Research progress and development trend of staged hydraulic fracturing technology in long-borehole underground coal mine

-

摘要:

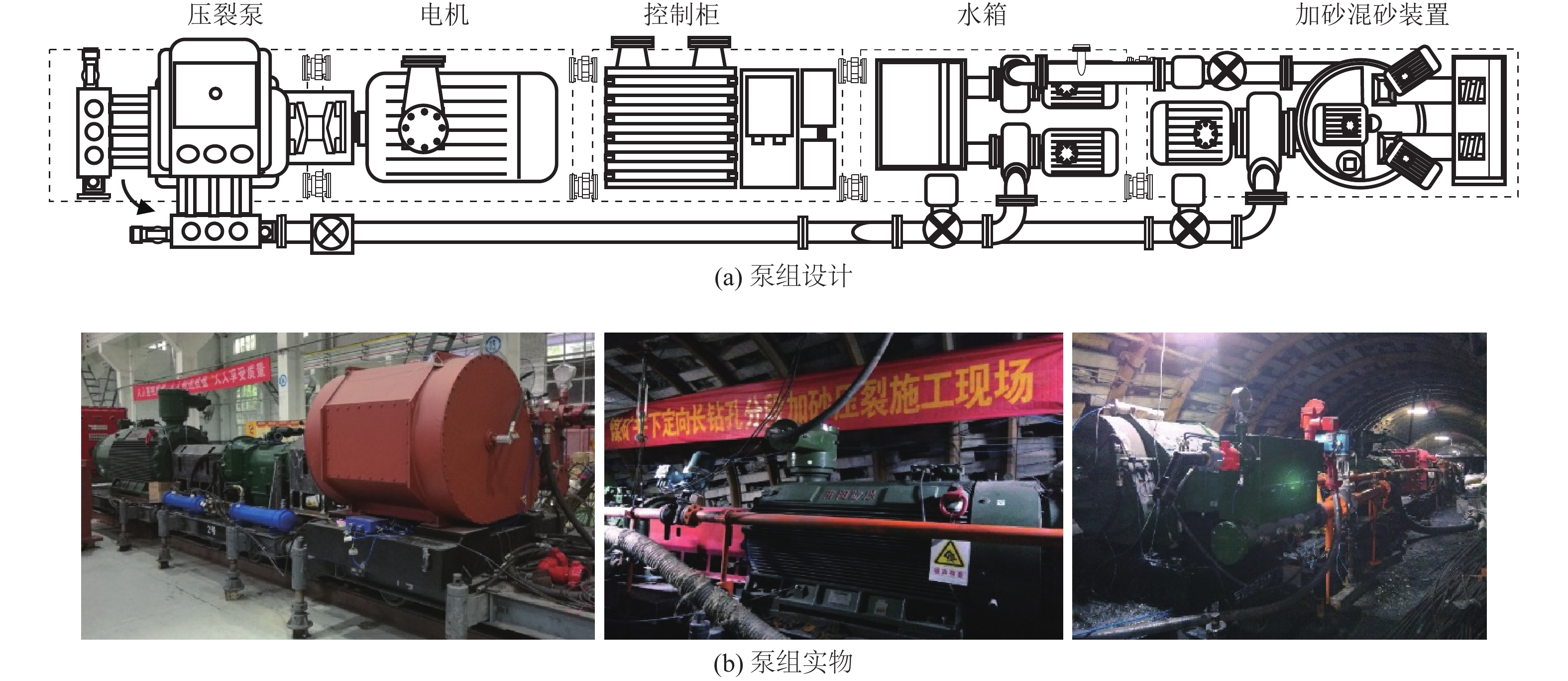

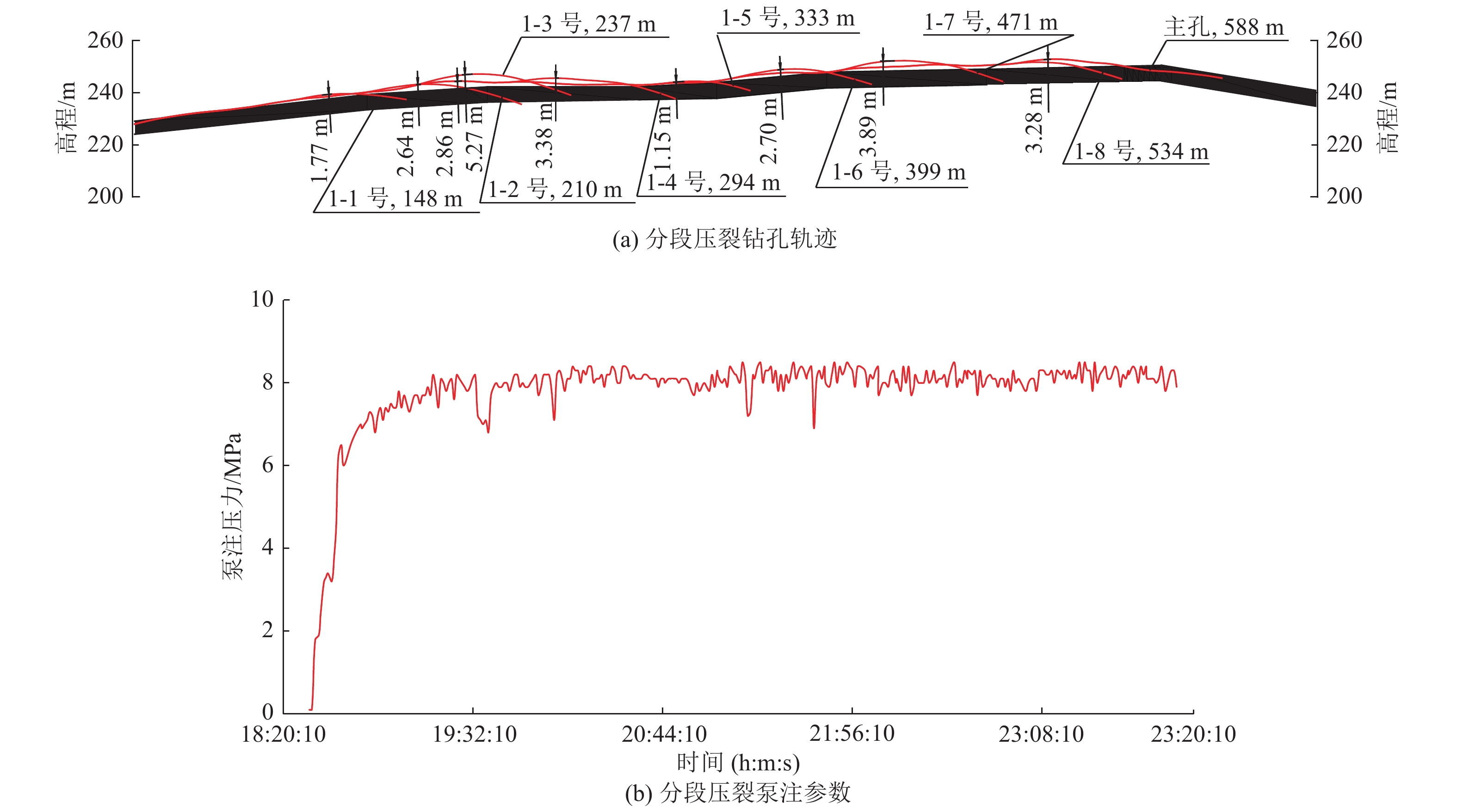

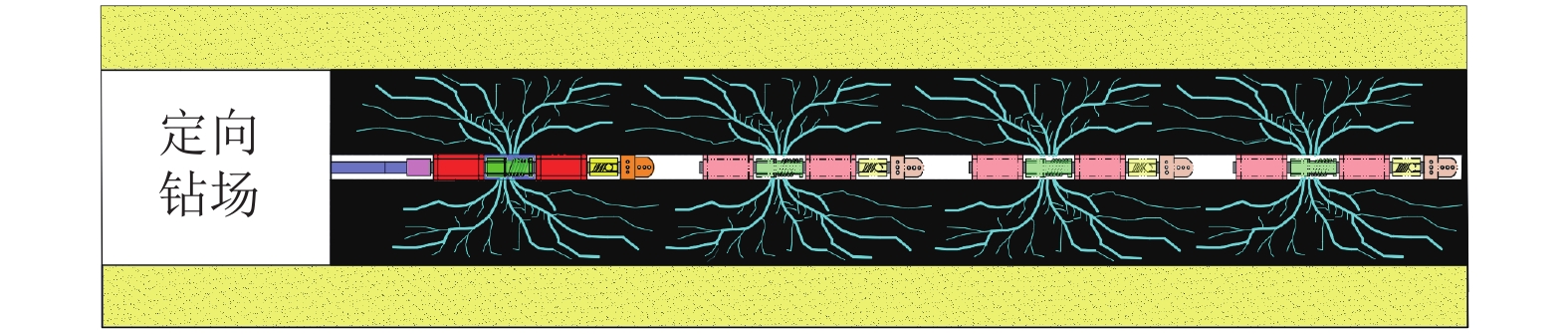

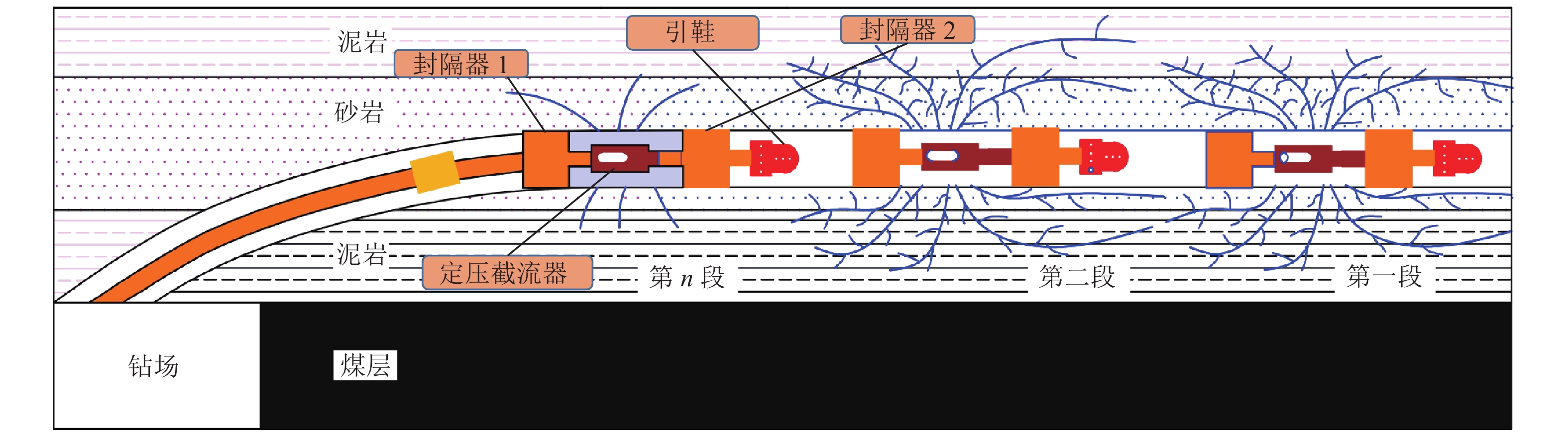

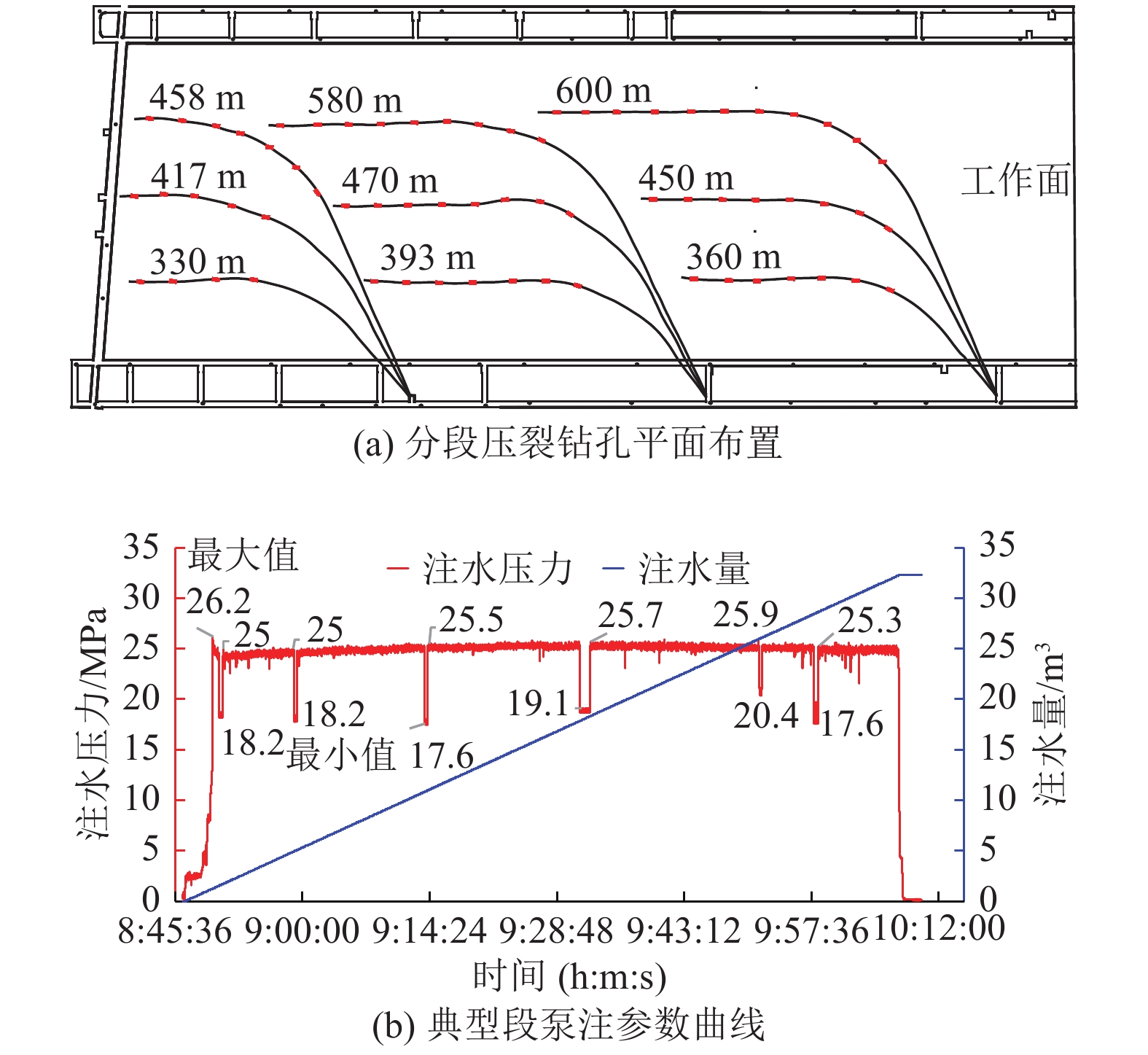

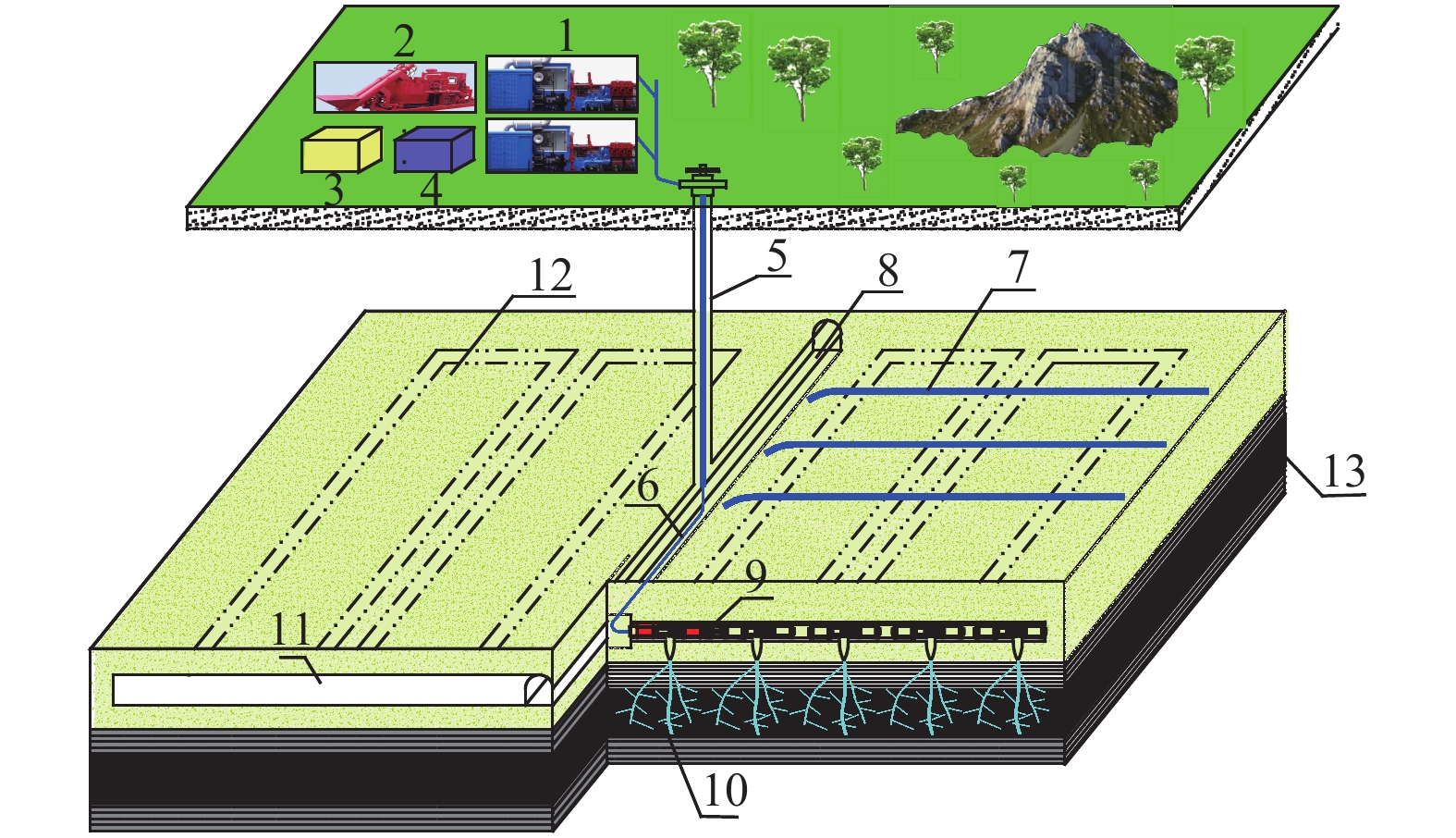

“十三五”以来,围绕“我国煤矿井下煤层区域增透瓦斯高效抽采和坚硬顶板岩层弱化区域治理”两大难题,将定向长钻孔与分段压裂技术结合,通过技术攻关与装备研发及工程试验,在煤矿井下定向长钻孔分段水力压裂技术和装备研发及工程示范应用等方面均取得了明显进展。主要表现在如下4个方面:(1)开发了适合于煤矿井下煤岩层裸眼定向长钻孔不动管柱和动管柱两种分段水力压裂工艺技术与工具,不动管柱分段压裂工程应用钻孔长度突破了500 m,单孔压裂实现了5段;动管柱分段压裂钻孔长度工程应用突破了800 m,单孔压裂实现了17段。(2)研发了煤矿井下低压端加砂压裂泵组和高压端加砂压裂装置,低压端加砂泵组压力达到了70 MPa,排量达到90 m3/h,携砂比达到20%;高压端加砂压裂装备耐压能力达到55 MPa,一次连续加砂压裂的砂量达到750 kg;低压端和高压端加砂装备均在现场进行了工程应用,应用结果表明装备均具有较好携砂压裂能力。(3)建立了碎软煤层围岩分段压裂和硬煤顺层钻孔分段压裂区域增透瓦斯高效抽采技术模式,前者在山西阳泉矿区和陕西韩城矿区应用钻孔瓦斯抽采纯量均值分别达到了2 811 m3/d和1 559 m3/d,后者在陕西彬长矿区应用钻孔瓦斯抽采纯量达到了2 491 m3/d。(4)探索出了坚硬顶板强矿压煤矿井下定向长钻孔分段水力压裂主动超前区域弱化治理的新模式,工程应用钻孔长度突破了800 m,坚硬顶板分段水力压裂治理后,顶板来压步距、动载系数和最高压力值较未压裂区分别下降了18.9%~70.6%,5.8%~7.9%,13.7%~19.4%,有效治理了工作面坚硬顶板引起的强矿压灾害。随着煤矿井下分段水力压裂技术改进和煤矿智能开采发展的实际需要,提出了煤矿井下大排量高压力智能压裂泵组、井下长钻孔裸眼分段压裂智能工具等装备和煤矿井−地联合分段水力压裂技术研发方向,以更好地推动煤矿井下水力压裂技术与装备发展,为煤矿安全高效绿色智能开采提供技术和装备支撑。

Abstract:Since the “13th Five-Year Plan”, significant progress has been made in the directional long-borehole staged hydraulic fracturing technology, equipment development and engineering demonstration application of underground coal mine through the technical research, equipment development and engineering test with directional long-borehole and staged hydraulic fracturing technology in combination, focusing on the two major issues of regional permeability enhancement, efficient gas drainage and rock weakening treatment of hard roof for coal seams in underground coal mine in China. It is mainly manifested in the following four aspects: (1) Two staged hydraulic fracturing technologies and tools with/without rig movement have been developed. Specifically, the borehole hydraulically fractured in stages without rig movement has exceeded 500 m in engineering application, with up to 5 stages of single-hole fracturing achieved. Besides, the borehole hydraulically fractured in stages with rig movement has exceeded 800 m in engineering application, with up to 17 stages of single-hole fracturing achieved. (2) The sand fracturing pump set for the low-pressure end and the sand fracturing device for the high-pressure end of underground coal mine were developed. Definitely, the sand fracturing pump set for the low-pressure end has the pressure up to 70 MPa, the displacement up to 90 m3/h and the sand carrying ratio up to 20%. The sand fracturing device for the high-pressure end has the bearing pressure up to 55 MPa and the sand volume for one-time continuous sand fracturing reaching 750 kg. Besides, the sanding equipment for the low-pressure end and the high-pressure end have been applied in the field engineering, of which the results show that the equipment has good sand carrying and fracturing performance. (3) An efficient gas drainage technology model with regional permeability enhancement was established for the staged fracturing in the surrounding rock of broken-soft coal seam and in the borehole along the hard coal seam. The former was applied in Yangquan mining area in Shanxi and Hancheng mining area in Shaanxi, with the net volume of gas drained from the borehole reaching 2 811 m3/d and 1 559 m3/d respectively, while the latter was applied in Binchang mining area in Shaanxi, with the net volume of gas drained from the borehole up to 2 491 m3/d. (4) A new mode of regional weakening treatment for the active leading area of staged hydraulic fracturing of directional long-borehole in the underground coal mine with hard roof and strong underground pressure has been explored. Specifically, the directional long-borehole hydraulically fractured in stages has exceeded 800 m in engineering application. After the staged hydraulic fracturing treatment of hard roof, the pressure step, dynamic load coefficient and maximum pressure value of roof have been reduced by 18.9%‒70.6%, 5.8%‒7.9% and 13.7%‒19.4% respectively compared with those in the unfractured area, effectively controlling the strong ground pressure hazard caused by the hard roof of the working face. With the improvement of staged hydraulic fracturing technology in underground coal mine and the actual requirements of the development of intelligent coal mining, the research and development requirements have been put forward for the equipment such as the large-displacement and high-pressure intelligent fracturing pump set in underground coal mine, the intelligent tools for staged hydraulic fracturing in underground long-borehole and the integrated coal mine-ground staged hydraulic fracturing technology, so as to better promote the development of hydraulic fracturing technology and equipment for underground coal mine, and thus provide technical and equipment support for the safe, efficient, green and intelligent mining in coal mine.

-

煤炭作为我国重要的基础能源,其可持续开采和高效利用关系到国民经济健康发展和能源安全。随着采深不断加大,煤层赋存条件日益复杂,断层、构造、含水层等地质环境问题更加突出。受多种因素制约,工作面往往采用不等长面布局,如刀把式[1-2]、渐变式[3]等,这种特殊的开采布置易引发应力异常、岩体失稳、突水等灾害。因此,揭示不等长工作面回采时煤岩体的破裂失稳机制及其空间响应规律,对于煤矿安全高效生产具有重要意义。

目前国内外学者针对不等长工作面回采问题,主要从理论分析和数值模拟两个层面开展研究。在理论分析方面,卢邦稳等[1]提出了控顶厚度计算方法,揭示了作业面长度对采动岩层破裂分布的影响规律;高明中等[2]分析了不等长工作面推进过程中顶板的破裂规律;李杨杨等[4]建立了计算模型,研究了不同采场接续方式对采空区应力分布的影响。在数值模拟层面,王新丰等[5]基于离散元数值模拟分析了不同倾斜长度下的采场变形和支护设计参数;罗飞等[6]通过数值模拟研究了工作面长度对顶底板破坏的影响机制。上述研究工作对认识和分析不等长工作面煤岩体运动规律作出了贡献,但主要是基于简化后的理论条件或理想化的数值模型,缺乏实际工程测试数据的支撑,研究结果的应用价值存在一定局限性。

随着新型微震定位与监测系统的发展和广泛应用,利用现场实测微震数据研究不等长工作面开采问题成为可能。目前,国内外一些专家学者已基于微震监测开展了一些相关研究,主要集中在矿压显示[7-12]、突水预警[13-17]、顶板破裂[18-20]等方面。但针对影响不等长工作面微震时空分布的重要因素及其规律性研究较少,亟需开展深入系统的分析。

笔者以冀中能源峰峰矿区九龙矿15240刀把式工作面为工程背景,基于大量现场微震监测数据,结合详细的回采参数和地质资料,分阶段分析了不同倾斜长度条件下微震事件在平面和垂向上的时空分布特征及其影响因素,旨在揭示不等长工作面回采引发微震活动的基本规律,为深入挖掘煤岩体破裂场动态演化奠定基础,并为煤矿开采设计优化、矿压管理等实践提供技术支撑。

1 工程概况

九龙矿15240工作面位于南三采区东部,东北部为NF22-1断层,东南部为F1-1断层;西部为正在回采的152下36工作面,北部为15238、152下38工作面采空区。地面高程+111.6~+120.9 m,井下高程为−510~−653.4 m,走向长度1 063~1072 m,倾斜长度57~93 m。所采煤层为2号煤,煤层赋存稳定,平均2.7 m,煤层倾角9°~15°。该工作面外切眼上方存在多条断层,其中2条比较大的断层一条倾角为60 °,落差为5 m,另一条倾角为65 °,落差为6.5 m。

该矿煤层顶底板综合柱状图如图1所示,底板主要含水层有野青灰岩、山伏青灰岩、大青灰岩、奥陶系灰岩。奥灰顶界面水压约为9.3 MPa,回采前在工作面布置范围内进行了地面区域治理,治理层位为奥灰顶面以下11.4~40.0 m。

2 微震系统布置与数据处理

15240工作面微震系统布置如图2所示,充分结合工作面巷道情况、地质条件等,安装单轴检波器20个,4个监测分站,共计20通道。微震传感器选用GZC10拾震传感器,响应频率范围为4~1 000 Hz,灵敏度为100 V/ms。检波器采用包围形方式布置,间距80~100 m,钻孔均布置在两侧巷道外帮底板。

微震实时连续24 h采集和传输,井下光纤直接传输至九龙矿地面交换机,并通过局域网传输至微震监测总服务器,而后可触发微震事件。在微震监测系统构建之后,在工作面巷道中不同位置设计校正炮,通过质量控制速度扫描、速度回归等得到速度模型,与检波器位置、角度等信息一并载入微震数据处理软件中。利用STA/LTA模型[21-22]进行事件识别,由专业人员进行P波、S波初至拾取,为保障数据定位精度,至少需要拾取4个通道初至。定位过程中,在事件分析框界面既可直观地看到事件的三维空间位置,也可实时查看每个微震事件发生时间、位置、能量、定位残差等信息。在质量控制完成后,应用相关制图软件绘制平面图、剖面图等,并分析单日时空演化规律,形成微震监测日报,反馈至矿方。

3 微震事件平面分布特征

在微震事件可视化输出时,为更好地展现微震事件与所回采煤层的关系,结合三维地质模型,将微震事件投影划分为2煤以上、2煤底−野青下、野青下−伏青下、伏青下−大青下、大青下−奥灰顶界面、奥灰以深等6个层段。2煤以上为顶板事件,其他层段均为底板事件。结合倾斜长变化、微震时空演化规律等因素将工作面分为窄面、宽面、斜面,如图2所示,从窄面到宽面,倾斜长由57 m增为93 m。斜面阶段93~100 m不规则。3个阶段各层段数量统计结果见表1,窄面、宽面阶段底板占比大,原因在于底板岩性较顶板相对薄弱,回采时关注相关区域水文观测。斜面阶段2煤以上占比为53.59%,顶板比例较之前明显增大,分析在该阶段内,工作面处于2条大断层中间,NF22-1落差17 m,F1-1落差逐渐由50 m增至75 m,工作面处于上盘位置,断层破碎带岩性较弱,下伏岩层受到下盘支撑,在采动应力影响下,顶板上覆岩层受到剪切力作用较其他阶段大,微破裂频次大,因此,顶板事件比例增大。

表 1 各层段微震事件统计Table 1. Statistics of microseismic events in various sections层段 窄面 宽面 斜面 个数 占比% 个数 占比% 个数 占比% 2煤以上 322 41.98 6 273 37.99 1 171 53.59 2煤底−野青下 445 58.02 10 233 61.98 1 013 46.36 野青下−伏青下 5 0.03 1 0.05 总计 767 100 16 511 100 2 185 100 据统计,窄面阶段日均37个微震事件,宽面阶段日均频次为87个,增加135%。斜面阶段日均32个,较宽面下降63.2%,停采后日均13个,说明微震事件受采动活动影响明显。频次多少除受面长变化影响之外,也与采动速度相关。回采初期推进平均速度为4.8 m/d,采动速度较慢,扰动深度较浅。宽面阶段采宽增大且速度增加至6 m/d,事件频次明显增大,进入斜面后速度约3.8 m/d,日均频次降低。

3.1 窄面阶段平面分布特征

该工作面回采初期倾斜长为57 m,其顶底板事件分布如图3所示,事件主要分布在切眼前方220 m内以及工作面上方断层密集区附近。微震事件超前影响距离约为40 m,均为近煤层事件。外切眼附近有断层,岩石较为破碎,且该区域为由窄变宽巷道拐弯处,为应力集中区,在多因素耦合作用之下,微震事件较其他区域密度大。物探异常区处有零星微震事件分布。

3.2 宽面阶段平面分布特征

顶底板事件分布如图4所示,事件主要分布在切眼前方78~1030 m范围内。微震事件密度明显较窄面大,事件超前影响距离为80~100 m。5月份之后数据平面分布密度进一步增大,由图4b可知,底板事件较其他区域密集度更高的异常区为瓦斯抽采影响下的地质薄弱区,岩石易破碎,微震事件密集发育。底板事件分布范围扩展至两巷外侧130 m。推采至宽面末端时,巷道拐弯处一直到物探异常区,均有微震事件分布,此时该区域已经受到超前支承压力、采空区侧向支承压力影响,原始应力场平衡被打破,煤岩体发生失稳变形、破裂,从而产生大量微震事件。

宽面阶段共出现5个野青下−伏青下层段的微震事件,其平面分布如图5所示。第一次出现在3月7日,工作面进入宽面推进了28 m,当日微震事件数量较前期增加64%,达到小高峰,分析为进入宽面后的初次来压,采动压力释放剧烈,破坏深度增大。第二次出现在5月31日,此时工作面推进546.5 m,该事件距离终采线489 m,推进速度约6 m/d,最大扰动深度为80.93 m。第三次出现在6月18日,位于断层附近,日报中事件增幅较大,分析为矿压显现且此处较为破碎。第四次出现在6月20日,在终采线前方176 m,扰动深度为62 m。第五次在6月22日,在终采线前方183 m,扰动深度为59.61 m,分析原因为瓦斯抽采施工以及断层薄弱带影响,发育深度较大。上述野青下−伏青下事件在时空分布上不连续,未形成有效导水通道,未影响工作面安全回采。

3.3 斜面阶段平面分布特征

斜面阶段顶底板事件平面分布如图6所示。此阶段内存在一个物探异常区,为已知断层f01与f03共同向工作面内延伸所致,且巷道向北存在倾斜角度,此处地质条件较为薄弱,煤岩体较破碎,为微震事件优势发育区域,回采初期事件零星分布,推采至宽面末端时此处产生大量微震事件,推采至斜面阶段后仍有微震事件。进入斜面初期,巷道较为密集,为应力集中显现区,且断层F1-1距盲巷较近,此时断层落差约50 m,在采动应力影响下,断层附近围岩易发生破碎,发育深度有所增大。该阶段仅出现一次野青下−伏青下事件,9月14日在断层F1-1附近,为采动应力和原岩应力叠加影响底板岩石破碎程度较大,影响至伏青灰岩。

总之,空间分布上,随着回采推进微震事件随之向前推进。窄面阶段处于回采初期,煤岩体受采动影响较小,事件能量较小,处于萌芽期。进入宽面后,倾斜长变长,采空区面积增大,卸荷不断增大,煤岩体内裂纹扩张和宏观裂隙的产生急剧增加,并伴随着一定范围内局部煤岩体的断裂破坏,导致微震次数、能量等会有较大幅度增加。回采过程中在宽面阶段、斜面阶段出现过野青下−伏青下层段微震事件,扰动深度较大。

4 微震事件垂向分布特征

在分析微震事件平面分布的同时深入分析微震事件垂向上的发育特点,了解在采动应力、地应力等影响之下微震事件扰动深度变化情况,对做好防治水工作具有重要意义。经统计96.7%的微震事件在顶板44 m以下、底板55 m以内密集分布,野青下−伏青下层段微震事件离散点分布。

4.1 顶板破裂高度

在回采过程中共监测到顶板事件7 766个。顶板破裂高度按5 m分段统计结果如图7所示,单日顶板最大破裂高度如图8所示。由图7可知,窄面、宽面阶段总体趋势上大体一致,距离煤层越远,微震顶板事件频次逐渐降低,对微震数据统计后发现,窄面、宽面阶段0~5 m数据最多,60%以上的事件在15 m以内。而斜面阶段呈现单峰偏态式分布,在10~15 m出现峰值,两侧频次逐渐降低,该阶段内岩性较其他区域较为薄弱,发生下沉、变形、垮落的程度较大。斜面阶段60%以上的事件发育高度在20 m以内,斜面调采顶板裂隙集中发育高度相比前2个阶段向上延伸了33%。

如图8所示,窄面阶段顶板最高发育高度为61.21 m,发生在2月9日,此时采线距离开切眼49 m,该事件位于采线附近。宽面阶段顶板最大发育高度为112.8 m,发生在5月20日,此时进入宽面351 m,位于工作面中间位置。斜面阶段内,顶板最大发育高度为117 m,发生在9月14日,此时由宽面受到大断层影响,进行调斜回采,且此处巷道处应力集中,裂隙不断向上发育。综合来看,窄面阶段顶板发育高度范围在62 m之内,在3个阶段中最小,此时为工作面初采阶段,覆岩破坏程度不明显,在重力作用下发生弯曲变形。宽面、斜面阶段顶板破裂高度发育范围在120 m以内。随着工作面推进,采空区面积增加,上覆岩层在弯曲变形之后形成离层,当岩层应力状态超过其强度极限时发生垮落,岩层裂隙与离层空间进一步向上延展。微震数据表明,调采区域围岩裂隙发育高度更大,在此区域关注来压时对工作面的影响。

4.2 底板扰动深度

底板扰动深度按照5 m分段统计结果如图9所示,单日底板最大扰动深度随时间序列变化如图10所示,分析发现回采过程中不同阶段的扰动深度变化有以下规律。

(1)底板事件在煤层附近区域内密集分布,90%以上的底板事件集中在距离煤层25 m以内的范围。这是由回采扰动直接作用于底板煤岩体所致,属于采动破坏带范围内的破裂。

(2) 25 m以深则呈离散分布,出现频次较低。这些深部事件通常发生在一些特殊区域,如倾斜长变化区、调采区、断层构造区等,受到多种力源扰动的影响更显著。

(3)在窄面和斜面阶段,底板事件的垂向分布呈现出距离煤层越远频次逐渐降低的规律。而在宽面阶段,底板事件垂向分布表现为单峰偏态分布,在一定深度范围内出现峰值。

(4)个别深部事件发育至野青灰岩以下伏青灰岩层段,伴随扰动深度的增大,底板微破裂贯通的可能性加大,突水风险增大。

(5)不同回采阶段,底板最大扰动深度存在差异。宽面阶段最深可达80.93 m,斜面阶段最深62.45 m,这些深部事件常发生在应力集中区或地质构造复杂区。

倾斜长度变化、调采、断层构造等因素均会加剧底板岩层的扰动和损伤程度,导致深部底板事件活跃。宽面、斜面底板事件最大扰动范围已经发育到伏青灰岩,伏青灰岩富水性强,突水风险增大,因此,微震监测过程中对此层段事件进行重点分析,及时预警。

5 结果与讨论

综合上述不同阶段微震事件平面、垂向分布特征,分析总结在倾斜长度变化过程中微震事件空间分布存在以下特点。

(1)不等长工作面微震事件分布受到倾斜长度、采动速度、地质构造、巷道位置、物探异常区等多因素影响,规律更为复杂,具有明显的分区特征。倾斜长度发生变化区域微震活动性由弱到强,事件超前影响范围由小到大。

(2)不等长工作面回采过程中,微震总体能量释放先增大后减小,释放速率经历了先快后慢的变化过程。采线前方事件主要受采动超前支承压力影响,以小能量为主。在断层构造处、顶板大面积破断处能量释放较为剧烈。

(3)从顶板破裂高度上看,微震事件分布呈现非线性变化趋势。倾斜长度变宽后周期来压强度增大,调采区域顶板裂隙集中发育高度明显增大,通过微震事件及属性可实时分析裂隙发育形态和演化趋势,适时优化顶板管理方法,使得顶板及时垮落,以免造成应力集中,影响安全生产。

(4)从底板扰动深度上看,煤层底板下方25m以内微震事件密集分布,主要由回采扰动引起的煤岩体破裂,位于采动破坏带范围之内。在倾斜长度发生变化区域、受瓦斯抽采施工影响区、调采阶段巷道拐弯区内底板事件存在深部发展趋势,出现强含水层段事件,微破裂局部贯通深度增大,与奥灰水导通的危险系数变大,是重点关注区域。可见工作面倾斜长度变化、调采等对底板岩层扰动、变形影响显著,此类区域平面位置和垂向深度的精准描述是进行水害预警的关键。

(5)在工作面回采其他煤层时也需多关注倾斜长变化区、调采区、断层构造区,重复采动底板破坏范围会进一步增大,突水风险增加,应提前对此类区域采取相关措施确保安全回采。

6 结 论

(1) 煤矿不等长工作面回采过程中,微震事件呈现显著的时空分布阶段性特征。窄面阶段,处于采动初期,微震主要集中于宽面端附近前阶段窄面区域边缘;宽面阶段,处于采动中期,微震活动向后方宽面区域内部蔓延;进入斜面阶段后,微震则集中分布于巷道转弯处及物探异常区附近。

(2) 倾斜长度变化、采动扰动及速度、地质构造条件、巷道环境以及底板岩性是影响微震事件时空分布的关键因素。由窄变宽区域、调采区域,呈现底板事件活动性增强、扰动深度增大的特点,是加强水文地质观测的重点区域。

(3) 回采扰动与上覆煤层抬升引起的应力再分布,以及巷道围岩卸压失稳等是导致不同阶段微震事件产生和分布差异的根本原因,各影响因素存在耦合作用。

(4) 研究成果可为类似工作面的矿压监测、顶底板破坏深度评估、微震监测水害预警等提供新的理论指导,对确保煤矿安全高效生产具有重要指导价值。后续可基于深度学习刻画数据本质特征,探究其发生机理,优化大数据动态变化分析模型。

利益冲突声明/Conflict of Interests

所有作者声明不存在利益冲突。

All authors disclose no relevant conflict of interests.

-

表 1 煤矿顶板定向长钻孔加砂分段压裂施工参数与瓦斯抽采效果

Table 1 Pump injection parameters of staged fracturing with sand and gas drainage in roof directional long-borehole

孔号 孔长/m 孔径

/mm段距

/m卡距

/m段数 泵注压

力/MPa单段

液

量/m3累计

液

量/m3单段

加砂

量/t累计

加砂

量/t瓦斯抽采

纯

量/(m3·d−1)甲烷

体积分数/%1 609 120 50~75 7.8 6 21.3~29.6 153.8~235.1 963.9 1.76~3.49 13.1 1025 44.0 2 609 50 10 1844.7 23.4 2811 23.2 表 2 40206工作面顺煤层钻孔裸眼分段压裂施工参数与瓦斯抽采效果

Table 2 Parameters of staged fracturing and gas drainage of coal seam open borehole at 40206 working face

孔号 孔长/m 孔径/mm 段间距/m 卡距/m 压裂

段数泵注压

力/MPa累计压入

液量/m3瓦斯抽采纯量

均值/(m3·d−1)甲烷体积分数

均值/%2 568 96 30~50 10 8 14.4 947 2 491 67.5 3 555 14.9 910 2 218 58.8 4 540 15.6 1 154 1 037 42.4 -

[1] 袁亮, 林柏泉, 杨威. 我国煤矿水力化技术瓦斯治理研究进展及发展方向[J]. 煤炭科学技术, 2015, 43(1): 45–49. DOI: 10.13199/j.cnki.cst.2015.01.011 YUAN Liang, LIN Baiquan, YANG Wei. Research progress and development direction of gas control with mine hydraulic technology in China coal mine[J]. Coal Science and Technology, 2015, 43(1): 45–49. DOI: 10.13199/j.cnki.cst.2015.01.011

[2] OUYANG Zhihua,ELSWORTH D,LI Qiang. Characterization of hydraulic fracture with inflated dislocation moving within a semi–infinite medium[J]. Journal of China University of Mining and Technology,2007,17(2):220−225. DOI: 10.1016/S1006-1266(07)60076-5

[3] А. Б. 维里奇斯基, 安志雄. 采用水力压裂强化煤层瓦斯抽放的远景[J]. 煤矿安全, 1989, 20(9): 51–53. WIELICSKI A B, AN Zhixiong. Prospect of using hydraulic fracturing to enhance coal seam gas drainage[J]. Safety in Coal Mines, 1989, 20(9): 51–53.

[4] 张有狮. 煤矿井下水力压裂技术研究进展及展望[J]. 煤矿安全, 2012, 43(12): 163–165. ZHANG Youshi. Research progress and prospect of hydraulic fracturing technologies in coal mine underground[J]. Safety in Coal Mines, 2012, 43(12): 163–165.

[5] 翟成, 李贤忠, 李全贵. 煤层脉动水力压裂卸压增透技术研究与应用[J]. 煤炭学报, 2011, 36(12): 1996–2001. ZHAI Cheng, LI Xianzhong, LI Quangui. Research and application of coal seam pulse hydraulic fracturing technology[J]. Journal of China Coal Society, 2011, 36(12): 1996–2001.

[6] 李全贵, 林柏泉, 翟成, 等. 煤层脉动水力压裂中脉动参量作用特性的实验研究[J]. 煤炭学报, 2013, 38(7): 1185–1190. LI Quangui, LIN Baiquan, ZHAI Cheng, et al. Experimental study on action characteristic of pulsating parameters in coal seam pulse hydraulic fracturing[J]. Journal of China Coal Society, 2013, 38(7): 1185–1190.

[7] 孙四清, 郑凯歌. 井下高压水射流切割煤层增透效果数值模拟研究[J]. 煤田地质与勘探, 2017, 45(2): 45–49. DOI: 10.3969/j.issn.1001-1986.2017.02.008 SUN Siqing, ZHENG Kaige. Numerical simulation study on permeability enhancement effect of high pressure water cutting coal seam[J]. Coal Geology & Exploration, 2017, 45(2): 45–49. DOI: 10.3969/j.issn.1001-1986.2017.02.008

[8] 孙大发, 陈久福, 龙建明, 等. 高压水力压裂技术在石门揭煤中的试验研究[J]. 煤炭科学技术, 2013, 41(增刊1): 163–165. DOI: 10.13199/j.cnki.cst.2013.s2.082 SUN Dafa, CHEN Jiufu, LONG Jianming, et al. Experimental study on high pressure hydraulic fracturing technology to uncover coal in cross–cut[J]. Coal Science and Technology, 2013, 41(Sup. 1): 163–165. DOI: 10.13199/j.cnki.cst.2013.s2.082

[9] 雷毅, 武文宾, 陈久福. 松软煤层井下水力压裂增透技术及应用[J]. 煤矿开采, 2015, 20(1): 105–107. DOI: 10.13532/j.cnki.cn11-3677/td.2015.01.031 LEI Yi, WU Wenbin, CHEN Jiufu. Technology of underground permeability improvement of soft coal–seam with hydrofracture and its application[J]. Coal Mining Technology, 2015, 20(1): 105–107. DOI: 10.13532/j.cnki.cn11-3677/td.2015.01.031

[10] 蔡峰, 刘泽功. 深部低透气性煤层上向穿层水力压裂强化增透技术[J]. 煤炭学报, 2016, 41(1): 113–119. DOI: 10.13225/j.cnki.jccs.2015.9014 CAI Feng, LIU Zegong. Simulation and experimental research on upward cross–seams hydraulic fracturing in deep and low–permeability coal seam[J]. Journal of China Coal Society, 2016, 41(1): 113–119. DOI: 10.13225/j.cnki.jccs.2015.9014

[11] 代志旭. 高压水力压裂技术在瓦斯综合治理中的研究与应用[J]. 煤炭工程, 2010(12): 82–84. DOI: 10.3969/j.issn.1671-0959.2010.12.032 DAI Zhixu. Research and application of high pressure hydraulic fracturing technology to mine gas comprehensive control[J]. Coal Engineering, 2010(12): 82–84. DOI: 10.3969/j.issn.1671-0959.2010.12.032

[12] 张春华, 张勇志, 李江涛, 等. 深部煤层单段/多段水力压裂增透效果对比[J]. 煤炭科学技术, 2017, 45(6): 50–54. DOI: 10.13199/j.cnki.cst.2017.06.008 ZHANG Chunhua, ZHANG Yongzhi, LI Jiangtao, et al. Comparison analysis on permeability improved effect of single and multi section hydraulic fracturing in deep depth seam[J]. Coal Science and Technology, 2017, 45(6): 50–54. DOI: 10.13199/j.cnki.cst.2017.06.008

[13] 吕有厂. 水力压裂技术在高瓦斯低透气性矿井中的应用[J]. 重庆大学学报, 2010, 33(7): 102–107. DOI: 10.11835/j.issn.1000-582X.2010.07.019 LYU Youchang. Application the hydraulic fracturing technology in the high pressure and low permeability mine[J]. Journal of Chongqing University, 2010, 33(7): 102–107. DOI: 10.11835/j.issn.1000-582X.2010.07.019

[14] 卫修君, 王满. 平顶山矿区单一突出煤层瓦斯抽采新技术[J]. 煤炭科学技术, 2012, 40(12): 42–47. DOI: 10.13199/j.cst.2012.12.48.weixj.022 WEI Xiujun, WANG Man. New gas drainage technology of single outburst seam in Pingdingshan mining area[J]. Coal Science and Technology, 2012, 40(12): 42–47. DOI: 10.13199/j.cst.2012.12.48.weixj.022

[15] 张群, 葛春贵, 李伟, 等. 碎软低渗煤层顶板水平井分段压裂煤层气高效抽采模式[J]. 煤炭学报, 2018, 43(1): 150–159. DOI: 10.13225/j.cnki.jccs.2017.1422 ZHANG Qun, GE Chungui, LI Wei, et al. A new model and application of coalbed methane high efficiency production from broken soft and low permeable coal seam by roof strata–in horizontal well and staged hydraulic fracture[J]. Journal of China Coal Society, 2018, 43(1): 150–159. DOI: 10.13225/j.cnki.jccs.2017.1422

[16] 巫修平, 张群. 碎软低渗煤层顶板水平井分段压裂裂缝扩展规律及控制机制[J]. 天然气地球科学, 2018, 29(2): 268–276. WU Xiuping, ZHANG Qun. Research on controlling mechanism of fracture propagation of muti–stage hydraulic fracturing horizontal well in roof of broken soft and low permeability coal seam[J]. Natural Gas Geoscience, 2018, 29(2): 268–276.

[17] 闫志铭. 低透煤层井下长钻孔水力压裂增透技术[J]. 煤田地质与勘探, 2017, 45(3): 45–48. DOI: 10.3969/j.issn.1001-1986.2017.03.008 YAN Zhiming. Hydraulic fracturing technology for permeability improvement through underground long borehole along coal seam[J]. Coal Geology & Exploration, 2017, 45(3): 45–48. DOI: 10.3969/j.issn.1001-1986.2017.03.008

[18] 孙四清, 张群, 闫志铭, 等. 碎软低渗高突煤层井下长钻孔整体水力压裂增透工程实践[J]. 煤炭学报, 2017, 42(9): 2337–2344. DOI: 10.13225/j.cnki.jccs.2017.0689 SUN Siqing, ZHANG Qun, YAN Zhiming, et al. Practice of permeability enhancement through overall hydraulic fracturing of long hole in outburst–prone soft crushed coal seam with low permeability[J]. Journal of China Coal Society, 2017, 42(9): 2337–2344. DOI: 10.13225/j.cnki.jccs.2017.0689

[19] 王建利, 陈冬冬, 贾秉义. 韩城矿区碎软煤层顶板梳状孔水力压裂瓦斯抽采工程实践[J]. 煤田地质与勘探, 2018, 46(4): 17–21. DOI: 10.3969/j.issn.1001-1986.2018.04.003 WANG Jianli, CHEN Dongdong, JIA Bingyi. Practice of gas drainage by hydraulic fracturing of roof pectination boreholes in broken soft coal seam in Hancheng mining area[J]. Coal Geology & Exploration, 2018, 46(4): 17–21. DOI: 10.3969/j.issn.1001-1986.2018.04.003

[20] 贾秉义, 陈冬冬, 吴杰, 等. 煤矿井下顶板梳状长钻孔分段压裂强化瓦斯抽采实践[J]. 煤田地质与勘探, 2021, 49(2): 70–76. DOI: 10.3969/j.issn.1001-1986.2021.02.009 JIA Bingyi, CHEN Dongdong, WU Jie, et al. Practice of enhanced gas extraction by staged fracturing with comb–shaped long hole in coal mine roof[J]. Coal Geology & Exploration, 2021, 49(2): 70–76. DOI: 10.3969/j.issn.1001-1986.2021.02.009

[21] 郭超奇, 赵继展, 李小建, 等. 中硬低渗煤层定向长钻孔水力压裂瓦斯高效抽采技术与应用[J]. 煤田地质与勘探, 2020, 48(6): 103–108. DOI: 10.3969/j.issn.1001-1986.2020.06.014 GUO Chaoqi, ZHAO Jizhan, LI Xiaojian, et al. Technology and application of high efficiency gas extraction by directional long borehole hydraulic fracturing in coal seams of medium hardness and low permeability[J]. Coal Geology & Exploration, 2020, 48(6): 103–108. DOI: 10.3969/j.issn.1001-1986.2020.06.014

[22] ZHANG Jingfei,SUN Siqing,LI Shugang,et al. Research and engineering practice of high−efficiency gas extraction technology by hydraulic fracturing:A case study of Huanglong coalfield in China[J]. Arabian Journal of Geosciences,2022,15:1012. DOI: 10.1007/s12517-022-10299-9

[23] 龙威成, 赵乐凯, 陈冬冬, 等. 顺煤层定向长钻孔水力压裂煤层增透技术及试验研究[J]. 河南理工大学学报(自然科学版), 2019, 38(3): 10–15. DOI: 10.16186/j.cnki.1673-9787.2019.3.2 LONG Weicheng, ZHAO Lekai, CHEN Dongdong, et al. Experimental study on coal seam permeability enhancement by directional long borehole hydraulic fracturing along seam direction[J]. Journal of Henan Polytechnic University(Natural Science), 2019, 38(3): 10–15. DOI: 10.16186/j.cnki.1673-9787.2019.3.2

[24] 李国栋, 郑凯歌, 陈冬冬. 赵固二矿本煤层定向长钻孔水力压裂增透技术研究[J]. 煤炭工程, 2019, 51(7): 53–57. LI Guodong, ZHENG Kaige, CHEN Dongdong. Study on permeability enhancement technology through overall hydraulic fracturing of long directional hole in Zhaogu No. 2 coal mine mining coal seam[J]. Coal Engineering, 2019, 51(7): 53–57.

[25] 杨俊哲, 郑凯歌, 王振荣, 等. 坚硬顶板动力灾害超前弱化治理技术[J]. 煤炭学报, 2020, 45(10): 3371–3379. YANG Junzhe, ZHENG Kaige, WANG Zhenrong, et al. Technology of weakening and danger–breaking dynamic disasters by hard roof[J]. Journal of China Coal Society, 2020, 45(10): 3371–3379.

[26] 郑凯歌, 杨俊哲, 李彬刚, 等. 基于垮落充填的坚硬顶板分段压裂弱化解危技术[J]. 煤田地质与勘探, 2021, 49(5): 77–87. ZHENG Kaige, YANG Junzhe, LI Bingang, et al. Collapse filling–based technology of weakening and danger–solving by staged fracturing in hard roof[J]. Coal Geology & Exploration, 2021, 49(5): 77–87.

[27] 谢华东, 张静非, 王富刚, 等. 煤层巨厚砂岩顶板定向长钻孔水力压裂矿震防治技术研究[J]. 中国矿业, 2021, 30(12): 106–111. XIE Huadong, ZHANG Jingfei, WANG Fugang, et al. Study on mine earthquake prevention technology of directional long drilling hydraulic fracturing in super thick sandstone roof of coal seam[J]. China Mining Magazine, 2021, 30(12): 106–111.

[28] 曹怀轩, 谢华东, 杨欢, 等. 东滩矿弱化低位关键层治理矿震技术研究[J]. 煤炭工程, 2021, 53(4): 71–75. CAO Huaixuan, XIE Huadong, YANG Huan, et al. Mine earthquake control through weakening the low key stratum in Dongtan coal mine[J]. Coal Engineering, 2021, 53(4): 71–75.

[29] 卫秀芬, 唐洁. 水平井分段压裂工艺技术现状及发展方向[J]. 大庆石油地质与开发, 2014, 33(6): 104–111. DOI: 10.3969/J.ISSN.1000-3754.2014.06.020 WEI Xiufen, TANG Jie. Technical current status and development direction of horizontal–well staged fracturing technology[J]. Petroleum Geology and Oilfield Development in Daqing, 2014, 33(6): 104–111. DOI: 10.3969/J.ISSN.1000-3754.2014.06.020

[30] 刘巨保, 黄茜, 杨明, 等. 水平井分段压裂工具技术现状与展望[J]. 石油机械, 2021, 49(2): 110–119. LIU Jubao, HUANG Qian, YANG Ming, et al. Current status and prospects of horizontal well staged fracturing tools and technologies[J]. China Petroleum Machinery, 2021, 49(2): 110–119.

[31] THEMIG D. Advances in OH multistage fracturing systems–A return to good frac–treatment practices[J]. Journal of Petroleum Technology,2015,62(5):26−29.

[32] THEMIG D. New technologies enhance efficiency of horizontal,multistage fracturing[J]. Journal of Petroleum Technology,2011,63(4):26−31. DOI: 10.2118/0411-0026-JPT

[33] 石建文, 张俭, 范毅伟, 等. 碎软低透煤层分段水力压裂增透技术研究[J]. 能源技术与管理, 2017, 42(4): 20–22. DOI: 10.3969/j.issn.1672-9943.2017.04.008 SHI Jianwen, ZHANG Jian, FAN Yiwei, et al. Research on permeability enhancement technology of segmented hydraulic fracturing in crushed soft and low permeability coal seams[J]. Energy Technology and Management, 2017, 42(4): 20–22. DOI: 10.3969/j.issn.1672-9943.2017.04.008

[34] 郑凯歌. 碎软低透煤层底板梳状长钻孔分段水力压裂增透技术研究[J]. 采矿与安全工程学报, 2020, 37(2): 272–281. ZHENG Kaige. Permeability improving technology by sectional hydraulic fracturing for comb–like long drilling in floor of crushed and soft coal seam with low permeability[J]. Journal of Mining & Safety Engineering, 2020, 37(2): 272–281.

[35] 陈冬冬, 孙四清, 张俭, 等. 井下定向长钻孔水力压裂煤层增透技术体系与工程实践[J]. 煤炭科学技术, 2020, 48(10): 84–89. CHEN Dongdong, SUN Siqing, ZHANG Jian, et al. Technical system and engineering practice of coal seam permeability improvement through underground directional long borehole hydraulic fracturing[J]. Coal Science and Technology, 2020, 48(10): 84–89.

[36] 蔺海晓, 刘晓, 王鹏. 煤矿井下水力压裂泵组的研发与应用[J]. 矿山机械, 2014, 42(3): 107–109. DOI: 10.16816/j.cnki.ksjx.2014.03.028 LIN Haixiao, LIU Xiao, WANG Peng. Development and application on pump group for hydraulic fracturing in underground collieries[J]. Mining & Processing Equipment, 2014, 42(3): 107–109. DOI: 10.16816/j.cnki.ksjx.2014.03.028

[37] 周俊杰, 张尚斌, 敖锋, 等. 井下高压水力压裂泵组的研发及应用[J]. 矿山机械, 2017, 45(8): 13–15. DOI: 10.3969/j.issn.1001-3954.2017.08.004 ZHOU Junjie, ZHANG Shangbin, AO Feng, et al. Development and application of pump group for underground high–pressure hydraulic fracturing[J]. Mining & Processing Equipment, 2017, 45(8): 13–15. DOI: 10.3969/j.issn.1001-3954.2017.08.004

[38] 赵继展, 李迎科, 孙四清, 等. 一种煤矿井下加砂压裂控制系统及其控制方法: ZL201811421241.8[P]. 2021-08-10. [39] 赵继展, 郑凯歌, 张俭, 等. 煤矿水力压裂用摆动式连续加注支撑剂装置及加注方法: CN201811093252. 8[P]. 2018-09-19. [40] 贾秉义, 陈冬冬, 孙四清, 等. 一种煤矿井下用封闭高压液动旋流连续混供砂装置及系统: CN202122172689. 4[P]. 2021-09-08. [41] 陈建, 贾秉义, 董瑞刚, 等. 煤矿井下水力压裂加骨料增透瓦斯抽采技术应用[J]. 煤炭工程, 2021, 53(2): 90–94. CHEN Jian, JIA Bingyi, DONG Ruigang, et al. Application of hydraulic fracturing and aggregate injecting for permeability enhancement in underground coal mine gas extraction[J]. Coal Engineering, 2021, 53(2): 90–94.

[42] 石智军, 董书宁, 杨俊哲, 等. 煤矿井下3000m顺煤层定向钻孔钻进关键技术[J]. 煤田地质与勘探, 2019, 47(6): 1–7. SHI Zhijun, DONG Shuning, YANG Junzhe, et al. Key technology of drilling in–seam directional borehole of 3000m in underground coal mine[J]. Coal Geology & Exploration, 2019, 47(6): 1–7.

[43] 姚宁平, 王毅, 姚亚峰, 等. 我国煤矿井下复杂地质条件下钻探技术与装备进展[J]. 煤田地质与勘探, 2020, 48(2): 1–7. DOI: 10.3969/j.issn.1001-1986.2020.02.001 YAO Ningping, WANG Yi, YAO Yafeng, et al. Progress of drilling technologies and equipments for complicated geological conditions in underground coal mines in China[J]. Coal Geology & Exploration, 2020, 48(2): 1–7. DOI: 10.3969/j.issn.1001-1986.2020.02.001

[44] 王力, 姚宁平, 姚亚峰, 等. 煤矿井下碎软煤层顺层钻完孔技术研究进展[J]. 煤田地质与勘探, 2021, 49(1): 285–296. DOI: 10.3969/j.issn.1001-1986.2021.01.032 WANG Li, YAO Ningping, YAO Yafeng, et al. Research progress of drilling and borehole completion technologies in broken soft coal seam in underground coal mine[J]. Coal Geology & Exploration, 2021, 49(1): 285–296. DOI: 10.3969/j.issn.1001-1986.2021.01.032

[45] 刘徐三. 煤矿井下大直径定向钻进技术在水力压裂中的应用[J]. 煤炭工程, 2020, 52(5): 58–62. LIU Xusan. Application of large diameter directional drilling in hydraulic fracturing of underground coal mine[J]. Coal Engineering, 2020, 52(5): 58–62.

[46] 康红普, 冯彦军. 煤矿井下水力压裂技术及在围岩控制中的应用[J]. 煤炭科学技术, 2017, 45(1): 1–9. KANG Hongpu, FENG Yanjun. Hydraulic fracturing technology and its applications in strata control in underground coal mines[J]. Coal Science and Technology, 2017, 45(1): 1–9.

[47] 杨俊哲, 郑凯歌. 厚煤层综放开采覆岩动力灾害原理及防治技术[J]. 采矿与安全工程学报, 2020, 37(4): 750–758. YANG Junzhe, ZHENG Kaige. The mechanism of overburden dynamic disasters and its control technology in top–coal caving in the mining of thick coal seams[J]. Journal of Mining & Safety Engineering, 2020, 37(4): 750–758.

[48] 王元杰, 徐刚, 陈法兵, 等. 深部厚硬岩层压裂控制冲击弱化机理及可压裂性评价[J]. 采矿与岩层控制工程学报, 2022, 4(2): 023027. WANG Yuanjie, XU Gang, CHEN Fabing, et al. Mining pressure weakening mechanism by ground fracturing and fracturing evaluation of hard rock strata[J]. Journal of Mining and Strata Control Engineering, 2022, 4(2): 023027.

[49] 黄炳香, 赵兴龙, 陈树亮, 等. 坚硬顶板水压致裂控制理论与成套技术[J]. 岩石力学与工程学报, 2017, 36(12): 2954–2970. HUANG Bingxiang, ZHAO Xinglong, CHEN Shuliang, et al. Theory and technology of controlling hard roof with hydraulic fracturing in underground mining[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(12): 2954–2970.

[50] 王国法, 刘峰, 庞义辉, 等. 煤矿智能化——煤炭工业高质量发展的核心技术支撑[J]. 煤炭学报, 2019, 44(2): 349–357. DOI: 10.13225/j.cnki.jccs.2018.2041 WANG Guofa, LIU Feng, PANG Yihui, et al. Coal mine intellectualization: The core technology of high quality development[J]. Journal of China Coal Society, 2019, 44(2): 349–357. DOI: 10.13225/j.cnki.jccs.2018.2041

[51] 张洪生, 李鹏飞. 我国大功率压裂泵发展趋势及展望[J]. 机床与液压, 2018, 46(2): 142–144. DOI: 10.3969/j.issn.1001-3881.2018.02.039 ZHANG Hongsheng, LI Pengfei. Domestic high–power fracturing pump development trends and prospects[J]. Machine Tool & Hydraulics, 2018, 46(2): 142–144. DOI: 10.3969/j.issn.1001-3881.2018.02.039

[52] 许耀波, 郭盛强. 软硬煤复合的煤层气水平井分段压裂技术及应用[J]. 煤炭学报, 2019, 44(4): 1169–1177. XU Yaobo, GUO Shengqiang. Technology and application of staged fracturing in coalbed methane horizontal well of soft and hard coal composite coal seam[J]. Journal of China Coal Society, 2019, 44(4): 1169–1177.

[53] 杜新锋, 袁崇亮, 王正喜, 等. 窑街矿区浅层煤系气储层特征及勘探开发关键技术[J]. 煤田地质与勘探, 2021, 49(6): 58–66. DU Xinfeng, YUAN Chongliang, WANG Zhengxi, et al. Characteristics of shallow coal measure gas reservoir and key technologies of exploration and development in Yaojie mining area[J]. Coal Geology & Exploration, 2021, 49(6): 58–66.

[54] 黎伟, 夏杨, 陈曦. RFID智能滑套设计与试验研究[J]. 石油钻探技术, 2019, 47(6): 83–88. DOI: 10.11911/syztjs.2019123 LI Wei, XIA Yang, CHEN Xi. Design and experimental study of an RFID intelligent sliding sleeve[J]. Petroleum Drilling Techniques, 2019, 47(6): 83–88. DOI: 10.11911/syztjs.2019123

[55] 蒋廷学, 周珺, 廖璐璐. 国内外智能压裂技术现状及发展趋势[J]. 石油钻探技术, 2022, 50(3): 1–9. DOI: 10.11911/syztjs.2021101 JIANG Tingxue, ZHOU Jun, LIAO Lulu. Development status and future trends of intelligent fracturing technologies[J]. Petroleum Drilling Techniques, 2022, 50(3): 1–9. DOI: 10.11911/syztjs.2021101

[56] 高德利. 非常规油气井工程技术若干研究进展[J]. 天然气工业, 2021, 41(8): 153–162. DOI: 10.3787/j.issn.1000-0976.2021.08.014 GAO Deli. Some research advances in well engineering technology for unconventional hydrocarbon[J]. Natural Gas Industry, 2021, 41(8): 153–162. DOI: 10.3787/j.issn.1000-0976.2021.08.014

-

期刊类型引用(2)

1. 代晓亮,孙建维,赵帅,刘发义,张豪. 胡底煤矿强矿压微震监测预警技术研究. 建井技术. 2024(05): 11-16 .  百度学术

百度学术

2. 张寅,李家俊,赵乾,杨晨晨,刘家麒,周雨. 微震监测在复合坚硬砂岩体顶板控制策略优化中的应用. 煤田地质与勘探. 2024(12): 179-189 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: