Friction law of compound drilling along the coal seam with super-long directional drilling

-

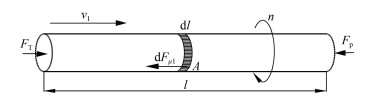

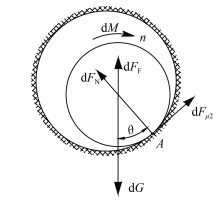

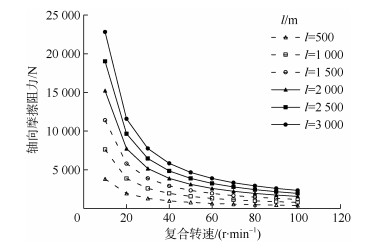

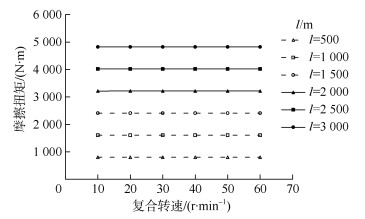

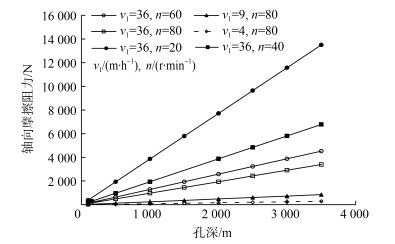

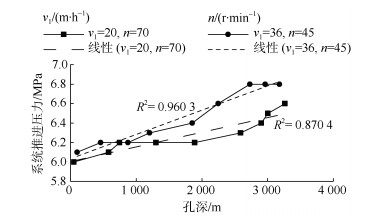

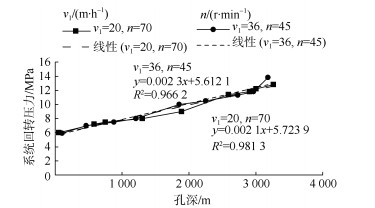

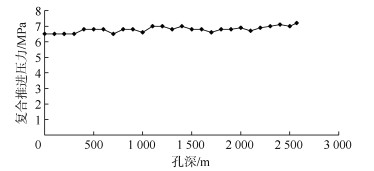

摘要: 煤矿井下超长孔定向钻进中孔内摩阻是限制其成孔率及成孔效率的主要因素, 为适应大盘区瓦斯抽采模式的客观需求, 研究实钻过程中摩阻及其影响规律。为顺煤层超长定向钻孔复合钻进减摩阻工艺参数选取提供依据, 对煤矿井下顺煤层近水平复合钻进工况下钻柱的钻具运动特性及受力状态进行分析。通过一定的条件假设, 建立复合钻进轴向摩擦阻力和旋转摩擦扭矩力学模型, 通过数值计算, 针对常用ø89 mm定向钻具组合, 在不同孔深及钻进工艺参数匹配下的摩阻规律特性进行分析。结果表明:机械钻速、钻具转速、钻孔深度是滑动摩擦阻力和旋转摩擦扭矩的主控影响因素, 与超长定向钻孔实钻参数统计分析对比, 推进阻力和旋转扭矩变化规律与模型计算结果吻合, 该结果对于指导近水平钻孔复合定向钻进工艺参数选取、钻进工况判断具有重要的现实意义, 同时, 对于煤矿井下自动化、智能化定向钻进控制系统设计开发具有借鉴意义。Abstract: The internal friction is the main factor affecting the drilling rate and drilling efficiency in super-long directional drilling in coal mines. In order to meet the objective demand of gas drainage mode in big panels, the friction and its influence law in drilling process are studied. To provide a basis for the selection of friction reduction process parameters of compound drilling along coal seam with super-long directional drilling, the drill string motion characteristics and stress state under the condition of near-horizontal compound drilling in the coal mine are analyzed. With certain conditional assumptions, the mechanical models of axial frictional resistance and rotational frictional torque of composite drilling are established. Under different hole depths and matching drilling process parameters, numerical calculations are carried out to analyze the friction law characteristics of the common ø89 mm directional assembly. The results reveal that the mechanical drilling speed, drilling rotation speed and drilling depth are the main controlling factors of sliding friction resistance and rotating friction torque. Compared with the statistical analysis of actual drilling parameters of super-long directional drilling, the changes of propulsion resistance and rotating torque are consistent with the calculation of the model. The result is of important practical significance for guiding the selection of technological parameters and drilling conditions of compound directional drilling near horizontal holes. Furthermore, it has referential significance for the design of automatic and intelligent directional drilling control system in underground coal mines.

-

-

-

[1] 李泉新, 石智军, 田宏亮, 等. 我国煤矿区钻探技术装备研究进展[J]. 煤田地质与勘探, 2019, 47(2): 1-6. http://mdkt.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=b6052c8d-7f8f-41f8-b2ca-50008c5e60c1 LI Quanxin, SHI Zhijun, TIAN Hongliang, et al. Progress in the research on drilling technology and equipment in coal mining areas of China[J]. Coal Geology & Exploration, 2019, 47(2): 1-6. http://mdkt.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=b6052c8d-7f8f-41f8-b2ca-50008c5e60c1

[2] 石智军, 李泉新, 姚克. 煤矿井下水平定向钻进技术与装备的新进展[J]. 探矿工程(岩土钻掘工程), 2015, 42(1): 12-16. DOI: 10.3969/j.issn.1672-7428.2015.01.002 SHI Zhijun, LI Quanxin, YAO Ke. Latest developments of horizontal directional drilling technology and the equipments for underground coal mine[J]. Exploration Engineering(Rock & Soil Drilling and Tunneling), 2015, 42(1): 12-16. DOI: 10.3969/j.issn.1672-7428.2015.01.002

[3] 石智军, 董书宁, 杨俊哲, 等. 煤矿井下3 000 m顺煤层定向钻孔钻进关键技术[J]. 煤田地质与勘探, 2019, 47(6): 1-7. http://mdkt.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=a6ec73b9-a04a-4722-903e-ce6d9754b13b SHI Zhijun, DONG Shuning, YANG Junzhe, et al. Key technology of drilling in-seam directional borehole of 3 000 m in underground coal mine[J]. Coal Geology & Exploration, 2019, 47(6): 1-7. http://mdkt.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=a6ec73b9-a04a-4722-903e-ce6d9754b13b

[4] 石智军, 姚克, 姚宁平, 等. 我国煤矿井下坑道钻探技术装备40年发展与展望[J]. 煤炭科学技术, 2020, 48(4): 1-34. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202004001.htm SHI Zhijun, YAO Ke, YAO Ningping, et al. 40 years of development and prospect on underground coal mine tunnel drilling technology and equipment in China[J]. Coal Science and Technology, 2020, 48(4): 1-34. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202004001.htm

[5] 石智军, 李泉新, 姚克. 煤矿井下智能化定向钻探发展路径与关键技术分析[J]. 煤炭学报, 2020, 45(6): 2217-2224. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202006028.htm SHI Zhijun, LI Quanxin, YAO Ke. Development path and key technology analysis of intelligent directional drilling in underground coal mine[J]. Journal of China Coal Society, 2020, 45(6): 2217-2224. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB202006028.htm

[6] 霍福星, 方俊, 李泉新, 等. 复杂破碎地层中定向孔复合排渣钻进技术[J]. 煤矿安全, 2019, 50(7): 112-115. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201907026.htm HUO Fuxing, FANG Jun, LI Quanxin, et al. Technology of composite slag discharge for directional drilling in complicated broken stratum[J]. Safety in Coal Mines, 2019, 50(7): 112-115. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201907026.htm

[7] 李泉新, 石智军, 许超, 等. 2 311 m顺煤层超长定向钻孔高效钻进技术[J]. 煤炭科学技术, 2018, 46(4): 27-32. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201804005.htm LI Quanxin, SHI Zhijun, XU Chao, et al. Efficient drilling technique of 2 311 m ultra-long directional borehole along coal seam[J]. Coal Science and Technology, 2018, 46(4): 27-32. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201804005.htm

[8] 李泉新. 碎软煤层复合定向钻进技术研究与应用[J]. 煤炭科学技术, 2018, 46(11): 101-106. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201811016.htm LI Quanxin. Research and application of drilling technology combined rotary with direction in soft-fragmentized coal seam[J]. Coal Science and Technology, 2018, 46(11): 101-106. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201811016.htm

[9] 许超. 煤矿井下复合定向钻进技术优势探讨[J]. 金属矿山, 2014(2): 112-116. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201402026.htm XU Chao. Discussion on superiority of compound directional drilling technology in underground coal mine[J]. Metal Mine, 2014(2): 112-116. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201402026.htm

[10] XU Chao, WANG Xian, LIU Fei, et al. Practice and challenge of in-seam directional borehole over 2 000 m in coal mines in China[J]. IOP Conference Series: Earth and Environmental Science, 2019, 332(2): 022016. DOI: 10.1088/1755-1315/332/2/022016

[11] 刘建林, 李泉新. 基于轨迹控制的煤矿井下复合定向钻进工艺[J]. 煤矿安全, 2017, 48(7): 78-81. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201707020.htm LIU Jianlin, LI Quanxin. Composite directional drilling technology for underground coal mine based on trajectory control[J]. Safety in Coal Mines, 2017, 48(7): 78-81. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201707020.htm

[12] 赵建国, 赵江鹏, 许超, 等. 煤矿井下复合定向钻进技术研究与应用[J]. 煤田地质与勘探, 2018, 46(4): 202-206. DOI: 10.3969/j.issn.1001-1986.2018.04.033 ZHAO Jianguo, ZHAO Jiangpeng, XU Chao, et al. Composite directional drilling technology in underground coal mine[J]. Coal Geology & Exploration, 2018, 46(4): 202-206. DOI: 10.3969/j.issn.1001-1986.2018.04.033

[13] 徐保龙, 姚宁平, 王力. 煤矿井下定向深孔复合钻进减阻规律研究[J]. 煤矿安全, 2018, 49(2): 92-95. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201802024.htm XU Baolong, YAO Ningping, WANG Li. Friction reduction law of compound drilling in directional deep hole of underground mine[J]. Safety in Coal Mines, 2018, 49(2): 92-95. https://www.cnki.com.cn/Article/CJFDTOTAL-MKAQ201802024.htm

[14] 石智军, 许超, 李泉新, 等. 煤矿井下2 570 m顺煤层超深定向孔高效成孔关键技术[J]. 煤炭科学技术, 2020, 48(1): 196-201. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202001025.htm SHI Zhijun, XU Chao, LI Quanxin, et al. Key technology of high efficiency hole formation for ultra deep directional hole with long 2 570 m along seam in underground coal mine[J]. Coal Science and Technology, 2020, 48(1): 196-201. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202001025.htm

[15] 谢锡纯, 李晓豁. 矿山机械与设备[M]. 徐州: 中国矿业大学出版社, 2012: 6-7. XIE Xichun, LI Xiaohuo. Mining Machinery[M]. Xuzhou: China University of Mining and Technology Press, 2012: 6-7.

[16] 马善洲, 韩志勇. 水平井钻柱摩阻力和摩阻力矩的计算[J]. 石油大学学报(自然科学版), 1996, 20(6): 24-28. https://www.cnki.com.cn/Article/CJFDTOTAL-SYDX606.006.htm MA Shanzhou, HAN Zhiyong. Calculation of torque and drag of drill string in horizontal well[J]. Journal of the University of Petroleum(Edition of Natural Science), 1996, 20(6): 24-28. https://www.cnki.com.cn/Article/CJFDTOTAL-SYDX606.006.htm

[17] 吕苗荣. 石油工程管柱力学[M]. 北京: 中国石化出版社, 2012. LYU Miaorong. Pipe string mechanics of petroleum engineering[M]. Beijing: China Petrochemical Press, 2012.

[18] 闫铁, 李庆明, 王岩, 等. 水平井钻柱摩阻扭矩分段计算模型[J]. 大庆石油学院学报, 2015, 35(5): 69-72. https://www.cnki.com.cn/Article/CJFDTOTAL-DQSY201105015.htm YAN Tie, LI Qingming, WANG Yan, et al. Segmental calculation model for torque and drag of drillstring in horizontal wells[J]. Journal of Daqing Petroleum Institute, 2015, 35(5): 69-72. https://www.cnki.com.cn/Article/CJFDTOTAL-DQSY201105015.htm

[19] 王国华, 张军伟, 熊继有, 等. 水平井钻井摩阻扭矩计算模型研究[J]. 地下空间与工程学报, 2016, 12(增刊2): 651-655. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE2016S2037.htm WANG Guohua, ZHANG Junwei, XIONG Jiyou, et al. Research of calculation model for friction and torque in horizontal wells[J]. Chinese Journal of Underground Space and Engineering, 2016, 12(Sup. 2): 651-655. https://www.cnki.com.cn/Article/CJFDTOTAL-BASE2016S2037.htm

[20] 李乾, 纪国栋, 张辉, 等. 滑动钻进中顶驱扭摆减阻控制技术研究[J]. 石油机械, 2018, 46(5): 1-6. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJI201805001.htm LI Qian, JI Guodong, ZHANG Hui, et al. Drag reduction control for torsion and oscillation in top drive system slide drilling[J]. China Petroleum Machinery, 2018, 46(5): 1-6. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJI201805001.htm

-

期刊类型引用(6)

1. 王永龙,郭佳宽,余在江,杜康,孙玉宁. 松软煤层钻进钻杆减重降阻机制及应用研究. 煤田地质与勘探. 2024(05): 174-182 .  本站查看

本站查看

2. 陈超,陈天柱,张马军,王常委. 孤岛工作面碎软煤层跟管护孔钻进工艺研究. 工矿自动化. 2023(01): 73-79 .  百度学术

百度学术

3. 李冬生. 复合钻进近水平超长钻柱动力学特性研究. 煤矿机械. 2023(04): 72-74 .  百度学术

百度学术

4. 刘伟吉,冯嘉豪,汪洋,祝效华,李枝林. 深层页岩气水平井钻柱动态摩阻扭矩分析. 石油机械. 2023(08): 18-25 .  百度学术

百度学术

5. 姜磊. 大盘区瓦斯抽采超长定向钻孔施工关键技术措施. 煤炭技术. 2023(10): 137-141 .  百度学术

百度学术

6. 许超,姜磊,陈盼,张迪. 煤矿井下大盘区瓦斯抽采定向钻进技术与装备. 煤田地质与勘探. 2022(04): 147-152 .  本站查看

本站查看

其他类型引用(3)

下载:

下载: