A model predictive control method for directional borehole trajectories in underground coal mines

-

摘要:目的

针对煤矿井下复杂地层定向钻进过程中存在的实钻轨迹控制难度大、与设计轨迹偏差较大的问题,提出了基于模型预测控制(model predictive control,MPC)的定向钻孔轨迹跟踪控制方法。

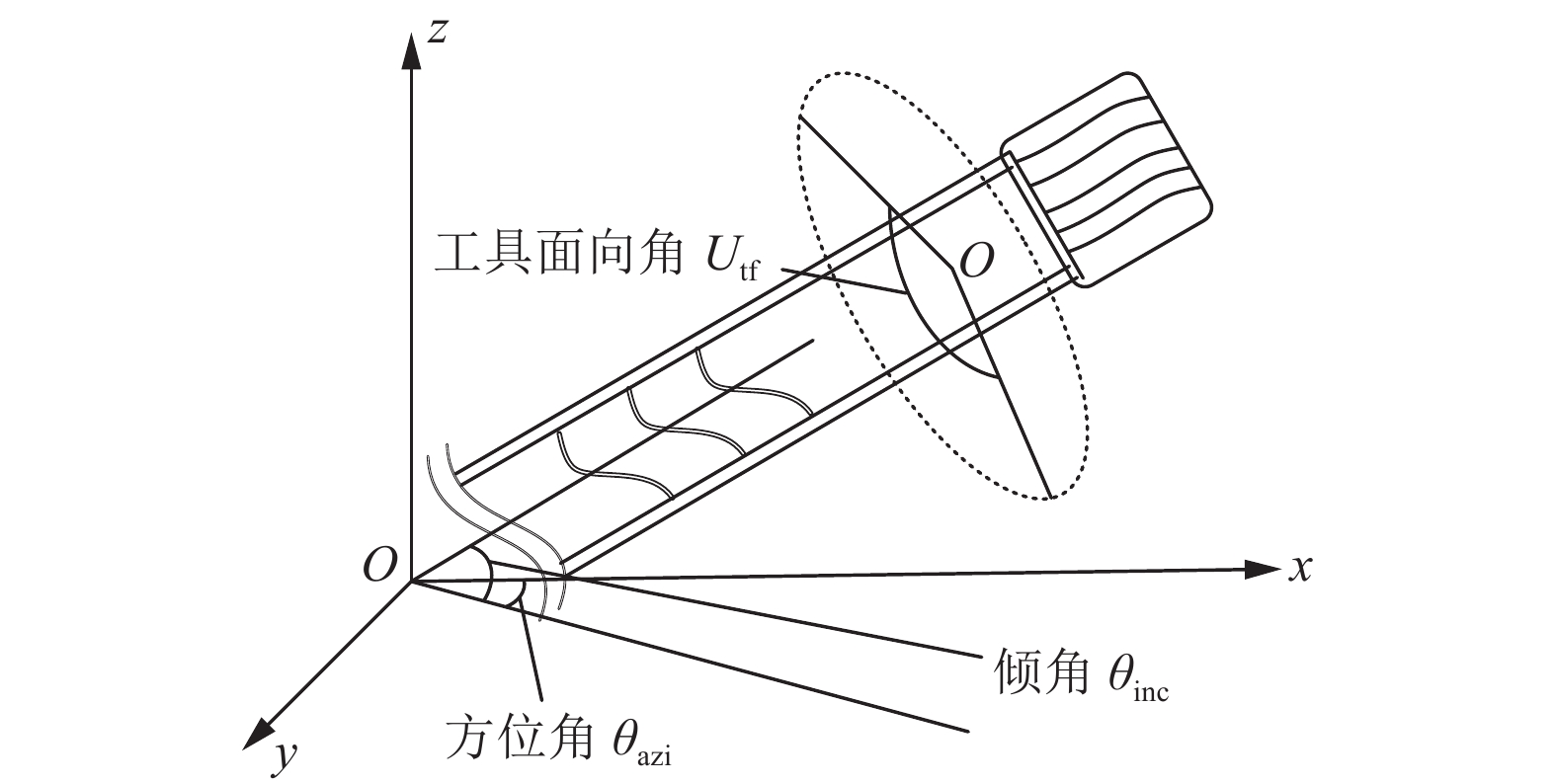

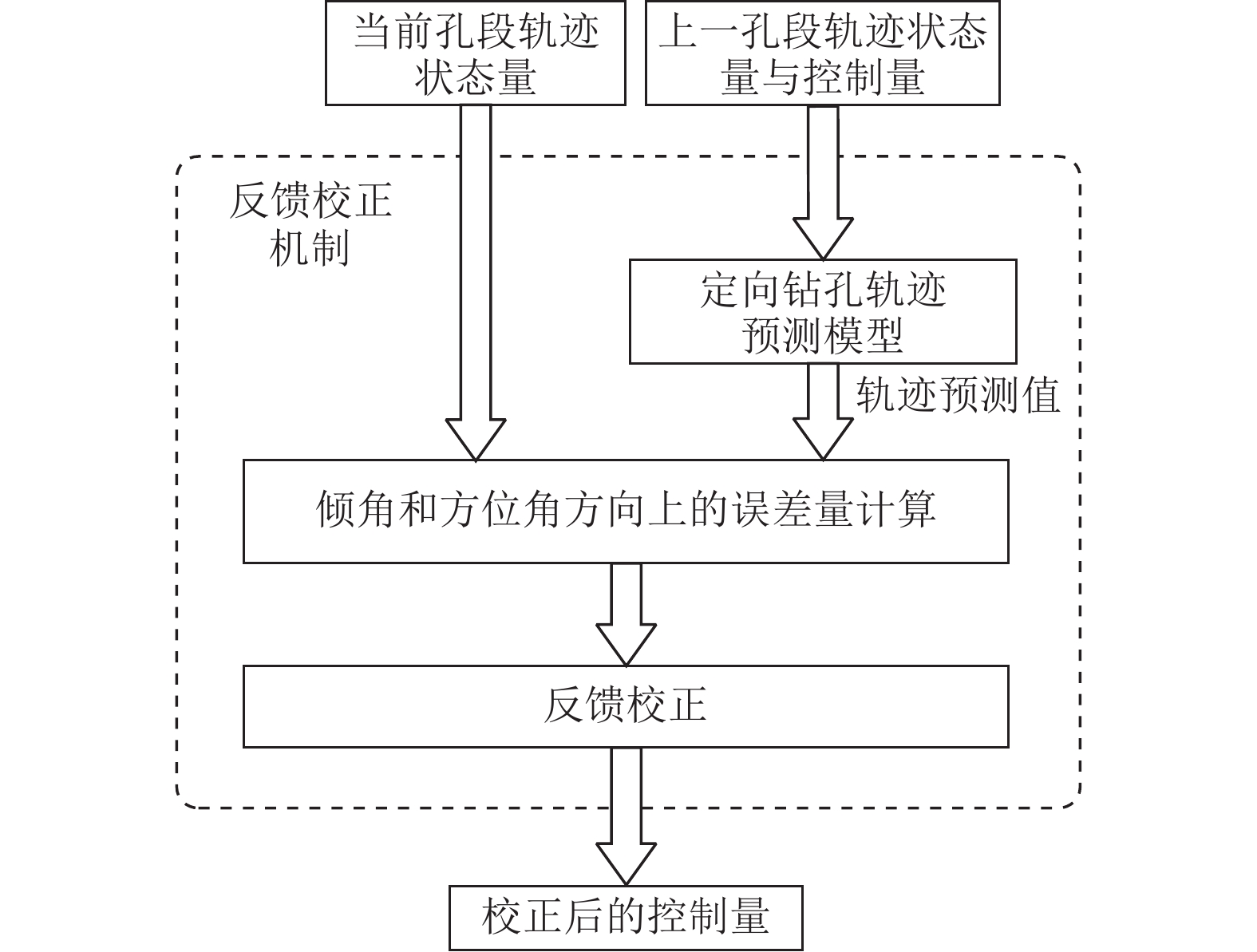

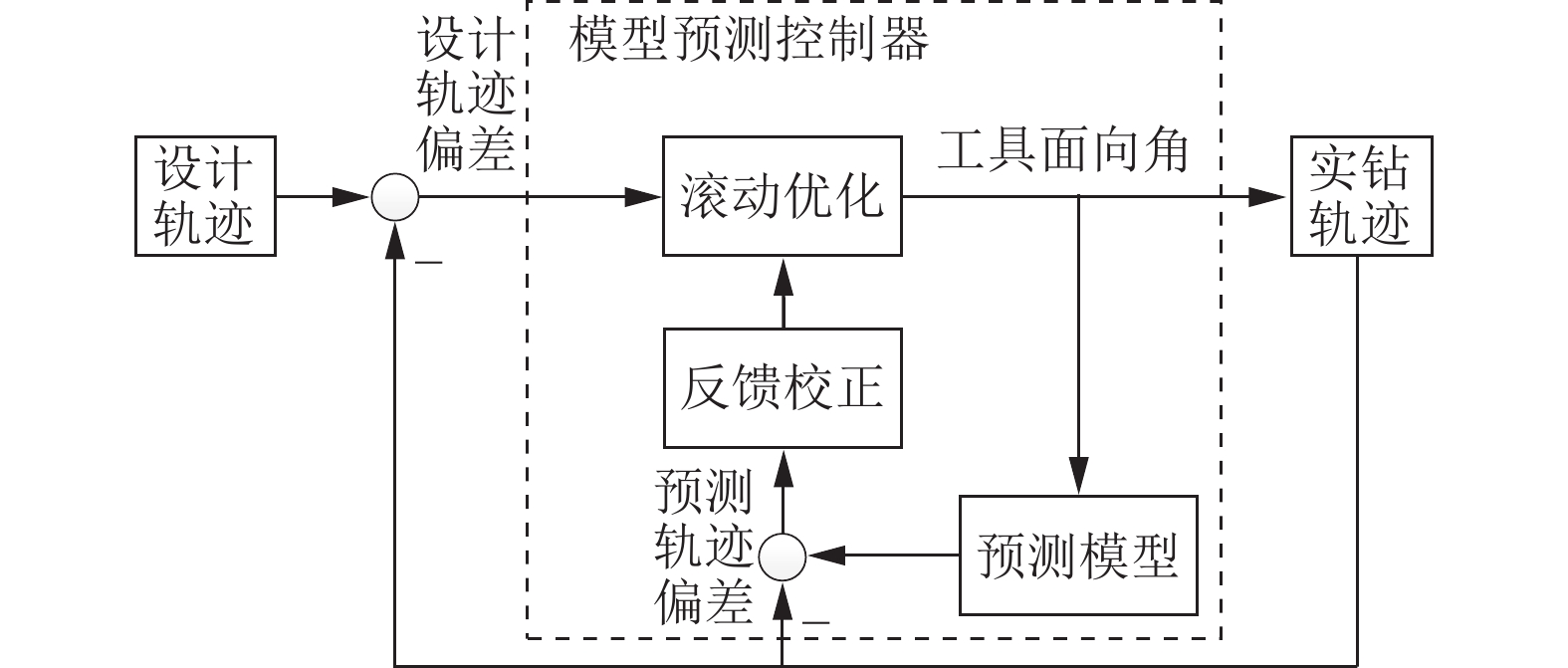

方法以螺杆钻具定向钻进过程为研究对象,在分析煤矿井下复杂地层条件下定向钻进特性的基础上,研究定向钻具的运动规律,采用运动学理论建立滑动定向钻进的钻孔轨迹延伸模型,并用泰勒级数展开方式对模型进行线性化处理,以消除钻孔倾角与方位角等状态量之间的耦合关系,在此基础上构建钻孔轨迹预测模型和以最小轨迹偏差作为控制目标的目标函数,采用反馈校正方法解决预测模型的稳态误差问题,并设计具有预测模型、滚动优化、反馈校正功能的模型预测控制器,得到钻孔轨迹最优控制量的推荐−工具面向角,最终实现定向钻孔轨迹跟踪优化控制。最后,利用陕西韩城某煤矿钻孔实钻数据,对控制算法进行了验证。

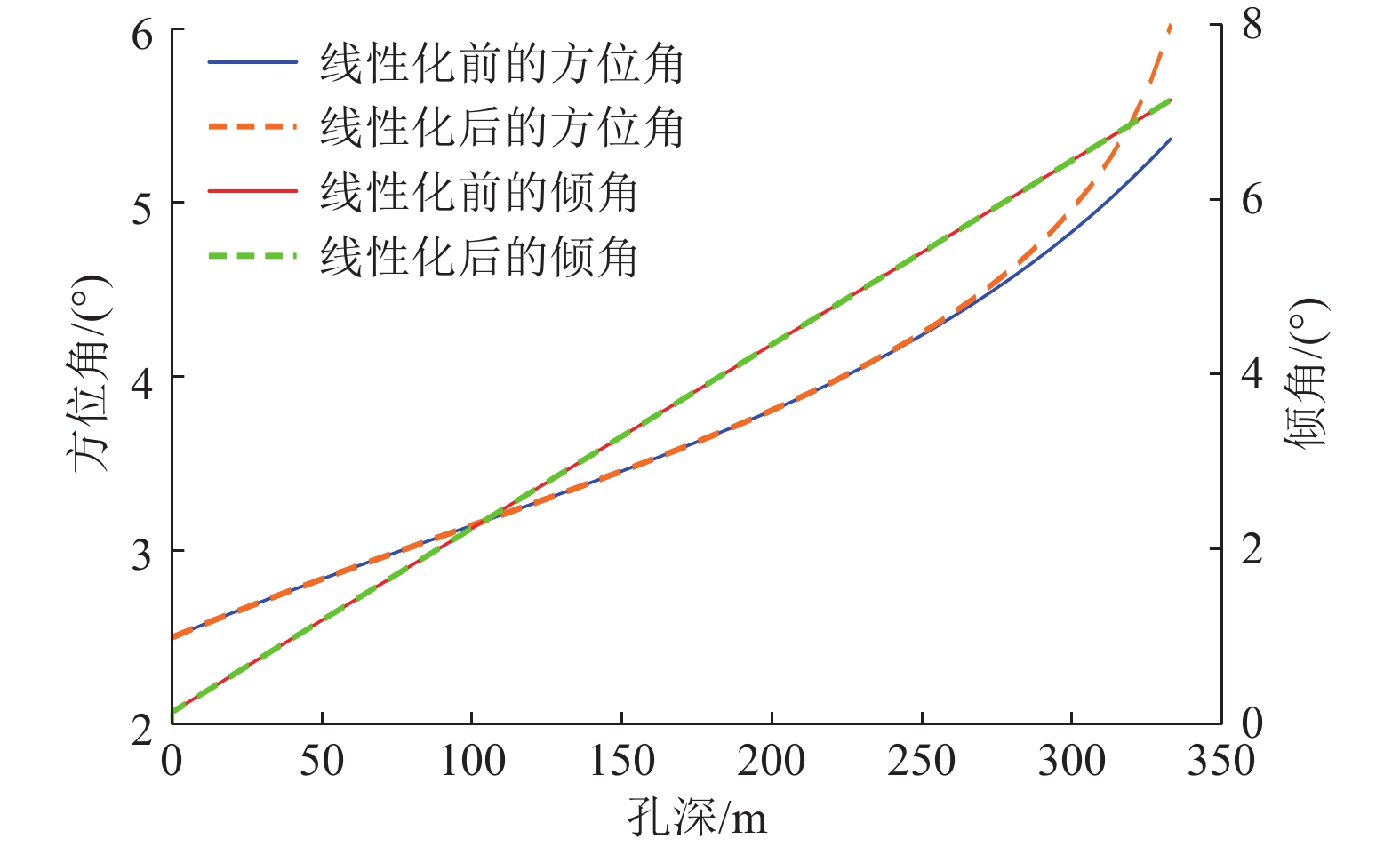

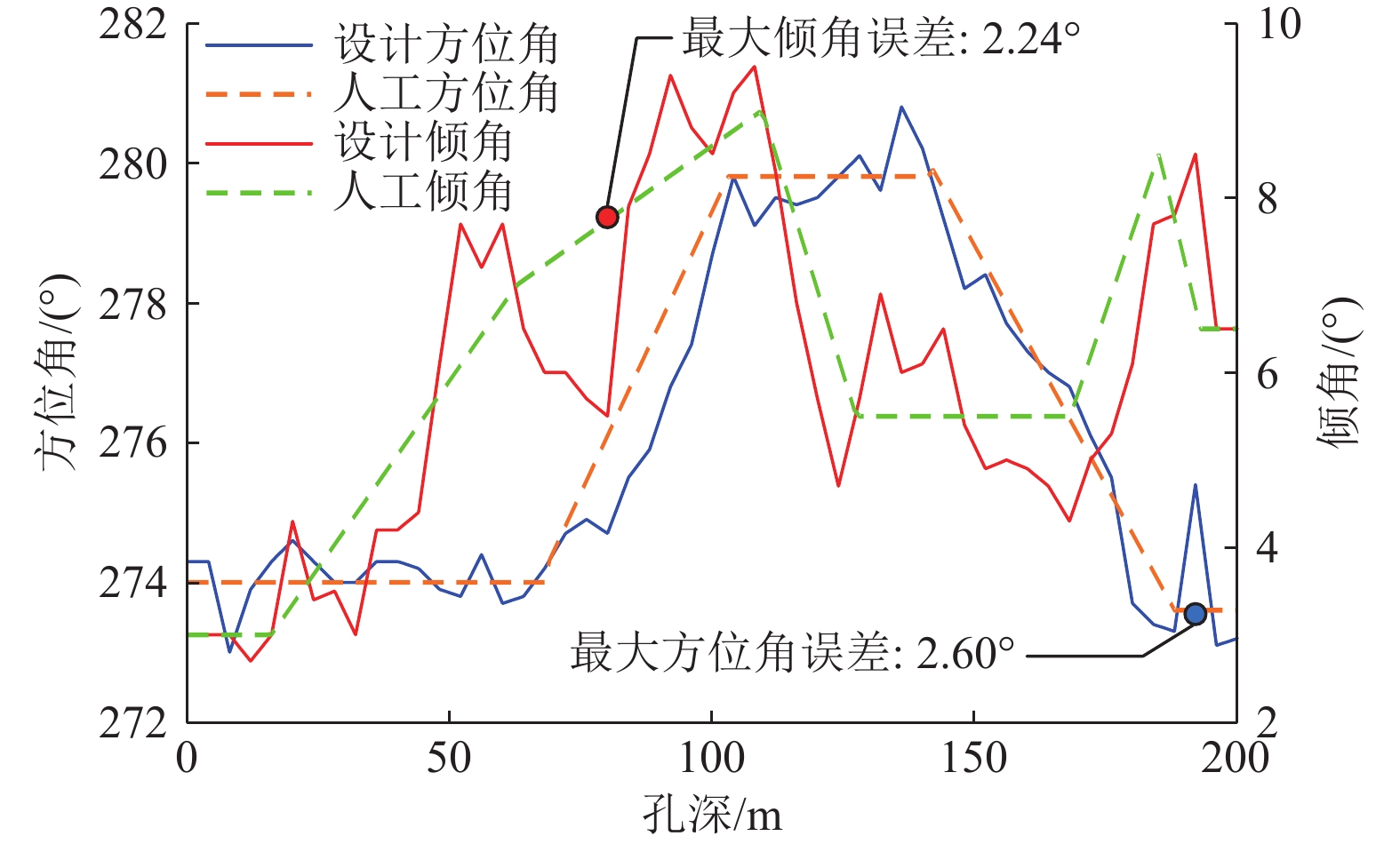

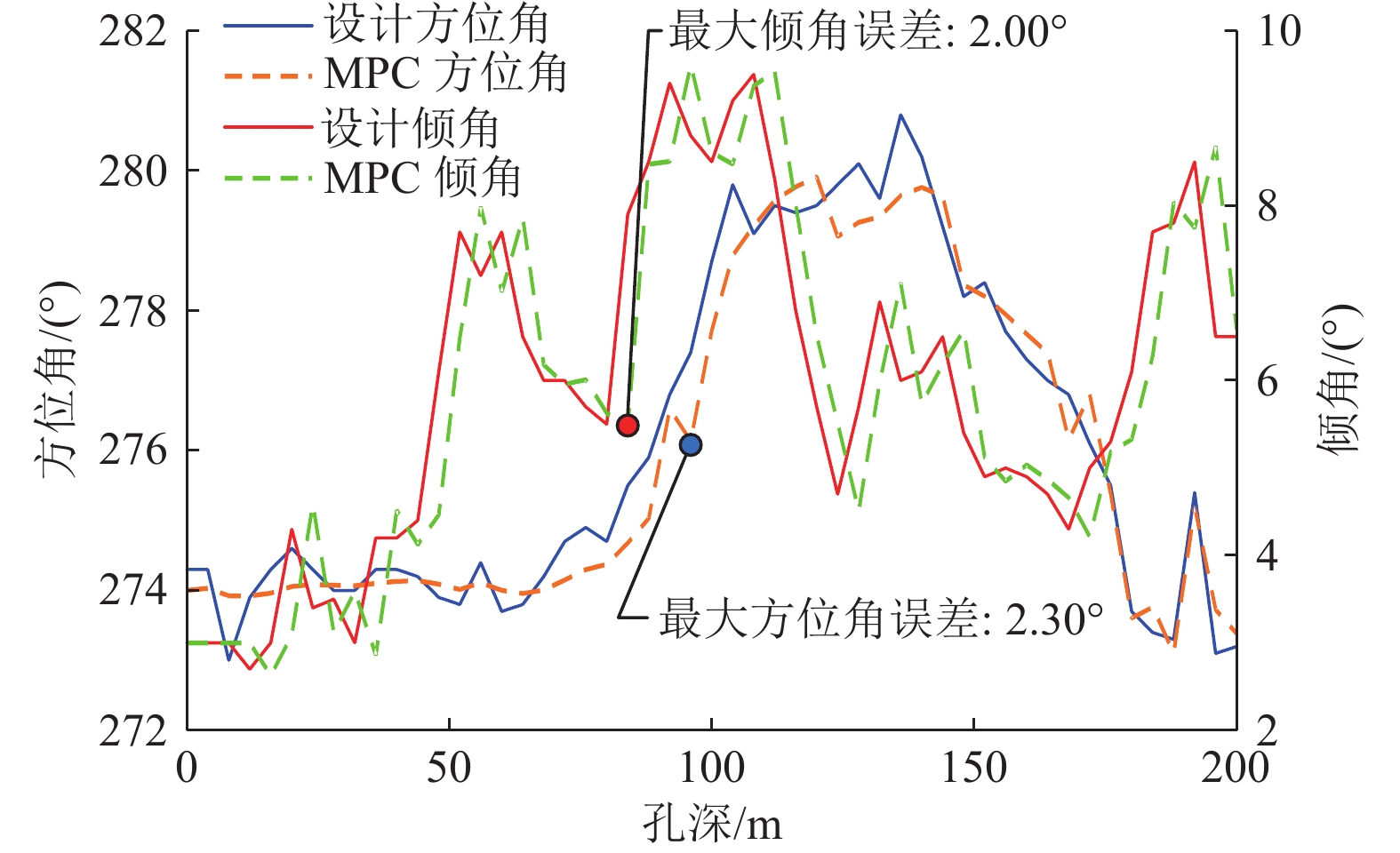

结果和结论结果表明,线性化处理后的钻孔轨迹延伸模型有效保留了原有模型的特征,并简化了控制器的设计过程。改进后的定向钻孔轨迹反馈校正模型预测控制方法克服了模型适配和稳态误差的影响,相比于基于螺杆钻具造斜规律的人工经验控制决策方法,倾角平均绝对误差和方位角平均绝对误差分别降低79.5%和70.5%,为复杂地层定向钻孔轨迹控制提供了一种新的控制算法。

Abstract:ObjectiveIt is challenging to control the borehole trajectories during directional drilling in complex strata in underground coal mines, resulting in significant deviations from the designed trajectories. Given this, this study proposed a method for tracking and controlling directional borehole trajectories based on model predictive control (MPC).

MethodsFocusing on the directional drilling process conducted using a screw drill, this study investigated the movement patterns of the directional screw drill by analyzing the characteristics of directional drilling in complex strata in underground coal mines. Based on the kinematic theory, this study developed a borehole trajectory extension model for sliding directional drilling. Then, the model linearization was processed using Taylor series expansion, aiming to eliminate the coupling relationships between state variables such as dip angle and azimuth. Accordingly, this study constructed a borehole trajectory prediction model and an objective function with the minimum trajectory deviation as the control target. The steady-state errors of the prediction model were reduced using feedback correction. Furthermore, this study designed a model predictive controller with functions of predictive modeling, rolling optimization, and feedback correction. As a result, the optimal control variable for the borehole trajectory—toolface angle—was recommended. Accordingly, the optimized control for tracking directional borehole trajectories was achieved. Finally, the control algorithm was validated using the drilling data from a coal mine in Hancheng City, Shaanxi Province.

Results and ConclusionsThe results indicate that the linearized borehole trajectory extension model simplifies the design process of the controller while effectively preserving the characteristics of the original model. The improved MPC method with the feedback correction mechanism for predicting directional borehole trajectories removes the impacts of model adaptation and steady-state errors. Compared to the human experience-controlled decision-making method based on the deflection rules of a screw drill, the improved MPC method reduces the average absolute errors of the dip angle and azimuth by 79.5% and 70.5%, respectively, providing a novel control algorithm for directional borehole trajectories in complex strata.

-

-

表 1 轨迹模型线性化参数

Table 1 Parameters for linearization of the trajectory model

参数 $ {\hat \theta _{\text{inc}}}/(^\circ ) $ $ {v}_{\text{rop}}/({\mathrm{m}}\cdot {{\mathrm{h}}}^{-1}) $ $ {K_{{\mathrm{dlc}}}}{{ /}}{{\mathrm{m}}^{ - 1}} $ $ {\theta _{\text{inc}}}{\text{ /}}(^ \circ ) $ $ {\theta _{\text{azi}}}{\text{ /}}(^ \circ ) $ 取值 8 6 0.08 2.2 2.2 表 2 轨迹控制仿真参数

Table 2 Parameters for trajectory control simulation

参数 $ a{{ /}}{{\mathrm{m}}^{ - 1}} $ $ b{{/}}{{\mathrm{m}}^{ - 1}} $ $ c/{{\mathrm{m}}^{ - 1}} $ $ {\theta _{\text{inc}}}{{/}}(^ \circ ) $ $ {\theta _{\text{azi}}}{{/}}( ^\circ ) $ 取值 16 16 −16 3 274 -

[1] 姚宁平,姚亚峰,方鹏,等. 我国煤矿坑道钻探装备技术进展与展望[J]. 钻探工程,2021,48(1):81−87. YAO Ningping,YAO Yafeng,FANG Peng,et al. Advances and outlook of coal mine tunnel drilling equipment and technology[J]. Drilling Engineering,2021,48(1):81−87.

[2] 李泉新. 碎软煤层复合定向钻进技术研究与应用[J]. 煤炭科学技术,2018,46(11):101−106. LI Quanxin. Research and application of drilling technology combined rotary with direction in soft–fragmentized coal seam[J]. Coal Science and Technology,2018,46(11):101−106.

[3] INYANG I. J, WHIDBORNE J. F. Bilinear modelling, control and stability of directional drilling[J]. Control Engineering Practice,2019,82:161−172.

[4] 姚宁平,魏宏超,张金宝,等. 基于钻柱状态估计的坑道回转钻进智能优化方法[J]. 煤田地质与勘探,2023,51(11):141−148. DOI: 10.12363/issn.1001-1986.23.06.0329 YAO Ningping,WEI Hongchao,ZHANG Jinbao,et al. Intelligent optimization method for tunnel rotary drilling based on drill string status estimation[J]. Coal Geology & Exploration,2023,51(11):141−148. DOI: 10.12363/issn.1001-1986.23.06.0329

[5] 方俊,刘飞,李泉新,等. 煤矿井下碎软煤层空气复合定向钻进技术与装备[J]. 煤炭科学技术,2019,47(2):224−229. FANG Jun,LIU Fei,LI Quanxin,et al. Air compound directional drilling technology and equipment for soft–fragmentized seam underground coal mine[J]. Coal Science and Technology,2019,47(2):224−229.

[6] LESNIAK G,BRUNNER D J,TOPOR T,et al. Application of long–reach directional drilling boreholes for gas drainage of adjacent seams in coal mines with severe geological conditions[J]. International Journal of Coal Science & Technology,2022,9(1):88.

[7] XU Yanpeng,WANG Liguo,CHEN Xiangjun,et al. Improvement of drilling quality using precision directional drilling technology[J]. Journal of Petroleum Exploration and Production Technology,2022,12(11):3149−3164. DOI: 10.1007/s13202-022-01510-4

[8] 田宏亮,陈建,张杰,等. 淮南矿区软煤气动定向钻进技术与装备研究及应用[J]. 煤田地质与勘探,2022,50(10):151−158. DOI: 10.12363/issn.1001-1986.22.01.0014 TIAN Hongliang,CHEN Jian,ZHANG Jie,et al. Air–driven directional drilling technology and equipment in soft coal seam of Huainan mining area[J]. Coal Geology & Exploration,2022,50(10):151−158. DOI: 10.12363/issn.1001-1986.22.01.0014

[9] 聂超,王毅,姚亚峰,等. 碎软煤层气动双管定向钻进排粉特性分析及应用[J]. 煤田地质与勘探,2022,50(5):159−166. DOI: 10.12363/issn.1001-1986.21.12.0789 NIE Chao,WANG Yi,YAO Yafeng,et al. Powder discharge characteristics of pneumatic double pipe directional drilling in broken soft coal seams and its application[J]. Coal Geology & Exploration,2022,50(5):159−166. DOI: 10.12363/issn.1001-1986.21.12.0789

[10] BINA S M,FUJII H,TSUYA S,et al. Evaluation of utilizing horizontal directional drilling technology for ground source heat pumps[J]. Geothermics,2020,85:101769.

[11] 祖雨彤,王璐,巩达,等. 基于磁信标的水平定向钻进导向技术研究[J]. 煤田地质与勘探,2023,51(9):100−108. DOI: 10.12363/issn.1001-1986.23.05.0155 ZU Yutong,WANG Lu,GONG Da,et al. Magnetic beacon–based horizontal directional drilling guidance technology[J]. Coal Geology & Exploration,2023,51(9):100−108. DOI: 10.12363/issn.1001-1986.23.05.0155

[12] ZAFARIAN H,AMERI M,VAGHASLOO Y A,et al. Error reduction of tracking planned trajectory in a thin oil layer drilling using smart rotary steerable system[J]. Journal of Petroleum Science and Engineering,2021,196:107668. DOI: 10.1016/j.petrol.2020.107668

[13] VILLARREAL MAGANA O A,MONSIEURS F H A,DETOURNAY E,et al. Robust output–feedback control of 3D directional drilling systems[J]. International Journal of Robust and Nonlinear Control,2018,28(18):5915−5942. DOI: 10.1002/rnc.4362

[14] KE Chong,SONG Xingyong. Control design for directional down–hole drilling using dual–heuristic programming with a high–order dynamic model[J]. IEEE Transactions on Control Systems Technology,2022,30(3):1009−1020. DOI: 10.1109/TCST.2021.3094537

[15] WEI Hongchao,YAO Ningping,TIAN Hongliang,et al. A predicting model for near–horizontal directional drilling path based on BP neural network in underground coal mine[J]. Journal of Advanced Computational Intelligence and Intelligent Informatics,2022,26(3):279−288. DOI: 10.20965/jaciii.2022.p0279

[16] ZHANG Chi,ZOU Wei,CHENG Ningbo,et al. Trajectory tracking control for rotary steerable systems using interval type–2 fuzzy logic and reinforcement learning[J]. Journal of the Franklin Institute,2018,355(2):803−826. DOI: 10.1016/j.jfranklin.2017.12.001

[17] ZHANG Chi,ZOU Wei,CHENG Ningbo,et al. Adaptive fault–tolerant control for trajectory tracking and rectification of directional drilling[J]. International Journal of Control,Automation and Systems,2022,20(1):334−348.

[18] ZHANG Dian,WU Min,LU Chengda,et al. A deviation correction strategy based on particle filtering and improved model predictive control for vertical drilling[J]. ISA Transactions,2021,111:265−274. DOI: 10.1016/j.isatra.2020.11.023

[19] ZHANG Dian,WU Min,LU Chengda,et al. Tube–based adaptive model predictive control for deviation correction in vertical drilling process[J]. IEEE Transactions on Industrial Electronics,2022,69(9):9419−9428. DOI: 10.1109/TIE.2021.3113020

下载:

下载: