Factors affecting the attitude accuracy of wireless electromagnetic wave MWD system

-

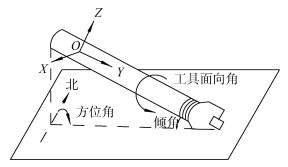

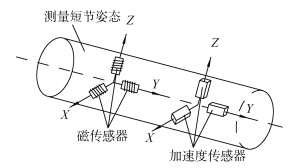

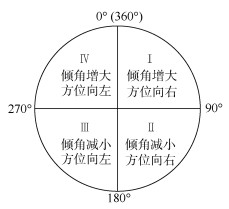

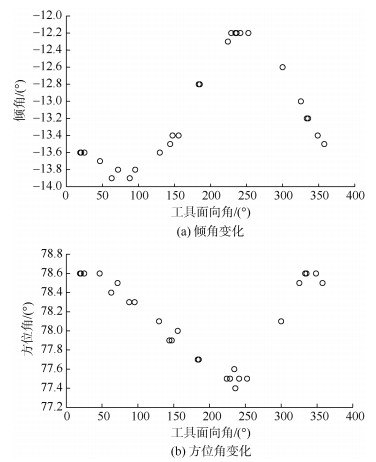

摘要: 煤矿井下采用水力钻进方式进行碎软煤层瓦斯抽采时,容易出现塌孔、孔壁失稳,电磁波随钻测量系统适用于气体钻进,在碎软煤层瓦斯抽采中逐步得到应用。钻孔轨迹的准确性是影响碎软煤层瓦斯抽采效果的关键,电磁波随钻测量系统使用中,出现轨迹测量精度不够、误差大的现象。为解决这一问题,分析测量系统从设计到应用全过程中影响姿态精度的因素,列举因素产生的原因及解决方案,重点针对钻进现场出现的电磁波系统精度问题进行分析。通过现场采集数据、分析曲线趋势规律,确定造成误差大的原因为测量短节与外无磁钻杆不同轴,设计现场自校准方法和流程要求。提出查表补偿法和拟合函数法2种校准方式,对2种方法的原理、方法选择以及相关参数计算给出了说明。最后采用拟合函数法对实测数据进行了校准修正,修正后的姿态数据精度达到0.2°,解决了无线电磁波随钻测量系统在使用中的姿态精度不高问题,满足碎软煤层瓦斯抽采轨迹测量精度要求。Abstract: In broken soft coal seams of coal mine where hydraulic driving directional drilling is used, hole collapse and hole wall instability are easy to occur. Electromagnetic wave measurement while drilling system is suitable for gas driving drilling, so it is widely used in broken soft coal seams. The accuracy of drilling trajectory is the key to gas drainage effect in broken soft coal seams. In the use of electromagnetic wave measurement while drilling system, the phenomenon of insufficient accuracy and large error of trajectory measurement appears irregularly. In order to solve this problem, this paper analyzes all the factors that affect the attitude accuracy of wireless electromagnetic wave MWD system from design to application, lists the influence sources and treatment schemes one by one, and focuses on the accuracy problems of electromagnetic wave MWD system in drilling field. By collecting data and analyzing the trend of the curves, the causes of the problems are determined, and the self calibration method and process requirements are designed. At the same time, two calibration methods of look-up table compensation method and fitting function method are given, and the principle, method selection and related parameter calculation of the two methods are explained. Finally, the fitting function method is used to calibrate and correct the measured data, and the accuracy of the corrected attitude data was better than 0.2°, which solved the problem of poor attitude accuracy of the wireless electromagnetic wave MWD system and met the requirements of the measurement accuracy of gas extraction trajectory in broken soft coal seams.

-

-

表 1 同一位置不同工具面实测姿态数据

Table 1 The actual attitude data of different tool surfaces at the same position

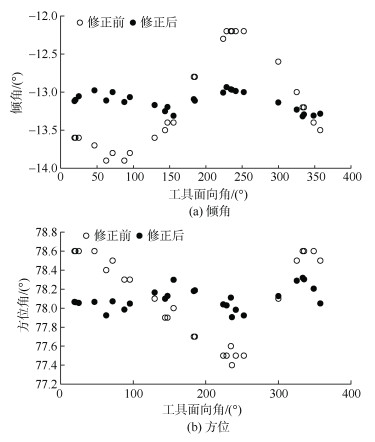

序号 工具面向角/(°) 倾角/(°) 方位角/(°) 1 357.7 –13.5 78.5 2 25.0 –13.6 78.6 3 46.6 –13.7 78.6 4 71.6 –13.8 78.5 5 95.4 –13.8 78.3 6 129.5 –13.6 78.1 7 185.0 –12.8 77.7 8 155.6 –13.4 78.0 9 234.5 –12.2 77.6 10 299.9 –12.6 78.1 11 325.3 –13.0 78.5 12 183.5 –12.8 77.7 13 241.3 –12.2 77.5 14 333.5 –13.2 78.6 15 19.1 –13.6 78.6 16 228.6 –12.2 77.5 18 224.0 –12.3 77.5 19 20.4 –13.6 78.6 20 143.9 –13.5 77.9 21 236.0 –12.2 77.4 22 335.3 –13.2 78.6 23 62.8 –13.9 78.4 24 147.2 –13.4 77.9 25 252.4 –12.2 77.5 26 348.6 –13.4 78.6 表 2 姿态数据修正前后对比

Table 2 Comparison table of attitude data before and after correction

工具面向角/(°) 倾角/(°) 方位角/(°) 修正前 修正后 修正前 修正后 19.1 –13.6 –13.12 78.6 78.07 20.4 –13.6 –13.10 78.6 78.06 25.0 –13.6 –13.05 78.6 78.05 46.6 –13.7 –12.98 78.6 78.07 62.8 –13.9 –13.11 78.4 77.92 71.6 –13.8 –13.00 78.5 78.07 87.8 –13.9 –13.13 78.3 77.99 95.4 –13.8 –13.07 78.3 78.05 129.5 –13.6 –13.17 78.1 78.17 143.9 –13.5 –13.25 77.9 78.10 147.2 –13.4 –13.20 77.9 78.13 155.6 –13.4 –13.31 78.0 78.30 183.5 –12.8 –13.09 77.7 78.18 185.0 –12.8 –13.11 77.7 78.19 224.0 –12.3 –13.01 77.5 78.04 228.6 –12.2 –12.93 77.5 78.03 228.6 –12.2 –12.93 77.5 78.03 234.5 –12.2 –12.96 77.6 78.11 236.0 –12.2 –12.97 77.4 77.91 241.3 –12.2 –12.99 77.5 77.98 252.4 –12.2 –13.00 77.5 77.92 299.9 –12.6 –13.14 78.1 78.13 325.3 –13.0 –13.23 78.5 78.29 333.5 –13.2 –13.32 78.6 78.32 335.3 –13.2 –13.29 78.6 78.30 348.6 –13.4 –13.31 78.6 78.21 357.7 –13.5 –13.28 78.5 78.05 -

[1] 胡省三, 成玉琪. 21世纪前期我国煤炭科技重点发展领域探讨[J]. 煤炭学报, 2005, 30(1): 1–7. DOI: 10.3321/j.issn:0253-9993.2005.01.001 HU Shengsan, CHENG Yuqi. Discussions on key development fields of China's coal science and technology at early stage of 21st century[J]. Journal of China Coal Society, 2005, 30(1): 1–7. DOI: 10.3321/j.issn:0253-9993.2005.01.001

[2] 胡千庭. "先抽后采"是确保煤矿安全高效生产的重要条件[R/OL]. [2019-03-16]. HU Qianting. "Pumping before mining"is an important condition to ensure safe and efficient production of coal mine[R/OL]. [2019-03-16].

[3] 中国煤炭工业技术委员会煤矿安全专家委员会. 煤矿瓦斯治理和利用先进技术及示范[M]. 徐州: 中国矿业大学出版社, 2009. Coal Mine Safety Expert Committee of China Coal Industry Technical Committee. Meikuang Wasi Zhili he Liyong Xianjin Jinshu ji Shifan[M]. Xuzhou: China University of Mining and Technology Press, 2009.

[4] 张杰, 蒋玉玺, 姚宁平. 九里山矿井下定向钻孔卡钻事故处理实践[J]. 煤矿安全, 2012, 43(11): 125–127. ZHANG Jie, JIANG Yuxi, YAO Ningping. The practice of sticking accident treatment for directional drilling in Jiulishan coal mine[J]. Safety in Coal Mines, 2012, 43(11): 125–127.

[5] 方俊, 李泉新, 许超, 等. 松软突出煤层瓦斯抽采钻孔施工技术及发展趋势[J]. 煤炭科学技术, 2018, 46(5): 130–137. FANG Jun, LI Quanxin, XU Chao, et al. Construction technology and development tendency of gas drainage borehole in soft and outburst seam[J]. Coal Science and Technology, 2018, 46(5): 130–137.

[6] 袁亮. 低透气性煤层群无煤柱煤与瓦斯共采理论与实践[M]. 北京: 煤炭工业出版社, 2008. YUAN Liang. Theory and practice of integrated pillarless coal production and methane extraction in multiseams of low perme ability[M]. Beijing: China Coal Industry Publishing House, 2008.

[7] 张镇, 孙永新, 付玉凯, 等. 松软破碎煤体瓦斯抽采钻场预加固技术研究与应用[J]. 煤炭工程, 2019, 51(8): 44–47. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ201908012.htm ZHANG Zhen, SUN Yongxin, FU Yukai, et al. Study and application of pre-reinforcement of soft and breaking coal mass in gas drainage drilling field[J]. Coal Engineering, 2019, 51(8): 44–47. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ201908012.htm

[8] 刘京科. 矿用电磁波随钻测量仪在定向钻进中的应用[J]. 煤炭技术, 2019, 38(4): 174–177. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201904061.htm LIU Jingke. Application of mining electromagnetic wave drilling measuring instrument in directional drilling[J]. Coal Technology, 2019, 38(4): 174–177. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201904061.htm

[9] 殷新胜, 刘建林, 冀前辉. 松软煤层中风压空气钻进技术与装备[J]. 煤矿安全, 2012, 43(7): 63–65. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201207020.htm YIN Xinsheng, LIU Jianlin, JI Qianhui. Medium wind pressure air drilling technique and equipments in soft coal seam[J]. Safety in Coal Mines, 2012, 43(7): 63–65. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201207020.htm

[10] 邵养涛, 姚爱国, 张明光. 电磁波随钻遥测技术在钻井中的应用与发展[J]. 煤田地质与勘探, 2007, 35(3): 77–80. DOI: 10.3969/j.issn.1001-1986.2007.03.022 SHAO Yangtao, YAO Aiguo, ZHANG Mingguang. Application and development of electro-magnetic telemetry in drilling operation[J]. Coal Geology & Exploration, 2007, 35(3): 77–80. DOI: 10.3969/j.issn.1001-1986.2007.03.022

[11] 王力, 姚宁平, 姚亚峰, 等. 煤矿井下碎软煤层顺层钻完孔技术研究进展[J]. 煤田地质与勘探, 2021, 49(1): 285–296. DOI: 10.3969/j.issn.1001-1986.2021.01.032 WANG Li, YAO Ningping, YAO Yafeng, et al. Research progress of drilling and borehole completion technologies in broken soft coal seam in underground coal mine[J]. Coal Geology & Exploration, 2021, 49(1): 285–296. DOI: 10.3969/j.issn.1001-1986.2021.01.032

[12] 汪凯斌. YSDC矿用电磁波随钻测量系统及在煤矿井下空气钻进中的应用[J]. 煤矿安全, 2019, 50(7): 153–156. WANG Kaibin. YSDC mine-used electromagnetic wave measurement while drilling system and its application in air drilling for soft coal seam[J]. Safety in Coal Mines, 2019, 50(7): 153–156.

[13] 蒋必辞, 汪凯斌, 潘保芝, 等. 煤矿井下电磁波无线随钻测井软件设计与实现[J]. 煤田地质与勘探, 2016, 44(6): 152–158. DOI: 10.3969/j.issn.1001-1986.2016.06.028 JIANG Bici, WANG Kaibin, PAN Baozhi, et al. Design and implementation of LWDEWCM software[J]. Coal Geology & Exploration, 2016, 44(6): 152–158. DOI: 10.3969/j.issn.1001-1986.2016.06.028

[14] 张典荣, 李静, 张佳, 等. 新型多用钻孔测斜仪的研制及应用[J]. 西安科技大学学报, 2018, 38(2): 224–229. https://www.cnki.com.cn/Article/CJFDTOTAL-XKXB201802009.htm ZHANG Dianrong, LI Jing, ZHANG Jia, et al. Development and application of new type multi-usage borehole inclinomlter[J]. Journal of Xi'an University of Science and Technology, 2018, 38(2): 224–229. https://www.cnki.com.cn/Article/CJFDTOTAL-XKXB201802009.htm

[15] 郭爱煌, 薛忍霞. 矿井全方位钻孔测斜仪的数值计算与误差校正[J]. 物探化探计算技术, 1997, 19(1): 50–55. GUO Aihuang, XUE Renxia. Numerical calculation and error correction of all-directional borehole inclinometer in coal mine[J]. Computing Techniques for Geophysical and Geochemical Exploration, 1997, 19(1): 50–55.

[16] 邢馨婷, 熊磊, 赵君辙, 等. 加速度计温度补偿方法[J]. 计测技术, 2008, 28(1): 51–52. DOI: 10.3969/j.issn.1674-5795.2008.01.017 XING Xinting, XIONG Lei, ZHAO Junzhe, et al. Study of accelerometer temperature compensation method[J]. Metrology and Measurement Technology, 2008, 28(1): 51–52. DOI: 10.3969/j.issn.1674-5795.2008.01.017

[17] 燕斌. MEMS加速度传感器在矿用随钻轨迹测量系统中的误差校正[J]. 煤田地质与勘探, 2017, 45(4): 144–148. DOI: 10.3969/j.issn.1001-1986.2017.04.026 YAN Bin. Error correction of MEMS acceleration sensor used for trajectory measurement while drilling system[J]. Coal Geology & Exploration, 2017, 45(4): 144–148. DOI: 10.3969/j.issn.1001-1986.2017.04.026

[18] 姚宁平, 张杰, 李泉新, 等. 煤矿井下定向钻孔轨迹设计与控制技术[J]. 煤炭科学技术, 2013, 41(3): 7–11. YAO Ningping, ZHANG Jie, LI Quanxin, et al. Tracing design and control technology of directional drilling borehole in underground mine[J]. Coal Science and Technology, 2013, 41(3): 7–11.

[19] 姚宁平. 我国煤矿井下近水平定向钻进技术的发展[J]. 煤田地质与勘探, 2008, 36(4): 78–80. DOI: 10.3969/j.issn.1001-1986.2008.04.020 YAO Ningping. Development trend of nearly horizontal directional drilling technology in coal mines of China[J]. Coal Geology & Exploration, 2008, 36(4): 78–80. DOI: 10.3969/j.issn.1001-1986.2008.04.020

[20] 张迎接, 赵永哲, 杨忠, 等. 煤矿井下倾斜地层近水平定向钻孔造斜段轨迹设计[J]. 煤田地质与勘探, 2019, 47(2): 27–30. http://mdkt.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=54b55514-f5c7-4993-a1ff-8f09f7878902 ZHANG Yingjie, ZHAO Yongzhe, YANG Zhong, et al. Trajectory design of oblique section in nearly horizontal directional hole in inclined formation in underground coal mine[J]. Coal Geology & Exploration, 2019, 47(2): 27–30. http://mdkt.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=54b55514-f5c7-4993-a1ff-8f09f7878902

[21] 江浩, 燕斌. 基于PNI磁感式传感器的钻孔测斜仪的研制[J]. 煤田地质与勘探, 2016, 44(4): 132–135. DOI: 10.3969/j.issn.1001-1986.2016.04.025 JIANG Hao, YAN Bin. Borehole inclinometer based on PNI magnetic induction sensor[J]. Coal Geology & Exploration, 2016, 44(4): 132–135. DOI: 10.3969/j.issn.1001-1986.2016.04.025

[22] 薛琴. 双轴倾角传感器在钻孔测斜仪中测量算法的校正[J]. 煤田地质与勘探, 2007, 35(6): 70–73. DOI: 10.3969/j.issn.1001-1986.2007.06.018 XUE Qin. Measurement algorithmic adjustment of 2-axis inclinometer in borehole inclinometer[J]. Coal Geology & Exploration, 2007, 35(6): 70–73. DOI: 10.3969/j.issn.1001-1986.2007.06.018

下载:

下载: