Practice and cognition of efficient CBM development under complex geological conditions: A case study of Zhengzhuang Block, Qinshui Basin

-

摘要:

我国煤层气整体构造复杂且有诸多地质相似性,随着近年来逐步向中深部、超低渗、构造复杂区域迈进,总结探索一套复杂区域高效开发手段对盘活国内大批煤层气资源意义重大。以早期低产且地质相对复杂的郑庄区块的成功实践为例,针对区块高阶煤断裂构造复杂、非均质性强、渗透率低、早期工程技术匹配欠缺、早期达产率不足30%等不利因素和问题,通过深化煤层气地质富集规律研究和新技术研发与应用,形成了甜点区优选和高效开发理论,应用二开全通径水平井优快钻井、疏导式增产改造、定量化疏导排采控制等系列技术,大幅度提高单井产量,方案达产率由最初的29.3%提升至98.5%。实践研究认为:(1) 及时有效的开发方案调整能够实现复杂低渗的高阶煤煤层气高效开发,为技术持续升级提供了空间与平台。(2) 丛式井组滚动运行方式可有效降低产建风险,使整体方案达产率提高20%以上。(3) 水平井地质–工程一体化技术的持续创新,是实现达产率整体提升的关键。

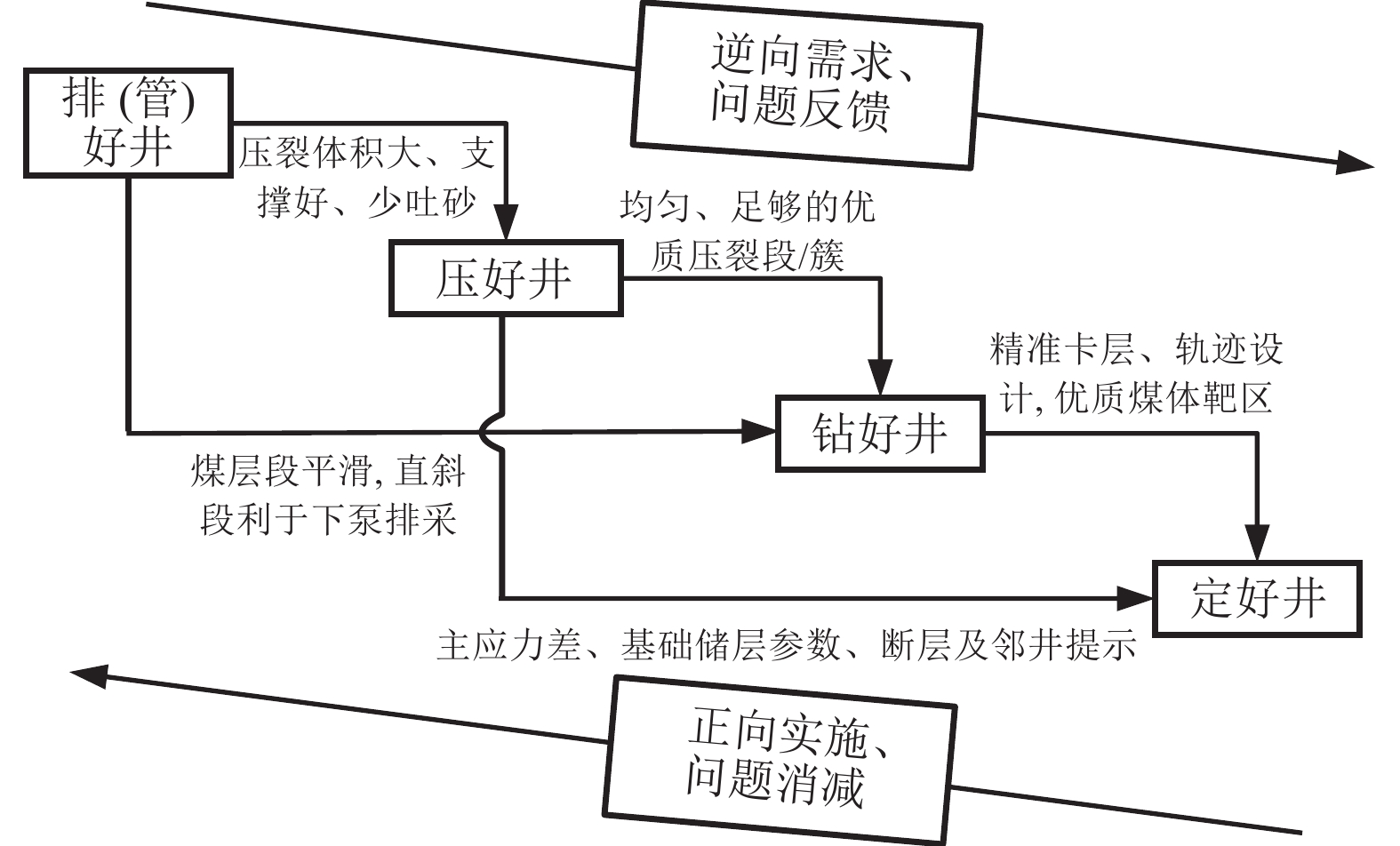

Abstract:Abstract: The geological conditions of various CBM sites in China are complicated and features similarly. With the recent development of exploring CBM towards the medium-deep, ultra-low permeability and structurally complex areas, it is of great significance to develop a set of efficient exploring techniques in complex areas to revitalize a large number of domestic CBM resources. Taking an example of the successful development of Zhengzhuang Block with early low yield and relatively complex geology, it had faced a series of problems, including complex geological conditions with internal fracture, strong heterogeneity, low permeability, lack of corresponding developing technologies for the early stage development, production rate less than 30% in the early stage. The sweet area optimization and efficient development theory was developed through deepening the research on CBM geological enrichment law and the development and application of new technologies. With these proposed techniques on optimal rapid drilling, dredging capacity increasing revamp and quantitative dredging and drainage control in two-open full-diameter horizontal wells, the production of single well was greatly increased, and the project yield increased from 29.3% to 98.5%. The research results indicate: (1) Timely and appropriate adjustment on the development plan is essential for the successful development of complex and low-permeability high-rank coalbed methane, providing space and platform for the continuous improvement in CBM exploring techniques; (2) The rolling operation mode of cluster well group can significantly reduce production and construction risks, and increase the overall scheme productivity by more than 20%; (3) The continuous innovation of horizontal well geology and engineering integration technology is a key element to achieve the overall improvement of productivity.

-

-

表 1 沁水盆地3号煤主要地质参数对比

Table 1 Comparison of main geological parameters of No.3 coal seam in Qinshui Basin

主要地质参数 郑庄 樊庄 潘庄 埋深/m 500~1200 400~800 250~600 煤厚/m 4~7 5~8 5~8 含气量/(m3·t−1) 21.5~28.5 15~32 10~40 临储比 0.24~0.33 0.45~0.83 0.94 渗透率/10−3 μm2 0.01~0.15 0.26~1.2 0.21~34.6 煤体结构 西南部原生结构为主、东部及北部碎裂结构为主 原生结构和原生–碎裂结构为主 原生结构为主 地应力梯度/(MPa·hm−1) 2.3 1.8 1.5 表 2 郑庄区块产建开发主要历程

Table 2 Practice history of production and construction development in the Zhengzhuang Block

开发/调整次数 主要区域及特点 关键工程技术 实施概况 达产率/% 第一次 分散布井:未认识到区块地质复杂性 常规直井压裂技术、裸眼多分支水平井 直斜井1 029口、裸眼多分支水平井50口 29.3 第二次 西部为主,中东部:渗透率>0.1×10−3 μm2,埋深浅,构造简单 低前置比−快速返排、集中射孔的直井压裂、L型筛管水平井 直斜井229口、筛管水平井15口、L型套管分段压裂水平井12口 85.3 第三次 区块3号煤全部可采区、西南15号煤甜点区:渗透率<0.1×10−3 μm2,埋深加大,构造相对复杂,需精细选区、选井 丛式水平井组、水平井分段压裂、疏导式排采 丛式L型套管分段压裂水平井165口,加密直斜井10口 98.5 表 3 煤层气无杆举升工艺指标

Table 3 CBM rod-free lifting process indexes

举升工艺 主要技术指标 最大垂深/m 最大日排水量/m3 射流泵 设备允许固体粒径从1.5 mm提至1.8 mm 2 000 30 水力管式泵 排水量范围0.1~10 m3/d、0.1~30 m3/d两种井下泵 1 000 30 煤层气专用电潜螺杆泵 泵挂深度可满足井斜85°、排水量大于50 m3/d的需求 1 500 60 双循环液压无杆泵 井下泵作业起下时间从12 h降至4 h 1 000 30 -

[1] 徐凤银,闫霞,林振盘,等. 我国煤层气高效开发关键技术研究进展与发展方向[J]. 煤田地质与勘探,2022,50(3):1−14. DOI: 10.12363/issn.1001-1986.21.12.0736 XU Fengyin,YAN Xia,LIN Zhenpan,et al. Research progress and development direction of key technologies for efficient coalbed methane development in China[J]. Coal Geology & Exploration,2022,50(3):1−14. DOI: 10.12363/issn.1001-1986.21.12.0736

[2] 朱庆忠,左银卿,杨延辉. 如何破解我国煤层气开发的技术难题:以沁水盆地南部煤层气藏为例[J]. 天然气工业,2015,35(2):106−109. DOI: 10.3787/j.issn.1000-0976.2015.02.017 ZHU Qingzhong,ZUO Yinqing,YANG Yanhui. How to solve the technical problems in the CBM development:A case study of a CBM gas reservoir in the Southern Qinshui Basin[J]. Natural Gas Industry,2015,35(2):106−109. DOI: 10.3787/j.issn.1000-0976.2015.02.017

[3] 韩旭. 非常规气勘探开发一体化部署研究与实践[J]. 中国石油和化工标准与质量,2020,40(13):109−110. DOI: 10.3969/j.issn.1673-4076.2020.13.054 HAN Xu. Research and practice on integrated deployment of unconventional gas exploration and development[J]. China Petroleum and Chemical Standard and Quality,2020,40(13):109−110. DOI: 10.3969/j.issn.1673-4076.2020.13.054

[4] 叶建平,侯淞译,张守仁. “十三五”期间我国煤层气勘探开发进展及下一步勘探方向[J]. 煤田地质与勘探,2022,50(3):15−22. DOI: 10.12363/issn.1001-1986.21.12.0738 YE Jianping,HOU Songyi,ZHANG Shouren. Progress of coalbed methane exploration and development in China during the 13th Five–Year Plan period and the next exploration direction[J]. Coal Geology & Exploration,2022,50(3):15−22. DOI: 10.12363/issn.1001-1986.21.12.0738

[5] 朱庆忠. 我国高阶煤煤层气疏导式高效开发理论基础:以沁水盆地为例[J]. 煤田地质与勘探,2022,50(3):82−91. DOI: 10.12363/issn.1001-1986.21.12.0845 ZHU Qingzhong. Theoretical basis of dredging and efficient development of high–rank coalbed methane in China:A case study of the Qinshui Basin[J]. Coal Geology & Exploration,2022,50(3):82−91. DOI: 10.12363/issn.1001-1986.21.12.0845

[6] 贾慧敏,胡秋嘉,樊彬,等. 沁水盆地郑庄区块北部煤层气直井低产原因及高效开发技术[J]. 煤田地质与勘探,2021,49(2):34−42. DOI: 10.3969/j.issn.1001-1986.2021.02.005 JIA Huimin,HU Qiujia,FAN Bin,et al. Causes for low CBM production of vertical wells and efficient development technology in Northern Zhengzhuang Block in Qinshui Basin[J]. Coal Geology & Exploration,2021,49(2):34−42. DOI: 10.3969/j.issn.1001-1986.2021.02.005

[7] 谢玉洪,蔡东升,孙晗森. 中国海油非常规气勘探开发一体化探索与成效[J]. 中国石油勘探,2020,25(2):27−32. DOI: 10.3969/j.issn.1672-7703.2020.02.003 XIE Yuhong,CAI Dongsheng,SUN Hansen. Exploration and effect of exploration and development integration in unconventional gas of CNOOC[J]. China Petroleum Exploration,2020,25(2):27−32. DOI: 10.3969/j.issn.1672-7703.2020.02.003

[8] 胡秋嘉,李梦溪,贾慧敏,等. 沁水盆地南部高煤阶煤层气水平井地质适应性探讨[J]. 煤炭学报,2019,44(4):1178−1187. DOI: 10.13225/j.cnki.jccs.2018.0746 HU Qiujia,LI Mengxi,JIA Huimin,et al. Discussion of the geological adaptability of coal−bed methane horizontal wells of high–rank coal formation in Southern Qinshui Basin[J]. Journal of China Coal Society,2019,44(4):1178−1187. DOI: 10.13225/j.cnki.jccs.2018.0746

[9] 朱庆忠,刘立军,陈必武,等. 高煤阶煤层气开发工程技术的不适应性及解决思路[J]. 石油钻采工艺,2017,39(1):92−96. DOI: 10.13639/j.odpt.2017.01.018 ZHU Qingzhong,LIU Lijun,CHEN Biwu,et al. Inadaptability of high–rank CBM development engineering and its solution idea[J]. Oil Drilling & Production Technology,2017,39(1):92−96. DOI: 10.13639/j.odpt.2017.01.018

[10] 朱庆忠,杨延辉,左银卿,等. 对于高煤阶煤层气资源科学开发的思考[J]. 天然气工业,2020,40(1):55−60. DOI: 10.3787/j.issn.1000-0976.2020.01.007 ZHU Qingzhong,YANG Yanhui,ZUO Yinqing,et al. On the scientific exploitation of high–rank CBM resources[J]. Natural Gas Industry,2020,40(1):55−60. DOI: 10.3787/j.issn.1000-0976.2020.01.007

[11] 赵贤正,杨延辉,孙粉锦,等. 沁水盆地南部高阶煤层气成藏规律与勘探开发技术[J]. 石油勘探与开发,2016,43(2):303−309. DOI: 10.11698/PED.2016.02.19 ZHAO Xianzheng,YANG Yanhui,SUN Fenjin,et al. Enrichment mechanism and exploration and development technologies of high rank coalbed methane in South Qinshui Basin,Shanxi Province[J]. Petroleum Exploration and Development,2016,43(2):303−309. DOI: 10.11698/PED.2016.02.19

[12] 赵贤正,杨延辉,陈龙伟,等. 高阶煤储层固–流耦合控产机理与产量模式[J]. 石油学报,2015,36(9):1029−1034. ZHAO Xianzheng,YANG Yanhui,CHEN Longwei,et al. Production controlling mechanism and mode of solid–fluid coupling of high rank coal reservoirs[J]. Acta Petrolei Sinica,2015,36(9):1029−1034.

[13] 喻鹏,杨延辉,朱庆忠,等. 沁水盆地高阶煤层气压裂工艺反思与技术改进试验研究[J]. 中国煤层气,2015,12(1):21−26. DOI: 10.3969/j.issn.1672-3074.2015.01.005 YU Peng,YANG Yanhui,ZHU Qingzhong,et al. Study on CBM fracturing technology and technical improvement test for high–rank coal in Qinshui Basin[J]. China Coalbed Methane,2015,12(1):21−26. DOI: 10.3969/j.issn.1672-3074.2015.01.005

[14] 宋帅,周劲辉,范德元,等. 高阶煤压裂液伤害机理研究[J]. 煤炭技术,2018,37(5):161−163. DOI: 10.13301/j.cnki.ct.2018.05.062 SONG Shuai,ZHOU Jinhui,FAN Deyuan,et al. Study on damage mechanism of fracturing fluid in high rank coal[J]. Coal Technology,2018,37(5):161−163. DOI: 10.13301/j.cnki.ct.2018.05.062

[15] 刘立军,陈必武,李宗源,等. 华北油田煤层气水平井钻完井方式优化与应用[J]. 煤炭工程,2019,51(10):77−81. LIU Lijun,CHEN Biwu,LI Zongyuan,et al. Optimization of drilling and completion methods for horizontal wells of coalbed methane in Huabei Oilfield[J]. Coal Engineering,2019,51(10):77−81.

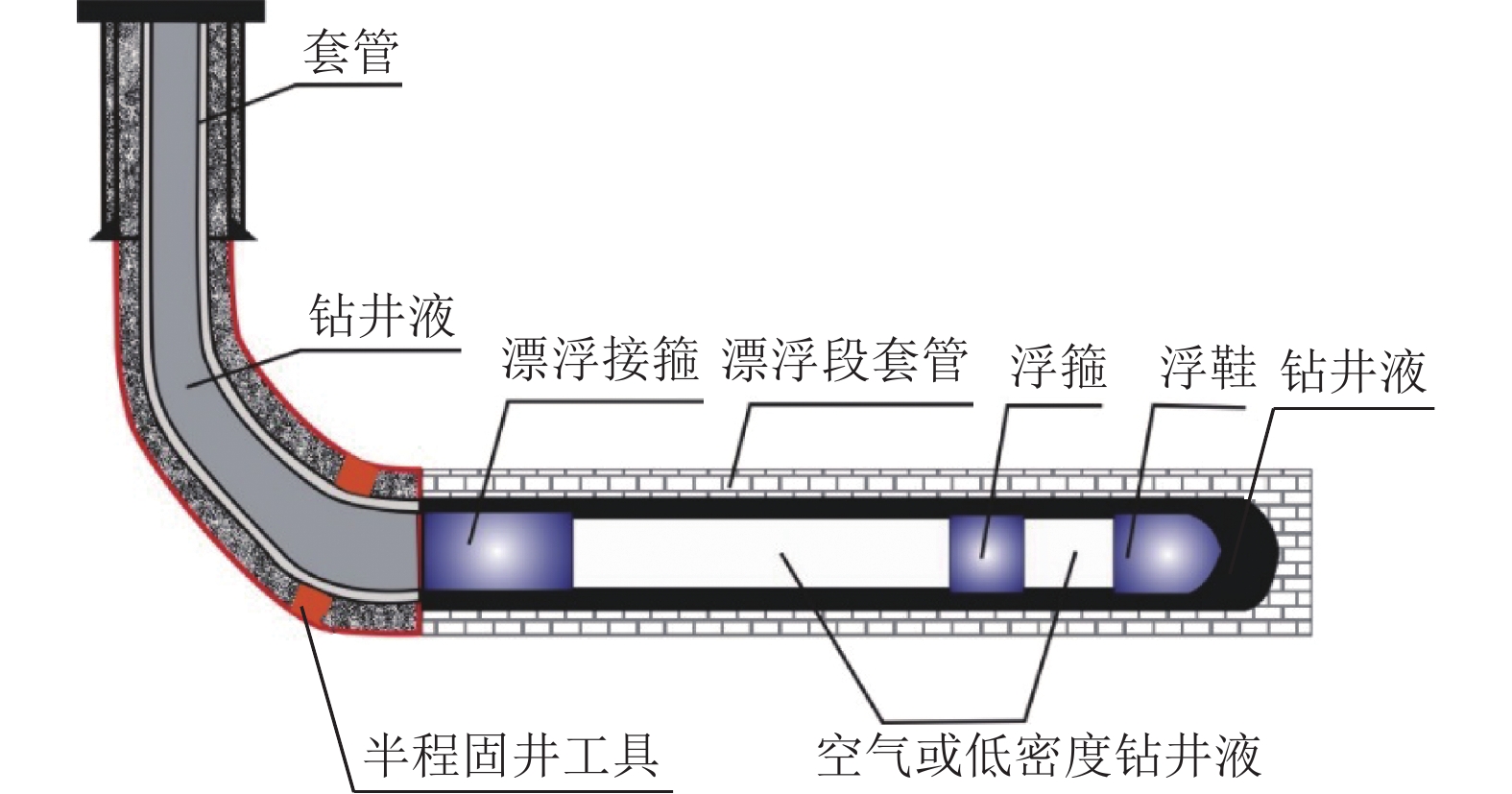

[16] 肖洋,宗庆伟,李榕,等. 漂浮下套管技术在川西长裸眼水平井的试验[J]. 钻采工艺,2022,45(5):34−38. XIAO Yang,ZONG Qingwei,LI Rong,et al. Experiment of floating casing technology in long open–hole horizontal well in Western Sichuan[J]. Drilling and Production Technology,2022,45(5):34−38.

[17] 梅永贵,郭简,苏雷,等. 无杆泵排采技术在沁水煤层气田的应用[J]. 煤炭科学技术,2016,44(5):64−67. DOI: 10.13199/j.cnki.cst.2016.05.013 MEI Yonggui,GUO Jian,SU Lei,et al. Application of rodless pump drainage technology to Qinshui Coalbed Methane Field[J]. Coal Science and Technology,2016,44(5):64−67. DOI: 10.13199/j.cnki.cst.2016.05.013

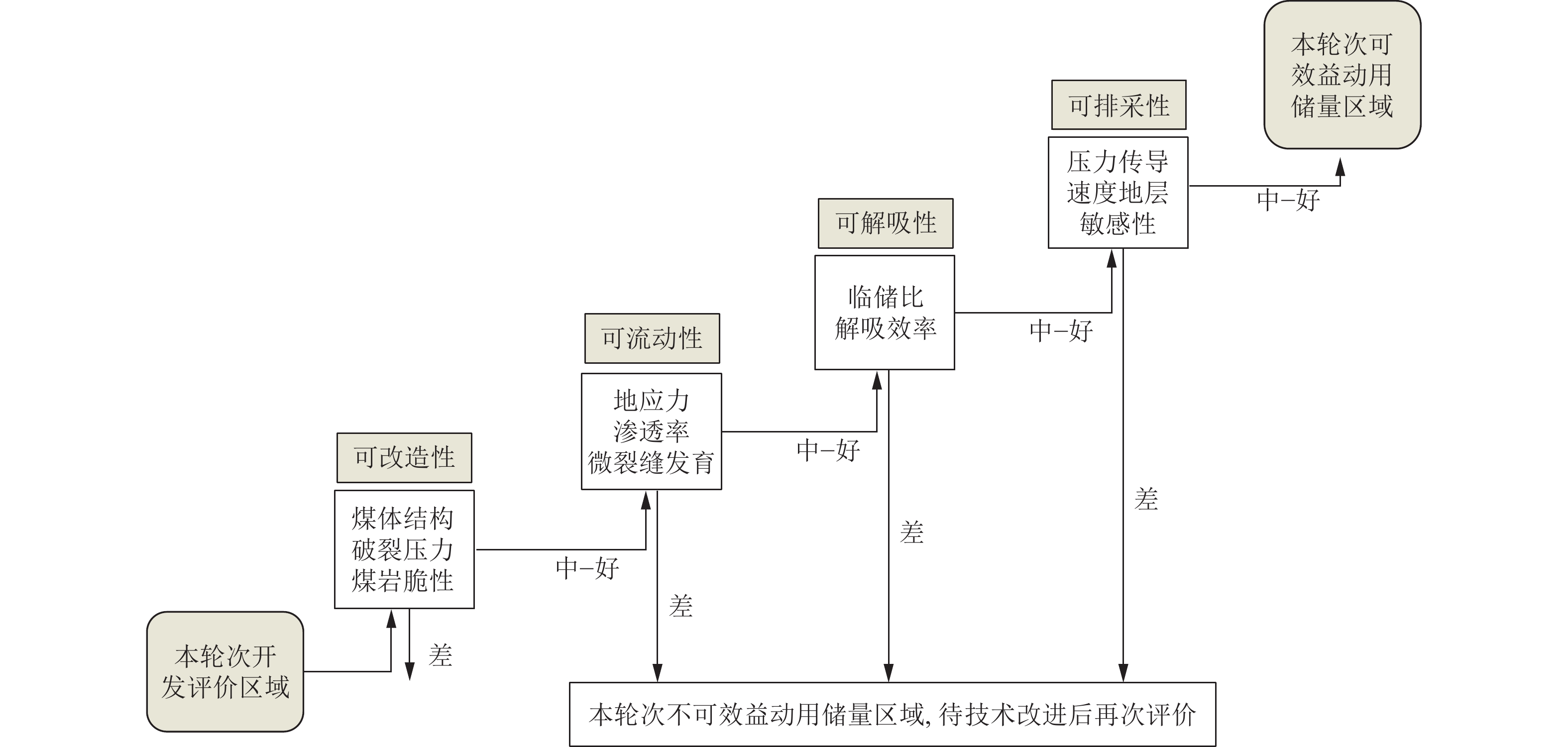

[18] 杨延辉,王玉婷,陈龙伟,等. 沁南西–马必东区块煤层气高效建产区优选技术[J]. 煤炭学报,2018,43(6):1620−1626. YANG Yanhui,WANG Yuting,CHEN Longwei,et al. Optimization technology of efficient CBM productivity areas in Qinnanxi–Mabidong Block,Qinshui Basin,Shanxi,China[J]. Journal of China Coal Society,2018,43(6):1620−1626.

[19] 姚艳斌,王辉,杨延辉,等. 煤层气储层可改造性评价:以郑庄区块为例[J]. 煤田地质与勘探,2021,49(1):119−129. DOI: 10.3969/j.issn.1001-1986.2021.01.012 YAO Yanbin,WANG Hui,YANG Yanhui,et al. Evaluation of the hydro–fracturing potential for coalbed methane reservoir:A case study of Zhengzhuang CBM field[J]. Coal Geology & Exploration,2021,49(1):119−129. DOI: 10.3969/j.issn.1001-1986.2021.01.012

[20] 陈跃,汤达祯,许浩,等. 应用测井资料识别煤体结构及分层[J]. 煤田地质与勘探,2014,42(1):19−23. DOI: 10.3969/j.issn.1001-1986.2014.01.004 CHEN Yue,TANG Dazhen,XU Hao,et al. Application of logging data in recognition of coal structure and stratification[J]. Coal Geology & Exploration,2014,42(1):19−23. DOI: 10.3969/j.issn.1001-1986.2014.01.004

[21] 黄中伟,李志军,李根生,等. 煤层气水平井定向喷射防砂压裂技术及应用[J]. 煤炭学报,2022,47(7):2687−2697. DOI: 10.13225/j.cnki.jccs.2021.1906 HUANG Zhongwei,LI Zhijun,LI Gensheng,et al. Oriented and sand control hydra–jet fracturing in coalbed methane horizontal wells and field applications[J]. Journal of China Coal Society,2022,47(7):2687−2697. DOI: 10.13225/j.cnki.jccs.2021.1906

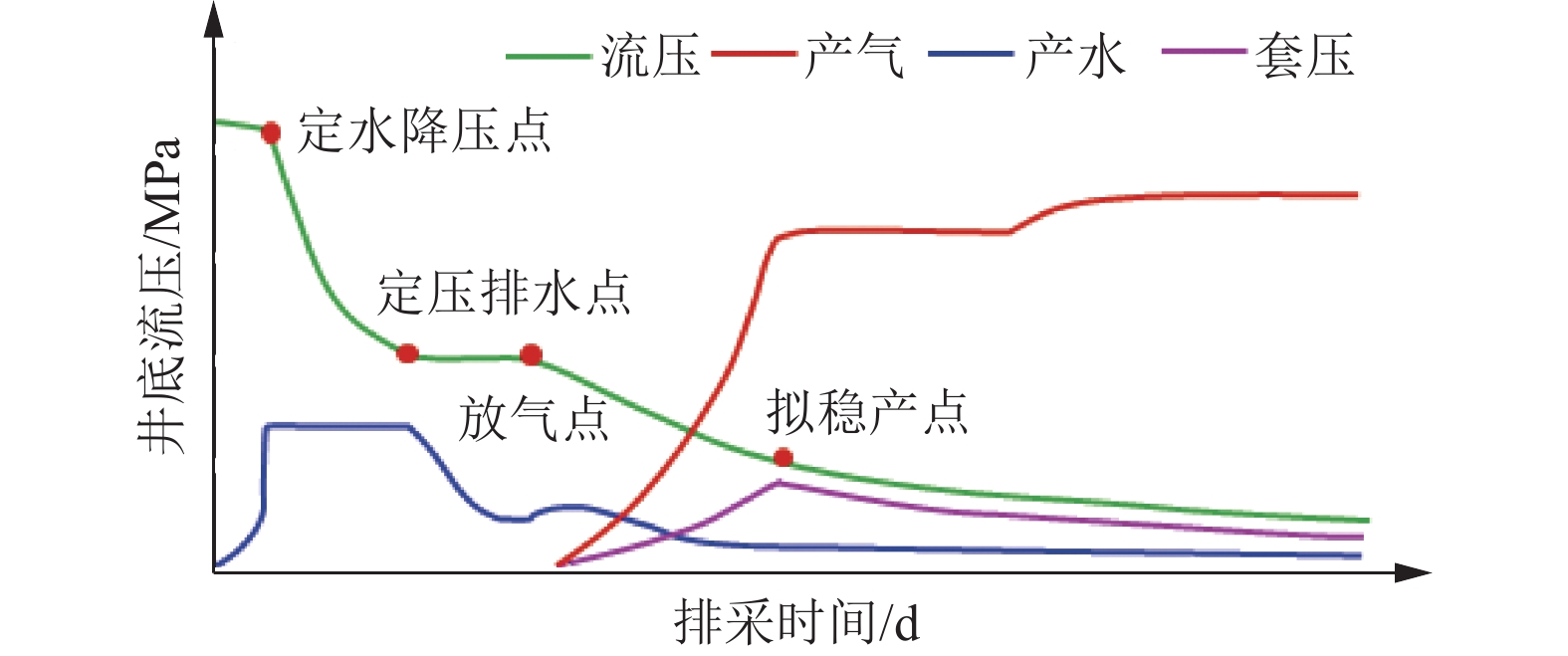

[22] 朱庆忠,王宁,张学英,等. 煤层气井单相水流拟稳态排采模型与应用效果分析[J]. 煤炭学报,2020,45(3):1116−1124. DOI: 10.13225/j.cnki.jccs.2019.0275 ZHU Qingzhong,WANG Ning,ZHANG Xueying,et al. Single–phase water flow quasi–steady–state drainage model and its application effect analysis in coal–bed methane wells[J]. Journal of China Coal Society,2020,45(3):1116−1124. DOI: 10.13225/j.cnki.jccs.2019.0275

[23] 李俊. 沁水盆地中东部深部煤层气勘探开发目标优选研究[D]. 北京: 中国矿业大学(北京), 2020. LI Jun. Study on the optimized selection of deep coalbed methane targets for exploration and development in Mid−eastern Qinshui Basin[D]. Beijing: China University of Mining & Technology (Beijing), 2020.

[24] 杨兆中,何睿,李小刚,等. 深埋煤层气同步压裂应力干扰机理研究及应用[J]. 油气藏评价与开发,2017,7(4):65−72. DOI: 10.3969/j.issn.2095-1426.2017.04.013 YANG Zhaozhong,HE Rui,LI Xiaogang,et al. Mechanism research on stress interference of simultaneous fracturing and its application in deep coalbed methane[J]. Reservoir Evaluation and Development,2017,7(4):65−72. DOI: 10.3969/j.issn.2095-1426.2017.04.013

下载:

下载: