Numerical simulation of the influence of karst structure on heat transfer efficiency of buried pipeline group

-

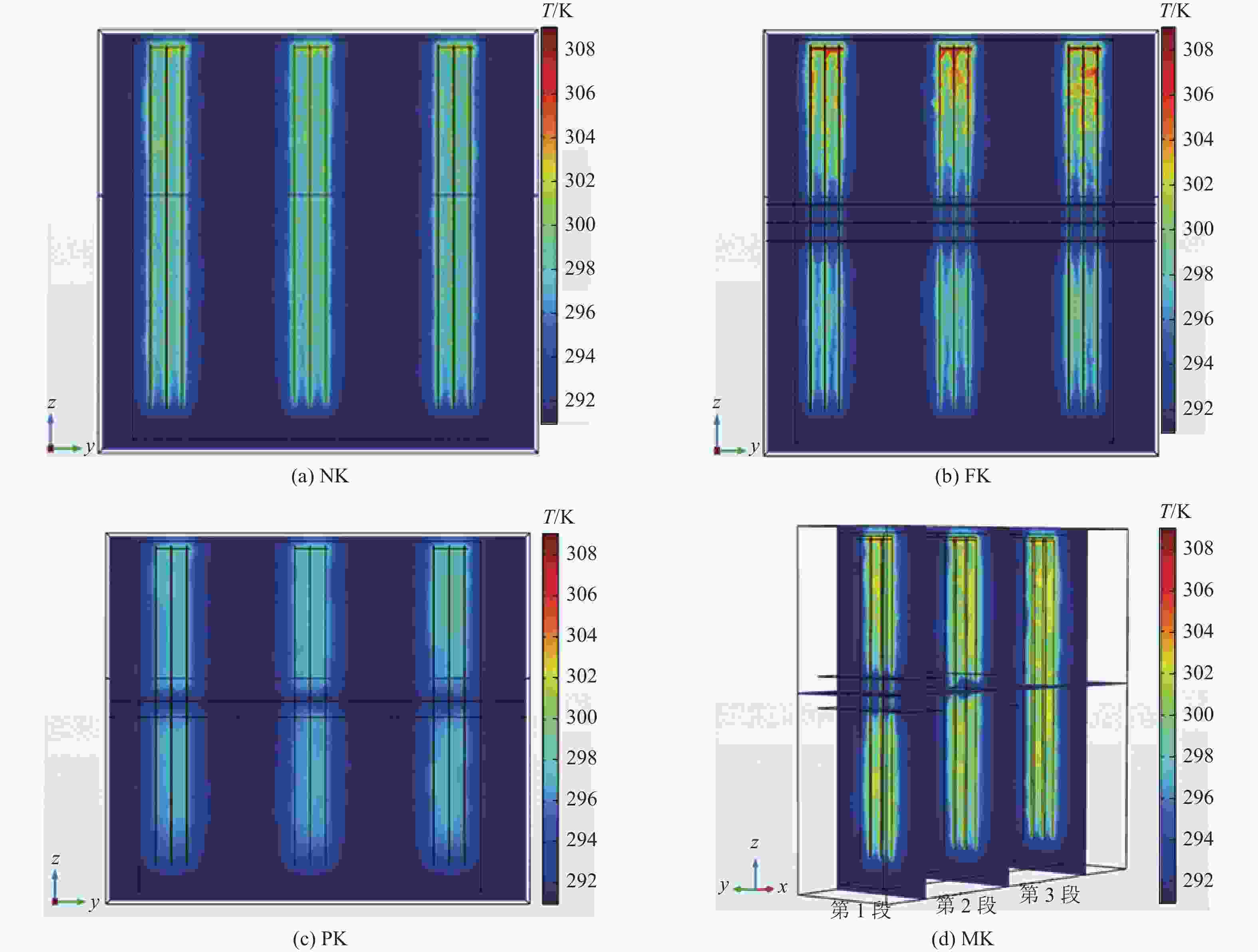

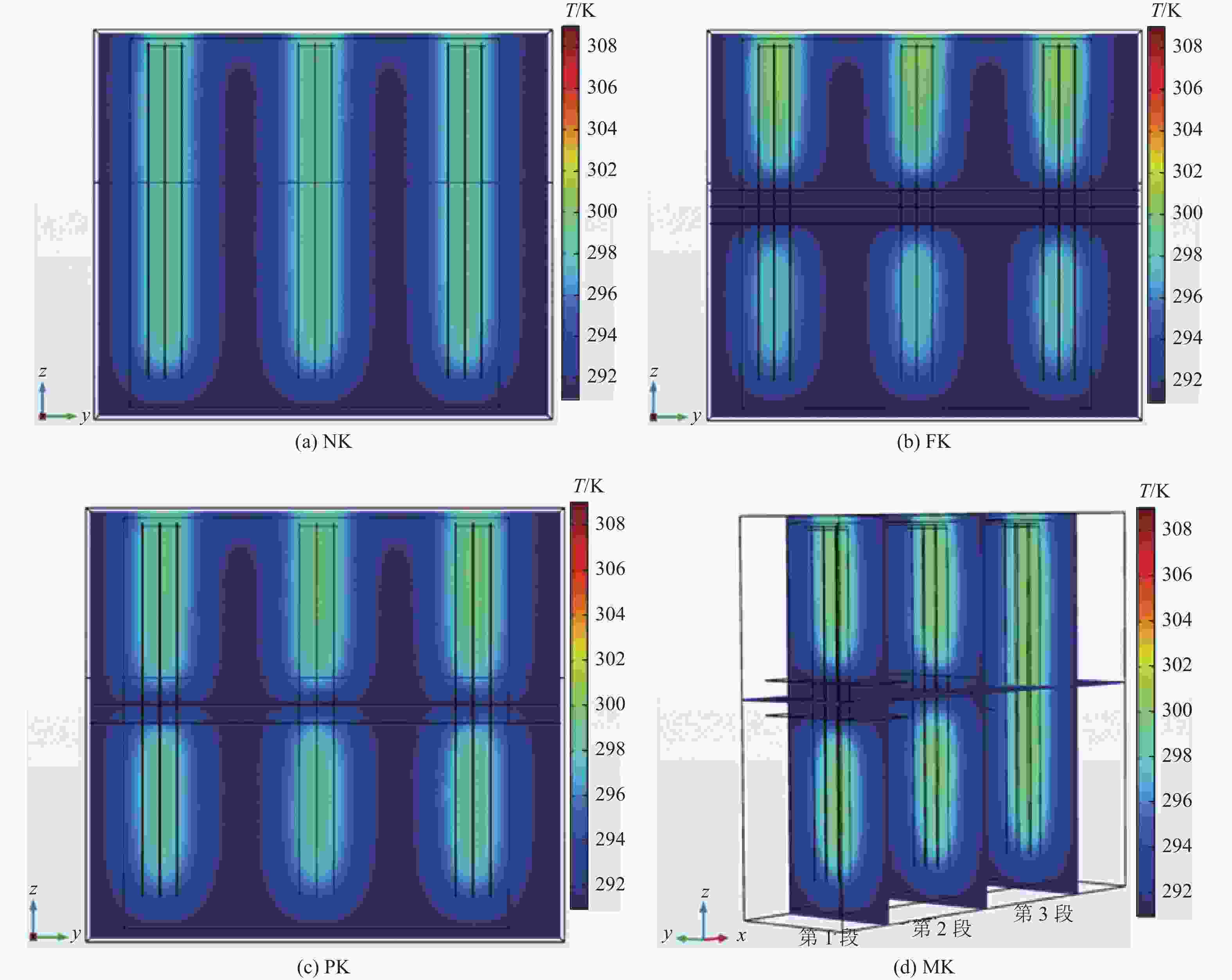

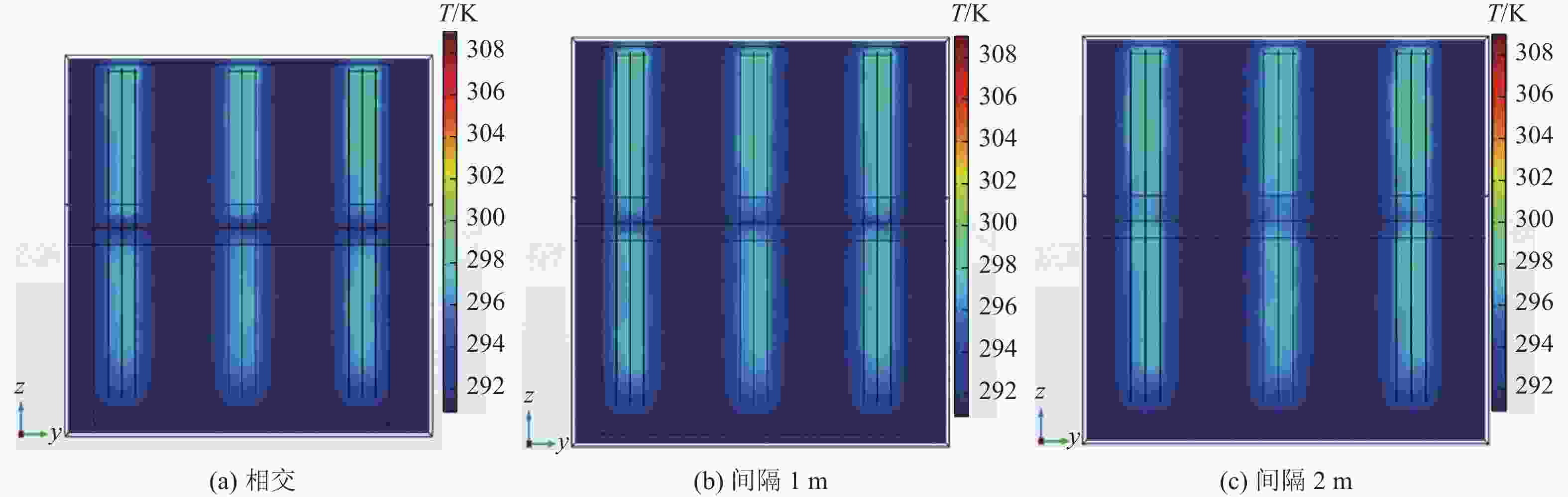

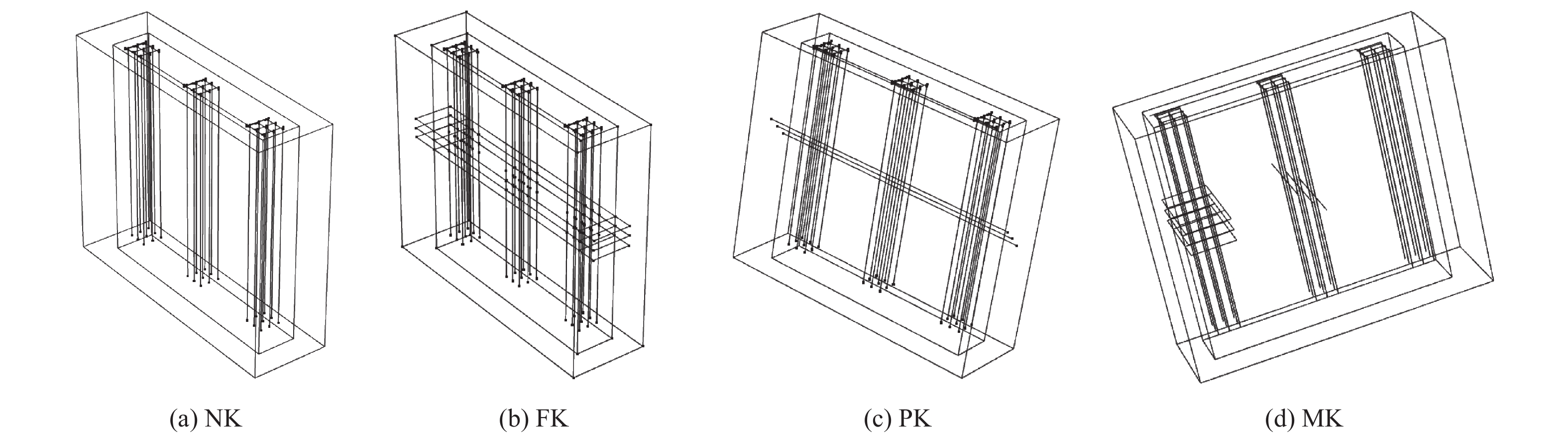

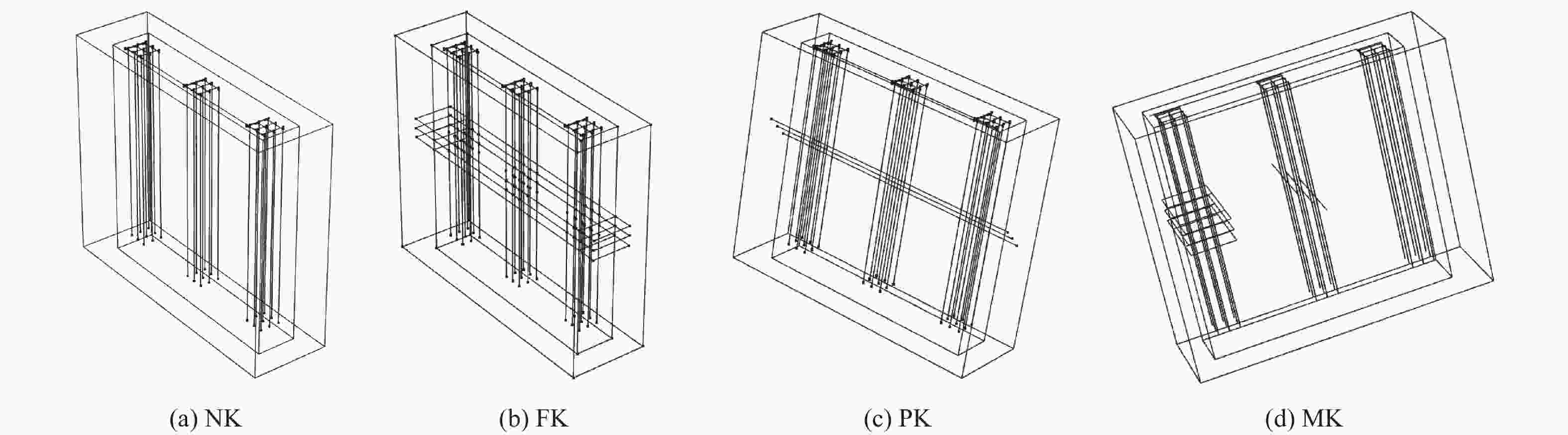

摘要: 地埋管是岩体热泵系统与地层直接交换冷热量的部分。岩溶地区含水构造复杂多样,对地埋管群换热储热有明显影响。对27根垂直地埋管群在无岩溶构造、岩溶裂隙构造、岩溶管道构造以及混合岩溶构造4种地质构造类型中的换热过程进行了模拟,并对比了岩体内温度场、埋管出口水温、热泵机组制冷系数(COP)以及单位井深换热量等参数的变化。结果表明:在制冷工况下,不同模型温度场中,岩体中存在岩溶裂隙构造或岩溶管道构造时,地下水流动对岩体热堆积有明显缓解作用;岩溶导水构造与地埋管的距离也是重要影响因素。模型运行到第1个制冷周期末期时,含岩溶裂隙构造岩体和含岩溶管道构造岩体的进出口水温差比混合岩溶构造岩体的分别升高了0.87、4.00 K;无岩溶构造岩体进出口水温差比混合岩溶构造岩体的下降了1.16 K。无岩溶构造岩体、岩溶裂隙构造岩体、岩溶管道构造岩体和混合岩溶构造岩体的COP分别为7.2、7.4、7.8和7.3;单位井深换热量分别为64.1、90.3、130.7和79.1 W/m。研究结果表明,岩溶导水构造明显增强了地埋管群的换热效率,不同的地质构造类型对地埋管换热效率的影响也不一样。Abstract: The buried pipeline is the part where the rock mass heat pump system performs direct heat transfer with the ground. The water-bearing structure in the karst area is complex and diverse, which has a significant impact on the heat transfer and storage of the buried pipeline group. Herein, the heat transfer process of a group of 27 vertical buried pipelines in four geological structure types was simulated, including the non-karst structure, fractured karst structure, karst conduit structure and mixed karst structure. Meanwhile, comparison was made for the change of parameters, such as the temperature field in the rock mass, the outlet water temperature of buried pipeline, the coefficient of performance (COP) of heat pump unit, and the heat change in unit well depth. The results show that the flow of groundwater can significantly relieve the heat build-up in the rock mass where fractured karst structure and karst conduit structure exist in different model temperature fields under the refrigeration conditions, and the distance between the karst water-conducting structure and the buried pipeline is also an important influencing factor. When the model operates to the end of the first refrigeration cycle, the temperature difference between the inlet and outlet of rock mass in fractured karst structure and karst conduit structure is 0.87 K and 4.00 K higher than that in mixed karst structure respectively, while the temperature difference between the inlet and outlet of rock mass in non-karst structure is 1.16 K lower than that in mixed karst structure. The COPs of rock mass in non-karst structure, fractured karst structure, karst conduit structure, and mixed karst structure are 7.2, 7.4, 7.8 and 7.3 respectively. Besides, the heat transfer per well depth is 64.1, 90.3, 130.7 and 79.1 W/m respectively. The research results show that the karst water-conducting structure significantly enhances the heat transfer efficiency of the buried pipeline group, and different geological structure types have different effects on the heat transfer efficiency of the buried pipeline.

-

表 1 模拟设计参数

Table 1 Simulation design parameters

表 2 热响应测试数据

Table 2 Thermal response test data

指标 数值 岩体平均原始地温/K 290.95 供水温度/K 291.15 流速/(m·s–1) 0.8 U型管深度/m 150 U型管内/外径/mm 26/32 U型管管间距/mm 80 运行时间/h 48 岩体导热系数/(W·m–1∙K–1) 2.85 回填材料导热系数/(W·m–1∙K–1) 2.2 表 3 地埋管群出口水温

Table 3 Outlet water temperature of buried pipe group

时间/月 温度/K PK MK FK NK 1.5 300.41 300.10 300.97 301.69 2.0 300.89 300.75 301.23 302.18 2.5 301.36 301.17 301.46 302.44 3.0 300.54 301.45 301.62 302.71 3.5 299.28 301.74 301.35 302.97 4.0 298.02 302.02 301.15 303.18 4.5 296.76 301.78 299.03 301.68 13.5 300.03 302.11 301.81 303.13 14.0 301.65 302.37 302.04 303.53 14.5 302.02 302.62 302.18 303.78 15.0 302.32 302.88 302.33 304.02 15.5 302.63 303.13 302.47 304.17 16.0 302.93 301.91 302.30 304.31 16.5 302.29 300.29 300.89 303.59 表 4 热泵机组制冷系数COP

Table 4 Unit performance coefficient COP

时间/月 制冷系数COP PK MK FK NK 1.5 7.5 7.5 7.4 7.3 2.0 7.4 7.4 7.4 7.3 2.5 7.4 7.4 7.4 7.2 3.0 7.5 7.4 7.3 7.2 3.5 7.6 7.3 7.4 7.2 4.0 7.8 7.3 7.4 7.2 4.5 7.9 7.3 7.7 7.3 13.5 7.5 7.3 7.3 7.2 14.0 7.3 7.3 7.3 7.1 14.5 7.3 7.2 7.3 7.1 15.0 7.3 7.2 7.3 7.1 15.5 7.2 7.2 7.2 7.0 16.0 7.2 7.3 7.3 7.0 16.5 7.3 7.5 7.4 7.1 表 5 单位井深换热量

Table 5 Heat transfer per well depth

时间/月 单位井深换热量/(W·m−1) PK MK FK NK 1.5 100 104 93 83 2.0 94 95 89 77 2.5 88 90 86 74 3.0 98 86 84 70 3.5 114 83 88 67 4.0 131 79 90 64 4.5 147 82 118 83 13.5 105 78 82 65 14.0 84 75 79 60 14.5 79 71 77 56 15.0 75 68 75 53 15.5 71 65 73 51 16.0 67 81 75 50 16.5 76 101 94 59 -

[1] SANDS D. The carnot cycle,reversibility and entropy[J]. Entropy,2021,23(7):810.. doi: 10.3390/e23070810 [2] ZHOU Weisong,PEI Peng,MAO Ruiyong,et al. Selection and techno–economic analysis of hybrid ground source heat pumps used in karst regions[J]. Science Progress,2020,103(2):1−17. [3] BIDARMAGHZ A,CHOUDHARY R,SOGA K,et al. Influence of geology and hydrogeology on heat rejection from residential basements in urban areas[J]. Tunnelling and Underground Space Technology,2019,92:103068.. doi: 10.1016/j.tust.2019.103068 [4] BAHMANI M H,AKBARI O A,ZARRINGHALAM M,et al. Forced convection in a double tube heat exchanger using nanofluids with constant and variable thermophysical properties[J]. International Journal of Numerical Methods for Heat & Fluid Flow,2019,30(6):3247−3265. [5] COVINGTON M D,LUHMANN A J,GABROVEK F,et al. Mechanisms of heat exchange between water and rock in karst conduits[J]. Water Resources Research,2011,47(10):10514. [6] BOROVIC S,TERZIC J,URUMOVIC K. Conditions for shallow geothermal energy utilization in Dinaric karst terrains in Croatia[J]. Environmental Earth Sciences,2019,78(7):245.. doi: 10.1007/s12665-019-8251-y [7] 曹琦, 张道. 地源热泵空调系统和水文地质构造之间的关系[C]//地温资源与地源热泵技术应用论文集(第一集). 中国资源综合利用协会地温资源综合利用专业委员会. 北京: 中国大地出版社, 2007. [8] 张道,曹琦. 浅论陕西省水文地质构造及其适合的地源热泵形式[J]. 制冷与空调,2010,10(2):14−17.. doi: 10.3969/j.issn.1009-8402.2010.02.004ZHANG Dao,CAO Qi. Discussion of hydrogeological structures of Shaanxi Province and the applicable forms of GSHP[J]. Refrigeration and Air–Conditioning,2010,10(2):14−17.. doi: 10.3969/j.issn.1009-8402.2010.02.004 [9] CUI Xianze,FAN Yong,WANG Hongxing,et al. Ground environment characteristics during the operation of GWHP considering the particle deposition effect[J]. Energy and Buildings,2020,206:109593.. doi: 10.1016/j.enbuild.2019.109593 [10] KARABETOGLU S,OZTURK Z F,KASLILAR A,et al. Effect of layered geological structures on borehole heat transfer[J]. Geothermics,2021,91:102043.. doi: 10.1016/j.geothermics.2021.102043 [11] LEI Xinbo,ZHENG Xiuhua,DUAN Chenyang,et al. Three–dimensional numerical simulation of geothermal field of buried pipe group coupled with heat and permeable groundwater[J]. Energies,2019,12(19):3698.. doi: 10.3390/en12193698 [12] WANG Wanli,LUO Jin,WANG Guiling,et al. Study of the sustainability of a ground source heat pump system by considering groundwater flow and intermittent operation strategies[J]. Energy Exploration & Exploitation,2019,37(2):677−690. [13] 罗玮潇,王若帆. 贵州岩溶地区地下水系统划分浅析[J]. 有色金属设计,2021,48(2):118−120.. doi: 10.3969/j.issn.1004-2660.2021.02.033LUO Weixiao,WANG Ruofan. Division of groundwater systems in karst area of Guizhou Province[J]. Nonferrous Metals Design,2021,48(2):118−120.. doi: 10.3969/j.issn.1004-2660.2021.02.033 [14] 曲伸,齐子姝,郭磊. 地源热泵地埋管换热量影响因素研究[J]. 吉林建筑大学学报,2020,37(5):49−55.. doi: 10.3969/j.issn.1009-0185.2020.05.009QU Shen,QI Zishu,GUO Lei. Study on the influencing factors of heat exchange amount of buried pipe of ground source heat pump[J]. Journal of Jilin Jianzhu University,2020,37(5):49−55.. doi: 10.3969/j.issn.1009-0185.2020.05.009 [15] 仵彦卿,张倬元. 《岩体水力学导论》[J]. 地质灾害与环境保护,1997(3):38.WU Yanqing,ZHANG Zhuoyuan. 《Introduction to rock mass hydraulics》[J]. Journal of Geological Hazards and Environmental Preservation,1997(3):38. [16] ZHOU Weisong,PEI Peng,HAO Dingyi,et al. A numerical study on the performance of ground heat exchanger buried in fractured rock bodies[J]. Energies,2020,13(7):1−17. [17] 王明章, 陈革平, 王伟, 等. 贵州省岩溶地下水及地质环境: 20120148[P]. 2009-12-28. [18] 郭忠华. 基于裂隙几何特征的岩体渗透率预测[J]. 煤炭工程,2021,53(5):156−161.GUO Zhonghua. Prediction of rock mass permeability based on geometric features of fractures[J]. Coal Engineering,2021,53(5):156−161. [19] 蒋文豪,周宏,李玉坤,等. 基于钻孔内地下水流速和流向的岩溶裂隙介质渗透性研究[J]. 安全与环境工程,2018,25(6):1−7.. doi: 10.13578/j.cnki.issn.1671-1556.2018.06.001JIANG Wenhao,ZHOU Hong,LI Yukun,et al. Permeability measurement of karst fractured media based on groundwater velocity and direction within a borehole[J]. Safety and Environmental Engineering,2018,25(6):1−7.. doi: 10.13578/j.cnki.issn.1671-1556.2018.06.001 [20] HEIN P,KOLDITZ O,GÖRKE U J,et al. A numerical study on the sustainability and efficiency of borehole heat exchanger coupled ground source heat pump systems[J]. Applied Thermal Engineering,2016,100:421−433.. doi: 10.1016/j.applthermaleng.2016.02.039 [21] 闵杰. 土壤源热泵地埋管换热器性能影响因素研究[D]. 合肥: 安徽建筑大学, 2021.MIN Jie. Research on influencing factors of performance of underground heat exchanger of ground source heat pump[D]. Hefei: Anhui Jianzhu University, 2021. -

下载:

下载: