The concealed small faults detection based on gas drainage boreholes along and cross the coal seam

-

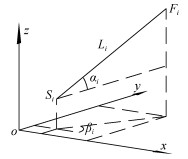

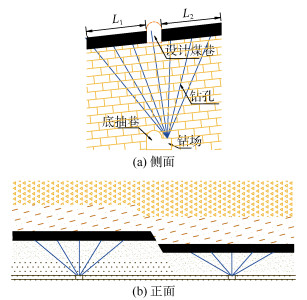

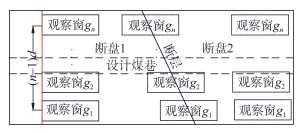

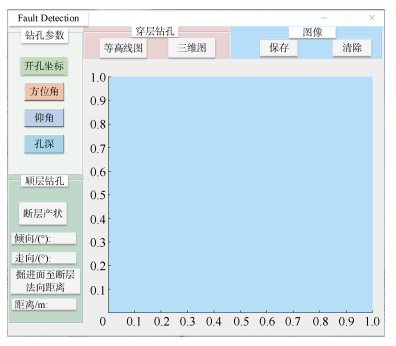

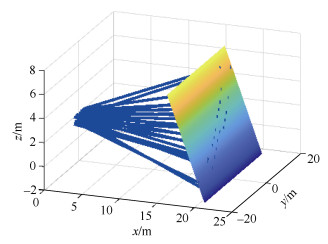

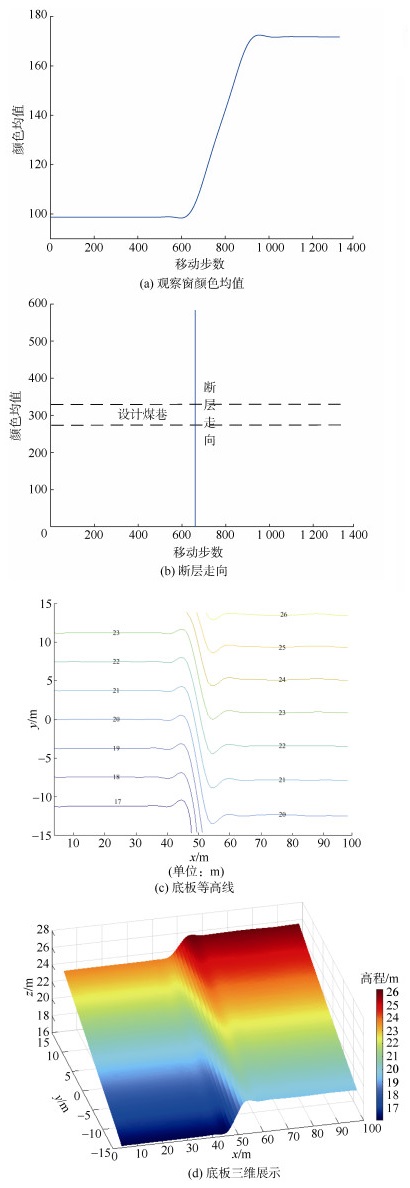

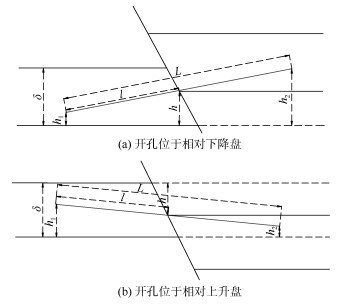

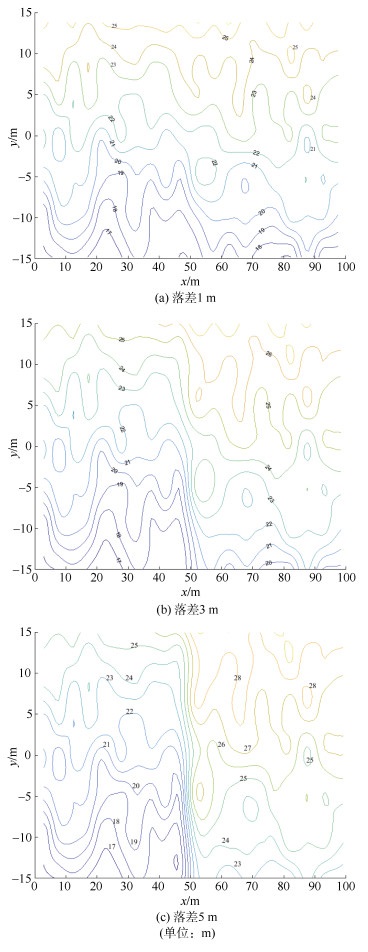

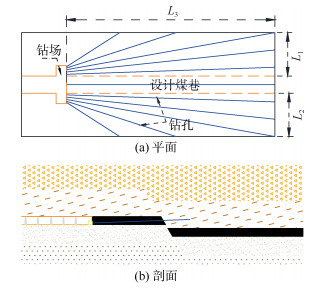

摘要: 断层对煤与瓦斯突出危险性影响较大,准确探测断层位置对预防灾害具有重要作用。目前,煤矿进行采掘作业之前,施工大量瓦斯抽采钻孔,但是这些钻孔包含的地质信息未被充分重视,为此,提出了利用穿层、顺层瓦斯抽采钻孔群探测隐伏断层的技术方法。通过建立瓦斯抽采钻孔探测断层的数学模型,计算断层面、煤层底板的三维坐标,通过绘制煤层底板等高线图及其三维图,确定断层位置、落差、产状和断层性质等基础参数。基于Matlab软件的图形用户界面(GUI)工具,编写了瓦斯抽采钻孔探测断层的软件,实现了断层信息的可视化,为准确判识断层提供了技术平台。通过钻孔定位、模型计算、图像处理、断层识别等综合技术方法,成功实现了利用瓦斯抽采钻孔进行隐伏小断层探测。Abstract: The faults have great influence on coal and gas outburst disasters, and accurate detection of faults location is very important to prevent such disasters. At present, large number of gas drainage boreholes were drilled in coal mines, but the geological information contained in these boreholes is not fully paid attention to, thus the method to detect concealed faults by gas-drainage boreholes was proposed. In this paper, by establishing a mathematical model for fault detection based on gas drainage drilling, a three-dimensional coordinate of fault planes and coal seam floors is calculated, and basic parameters such as fault location, drop, attitude and fault properties are determined by drawing contour maps of coal seam floors and their three-dimensional maps. Based on the graphical user interface(GUI) of Matlab, a software for fault detection by gas drainage drilling is designed to visualize fault information and provide a technical platform for accurate fault identification. The technical method of detecting small hidden faults by gas drainage drilling is successfully implemented through a combination of drilling location, model calculation, image processing and fault identification.

-

Keywords:

- geological exploration /

- small fault /

- coal roadway /

- gas drainage /

- drilling borehole

-

-

表 1 顺层钻孔施工参数

Table 1 The parameters of boreholes along the coal seam

钻孔编号 开孔坐标/m 方位角/(°) 仰角/(°) 设计孔深/m 施工孔深/m x y z 1 0 2.8 1.5 55.6 10.5 24.7 20.9 2 0 2.6 2.0 66.4 11.9 33.5 18.6 3 0 2.4 1.5 70.6 6.0 42.7 19.2 4 0 2.2 2.0 74.9 7.6 52.3 18.2 5 0 2.0 1.5 78.6 3.6 61.3 18.9 6 0 1.8 2.0 81.4 5.3 60.9 18.2 7 0 1.6 1.5 82.7 2.4 60.5 18.8 8 0 1.4 2.0 85.5 4.1 60.3 18.2 9 0 1.2 1.5 86.9 1.2 60.1 18.9 10 0 1.0 2.0 89.8 2.9 60.1 18.3 11 0 0 2.0 90.4 –0.5 60.0 18.9 12 0 –1.0 1.5 92.5 2.1 60.1 18.8 13 0 –1.2 2.0 93.8 –1.8 60.2 19.2 14 0 –1.4 1.5 96.7 0.9 60.4 19.1 15 0 –1.6 2.0 98.0 –3.0 60.7 19.6 16 0 –1.8 1.5 100.8 –0.4 61.1 19.6 17 0 –2.0 2.0 102.1 –4.1 61.5 20.2 18 0 –2.2 1.5 127.0 –3.8 25.1 25.2 19 0 –2.4 2.0 117.6 –8.6 34.2 23.8 20 0 –2.6 1.5 110.2 –2.2 42.6 20.9 21 0 –2.8 2.0 107.0 –5.6 52.5 21.0 -

[1] 杜文凤, 彭苏萍, 师素珍. 深部隐伏构造特征地震解释及对煤矿安全的影响[J]. 煤炭学报, 2015, 40(3): 640-645. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201503025.htm DU Wenfeng, PENG Suping, SHI Suzhen. Seismic interpretation of deep buried structure characteristics and its influence on coal mine safety[J]. Journal of China Coal Society, 2015, 40(3): 640-645. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201503025.htm

[2] 李胜, 祁晓鑫, 李军文. 瑞利波技术超前探测掘进工作面构造异常[J]. 煤田地质与勘探, 2015, 43(1): 96-99. DOI: 10.3969/j.issn.1001-1986.2015.01.020 LI Sheng, QI Xiaoxin, LI Junwen. Advanced detection technology of Rayleigh wave for detection of abnormal geological structure in excavation face[J]. Coal Geology & Exploration, 2015, 43(1): 96-99. DOI: 10.3969/j.issn.1001-1986.2015.01.020

[3] 姬广忠, 程建远, 胡继武, 等. 槽波衰减系数成像方法及其应用[J]. 煤炭学报, 2014, 39(增刊2): 471-475. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2014S2029.htm JI Guangzhong, CHENG Jianyuan, HU Jiwu, et al. In-seam wave imaging using attenuation coefficient: Method and application[J]. Journal of China Coal Society, 2014, 39(Sup. 2): 471-475. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB2014S2029.htm

[4] 乐勇, 王伟, 申青春, 等. 槽波地震勘探技术在工作面小构造探测中的应用[J]. 煤田地质与勘探, 2013, 41(4): 74-77. DOI: 10.3969/j.issn.1001-1986.2013.04.018 LE Yong, WANG Wei, SHEN Qingchun, et al. Application of ISS in detection of small structures in working face[J]. Coal Geology & Exploration, 2013, 41(4): 74-77. DOI: 10.3969/j.issn.1001-1986.2013.04.018

[5] 梁庆华, 吴燕清, 宋劲, 等. 探地雷达在煤巷掘进中超前探测试验研究[J]. 煤炭科学技术, 2014, 42(5): 91-94. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201405028.htm LIANG Qinghua, WU Yanqing, SONG Jin, et al. Experimental study on advanced detection in coal seam driving roadway by ground penetrating radar[J]. Coal Science and Technology, 2014, 42(5): 91-94. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201405028.htm

[6] 刘最亮, 王鹤宇. 大定源瞬变电磁法在含水断层构造探测中的应用[J]. 煤田地质与勘探, 2012, 40(5): 67-70. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201205021.htm LIU Zuiliang, WANG Heyu. Application of transient electromagnetic method in the detection of water bearing fault structure[J]. Coal Geology & Exploration, 2012, 40(5): 67-70. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201205021.htm

[7] 杨华忠, 胡雄武, 张平松. 井巷直流电法三维超前探测数值模拟[J]. 工程地球物理学报, 2013, 10(2): 200-204. DOI: 10.3969/j.issn.1672-7940.2013.02.015 YANG Huazhong, HU Xiongwu, ZHANG Pingsong. Numerical Simulation of advanced detection by direct current direct current electrical method in tunnel[J]. Chinese Journal of Engineering Geophysics, 2013, 10(2): 200-204. DOI: 10.3969/j.issn.1672-7940.2013.02.015

[8] 韩德品, 李丹, 程久龙, 等. 超前探测灾害性含导水地质构造的直流电法[J]. 煤炭学报, 2010, 35(4): 635-639. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201004025.htm HAN Depin, LI Dan, CHENG Jiulong, et al. DC method of advanced detecting disastrous water-conducting or water-bearing geological structures along same layer[J]. Journal of China Coal Society, 2010, 35(4): 635-639. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201004025.htm

[9] 程久龙, 李飞, 彭苏萍, 等. 矿井巷道地球物理方法超前探测研究进展与展望[J]. 煤炭学报, 2014, 39(8): 1742-1750. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201408048.htm CHENG Jiulong, LI Fei, PENG Suping, et al. Research progress and development direction on advanced detection in mine roadway working face using geophysical methods[J]. Journal of China Coal Society, 2014, 39(8): 1742-1750. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201408048.htm

[10] 刘盛东, 刘静, 岳建华. 中国矿井物探技术发展现状和关键问题[J]. 煤炭学报, 2014, 39(1): 19-25. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201401004.htm LIU Shengdong, LIU Jing, YUE Jianhua. Development status and key problems of Chinese mining geophysical technology[J]. Journal of China Coal Society, 2014, 39(1): 19-25. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201401004.htm

[11] 国家煤矿安全监察局. 《防治煤与瓦斯突出规定》读本[M]. 北京: 煤炭工业出版社, 2009. State Administration of Work Safety. Provisions of prevention of coal and gas outburst[M]. Beijing: China Coal Industry Publishing House, 2009.

[12] 崔洪庆, 薛洪来. 利用瓦斯抽采钻孔探测煤层小断层[J]. 煤炭科学技术, 2014, 42(2): 34-37. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201402011.htm CUI Hongqing, XUE Honglai. Detection on small faults in coal seam based on gas drainage boreholes[J]. Coal Science and Technology, 2014, 42(2): 34-37. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201402011.htm

[13] 薛洪来, 崔洪庆. 基于瓦斯抽采钻孔的石门揭煤区域煤层地质精查方法[J]. 安全与环境学报, 2014, 14(6): 60-64. https://www.cnki.com.cn/Article/CJFDTOTAL-AQHJ201406018.htm XUE Honglai, CUI Hongqing. Meticulous geo-exploration and scrutiny approach based on the gas drainage boring hole in rock cross-cut coal uncovering[J]. Journal of Safety and Environment, 2014, 14(6): 60-64. https://www.cnki.com.cn/Article/CJFDTOTAL-AQHJ201406018.htm

[14] 石智军, 姚宁平, 叶根飞. 煤矿井下瓦斯抽采钻孔施工技术与装备[J]. 煤炭科学技术, 2009, 37(7): 1-4. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ200907000.htm SHI Zhijun, YAO Ningping, YE Genfei. Construction technology and equipment for gas drainage borehole drilling in underground coal mine[J]. Coal Science and Technology, 2009, 37(7): 1-4. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ200907000.htm

[15] 李泉新, 石智军, 史海岐. 煤矿井下定向钻进工艺技术的应用[J]. 煤田地质与勘探, 2014, 42(2): 85-88. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201402020.htm LI Quanxin, SHI Zhijun, SHI Haiqi. The application of directional drilling technology in coal mine[J]. Coal Geology & Exploration, 2014, 42(2): 85-88. https://www.cnki.com.cn/Article/CJFDTOTAL-MDKT201402020.htm

[16] 崔洪庆, 姚念岗. 不渗透断层与瓦斯灾害防治[J]. 煤炭学报, 2010, 35(9): 1486-1489. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201009019.htm CUI Hongqing, YAO Niangang. Impermeable faults and prevention of gas hazards[J]. Journal of China Coal Society, 2010, 35(9): 1486-1489. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201009019.htm

[17] 刘咸卫, 曹运兴, 刘瑞, 等. 正断层两盘的瓦斯突出分布特征及其地质成因浅析[J]. 煤炭学报, 2000, 25(6): 571-575. DOI: 10.3321/j.issn:0253-9993.2000.06.003 LIU Xianwei, CAO Yunxing, LIU Rui, et al. Analysis on distribution features of gas outburst from two walls of normal fault and geological origin[J]. Journal of China Coal Society, 2000, 25(6): 571-575. DOI: 10.3321/j.issn:0253-9993.2000.06.003

-

期刊类型引用(7)

1. 王博睿,张远航. 含隐伏断层底板原生缺陷致灾前兆研究. 煤炭技术. 2025(01): 216-220 .  百度学术

百度学术

2. 徐宏阳,翟成,夏济根,孙勇,董兴蒙,来永帅,余旭,徐吉钊,丛钰洲. 基于穿层钻孔声波远探测有限元方法的煤岩界面成像. 煤田地质与勘探. 2024(03): 118-129 .  本站查看

本站查看

3. 司佳鹏,刘艳领,李钰强,张常亮,姜建伟. 基于多种传统方式融合的断层识别. 西北水电. 2024(04): 135-141 .  百度学术

百度学术

4. 冯钰,朱亚飞. 断层群顺层瓦斯钻孔全覆盖施工方法. 山东煤炭科技. 2024(09): 82-86+92 .  百度学术

百度学术

5. 吴秀山,童仁园,李青. 近海浅层气甲烷浓度原位在线监测方法与仪器研究. 传感技术学报. 2023(01): 153-158 .  百度学术

百度学术

6. 冯雅杰,文广超,吴冰洁,胡祖栋. 基于空间统计的采煤工作面内断层识别方法. 煤田地质与勘探. 2023(10): 19-26 .  本站查看

本站查看

7. 郑亚迪,殷伟伟,李峰,丁学文,赵向佳,霍魁,任力伟. 微动探测在煤矿断层勘查中的应用. 山西地震. 2022(03): 47-51 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: