Experimental study on power matching of modular double pumping stations of tunnel drilling rig

-

摘要:

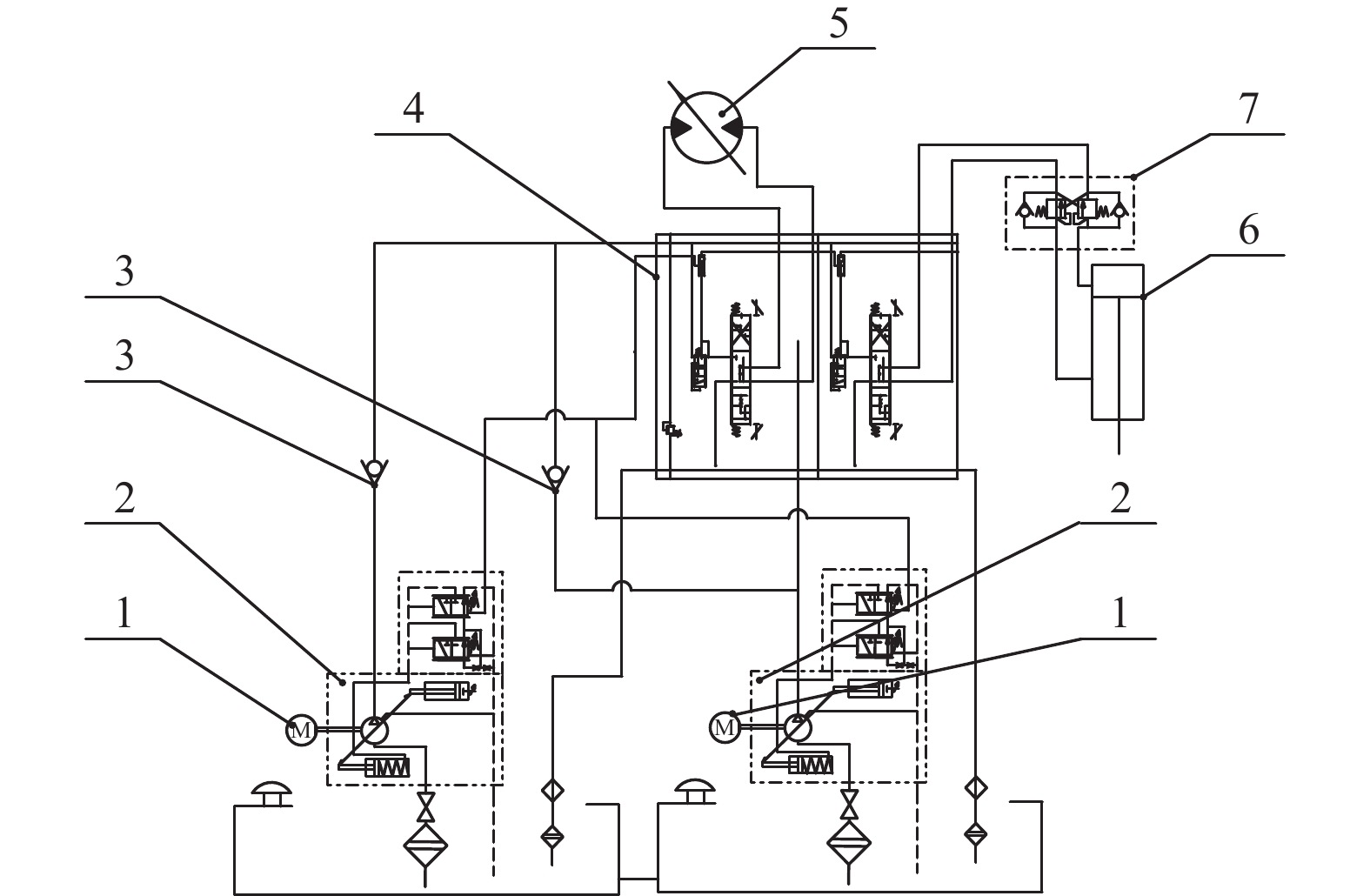

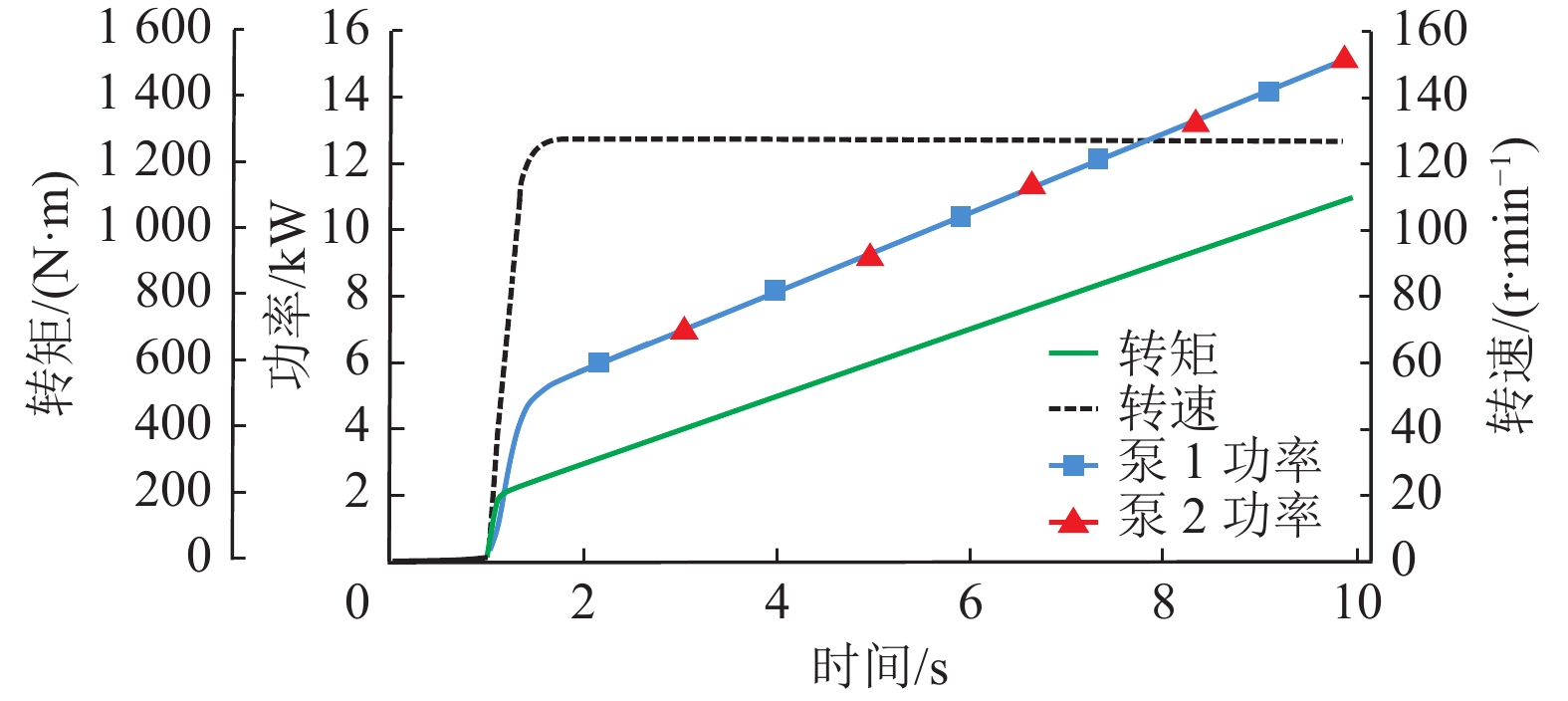

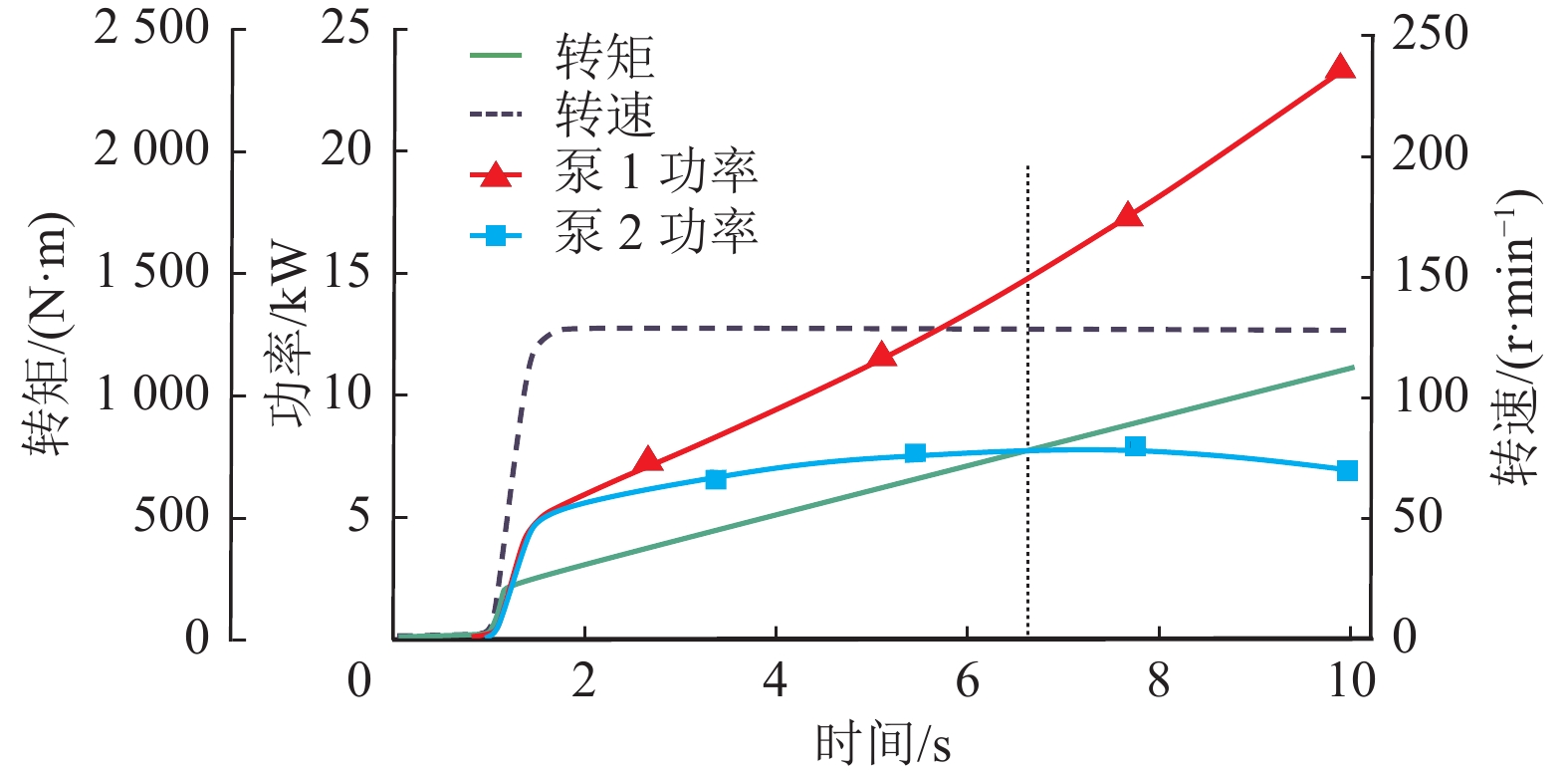

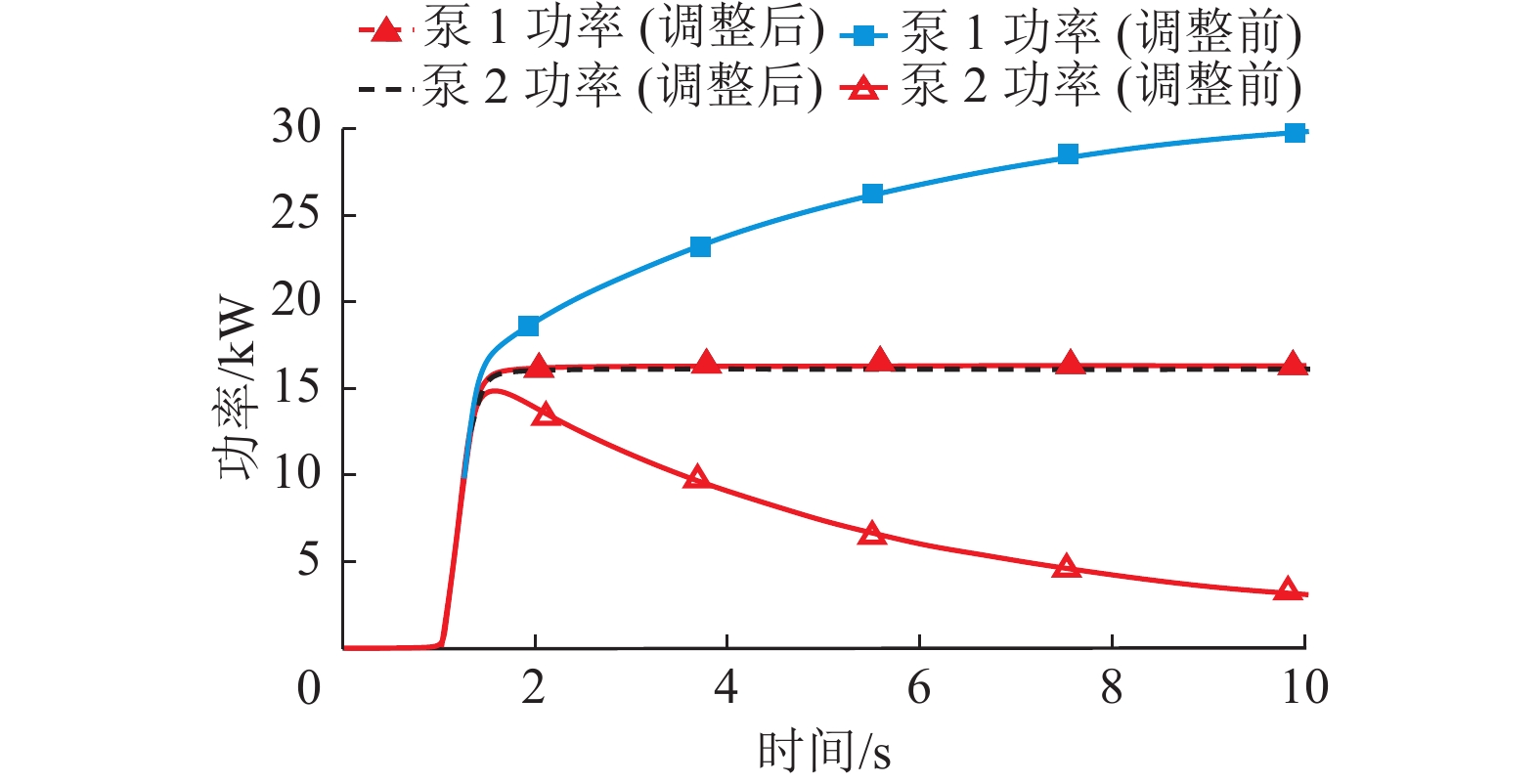

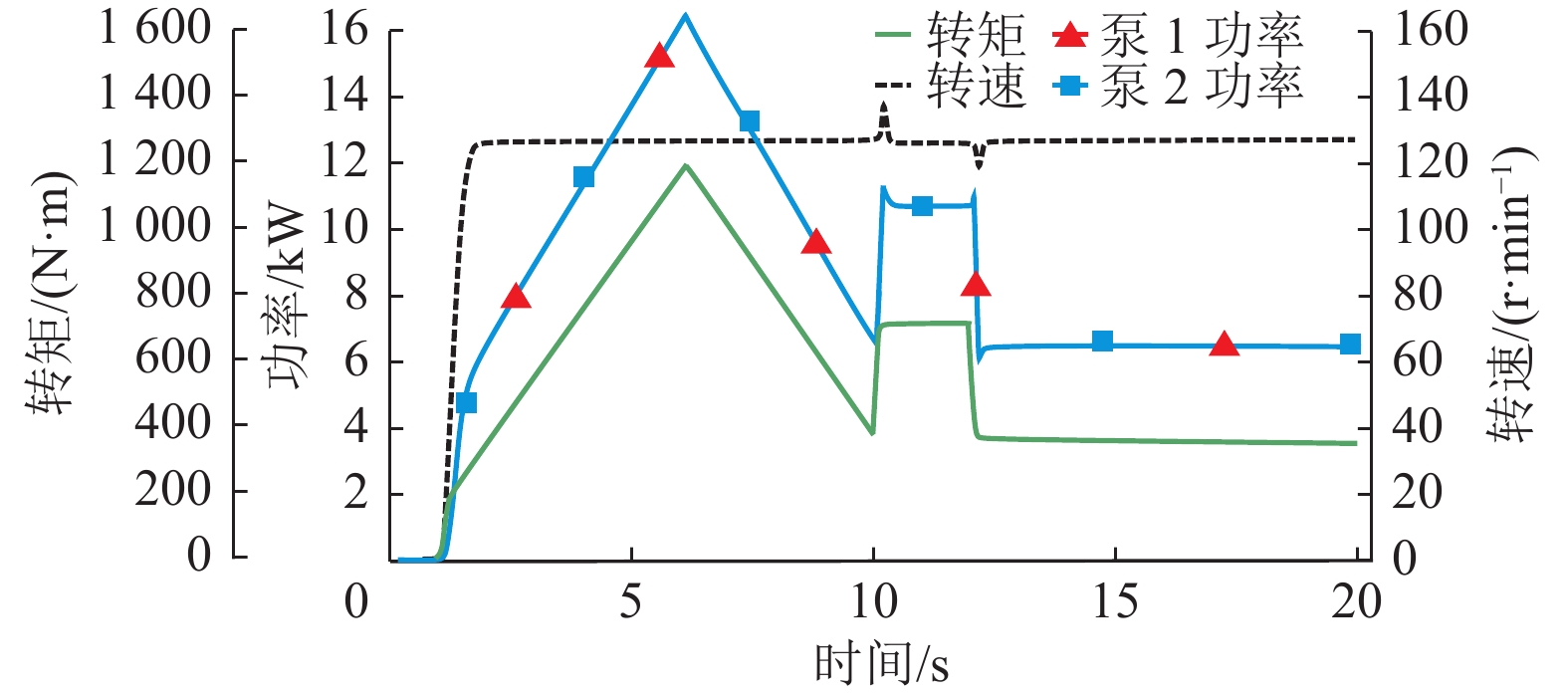

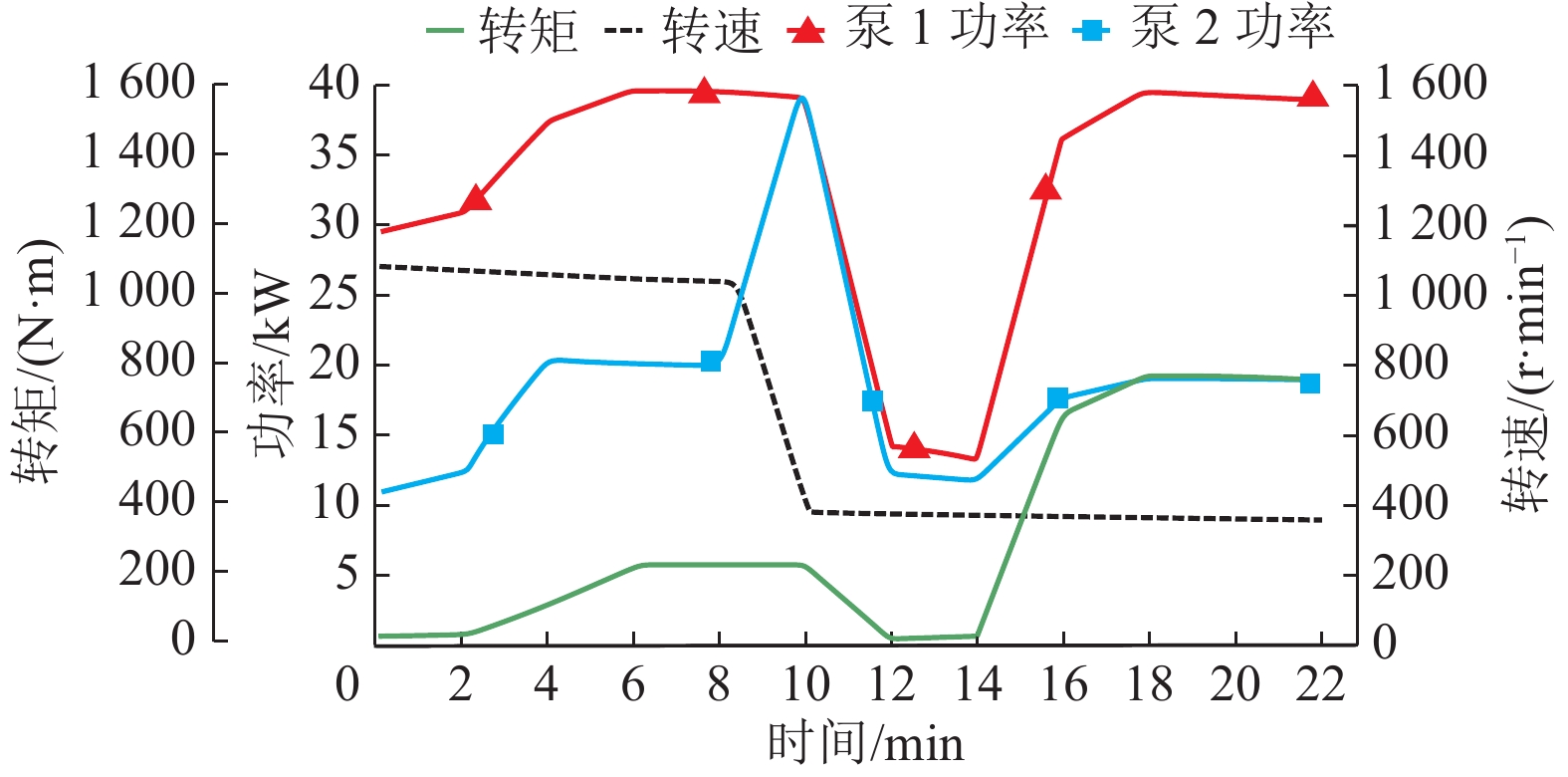

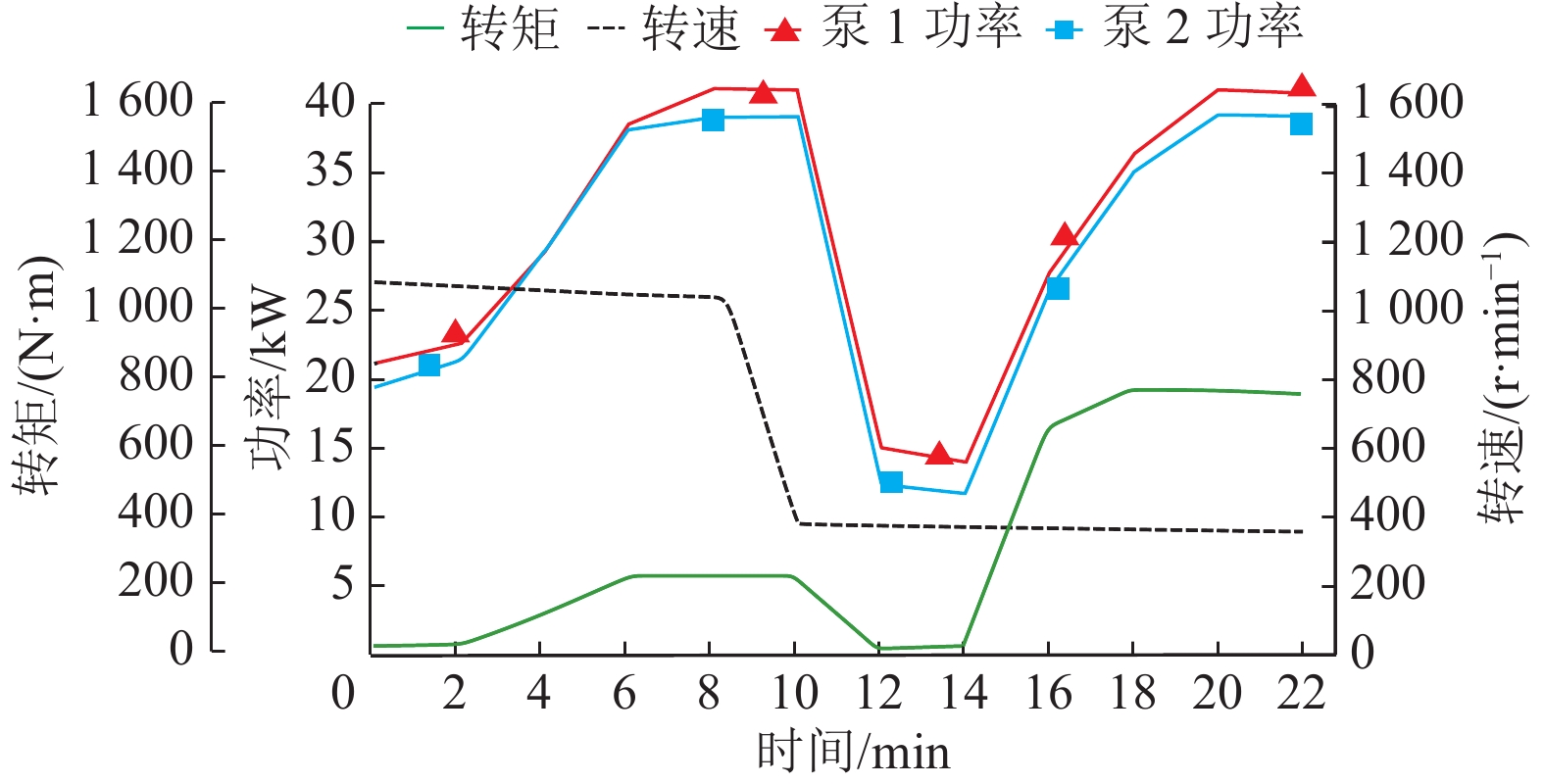

为解决坑道钻机动力泵站重量大、搬迁运输难题,提出通过模块设计,将泵站进行拆分,采用小排量双动力双泵合流解决方案。化整为零,可有效减小单个泵站的运输尺寸及重量,并可根据工况需求选择单泵站或双泵合流提高钻机使用的灵活性,同时降低能耗。负载敏感系统具有节能、负载适应性好、调速方便等优点,然而双负载敏感泵系统合流时,2个泵的输出功率不平衡,钻机输出参数不符合设计要求是亟需解决的难题。理论分析指出,两个负载敏感泵与负载敏感阀之间的反馈管路差异影响2个泵的功率平衡,然后建立双动力双泵负载敏感系统动态模型。基于该模型,动态分析双负载敏感泵系统压力流量特性,重点分析反馈管路以及压力补偿器对双泵站功率平衡的影响,并提出双负载敏感泵系统功率匹配方法。通过台架实验对理论分析结果进行验证,结果表明, 管路差异对双泵双动力负载敏感泵合流系统输出特性有较大的影响。在反馈管路中设置阻尼并根据管路匹配阻尼参数,可实现双泵输出参数的基本平衡。通过微调压力补偿器弹簧预压缩量,可使系统达到较好平衡,消除管路差异影响。该方法解决了2个泵站输出功率不平衡问题,该方法有较强的普适性和应用价值,对坑道钻机液压泵站的模块化设计具有重要的参考意义。

Abstract:In order to solve the problems of heavy weight, relocation and transportation of the power pumping station of tunnel drilling rigs, it is proposed to divide the pumping station through modular design, and adopt the solution of small-displacement, dual-power and dual-pump confluence, effectively reducing the transportation size and weight of a single pump station. A single-pump station or a double-pump confluence is chosen according to the working conditions to improve the flexibility of the drilling rig and reduce energy consumption. The load-sensing system has the advantages of energy saving, good load adaptability, and convenient speed regulation. However, when the dual-load-sensing pump system merges, the output power of the two pumps is unbalanced, and the output parameters of the drilling rig do not meet the design requirements, which are urgent problems to be solved. Through theoretical analysis, it is proposed that the difference of the feedback pipeline between the two load-sensitive pumps and the load-sensitive valve affects the power balance of the two pumps, and then the dynamic model of the dual-power dual-pump load-sensitive system is established. Based on the model, the pressure-flow characteristics of the dual-load sensitive pump system are dynamically analyzed, the influence of the feedback pipeline and pressure compensator on the power balance of the dual-pumping station is analyzed, and the power matching method of the dual-load-sensitive pump system is proposed. The theoretical analysis results are verified by the bench test. The results show that the pipeline difference has a great influence on the output characteristics of the dual-pump dual-dynamic load-sensitive pump confluence system. Setting damping in the feedback line and matching damping parameters according to the line can realize the basic balance of the output parameters of the two pumps. By fine-tuning the spring pre-compression of the pressure compensator, the system can achieve a better balance and eliminate the influence of pipeline differences. The problem of the unbalanced output power of the two pump stations is solved. The method has strong universality and application value, providing an important reference for the modular design of the hydraulic pump station of the tunnel drilling rig.

-

Keywords:

- modular /

- double power and double pump /

- power balance /

- load sensitive system /

- confluence /

- tunnel drilling rig

-

-

表 1 ZDY1200G主要性能参数

Table 1 ZDY1200G parameters

名称 参数 转速/(r·min−1) 300~1 000 转矩/(N·m) 0~1 200 动力头减速比 2.4 泵1功率/kW 40 泵2功率/kW 40 电机转速/(r·min−1) 1450 泵1排量/(mL·r−1) 45 泵2排量/(mL·r−1) 45 马达排量/(mL·r−1) 160 表 2 模型主要参数

Table 2 Main parameters of the model

名称 参数 马达排量/(mL·r−1) 160 动力头减速比 2.4 泵1排量/(mL·r−1) 45 泵2排量/(mL·r−1) 45 电机转速/(r·min−1) 1 450 多路阀通径/mm 15 反馈管路通径/mm 6 系统最高工作压力/MPa 28 表 3 测试台测试参数范围

Table 3 Test parameters and scope of the test bench

名称 参数 给进起拔力/kN 160 转速/(r·min−1) 0~1 500 转矩/(N·m) 0~7 000 回油压力/MPa 0~3 系统压力/MPa 40 马达进出口压力/MPa 0~30 流量/(L·min−1) 6.7~250.0 油温/℃ 0~100 功率/kW 45 -

[1] 凡东, 王瑞泽, 田宏亮, 等. 轻量化坑道钻机的研制及应用[J]. 煤田地质与勘探, 2020, 48(4): 46–52. DOI: 10.3969/j.issn.1001-1986.2020.04.007 FAN Dong, WANG Ruize, TIAN Hongliang, et al. Development and application of lightweight underground drill rig[J]. Coal Geology & Exploration, 2020, 48(4): 46–52. DOI: 10.3969/j.issn.1001-1986.2020.04.007

[2] 滕吉文. 强化开展地壳内部第二深度空间金属矿产资源地球物理找矿、勘探和开发[J]. 地质通报, 2006, 25(7): 767–771. DOI: 10.3969/j.issn.1671-2552.2006.07.001 TENG Jiwen. Strengthening geophysical exploration and exploitation of metallic minerals in the second deep space of the crustal interior[J]. Geological Bulletin of China, 2006, 25(7): 767–771. DOI: 10.3969/j.issn.1671-2552.2006.07.001

[3] 殷新胜, 田宏亮, 姚克, 等. 负载敏感技术在全液压动力头式坑道钻机上的应用[J]. 煤炭科学技术, 2008, 36(1): 75–77. DOI: 10.13199/j.cst.2008.01.80.yinxsh.007 YIN Xinsheng, TIAN Hongliang, YAO Ke, et al. Application of load sensitive technology to mine roadway hydraulic driving head drilling rig[J]. Coal Science and Technology, 2008, 36(1): 75–77. DOI: 10.13199/j.cst.2008.01.80.yinxsh.007

[4] 刘庆修, 田宏亮, 凡东, 等. 基于AMESim的GDY–2000L工程钻机负载敏感液压系统仿真分析[J]. 煤炭工程, 2012(1): 125–127. DOI: 10.3969/j.issn.1671-0959.2012.01.044 LIU Qingxiu, TIAN Hongliang, FAN Dong, et al. Simulation analysis on load sensitive hydraulic system of GDY–2000L engineering drilling rig base on AMESim[J]. Coal Engineering, 2012(1): 125–127. DOI: 10.3969/j.issn.1671-0959.2012.01.044

[5] 宋海涛, 吴晓光, 殷新胜, 等. 负载反馈油管对负载敏感液压系统动态特性影响的探讨[J]. 机械设计与制造, 2009(1): 200–201. DOI: 10.3969/j.issn.1001-3997.2009.01.079 SONG Haitao, WU Xiaoguang, YIN Xinsheng, et al. The influence of the feed back pipe to load sensing system dynamic characteristic[J]. Machinery Design & Manufacture, 2009(1): 200–201. DOI: 10.3969/j.issn.1001-3997.2009.01.079

[6] 孔晓武. 带长管道的负载敏感系统研究[D]. 杭州: 浙江大学, 2003. KONG Xiaowu. Research on load sensing system with long pipeline[D]. Hangzhou: Zhejiang University, 2003.

[7] 陈随英, 赵建军, 毛恩荣, 等. 负载敏感变量泵结构建模与性能分析[J]. 农业工程学报, 2017, 33(3): 40–49. DOI: 10.11975/j.issn.1002-6819.2017.03.006 CHEN Suiying, ZHAO Jianjun, MAO Enrong, et al. Structural modeling and performance analysis of load–sensing variable pump[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(3): 40–49. DOI: 10.11975/j.issn.1002-6819.2017.03.006

[8] 李昊. 单泵多执行器负载敏感液压系统稳定性的研究[D]. 西安: 长安大学, 2016. LI Hao. Study on stability of load sensing hydraulic system of one pump for multi–actuators[D]. Xi’an: Chang’an University, 2016.

[9] 王瑞泽, 鲁飞飞, 凡东, 等. ZDY1200G钻机在某铅锌矿坑道中深孔勘探中的应用[J]. 化工矿物与加工, 2020, 49(5): 38–41. DOI: 10.16283/j.cnki.hgkwyjg.2020.05.011 WANG Ruize, LU Feifei, FAN Dong, et al. Application of ZDY1200G in medium deep hole exploration in tunnel of lead–zinc mine[J]. Industrial Minerals & Processing, 2020, 49(5): 38–41. DOI: 10.16283/j.cnki.hgkwyjg.2020.05.011

[10] 付永领, 荆慧强. 弯管转角对液压管道振动特性影响分析[J]. 振动与冲击, 2013, 32(13): 165–169. DOI: 10.3969/j.issn.1000-3835.2013.13.031 FU Yongling, JING Huiqiang. Elbow angle effect on hydraulic pipeline vibration characteristics[J]. Journal of Vibration and Shock, 2013, 32(13): 165–169. DOI: 10.3969/j.issn.1000-3835.2013.13.031

[11] 冯婷, 刘文广, 胡显忠. 基于AMESim的单泵多执行器负载敏感 液压系统仿真分析[J]. 甘肃科学学报, 2017, 29(3): 117–120. FENG Ting, LIU Wenguang, HU Xianzhong. Simulation analysis of load sensing hydraulic system of single pump and multi actuator based on AMESim[J]. Journal of Gansu Sciences, 2017, 29(3): 117–120.

[12] 田宏亮. 瓦斯抽采履带式坑道钻机的研制与应用[J]. 煤田地质与勘探, 2008, 36(5): 77–80. DOI: 10.3969/j.issn.1001-1986.2008.05.020 TIAN Hongliang. Manufacture and application on track–mounted rig for gas drainage[J]. Coal Geology & Exploration, 2008, 36(5): 77–80. DOI: 10.3969/j.issn.1001-1986.2008.05.020

[13] 常江华, 凡东, 田宏亮. 全液压车载钻机给进回路负载特性分析及设计[J]. 煤田地质与勘探, 2017, 45(6): 182–186. DOI: 10.3969/j.issn.1001-1986.2017.06.030 CHANG Jianghua, FAN Dong, TIAN Hongliang. Analysis of load characteristics and design of feeding circuit of fully hydraulic truck–mounted drilling rig[J]. Coal Geology & Exploration, 2017, 45(6): 182–186. DOI: 10.3969/j.issn.1001-1986.2017.06.030

[14] 刘耀林. 负载敏感斜盘式轴向柱塞变量泵静动态特性研究[D]. 兰州: 兰州理工大学, 2016. LIU Yaolin. A study on static and dynamic characteristic of the load–sensing swash plate axial variable piston pump[D]. Lanzhou: Lanzhou University of Technology, 2016.

[15] 郭治富, 张子飞, 王虹. 负载敏感泵参数辨识与计算方法研究[J]. 液压与气动, 2017(7): 67–70. DOI: 10.11832/j.issn.1000-4858.2017.07.012 GUO Zhifu, ZHANG Zifei, WANG Hong. Parameter identification and calculation for load–sensing pump[J]. Chinese Hydraulics & Pneumatics, 2017(7): 67–70. DOI: 10.11832/j.issn.1000-4858.2017.07.012

[16] 胡引弟. M4系列负载敏感比例多路阀中压力补偿阀的静动态特性研究[D]. 兰州: 兰州理工大学, 2017. HU Yindi. The research on static and dynamic characteristics of the pressure compensation valve in M4 series load–sensing proportional multi–way valve[D]. Lanzhou: Lanzhou University of Technology, 2017.

[17] 方鹏. 15000 Nm大功率定向钻机关键技术研究[J]. 煤田地质与勘探, 2019, 47(2): 7–12. FANG Peng. Research on key technology of the 15000 Nm high–power directional drilling rig[J]. Coal Geology & Exploration, 2019, 47(2): 7–12.

[18] 鲁力群, 张鹏, 史蕾蕾, 等. 基于负载敏感控制的木墩机粉碎系统研究[J]. 机床与液压, 2018, 46(4): 70–74. DOI: 10.3969/j.issn.1001-3881.2018.04.018 LU Liqun, ZHANG Peng, SHI Leilei, et al. Research on crushing system of stump machine based on load–sensing control[J]. Machine Tool & Hydraulics, 2018, 46(4): 70–74. DOI: 10.3969/j.issn.1001-3881.2018.04.018

[19] 张锐, 姚克, 方鹏, 等. 煤矿井下自动化钻机研发关键技术[J]. 煤炭科学技术, 2019, 47(5): 59–63. DOI: 10.13199/j.cnki.cst.2019.05.009 ZHANG Rui, YAO Ke, FANG Peng, et al. Key technologies for research and development of automatic drilling rig in underground coal mine[J]. Coal Science and Technology, 2019, 47(5): 59–63. DOI: 10.13199/j.cnki.cst.2019.05.009

[20] 王晨升, 姚丽英, 苏芳, 等. 回撤吊车负载敏感液压系统设计及仿真分析[J]. 液压与气动, 2018(6): 49–53. DOI: 10.11832/j.issn.1000-4858.2018.06.010 WANG Chensheng, YAO Liying, SU Fang, et al. Design and simulation analysis of load sensing hydraulic system for shield mule[J]. Chinese Hydraulics & Pneumatics, 2018(6): 49–53. DOI: 10.11832/j.issn.1000-4858.2018.06.010

[21] 翁寅生, 邬迪, 鲁飞飞, 等. 煤矿井下钻机远程控制系统设计[J]. 煤田地质与勘探, 2019, 47(2): 20–26. WENG Yinsheng, WU Di, LU Feifei, et al. Design of remote control system of drilling rig in coal mines[J]. Coal Geology & Exploration, 2019, 47(2): 20–26.

[22] 梁春苗, 姚宁平, 姚亚峰, 等. 径向活塞式液压卡盘动态特性仿真与试验[J]. 煤田地质与勘探, 2020, 48(5): 246–253. DOI: 10.3969/j.issn.1001-1986.2020.05.031 LIANG Chunmiao, YAO Ningping, YAO Yafeng, et al. Simulation and experimental study on dynamic characteristics of radial piston hydraulic chuck[J]. Coal Geology & Exploration, 2020, 48(5): 246–253. DOI: 10.3969/j.issn.1001-1986.2020.05.031

-

期刊类型引用(7)

1. 王勇军,聂德久,袁宝宏,袁宝新,赵长亮,张涛,刘振新. 天阳盆地高温硬岩地热钻探PDC钻头的研究应用. 钻探工程. 2024(06): 125-131 .  百度学术

百度学术

2. 马亚超,陶垒,荣准. PDC钻头布齿技术研究综述. 工程设计学报. 2023(01): 1-12 .  百度学术

百度学术

3. 李勇,董仕明,姚建林. 锥形PDC齿单齿破岩有限元仿真研究. 石油和化工设备. 2023(10): 33-36+27 .  百度学术

百度学术

4. 刘送永,徐保龙,秦立学,孟庆皓,李洪盛. 煤矿巷道掘进长距离快速超前钻探工艺策略及配套机具研究. 煤炭科学技术. 2023(S2): 229-239 .  百度学术

百度学术

5. 王传留,金新,高晓亮,张朋. 硬岩PDC定向钻头优化设计及其表面增材技术研究. 煤田地质与勘探. 2022(08): 157-164 .  本站查看

本站查看

6. 陈新海. 巴彦河套新区异形齿PDC钻头研究与应用. 钻探工程. 2022(05): 127-135 .  百度学术

百度学术

7. 高晓亮,居培,赵建国. 煤层顶板大直径定向钻孔用双级双速PDC钻头设计及应用. 煤田地质与勘探. 2021(05): 272-277+285 .  本站查看

本站查看

其他类型引用(4)

下载:

下载: