基固废近2×108 t且气化渣堆存量大、规模化利用困难、简单填埋处理空间有限,充填开采能解决空间堆存难题,但成本高、性能亟待优化。根据响应面法设计气化渣在固体中的掺量(A)、气化渣与水泥质量比(B)、料浆含量(C)3因素3水平共17组中心组合实验,对气化渣基膏体充填材料的坍落度、扩展度、7和14 d单轴抗压强度等性能进行了对比优化研究。实验前使用X射线衍射仪(XRD)和扫描电镜(SEM)对原料的成分及微观形态进行观测分析,试块单轴压缩后通过SEM观测分析水化作用特点,揭示强度形成机制。综合强度和流动性得到最优配比及其性能特征为:A为48%,B为3,C为80%,脱硫石膏∶煤矸石∶炉底渣的质量按2∶1∶1配制,其7、14 d强度分别为1.15、2.41 MPa,坍落度为133 mm,扩展度为325.5 mm,坍落度与扩展度的比值为0.41。进一步基于响应面法分析得到7、14 d强度的单影响因素按显著性排序分别为:B>C=A、B>A>C;7、14 d强度的交互影响因素按显著性排序分别为:BC>AB>AC、AB> AC>BC;坍落度和扩展度的单影响因素按显著性排序分别为:C>B>A和C>A>B,进而为严控地表沉降、快充减少堵管、强度成本兼顾3种不同功能需求优选了对应配比方案及参数。研究成果为黄河流域的生态保护与煤炭低损伤开采提供了重要基础参数和优化方向。

-

关键词:

- 气化渣基膏体充填材料 /

- 响应面法 /

- 影响因素 /

- 性能优化 /

- 水化机理

Abstract: As one of the nine coal bases at hundred million ton level in Yellow River Basin, Ningdong Mining Area has nearly 2×108 t of coal-based solid waste produced annually, and faces to the problems of large stock of gasification slag, difficulty in scaled utilization, and limited space for simple landfill. Filling mining could solve the problem of stockpiling, of which the cost is high and the performance needs to be optimized. According to the response surface method, 17 groups of central composite experiments were designed for the three factors at three levels: the mixing amount of gasification slag in solid (A), the mass ratio of gasification slag to cement (B), and the slurry concentration (C). Meanwhile, comparative optimization research was conducted for the slump, expansion, 7 d and 14 d uniaxial compressive strength and other properties of gasification slag based paste filling materials. Before the experiment, the composition and micromorphology of the raw materials were observed and analyzed by XRD and SEM. Besides, the test block was observed by SEM and had its hydration characteristics analyzed after uniaxial compression, thereby revealing the strength formation mechanism. By integrating the strength and fluidity, the following optimum mixing ratio and performance characteristics of the filling material were obtained: 48% for A, 3 for B and 80% for C. Meanwhile, the desulfurized gypsum, coal gangue and bottom slag should be mixed at the mass ratio of 2∶1∶1 to reach the 7 d and 14 d strengths of 1.15 MPa and 2.41 MPa respectively, the slump of 133 mm, the expansion of 325.5 mm, and the slump to expansion ratio of 0.41. According to the further analysis based on response surface method, the single influencing factors of 7 d and 14 d strength are B>C=A and B>A>C, the interaction influencing factors of 7 d and 14 d strength are BC>AB>AC and AB>AC>BC, and the single influencing factors of slump and expansion are C>B>A and C>A>B respectively according to the significance. On this basis, the proportioning scheme and parameters were optimized for the 3 different functional requirements, including the strict control of surface settlement, rapid filling to reduce pipe plugging, and control of strength and cost. Generally, the research results provide important basic parameters and optimization direction for the ecological protection and low damage coal mining in Yellow River Basin. -

表 1 预实验结果

Table 1 Prepare test results

实验水平分组 7 d强度/MPa 14 d强度/MPa 坍落度/mm 扩展度/mm 低 1.22 2.01 139 351 中 0.83 1.39 135 322 高 0.75 0.94 121 308 表 2 实验方案

Table 2 Experimental scheme

组序号 A/% B C/% 1 52 5 80 2 50 4 80 3 48 3 80 4 50 5 83 5 50 5 77 6 50 4 80 7 48 5 80 8 50 4 80 9 48 4 83 10 50 3 83 11 50 4 80 12 50 3 77 13 52 4 77 14 52 4 83 15 52 3 80 16 50 4 80 17 48 4 77 表 3 7 d抗压强度推荐模型

Table 3 Recommended 7 d compressive strength model and analysis of variance

模型 校正R2 预测R2 备注 Linear 0.0077 −0.4844 2FI −0.2373 −2.1286 Quadratic 0.9431 0.7970 建议采用 Cubic 0.9459 表 4 14 d抗压强度推荐模型

Table 4 Recommended 14 d compressive strength model and analysis of variance

模型 校正R2 预测R2 备注 Linear −0.0640 −0.5018 2FI −0.1734 −1.4885 Quadratic 0.9181 0.7409 建议采用 Cubic 0.9130 表 5 坍落度推荐模型

Table 5 Recommended slump model

模型 校正R2 预测R2 备注 Linear 0.9329 0.8974 建议采用 2FI 0.9350 0.8391 Quadratic 0.9416 0.7517 Cubic 0.9555 表 6 扩展度推荐模型

Table 6 Extension recommendation model

模型 校正R2 预测R2 备注 Linear 0.9440 0.9103 建议采用 2FI 0.9432 0.8410 Quadratic 0.9214 0.5270 Cubic 0.9785 -

[1] 杨科,魏祯,赵新元,等. 黄河流域煤电基地固废井下绿色充填开采理论与技术[J]. 煤炭学报,2021,46(增刊2):925−935.. doi: 10.13225/j.cnki.jccs.st21.0284YANG Ke,WEI Zhen,ZHAO Xinyuan,et al. Theory and technology of green filling of solid waste in underground mine at coal power base of Yellow River Basin[J]. Journal of China Coal Society,2021,46(Sup.2):925−935.. doi: 10.13225/j.cnki.jccs.st21.0284 [2] 靳德武,王甜甜,赵宝峰,等. 宁东煤田东北部高矿化度地下水分布特征及形成机制[J]. 煤田地质与勘探,2022,50(7):118−127.. doi: 10.12363/issn.1001-1986.21.10.0593JIN Dewu,WANG Tiantian,ZHAO Baofeng,et al. Distribution characteristics and formation mechanism of high salinity groundwater in northeast Ningdong Coalfield[J]. Coal Geology & Exploration,2022,50(7):118−127.. doi: 10.12363/issn.1001-1986.21.10.0593 [3] 王景升,李佳,陈宝雄,等. 宁夏东部能源化工基地煤炭产业生态风险评估[J]. 资源科学,2013,35(10):2011−2016.WANG Jingsheng,LI Jia,CHEN Baoxiong,et al. Coal mining ecological risk assessment of the energy chemical production base in Eastern Ningxia[J]. Resource Science,2013,35(10):2011−2016. [4] 王璐,于瑶,任会斌,等. 积存超600亿吨工业固废如何走出“埋埋埋”尴尬[J]. 资源再生,2020(6):40−42.WANG Lu,YU Yao,REN Huibin,et al. How to get rid of the embarrassment of“buried and buried”for the accumulation of over 60 billion tons of industrial solid waste[J]. Resource Recycling,2020(6):40−42. [5] 张新国,江宁,张玉江,等. 矸石膏体充填材料力学特性试验[J]. 金属矿山,2012(12):127−131.. doi: 10.3969/j.issn.1001-1250.2012.12.033ZHANG Xinguo,JIANG Ning,ZHANG Yujiang,et al. Study on mechanical properties of coal waste paste filling materials[J]. Metal Mine,2012(12):127−131.. doi: 10.3969/j.issn.1001-1250.2012.12.033 [6] 王有志. 煤矸石–粉煤灰用作井下充填材料实验研究[J]. 有色金属工程,2020,10(11):108−113.. doi: 10.3969/j.issn.2095-1744.2020.11.016WANG Youzhi. Experimental study on coal gangue–fly ash as underground filling material[J]. Nonferrous Metals Engineering,2020,10(11):108−113.. doi: 10.3969/j.issn.2095-1744.2020.11.016 [7] 唐岳松,张令非,吕华永,等. 煤基固废制备充填材料配比优化试验研究[J]. 矿业科学学报,2019,4(4):327−336.. doi: 10.19606/j.cnki.jmst.2019.04.006TANG Yuesong,ZHANG Lingfei,LYU Huayong,et al. Study on proportion optimization of coal–based solid wastes filling materials[J]. Journal of Mining Science and Technology,2019,4(4):327−336.. doi: 10.19606/j.cnki.jmst.2019.04.006 [8] 崔增娣,孙恒虎. 煤矸石凝石似膏体充填材料的制备及其性能[J]. 煤炭学报,2010,35(6):896−899.. doi: 10.13225/j.cnki.jccs.2010.06.007CUI Zengdi,SUN Henghu. The preparation and properties of coal gangue based sialite paste–like backfill material[J]. Journal of China Coal Society,2010,35(6):896−899.. doi: 10.13225/j.cnki.jccs.2010.06.007 [9] 程海勇,吴爱祥,王贻明,等. 粉煤灰–水泥基膏体微观结构分形表征及动力学特征[J]. 岩石力学与工程学报,2016,35(增刊2):4241−4248.. doi: 10.13722/j.cnki.jrme.2015.1607CHENG Haiyong,WU Aixiang,WANG Yiming,et al. Fractal features and dynamical characters of the microstructure of paste backfill prepared from fly ash based binder[J]. Chinese Journal of Rock Mechanics and Engineering,2016,35(Sup.2):4241−4248.. doi: 10.13722/j.cnki.jrme.2015.1607 [10] 李茂辉,杨志强,王有团,等. 粉煤灰复合胶凝材料充填体强度与水化机理研究[J]. 中国矿业大学学报,2015,44(4):650−655.. doi: 10.13247/j.cnki.jcumt.000365LI Maohui,YANG Zhiqiang,WANG Youtuan,et al. Experiment study of compressive strength and mechanical property of filling body for fly ash composite cementitious materials[J]. Journal of China University of Mining & Technology,2015,44(4):650−655.. doi: 10.13247/j.cnki.jcumt.000365 [11] 杨宝贵,杨捷,于跃,等. 煤矿新型胶凝充填材料配比试验及水化机理研究[J]. 矿业科学学报,2017,2(5):475−481.. doi: 10.19606/j.cnki.jmst.2017.05.009YANG Baogui,YANG Jie,YU Yue,et al. Study on proportioning test of a new cementing filling material and hydration mechanism[J]. Journal of Mining Science and Technology,2017,2(5):475−481.. doi: 10.19606/j.cnki.jmst.2017.05.009 [12] 赵康,黄明,严雅静,等. 不同灰砂比尾砂胶结充填材料组合体力学特性及协同变形研究[J]. 岩石力学与工程学报,2021,40(增刊1):2781−2789.. doi: 10.13722/j.cnki.jrme.2020.0692ZHAO Kang,HUANG Ming,YAN Yajing,et al. Mechanical properties and synergistic deformation characteristics of tailings cemented filling assembled material body with different cement−tailings ratios[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(Sup.1):2781−2789.. doi: 10.13722/j.cnki.jrme.2020.0692 [13] 温亮,阎长虹,张政,等. 水泥–粉煤灰–煤渣–吹填粉细砂混合料强度试验[J]. 煤田地质与勘探,2019,47(1):149−154.. doi: 10.3969/j.issn.1001-1986.2019.01.023WEN Liang,YAN Changhong,ZHANG Zheng,et al. Test on the strength of the backfill fine sand mixture composed of cement−fly ash−cinder[J]. Coal Geology & Exploration,2019,47(1):149−154.. doi: 10.3969/j.issn.1001-1986.2019.01.023 [14] 李磊. 颚式破碎机能耗和齿板结构参数研究[D]. 长沙: 中南大学, 2009.LI Lei. Study on energy consumption and toothed plate structural parameters of jaw crusher[D]. Changsha: Central South University, 2009. [15] 刘智勇. 粉煤灰的经济价值和利用探讨[J]. 现代经济信息,2017(13):335.. doi: 10.3969/j.issn.1001-828X.2017.13.278LIU Zhiyong. Discussion on economic value and utilization of fly ash[J]. Modern Economic Information,2017(13):335.. doi: 10.3969/j.issn.1001-828X.2017.13.278 [16] 张明, 院晓丽. 砼拌合物的坍落度和坍落扩展度之关系[J]. 建筑与发展, 2012.ZHANG Ming, YUAN Xiaoli. The relationship between slump and slump expansion of concrete mixture[J]. Architecture and Development, 2012. [17] 李典,冯国瑞,郭育霞,等. 基于响应面法的充填体强度增长规律分析[J]. 煤炭学报,2016,41(2):392−398.. doi: 10.13225/j.cnki.jccs.2015.0240LI Dian,FENG Guorui,GUO Yuxia,et al. Analysis on the strength increase law of filling material based on response surface method[J]. Journal of China Coal Society,2016,41(2):392−398.. doi: 10.13225/j.cnki.jccs.2015.0240 [18] 张超,王星龙,李树刚,等. 基于响应面法治理煤矿硫化氢的改性碱液配比优化[J]. 煤炭学报,2020,45(8):2926−2932.. doi: 10.13225/j.cnki.jccs.2020.0094ZHANG Chao,WANG Xinglong,LI Shugang,et al. Optimization of the ratio of modified alkaline solution for hydrogen sulfide treatment in coal mine based on response surface method[J]. Journal of China Coal Society,2020,45(8):2926−2932.. doi: 10.13225/j.cnki.jccs.2020.0094 [19] 唐海,赵海龙,黄靖龙,等. 煤矿膏体充填材料配比试验研究[J]. 华北科技学院学报,2015,12(4):43−47.. doi: 10.3969/j.issn.1672-7169.2015.04.009TANG Hai,ZHAO Hailong,HUANG Jinglong,et al. Study on proportion experiment of paste filling material in coal mine[J]. Journal of North China Institute of Science and Technology,2015,12(4):43−47.. doi: 10.3969/j.issn.1672-7169.2015.04.009 [20] 徐文彬,潘卫东,丁明龙. 胶结充填体内部微观结构演化及其长期强度模型试验[J]. 中南大学学报(自然科学版),2015,46(6):2333−2341.XU Wenbin,PAN Weidong,DING Minglong. Experiment on evolution of microstructures and long–term strength model of cemented backfill mass[J]. Journal of Central South University (Science and Technology),2015,46(6):2333−2341. [21] 冯国瑞,任亚峰,张绪言,等. 塔山矿充填开采的粉煤灰活性激发实验研究[J]. 煤炭学报,2011,36(5):732−737.. doi: 10.13225/j.cnki.jccs.2011.05.018FENG Guorui,REN Yafeng,ZHANG Xuyan,et al. The activating experimental research of fly ash for mining fillingmaterial in Tashan Mine[J]. Journal of China Coal Society,2011,36(5):732−737.. doi: 10.13225/j.cnki.jccs.2011.05.018 [22] 屈慧升,索永录,刘浪,等. 改性煤气化渣基矿用充填材料制备与性能[J]. 煤炭学报,2022,47(5):1958−1973.QU Huisheng,SUO Yonglu,LIU Lang,et al. Preparation and properties of modified coal gasification slag–based filling materials for mines[J]. Journal of China Coal Society,2022,47(5):1958−1973. -

下载:

下载: