Strength and damage characteristics of cemented gangue backfill during saturated immersion

-

摘要:目的

受充填料浆水、工作面涌水和采空区内积水的影响,矸石胶结充填体的含水率会随浸水时间的增加而发生改变,进而改变了充填体的承载性能。研究矸石胶结充填体在饱和浸水过程的强度特性及损伤破坏特征,对于保持充填体的稳定性和保障煤矿安全至关重要。

方法通过对饱和浸水过程的矸石胶结充填体开展单轴压缩试验和微观电镜扫描测试,分析充填体强度随浸水时间的变化规律,并基于微元强度统计分布量,建立峰前阶段的分段损伤本构模型,通过微观电镜扫描,揭示饱和浸水过程中矸石胶结充填体强度弱化机制。

结果和结论结果表明:(1) 饱和浸水过程中,胶结充填体单轴压缩下的应力−应变曲线呈现出明显的“四阶段”特征,孔裂隙压密闭合阶段最大应变和应力及峰值应力点应变与浸水时间呈正相关,而峰值应力和弹性模量与浸水时间呈负相关。(2) 随着浸水时间的增加,矸石胶结充填体的破坏形态由剪切破坏为主过渡到以张拉−剪切共轭破坏为主,最终转化为以纵向张拉破坏为主,破坏位置主要集中在矸石胶结充填体的中部。(3) 建立了考虑孔裂隙压密闭合阶段最大应力和最大应变、弹性模量及峰值应力和峰值应力点应变的分段损伤本构模型,基于试验数据对模型进行了验证,理论模型曲线与试验曲线基本吻合。(4) 受水分张力作用、润滑作用及矿物溶解作用的影响,将饱和浸水过程中矸石胶结充填体强度弱化机制分为3个阶段,当充填体达到饱和状态后,其强度持续降低,但是降低速率减小。研究结果可为采空区富水环境下矸石胶结充填开采提供一定的数据支撑。

Abstract:ObjectiveUnder the influence of backfill slurry, water inrushes in mining face, and water accumulation in goaves, the water content in cemented gangue backfill varies with the immersion time, thus altering the bearing performance of the backfill. Investigating the strength and damage characteristics of cemented gangue backfill during saturated immersion is crucial for maintaining the stability of the backfill and ensuring the safety of coal mines.

MethodsUsing uniaxial compression tests and scanning electron microscopy (SEM) of cemented gangue backfill during saturated immersion, this study analyzed the law of changes in the backfill strength under varying immersion times. Based on the statistical distribution of microelement strength, this study established a piecewise damage constitutive model for the cemented gangue backfill in the pre-peak stage. Using SEM, this study revealed the mechanism underlying the strength weakening of the cemented gangue backfill during saturated immersion.

Results and ConclusionsThe results indicate that during saturated immersion, the cemented gangue backfill under uniaxial compression exhibited significant four-stage stress-strain curves. In the compaction and closure stage of pores and fractures, the maximum strain/stress and the strain at the peak stress point were positively correlated with the immersion time, while the peak stress and modulus of elasticit y were negatively correlated with the immersion time. With an increase in the immersion time, the primary failure morphologies of the cemented gangue backfill transitioned from shear failure to tension-shear conjugate failure, finally shifting to longitudinal tensile failure, with the failures concentrated in the central part of the cemented gangue backfill. This study established a piecewise damage constitutive model for the cemented gangue backfill in the compaction and closure stage of pores and fractures that considered the maximum stress and strain, modulus of elasticity, peak stress, and strain at the peak stress point. This model was verified using test data, indicating that the model-derived theoretical curves were roughly consistent with the test curves. Subjected to the surface tension and lubrication of water, as well as mineral dissolution, the cemented gangue backfill during saturated immersion manifested a three-stage strength weakening mechanism. As the cemented gangue backfill was saturated with water, its strength continued to decrease at a decreasing rate. The results of this study will provide certain data for coal mining based on cemented gangue backfill in environments with water-rich goaves.

-

-

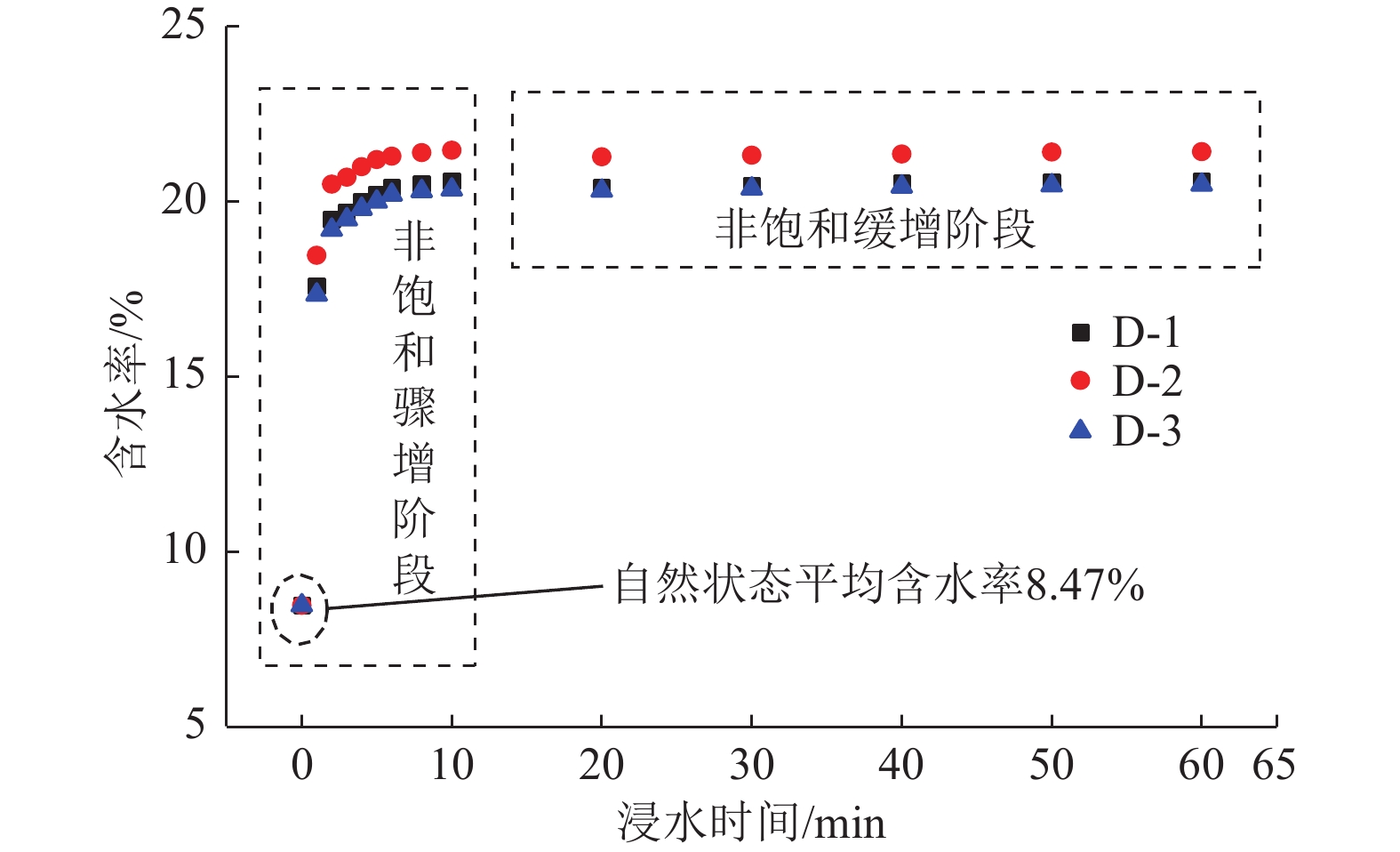

表 1 不同浸水时间下胶结充填体含水率变化情况

Table 1 Variations in water content in cemented gangue backfill under different immersion time

试样

编号浸水

时间/h浸水前

质量/g浸水后

质量/g含水率/% A-1 未浸水 35.09 — 8.35 A-2 349.81 — 8.45 A-3 36.81 — 8.61 B-1 12 350.55 391.71 21.20 B-2 350.23 39.75 21.64 B-3 350.84 39.78 21.44 C-1 24 356.70 397.93 21.01 C-2 35.83 397.60 21.89 C-3 355.35 394.48 21.33 D-1 48 354.69 396.70 21.32 D-2 346.07 389.81 22.19 D-3 35.38 39.86 21.24 表 2 不同浸水时间下模型拟合值

Table 2 Model fitting-derived values under different immersion times

浸水时间/h σat/MPa εat/% Et/MPa σct/MPa εct/% mt nt λ $\xi $ 未浸水 0.6055 0.2300 290.25 1.5410 0.6700 3.8174 4.8174 0.1656 0.8344 12 0.6352 0.2860 261.70 1.4284 0.7342 2.8974 3.8974 0.3599 0.6401 24 0.6750 0.3457 235.77 1.3496 0.7834 2.7132 3.7132 0.3327 0.6673 48 0.7850 0.4764 191.76 1.2940 0.8366 4.1706 5.1706 0.3952 0.6048 表 3 不同浸水时间下矸石胶结充填体损伤本构方程

Table 3 Damage constitutive equations for cemented gangue backfill under different immersion time

浸水时间/h 孔裂隙压密闭合阶段 峰前损伤扩展阶段 未浸水 σi = 18954.78 $\varepsilon_i^2 $+219.66εiσi = 290.25εi− 5.9682 ×1010×(εi−2.3×10−3)4.8174 −0.0621 12 σi = 27948.61 $\varepsilon_i^2 $+14.16εiσi = 261.7εi− 4.2821 ×108×(εi−2.86×10−3)3.8974 −0.1133 24 σi = 18791.34 $\varepsilon_i^2 $+130.29εiσi = 235.77εi− 1.5948 ×108×(εi−3.457×10−3)3.7132 −0.1401 48 σi = 13669.2 $\varepsilon_i^2 $+99.66εiσi = 191.76εi−5.753×1011×(εi−4.764×10−3) 5.1706 −0.1285 -

[1] 武强,涂坤,曾一凡. “双碳” 目标愿景下我国能源战略形势若干问题思考[J]. 科学通报,2023,68(15):1884−1898. WU Qiang,TU Kun,ZENG Yifan. Research on China’s energy strategic situation under the carbon peaking and carbon neutrality goals[J]. Chinese Science Bulletin,2023,68(15):1884−1898.

[2] 杨科,何淑欣,何祥,等. 煤电化基地大宗固废“三化” 协同利用基础与技术[J]. 煤炭科学技术,2024,52(4):69−82. YANG Ke,HE Shuxin,HE Xiang,et al. Foundation and technology of coordinated utilization of bulk solid waste ‘Three modernizations’ in coal power base[J]. Coal Science and Technology,2024,52(4):69−82.

[3] 张吉雄,张强,周楠,等. 煤基固废充填开采技术研究进展与展望[J]. 煤炭学报,2022,47(12):4167−4181. ZHANG Jixiong,ZHANG Qiang,ZHOU Nan,et al. Research progress and prospect of coal based solid waste backfilling mining technology[J]. Journal of China Coal Society,2022,47(12):4167−4181.

[4] 杨科,赵新元,何祥,等. 多源煤基固废绿色充填基础理论与技术体系[J]. 煤炭学报,2022,47(12):4201−4216. YANG Ke,ZHAO Xinyuan,HE Xiang,et al. Basic theory and key technology of multi-source coal-based solid waste for green backfilling[J]. Journal of China Coal Society,2022,47(12):4201−4216.

[5] 董猛,李江山,陈新,等. 煤系固废基绿色充填材料制备及其性能研究[J]. 煤田地质与勘探,2022,50(12):75−84. DONG Meng,LI Jiangshan,CHEN Xin,et al. Preparation of coal-series solid-waste-based green filling materials and their performance[J]. Coal Geology & Exploration,2022,50(12):75−84.

[6] 杨科,张继强,何祥,等. 多源煤基固废胶结充填体力学及变形破坏特征试验研究[J]. 煤田地质与勘探,2024,52(6):102−114. YANG Ke,ZHANG Jiqiang,HE Xiang,et al. Experimental study on the mechanics and deformation failure characteristics of multi-source coal-based solid waste cemented backfill[J]. Coal Geology & Exploration,2024,52(6):102−114.

[7] 刘志义. 水−力耦合作用下尾砂胶结充填体力学特性与损伤机理[D]. 唐山:华北理工大学,2023. LIU Zhiyi. Mechanical properties and damage mechanism of tailings cemented filling under water-force coupling[D]. Tangshan:North China University of Science and Technology,2023.

[8] 吴宝杨,王伟男,郭东明. 浸水次数影响下裂隙砂岩强度损伤及声发射特征[J]. 采矿与安全工程学报,2020,37(5):1054−1060. WU Baoyang,WANG Weinan,GUO Dongming. Strength damage and AE characteristics of fractured sandstone under the influence of water intrusion times[J]. Journal of Mining & Safety Engineering,2020,37(5):1054−1060.

[9] 陈田,姚强岭,杜茂,等. 浸水次数对煤样裂隙发育损伤的实验研究[J]. 岩石力学与工程学报,2016,35(增刊2):3756−3762. CHEN Tian,YAO Qiangling,DU Mao,et al. Experimental study on the damage of water immersion times to the crack development of coal samples[J]. Chinese Journal of Rock Mechanics and Engineering,2016,35(Sup.2):3756−3762.

[10] DONG Wenyu,XIA Zhiguo,HU Jun,et al. Mechanical and acoustic characteristics of sandstone failure at different immersion heights under tailings water erosion conditions[J]. Theoretical and Applied Fracture Mechanics,2024,132:104475. DOI: 10.1016/j.tafmec.2024.104475

[11] GAO Liyang,ZHANG Wenrui,LU Wei,et al. Study on the effects of temperature and immersion on the acoustic emission and electromagnetic radiation signals of coal rock damage under load[J]. Engineering Geology,2022,297:106503. DOI: 10.1016/j.enggeo.2021.106503

[12] 刘小玲,张泽天,张茹,等. 浸水煤体单轴压缩能量破坏机理及层理效应研究[J/OL]. 工程科学与技术,2024:1−15[2024-04-28]. http://kns.cnki.net/kcms/detail/51.1773.TB.20240428.1252.006.html. LIU Xiaoling,ZHANG Zetian,ZHANG Ru,et al. Energy failure mechanism and bedding effect of soaked coal under uniaxial compression[J/OL]. Advanced Engineering Sciences,2024:1−15[2024-04-28]. http://kns.cnki.net/kcms/detail/51.1773.TB.20240428.1252.006.html.

[13] 姜琳婧,赵会杰,赵怡晴,等. 层理煤岩浸水前后力学性质研究[J]. 煤炭科学技术,2023,51(10):97−108. JIANG Linjing,ZHAO Huijie,ZHAO Yiqing,et al. Study on mechanical properties of coal before and after flooding considering bedding direction[J]. Coal Science and Technology,2023,51(10):97−108.

[14] XU Yong,CHEN Xuexi,ZHAO Wei,et al. Effect of water intrusion on the characteristics of surface morphology and pore fracture spaces in argillaceous meagre coal[J]. Journal of Natural Gas Science and Engineering,2020,81:103404. DOI: 10.1016/j.jngse.2020.103404

[15] 尹大伟,丁屹松,汪锋,等. 考虑初始损伤的压力水浸煤岩力学特性试验研究[J]. 煤炭学报,2023,48(12):4417−4432. YIN Dawei,DING Yisong,WANG Feng,et al. Experimental study on mechanical properties of coal soaked in pressurized water considering initial damage[J]. Journal of China Coal Society,2023,48(12):4417−4432.

[16] DING Yisong,YIN Dawei,HU Hao,et al. Influence characteristics and macro-meso mechanism of pressure immersion time on tensile properties for coal materials[J]. Journal of Materials Research and Technology,2023,26:2358−2370. DOI: 10.1016/j.jmrt.2023.08.030

[17] 韩鹏华,赵毅鑫,高森,等. 长期水浸作用下煤样渐进破坏特征及损伤本构模型[J]. 岩石力学与工程学报,2024,43(4):918−933. HAN Penghua,ZHAO Yixin,GAO Sen,et al. Progressive damage characteristics and damage constitutive model of coal samples under long-term immersion[J]. Chinese Journal of Rock Mechanics and Engineering,2024,43(4):918−933.

[18] LIU Jiawei,SUI Wanghua,ZHANG Dingyang,et al. Durability of water-affected paste backfill material and its clean use in coal mining[J]. Journal of Cleaner Production,2020,250:119576. DOI: 10.1016/j.jclepro.2019.119576

[19] ZHOU Nan,DONG Chaowei,ZHANG Jixiong,et al. Influences of mine water on the properties of construction and demolition waste-based cemented paste backfill[J]. Construction and Building Materials,2021,313:125492. DOI: 10.1016/j.conbuildmat.2021.125492

[20] WANG Jie,ZHANG Chi,FU Jianxin,et al. Effect of water saturation on mechanical characteristics and damage behavior of cemented paste backfill[J]. Journal of Materials Research and Technology,2021,15:6624−6639. DOI: 10.1016/j.jmrt.2021.11.078

[21] 聂亚林,王晓军,黄广黎,等. 不同含水率纯尾砂胶结充填体强度及损伤模型分析[J]. 硅酸盐通报,2018,37(6):2008−2013. NIE Yalin,WANG Xiaojun,HUANG Guangli,et al. Strength and damage model analysis of pure tailings cemented filling body with different water content[J]. Bulletin of the Chinese Ceramic Society,2018,37(6):2008−2013.

[22] 王永岩,于卓群,崔立桩. 不同含水率膏体充填材料的单轴压缩试验研究[J]. 煤炭科学技术,2022,50(6):219−224. WANG Yongyan,YU Zhuoqun,CUI Lizhuang. Experimental study on compressive behavior of cemented paste backfill material with different water contents[J]. Coal Science and Technology,2022,50(6):219−224.

[23] 宋学朋,郝宇鑫,王石,等. 不同加载速率下差异性含水率尾砂胶结充填体力学行为及损伤特性研究[J]. 材料导报,20,36(24):107–116. SONG Xuepeng,HAO Yuxin,WANG Shi,et al. Study on mechanical behavior and damage characteristics of cemented tailings backfill with different water content under different loading rates[J]. Materials Reports,20,36(24):107–116.

[24] 李召峰,张晨,张健,等. 不同水饱和度充填体力学性能及损伤机制研究[J]. 采矿与安全工程学报,2021,38(5):1063−1069. LI Zhaofeng,ZHANG Chen,ZHANG Jian,et al. Mechanical properties and damage mechanism of backfill with different water saturation[J]. Journal of Mining & Safety Engineering,2021,38(5):1063−1069.

[25] 刘鼎,许军策,浦海. 不同含水率下矸石胶结充填体蠕变特性试验研究[J]. 采矿与安全工程学报,2021,38(5):1055−1062. LIU Ding,XU Junce,PU Hai. Experimental study on creep characteristics of gangue cemented fillers with different water content[J]. Journal of Mining & Safety Engineering,2021,38(5):1055−1062.

[26] LING Hao,LI Xilin,XUE Haowen,et al. The effect of acid mine drainage on the properties of an all-solid waste paste backfill body based on oil shale residue[J]. Construction and Building Materials,2024,425:136017. DOI: 10.1016/j.conbuildmat.2024.136017

[27] ZHAO Yonghui,GUO Yuxia,FENG Guorui,et al. Long-term strength and deformation size effect of gangue cemented backfill in acid mine water[J]. Structures,2023,57:105114. DOI: 10.1016/j.istruc.2023.105114

[28] ZHU Gengjie,ZHU Wancheng,FU You,et al. Effects of chloride salts on strength,hydration,and microstructure of cemented tailings backfill with one-part alkali-activated slag[J]. Construction and Building Materials,2023,374:130965. DOI: 10.1016/j.conbuildmat.2023.130965

[29] 杜兆文,陈绍杰,尹大伟,等. 氯盐侵蚀环境下膏体充填体稳定性试验研究[J]. 中国矿业大学学报,2021,50(3):532−538. DU Zhaowen,CHEN Shaojie,YIN Dawei,et al. Experimental study of stability of paste backfill under chloride erosion environment[J]. Journal of China University of Mining & Technology,2021,50(3):532−538.

[30] 高萌,刘娟红,吴爱祥. 碳酸盐溶液中富水充填材料的腐蚀及劣化机理[J]. 工程科学学报,2015,37(8):976−983. GAO Meng,LIU Juanhong,WU Aixiang. Corrosion and deterioration mechanism of water-rich filling materials in carbonate solutions[J]. Chinese Journal of Engineering,2015,37(8):976−983.

[31] HAN Penghua,ZHAO Yixin,ZHANG Cun,et al. Progressive damage characteristic and microscopic weakening mechanism of coal under long-term soaking[J]. Rock Mechanics and Rock Engineering,2023,56(11):7861−7881. DOI: 10.1007/s00603-023-03466-1

[32] FENG Guorui,RAN Hongyu,GUO Jun,et al. Experimental investigation on the deformation and strength properties of cemented gangue backfill column under long-term axial compression[J]. Structures,2022,43:1558−1572. DOI: 10.1016/j.istruc.2022.07.068

[33] 冯国瑞,赵永辉,郭育霞,等. 柱式充填体单轴压缩损伤演化及破坏特征研究[J]. 中南大学学报(自然科学版),2022,53(10):4012−4023. FENG Guorui,ZHAO Yonghui,GUO Yuxia,et al. Study on damage evolution and failure characteristics of backfill column under uniaxial compression[J]. Journal of Central South University (Science and Technology),2022,53(10):4012−4023.

[34] ZHAO Xinyuan,YANG Ke,DINO G A,et al. Feasibility and challenges of multi-source coal-based solid waste (CSW) for underground backfilling:A case study[J]. Process Safety and Environmental Protection,2024,181:8−25. DOI: 10.1016/j.psep.2023.11.013

[35] 郭育霞,赵永辉,冯国瑞,等. 矸石胶结充填体单轴压缩损伤破坏尺寸效应研究[J]. 岩石力学与工程学报,2021,40(12):2434−2444. GUO Yuxia,ZHAO Yonghui,FENG Guorui,et al. Study on damage size effect of cemented gangue backfill body under uniaxial compression[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(12):2434−2444.

[36] HOU Yongqiang,YIN Shenghua,YANG Shixing,et al. Mechanical properties,damage evolution and energy dissipation of cemented tailings backfill under impact loading[J]. Journal of Building Engineering,2023,66:105912. DOI: 10.1016/j.jobe.2023.105912

[37] 李海潮,张升. 基于修正Lemaitre应变等价性假设的岩石损伤模型[J]. 岩土力学,2017,38(5):1321−1326. LI Haichao,ZHANG Sheng. A constitutive damage model of rock based on the assumption of modified Lemaitre strain equivalence hypothesis[J]. Rock and Soil Mechanics,2017,38(5):1321−1326.

[38] 鲁祖德. 裂隙岩石水−岩作用力学特性试验研究与理论分析[D]. 武汉:中国科学院研究生院(武汉岩土力学研究所),2010. LU Zude. Experimental study and theoretical analysis on mechanical characteristics of water-rock interaction in fractured rocks[D]. Wuhan:Institute of Rock and Soil Mechanics,Chinese Academy of Sciences,2010.

下载:

下载: