Experimental study on the mechanical properties of coal-like materials for hydraulic fracturing simulation

-

摘要:

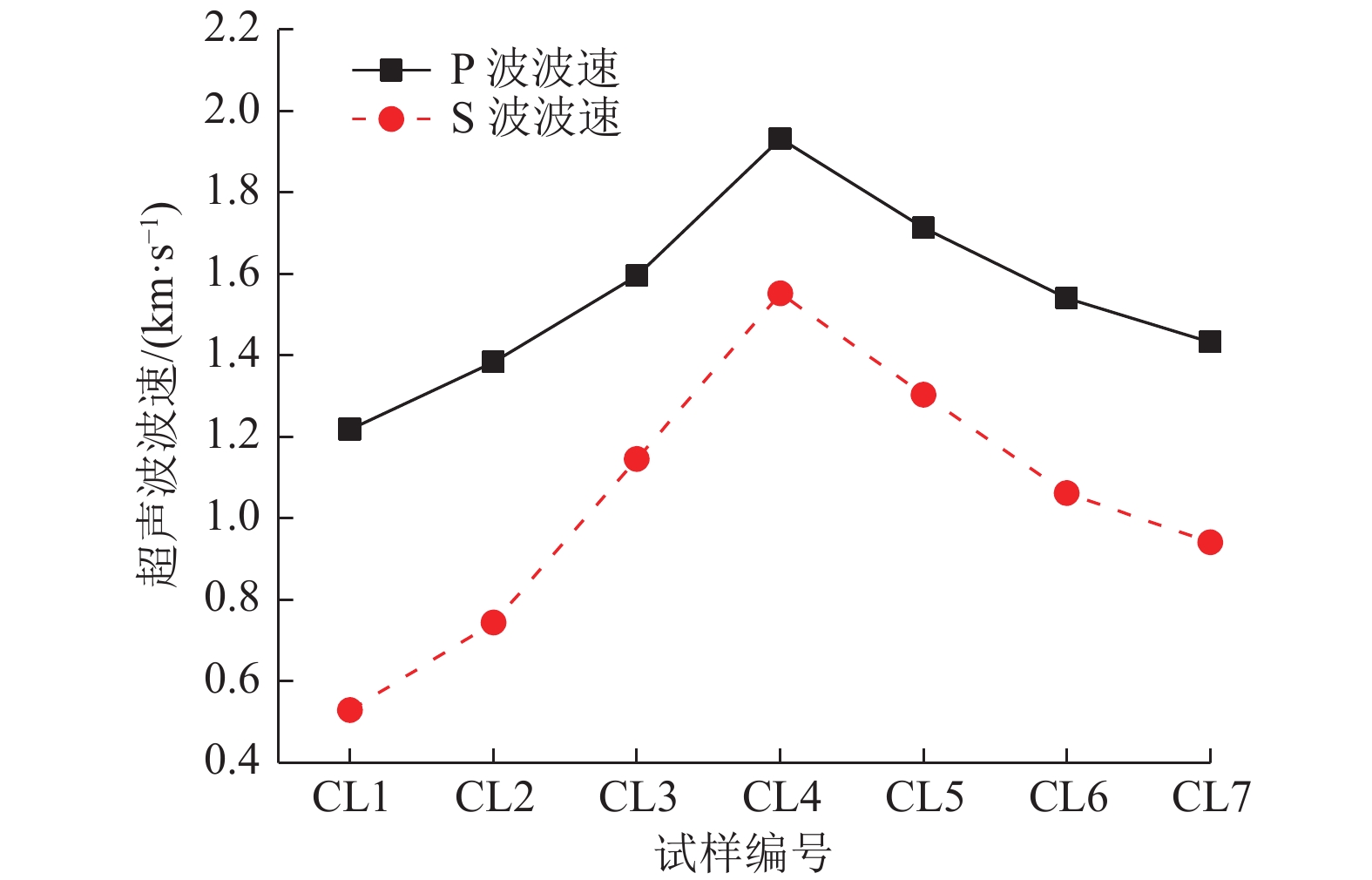

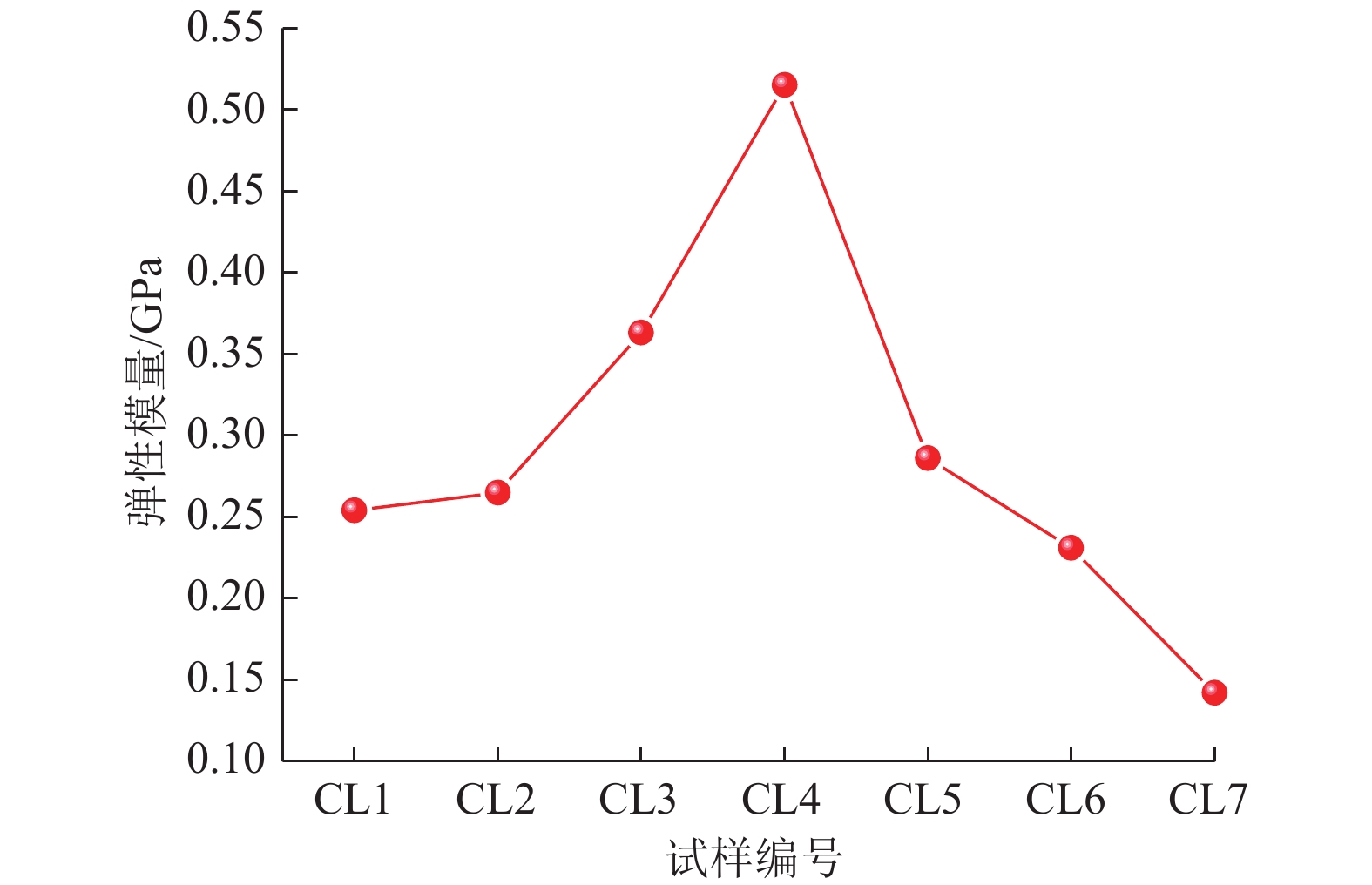

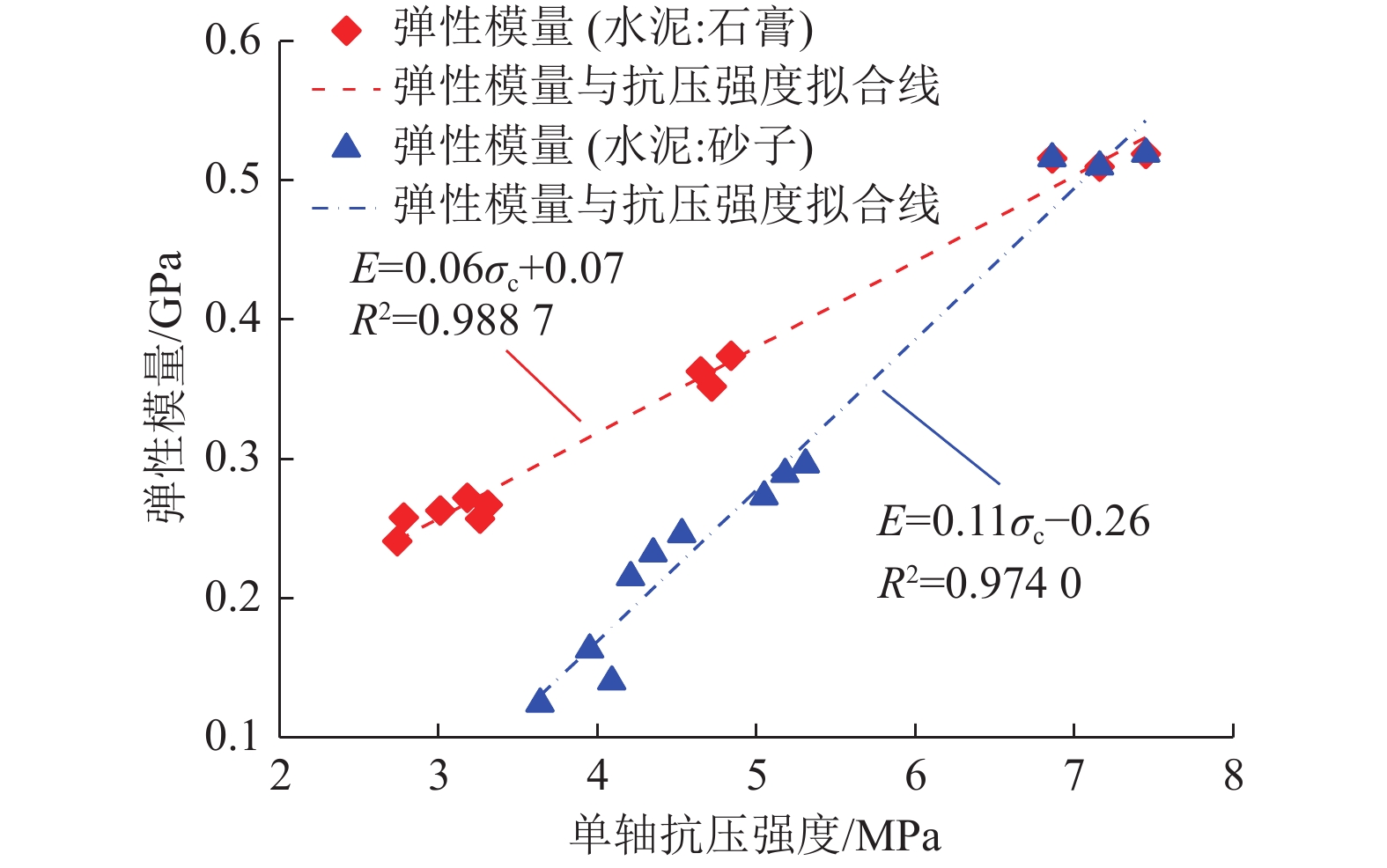

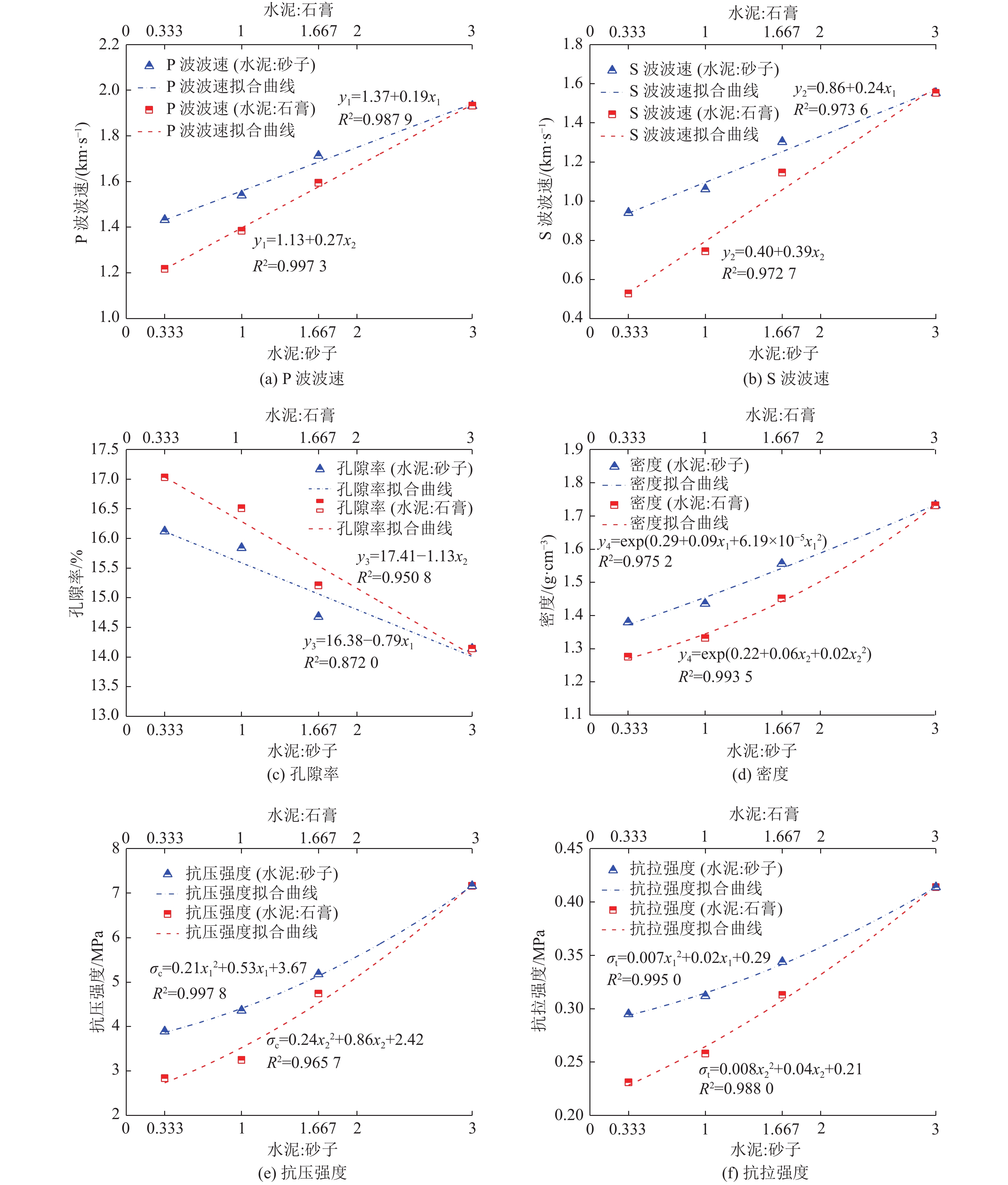

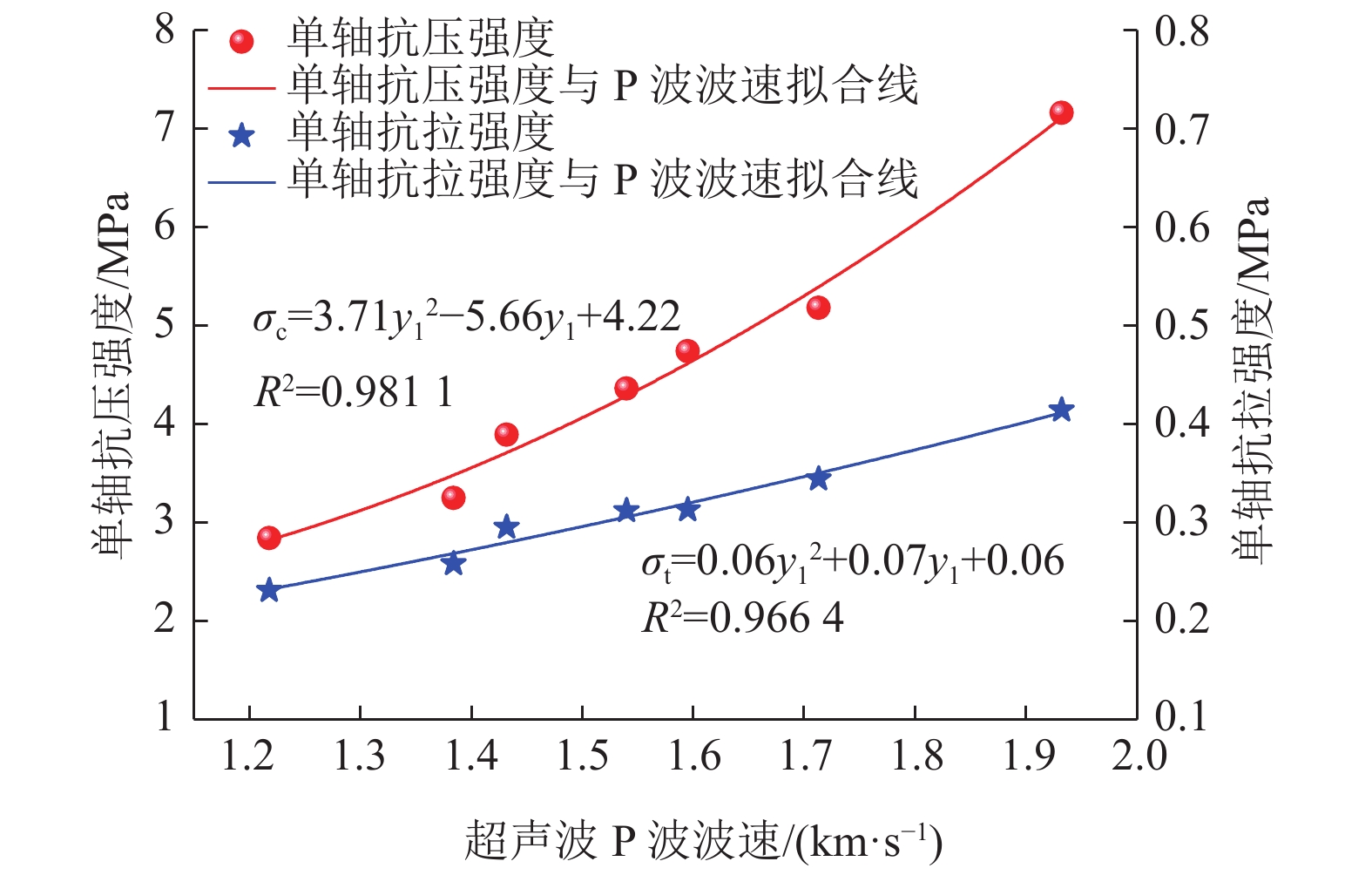

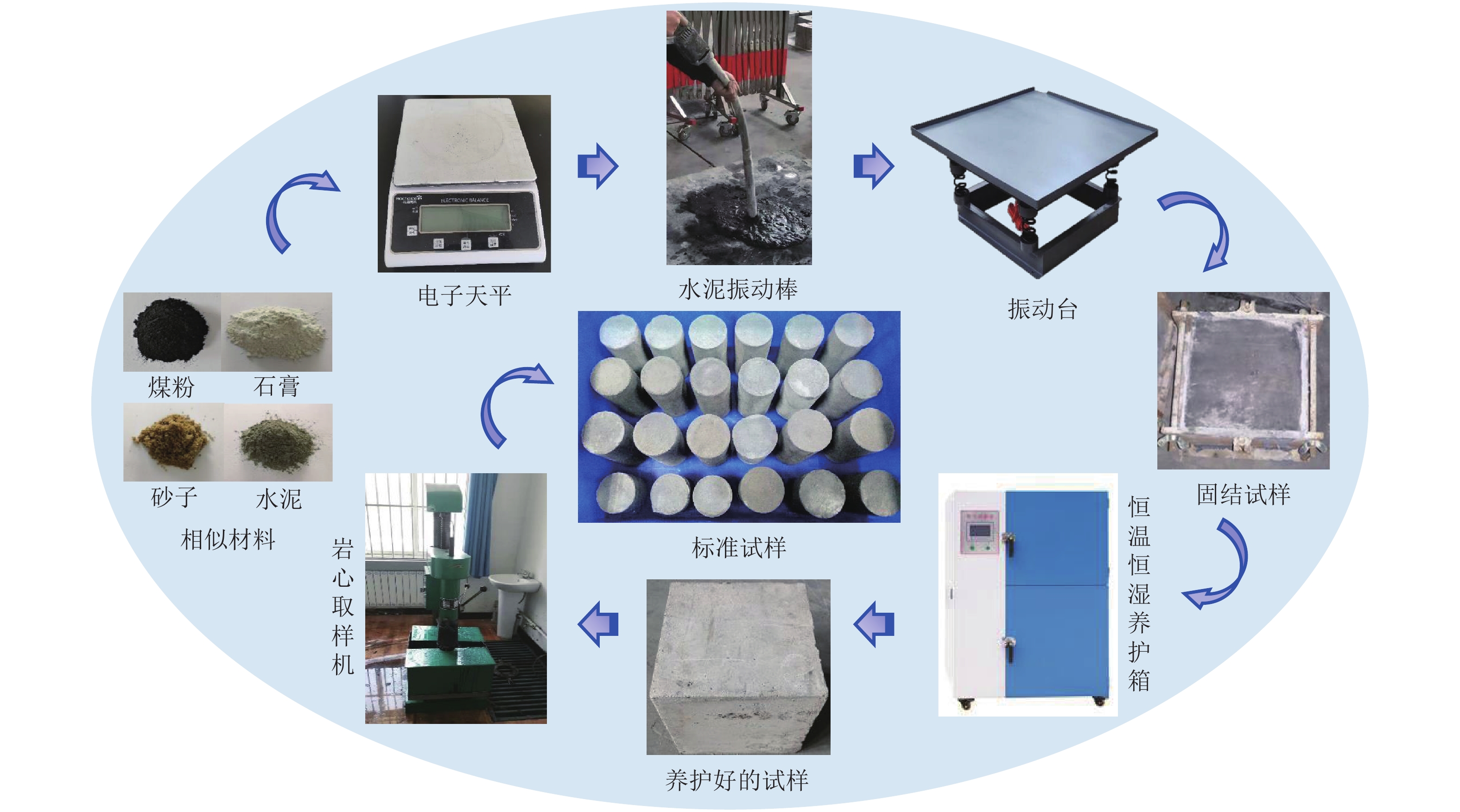

煤层水力压裂模拟实验是研究煤矿井下水力压裂煤岩体致裂增透、弱化机理的有效手段。然而,大尺寸煤岩体原位保真取样技术不成熟,已有大尺寸煤样块多取自卸压区,其在运输和制备过程中会发生二次破坏,导致实验结果失真。因此,使用煤岩体相似材料代替大尺寸原煤执行室内水力压裂模拟实验成为一种可行的选择。煤岩体相似材料试样的力学特性是影响水力压裂效果最重要因素。为精确表征煤岩体相似材料的基础力学特征,选择煤粉、水泥、石膏、砂子为相似材料,设计制作7种配比试样,进行超声波与力学特性耦合响应规律研究。结果表明:煤岩体相似材料试样超声波波速(P波和S波)和强度(单轴抗压和抗拉强度)随着密度的增大而增大,随着孔隙率的增大而减小;相似材料对于超声波波速、强度和密度增大幅度的影响为水泥>砂子>石膏,孔隙率正相反;相似材料水泥和石膏分别在调节试样强度和变形特性方面起主要作用;根据超声波P波波速与强度之间的二次多项式数学模型,通过测定超声波P波波速可提前预测试样的强度;试样力学参数可调整范围大,通过改变相似材料配比可以调整试样的力学性质,精确模拟煤岩体,且试样制作方法简单。此研究可为煤层水力压裂模拟用煤岩体相似材料力学特征相似设计提供依据,促进矿井瓦斯防治技术的发展,具有广泛的应用价值。

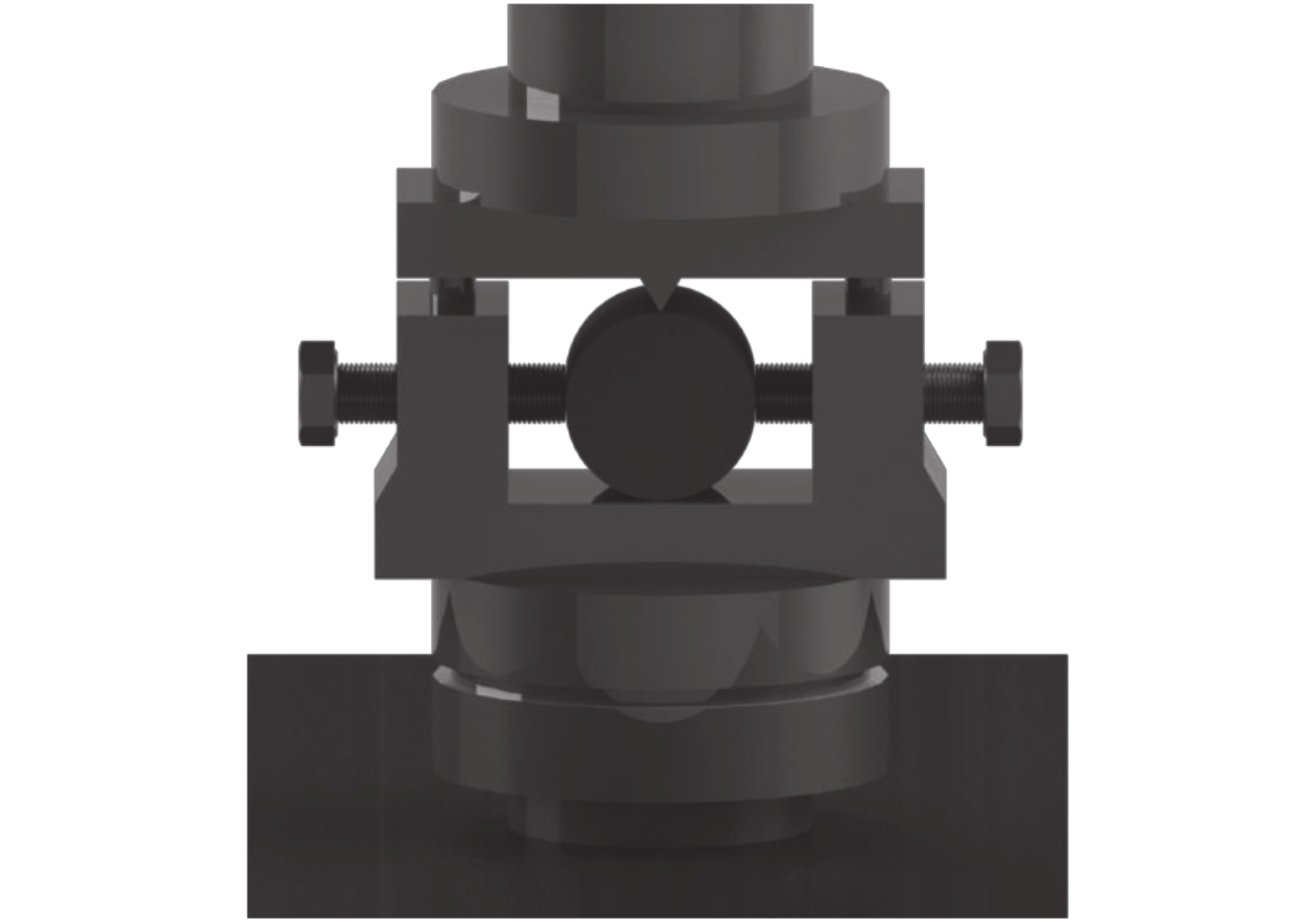

Abstract:Simulation experiments on hydraulic fracturing of the coal seam in the laboratory are an effective method to study the mechanism of fracturing and enhancing permeability of coal-rock mass by hydraulic fracturing in coal mines. However, the technology in-situ sampling for large-size coal mass is immature, and the existing large-size coal samples are mostly taken from the stress-relaxation area, which can be further damaged in the transportation and preparation processes, causing large dispersion in test results. Therefore, The use of coal-like materials is a viable option to replace large-size raw coal for hydraulic fracturing simulation experiments. The mechanical properties of coal-like specimens are the most important factor affecting the effectiveness of hydraulic fracturing. In this paper, in order to accurately characterize “the basic mechanical properties of coal-like materials”, coal powder, cement, gypsum, and sand are used to make coal-like samples with seven ratios for examining the coupling response law of ultrasonic and mechanical properties. The experiments results include: The ultrasonic wave velocity (P-and S-waves) and strength (uniaxial compressive and tensile strength) of coal-like samples increase with increasing density and decrease with increasing porosity. The effect of similar materials on ultrasonic wave velocity, strength, and density increments, cement > sand > gypsum, with the opposite porosity. Cement and gypsum play a major role in regulating the strength and deformation characteristics of coal-like samples, respectively. The strength of coal-like samples can be predicted in advance by measuring ultrasonic P-wave velocity based on the quadratic polynomial mathematical model between ultrasonic P-wave velocity and strength. The mechanical properties of the coal-like material can be adjusted in a wide range. Various properties of coal-like samples can be adjusted to simulate coal-rock mass accurately by changing the ratio of similar materials, and the sample can be made simply. This study provides a basis for a similar design of mechanical properties of coal-like materials for hydraulic fracturing simulation, which can promote the development of mine gas prevention technology and has high application value.

-

-

表 1 煤岩体相似材料配比设计

Table 1 Proportion scheme for different samples preparation

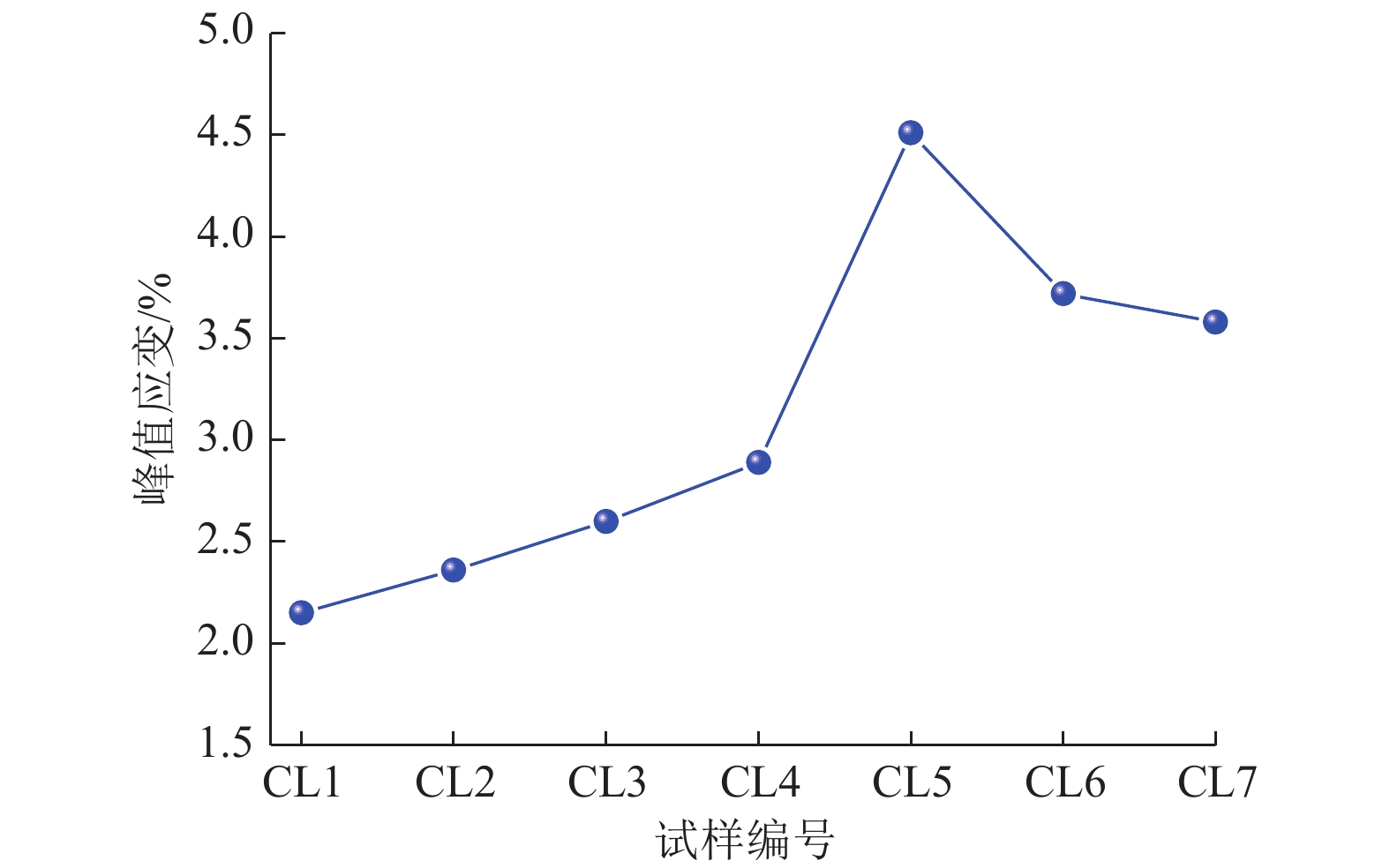

试样分组 煤粉 水泥 石膏 砂子 水 CL1 1 1 3 1 3 CL2 1 2 2 1 3 CL3 1 2.5 1.5 1 3 CL4 1 3 1 1 3 CL5 1 2.5 1 1.5 3 CL6 1 2 1 2 3 CL7 1 1 1 3 3 表 2 超声波波速、密度和孔隙率测试结果

Table 2 Ultrasonic wave velocity, density, and porosity test results

试样

分组编号 直径×高度/

(mm×mm)P波波速/

(km·s−1)P波波速平均值/

(km·s−1)S波波速/

(km·s−1)S波波速平均值

/

(km·s−1)密度

/

(g·cm−3)孔隙率

/

%CL1 CL1-1 50.02×100.23 1.301 1.218 0.521 0.529 1.276 17.03 CL1-2 49.93×99.95 1.159 0.536 CL1-3 50.02×100.25 1.193 0.531 CL2 CL2-1 49.95×101.23 1.389 1.384 0.853 0.744 1.332 16.51 CL2-2 50.01×99.85 1.453 0.664 CL2-3 50.02×100.72 1.309 0.715 CL3 CL3-1 50.01×100.25 1.506 1.595 0.985 1.145 1.452 15.21 CL3-2 49.99×100.44 1.667 1.239 CL3-3 49.95×99.76 1.613 1.212 CL4 CL4-1 50.01×101.14 1.934 1.932 1.523 1.552 1.732 14.14 CL4-2 49.99×100.78 1.938 1.769 CL4-3 50.02×101.61 1.923 1.663 CL5 CL5-1 49.89×101.04 1.689 1.713 1.329 1.303 1.556 14.68 CL5-2 50.03×100.58 1.748 1.563 CL5-3 50.02×101.05 1.701 1.018 CL6 CL6-1 50.01×100.44 1.543 1.540 0.872 1.062 1.436 15.84 CL6-2 49.99×101.26 1.543 1.126 CL6-3 49.97×101.25 1.534 1.187 CL7 CL7-1 50.01×100.17 1.458 1.432 1.023 0.941 1.380 16.12 CL7-2 50.00×100.06 1.521 0.928 CL7-3 50.02×100.09 1.318 0.871 表 3 力学参数测定结果

Table 3 Measurement results of mechanical parameters

试样

分组编号 抗压强度

/MPa抗压强度平均值/MPa 峰值应变

/%抗拉强度

/MPa抗拉强度平

均值/MPa弹性模量

/GPa弹性模量平均值/GPa CL1 CL1-1 3.01 2.84 2.15 0.245 0.231 0.263 0.254 CL1-2 2.74 0.213 0.241 CL1-3 2.78 0.235 0.258 CL2 CL2-1 3.31 3.25 2.36 0.246 0.258 0.267 0.265 CL2-2 3.18 0.269 0.272 CL2-3 3.26 0.258 0.257 CL3 CL3-1 4.65 4.74 2.60 0.321 0.313 0.363 0.363 CL3-2 4.84 0.299 0.374 CL3-3 4.72 0.319 0.352 CL4 CL4-1 7.45 7.16 2.89 0.421 0.414 0.519 0.515 CL4-2 6.86 0.416 0.516 CL4-3 7.16 0.406 0.510 CL5 CL5-1 5.05 5.18 4.51 0.352 0.344 0.273 0.286 CL5-2 5.31 0.339 0.296 CL5-3 5.18 0.341 0.289 CL6 CL6-1 4.53 4.36 3.72 0.304 0.312 0.246 0.231 CL6-2 4.35 0.313 0.232 CL6-3 4.21 0.319 0.215 CL7 CL7-1 3.95 3.89 3.58 0.302 0.295 0.163 0.142 CL7-2 3.64 0.291 0.124 CL7-3 4.09 0.293 0.140 表 4 原煤力学特性数据

Table 4 Mechanical properties data of raw coals

地点 煤样 P波波速

/(km·s−1)S波波速

/(km·s−1)抗压强度

/MPa抗拉强度

/MPa弹性模量

/GPa峰值应变

/%内蒙古 胜利煤田褐煤 1.58 1.15 12.50 — 0.69 2.32 陕西府谷 恒益煤矿烟煤 1.51 — 12.10 2.50 1.08 3.71 陕西榆林 张明沟矿褐煤 1.31 0.93 6.31 0.39 0.32 3.31 -

[1] 张道勇, 朱杰, 赵先良, 等. 全国煤层气资源动态评价与可利用性分析[J]. 煤炭学报, 2018, 43(6): 1598–1604. ZHANG Daoyong, ZHU Jie, ZHAO Xianliang, et al. Dynamic assessment of coalbed methane resources and availability in China[J]. Journal of China Coal Society, 2018, 43(6): 1598–1604.

[2] 庚勐, 陈浩, 陈艳鹏, 等. 第4轮全国煤层气资源评价方法及结果[J]. 煤炭科学技术, 2018, 46(6): 64–68. GENG Meng, CHEN Hao, CHEN Yanpeng, et al. Methods and results of the fourth round national CBM resources evaluation[J]. Coal Science and Technology, 2018, 46(6): 64–68.

[3] 桑树勋, 韩思杰, 刘世奇, 等. 高煤阶煤层气富集机理的深化研究[J]. 煤炭学报, 2022, 47(1): 388–403. SANG Shuxun, HAN Sijie, LIU Shiqi, et al. Comprehensive study on the enrichment mechanism of coalbed methane in high rank coal reservoirs[J]. Journal of China Coal Society, 2022, 47(1): 388–403.

[4] 倪冠华. 脉动压裂过程中瓦斯微观动力学特性及液相滞留机制研究[D]. 徐州: 中国矿业大学, 2015. NI Guanhua. Microscopic kinetics characteristics of methane under pulsating hydraulic fracturing and mechanism of liquid retention effect[D]. Xuzhou: China University of Mining and Technology, 2015.

[5] 王伟, 程远平, 袁亮, 等. 深部近距离上保护层底板裂隙演化及卸压瓦斯抽采时效性[J]. 煤炭学报, 2016, 41(1): 138–148. WANG Wei, CHENG Yuanping, YUAN Liang, et al. Floor fracture evolution and relief gas drainage timeliness in deeper underground short–distance upper protective coal seam extraction[J]. Journal of China Coal Society, 2016, 41(1): 138–148.

[6] 许江, 曹偈, 李波波, 等. 煤岩渗透率对孔隙压力变化响应规律的试验研究[J]. 岩石力学与工程学报, 2013, 32(2): 225–230. DOI: 10.3969/j.issn.1000-6915.2013.02.002 XU Jiang, CAO Jie, LI Bobo, et al. Experimental research on response law of permeability of coal to pore pressure[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(2): 225–230. DOI: 10.3969/j.issn.1000-6915.2013.02.002

[7] 许江, 李波波, 周婷, 等. 加卸载条件下煤岩变形特性与渗透特征的试验研究[J]. 煤炭学报, 2012, 37(9): 1493–1498. XU Jiang, LI Bobo, ZHOU Ting, et al. Experimental study of coal deformation and permeability characteristics under loading–unloading conditions[J]. Journal of China Coal Society, 2012, 37(9): 1493–1498.

[8] 尹光志, 李文璞, 李铭辉, 等. 加卸载条件下原煤渗透率与有效应力的规律[J]. 煤炭学报, 2014, 39(8): 1497–1503. YIN Guangzhi, LI Wenpu, LI Minghui, et al. Permeability properties and effective stress of raw coal under loading–unloading conditions[J]. Journal of China Coal Society, 2014, 39(8): 1497–1503.

[9] 李全贵, 邓羿泽, 胡千庭, 等. 煤层水力压裂应力与裂隙演化的细观规律[J]. 煤田地质与勘探, 2022, 50(6): 32−40. doi: 10.12363/issn.1001-1986.21.10.0603 LI Quangui, DENG Yize, HU Qianting, et al. Mesoscopic law of stress and fracture evolution of coal seams hydraulic fracturing[J]. Coal Geology & Exploration, 2022, 50(6): 32−40. doi: 10.12363/issn.1001-1986.21.10.0603

[10] 郭超奇, 赵继展, 李小建, 等. 中硬低渗煤层定向长钻孔水力压裂瓦斯高效抽采技术与应用[J]. 煤田地质与勘探, 2020, 48(6): 103–108. DOI: 10.3969/j.issn.1001-1986.2020.06.014 GUO Chaoqi, ZHAO Jizhan, LI Xiaojian, et al. Technology and application of high efficiency gas extraction by directional long borehole hydraulic fracturing in coal seams of medium hardness and low permeability[J]. Coal Geology & Exploration, 2020, 48(6): 103–108. DOI: 10.3969/j.issn.1001-1986.2020.06.014

[11] CHEN Jiangzhan,LI Xibing,CAO Han. Experimental investigation of coal–like materials for hydraulic fracturing based on fluid–solid interaction[J]. Journal of Natural Gas Science and Engineering,2019,69:102928. DOI: 10.1016/j.jngse.2019.102928

[12] BEAMISH B B,CROSDALE P J. Instantaneous outbursts in underground coal mines:An overview and association with coal type[J]. International Journal of Coal Geology,1998,35(1/4):27−55. DOI: 10.1016/S0166-5162(97)00036-0

[13] ZHAI Cheng,XU Jizhao,LIU Shimin,et al. Fracturing mechanism of coal–like rock specimens under the effect of non–explosive expansion[J]. International Journal of Rock Mechanics and Mining Sciences,2018,103:145−154. DOI: 10.1016/j.ijrmms.2018.01.037

[14] HUANG Bingxiang,LI Pengfeng. Experimental investigation on the basic law of the fracture spatial morphology for water pressure blasting in a drillhole under true triaxial stress[J]. Rock Mechanics and Rock Engineering,2015,48(4):1699−1709. DOI: 10.1007/s00603-014-0649-y

[15] 翟成, 李贤忠, 李全贵. 煤层脉动水力压裂卸压增透技术研究与应用[J]. 煤炭学报, 2011, 36(12): 1996–2001. ZHAI Cheng, LI Xianzhong, LI Quangui. Research and application of coal seam pulse hydraulic fracturing technology[J]. Journal of China Coal Society, 2011, 36(12): 1996–2001.

[16] 李贤忠, 林柏泉, 翟成, 等. 单一低透煤层脉动水力压裂脉动波破煤岩机理[J]. 煤炭学报, 2013, 38(6): 918–923. DOI: 10.13225/j.cnki.jccs.2013.06.016 LI Xianzhong, LIN Baiquan, ZHAI Cheng, et al. The mechanism of breaking coal and rock by pulsating pressure wave in single low permeability seam[J]. Journal of China Coal Society, 2013, 38(6): 918–923. DOI: 10.13225/j.cnki.jccs.2013.06.016

[17] 黄炳香. 煤岩体水力致裂弱化的理论与应用研究[J]. 煤炭学报, 2010, 35(10): 1765–1766. HUANG Bingxiang. Research on theory and application of hydraulic fracture weakening for coal–rock mass[J]. Journal of China Coal Society, 2010, 35(10): 1765–1766.

[18] HU Qianting,ZHANG Shutong,WEN Guangcai,et al. Coal–like material for coal and gas outburst simulation tests[J]. International Journal of Rock Mechanics & Mining Sciences,2015,74:151−156.

[19] WANG Gang,LI Wenxin,WANG Pengfei,et al. Deformation and gas flow characteristics of coal–like materials under triaxial stress conditions[J]. International Journal of Rock Mechanics and Mining Sciences,2017,91:72−80. DOI: 10.1016/j.ijrmms.2016.11.015

[20] 秦雷. 液氮循环致裂煤体孔隙结构演化特征及增透机制研究[D]. 徐州: 中国矿业大学, 2018. QIN Lei. Pore evolution after fracturing with cyclic liquid nitrogen and the mechanism of permeability enhancing[D]. Xuzhou: China University of Mining and Technology, 2018.

[21] LI Quangui,LIN Baiquan,ZHAI Cheng. The effect of pulse frequency on the fracture extension during hydraulic fracturing[J]. Journal of Natural Gas Science and Engineering,2014,21:296−303. DOI: 10.1016/j.jngse.2014.08.019

[22] 陆沛青. 径向井–脉动水力压裂对煤层应力扰动效果的影响规律研究[D]. 北京: 中国石油大学(北京), 2016. LU Peiqing. Research on stress disturbance effect of radial lateral pulsating hydraulic fracturing in coal seams[D]. Beijing: China University of Petroleum(Beijing), 2016.

[23] 李树刚, 别创峰, 赵鹏翔, 等. 新型“固–气”耦合相似材料特性影响因素研究[J]. 采矿与安全工程学报, 2017, 34(5): 981–986. LI Shugang, BIE Chuangfeng, ZHAO Pengxiang, et al. Study on influence factors of new solid–gas coupling simulation material[J]. Journal of Mining & Safety Engineering, 2017, 34(5): 981–986.

[24] ZHENG Yangfeng,ZHAI Cheng,SUN Yong,et al. Experimental study on the effect of coal particle size on the mechanics,pore structure,and permeability of coal–like materials for low–rank coalbed methane reservoir simulation[J]. Energy & Fuels,2021,35(21):17566−17579.

[25] 苏伟, 冷伍明, 雷金山, 等. 岩体相似材料试验研究[J]. 土工基础, 2008, 22(5): 73–75. DOI: 10.3969/j.issn.1004-3152.2008.05.024 SU Wei, LENG Wuming, LEI Jinshan, et al. Test study of similar material in rock mass[J]. Soil Engineering and Foundation, 2008, 22(5): 73–75. DOI: 10.3969/j.issn.1004-3152.2008.05.024

[26] 李宝富, 任永康, 齐利伟, 等. 煤岩体的低强度相似材料正交配比试验研究[J]. 煤炭工程, 2011(4): 93–95. DOI: 10.3969/j.issn.1671-0959.2011.04.035 LI Baofu, REN Yongkang, QI Liwei, et al. Study on orthogonal mixing rate experiment with low strength similar material of coal and rock mass[J]. Coal Engineering, 2011(4): 93–95. DOI: 10.3969/j.issn.1671-0959.2011.04.035

[27] 国际岩石力学学会实验室和现场试验标准委员会. 岩石力学试验建议方法[M]. 北京: 煤炭工业出版社, 1982. [28] KAHRAMAN S. The correlations between the saturated and dry P–wave velocity of rocks[J]. Ultrasonics,2007,46(4):341−348. DOI: 10.1016/j.ultras.2007.05.003

[29] SAFFET Y. P–wave velocity test for assessment of geotechnical properties of some rock materials[J]. Bulletin of Materials Science,2011,34(4):947−953. DOI: 10.1007/s12034-011-0220-3

[30] XU Jizhao,ZHAI Cheng,RANJITH P G,et al. Petrological and ultrasonic velocity changes of coals caused by thermal cycling of liquid carbon dioxide in coalbed methane recovery[J]. Fuel,2019,249:15−26. DOI: 10.1016/j.fuel.2019.03.089

[31] KHANDELWAL M. Correlating P−wave velocity with the physico−mechanical properties of different rocks[J]. Pure and Applied Geophysics,2013,170:507−514. DOI: 10.1007/s00024-012-0556-7

[32] AYDIN A. Upgraded ISRM suggested method for determining sound velocity by ultrasonic pulse transmission technique[J]. Rock Mechanics and Rock Engineering,2014,47:255−259. DOI: 10.1007/s00603-013-0454-z

[33] KARAMAN K,KAYA A,KESIMAL A. Effect of the specimen length on ultrasonic P–wave velocity in some volcanic rocks and limestones[J]. Journal of African Earth Sciences,2015,112:142−149. DOI: 10.1016/j.jafrearsci.2015.09.017

[34] GLADWIN M T. Ultrasonic stress monitoring in underground mining[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts,1982,19(5):221−228.

[35] 国家能源局. 岩样声波特性的实验室测量规范: SY/T 6351—2012[S]. 北京: 中国标准出版社, 2012. [36] 刘波, 张功, 李守定, 等. 砂质泥岩在低温劈裂试验中的声发射研究[J]. 岩石力学与工程学报, 2016, 35(增刊1): 2702–2709. LIU Bo, ZHANG Gong, LI Shouding, et al. Acoustic emission study on frozen sandy mudstone in Brazilian splitting test[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(Sup. 1): 2702–2709.

[37] 肖福坤, 刘刚, 秦涛, 等. 拉–压–剪应力下细砂岩和粗砂岩破裂过程声发射特性研究[J]. 岩石力学与工程学报, 2016, 35(增刊2): 3458–3472. XIAO Fukun, LIU Gang, QIN Tao, et al. Acoustic emission (AE) characteristics of fine sandstone and coarse sandstone fracture process under tension–compression–shear stress[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(Sup. 2): 3458–3472.

[38] 苏海健, 靖洪文, 赵洪辉, 等. 高温处理后红砂岩抗拉强度及其尺寸效应研究[J]. 岩石力学与工程学报, 2015, 34(增刊1): 2879–2887. SU Haijian, JING Hongwen, ZHAO Honghui, et al. Study on tensile strength and size effect of red sandstone after high temperature treatment[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(Sup. 1): 2879–2887.

[39] 蔡美峰, 何满潮, 刘东燕. 岩石力学与工程[M]. 北京: 科学出版社, 2002. [40] 何鹏, 刘长武, 王琛, 等. 沉积岩单轴抗压强度与弹性模量关系研究[J]. 四川大学学报(工程科学版), 2011, 43(4): 7–12. DOI: 10.15961/j.jsuese.2011.04.004 HE Peng, LIU Changwu, WANG Chen, et al. Correlation analysis of uniaxial compressive strength and elastic modulus of sedimentary rocks[J]. Journal of Sichuan University(Engineering Science Edition), 2011, 43(4): 7–12. DOI: 10.15961/j.jsuese.2011.04.004

[41] KAHRAMAN S,YEKEN T. Determination of physical properties of carbonate rocks from P–wave velocity[J]. Bulletin of Engineering Geology and the Environment,2008,67(2):277−281. DOI: 10.1007/s10064-008-0139-0

[42] KURTULUS C,BOZKURT A,ENDES H. Physical and mechanical properties of serpentinized ultrabasic rocks in NW Turkey[J]. Pure and Applied Geophysics,2012,169:1205−1215. DOI: 10.1007/s00024-011-0394-z

[43] AZIMIAN A,AJALLOEIAN R. Empirical correlation of physical and mechanical properties of marly rocks with P–wave velocity[J]. Arabian Journal of Geosciences,2015,8:2069−2079. DOI: 10.1007/s12517-013-1235-4

[44] REZAEI M,DAVOODI P K,NAJMODDINI I. Studying the correlation of rock properties with P–wave velocity index in dry and saturated conditions[J]. Journal of Applied Geophysics,2019,169:49−57. DOI: 10.1016/j.jappgeo.2019.04.017

[45] 徐吉钊. 液态CO2循环冲击致裂煤体孔隙结构及损伤力学特征研究[D]. 徐州: 中国矿业大学, 2020. XU Jizhao. Study of pore evolution and damage mechanical characteristics of coals under the effect of liquid CO2 cyclic shock fracturing[D]. Xuzhou: China University of Mining and Technology, 2020.

[46] QIN Lei,MA Chao,LI Shugang,et al. Liquid nitrogen’s effect on the mechanical properties of dried and water–saturated frozen coal[J]. Energy & Fuels,2022,36(4):1894−1903.

下载:

下载: