Parameter optimization for multistage horizontal well fracturing based on multi-cluster perforation for deep coal measure gas: A case study of the Jurassic Baijiahai area in the Junggar Basin

-

摘要:目的

水平井多簇射孔分段压裂已成为深层煤系气效益开发的有效途径之一。然而,深层煤特有的岩石力学性质、储层滤失特性和微裂缝发育特征与非常规页岩、致密砂岩及浅层煤等差异显著,现有压裂经验无法照搬,需要开展针对性压裂参数优化研究。

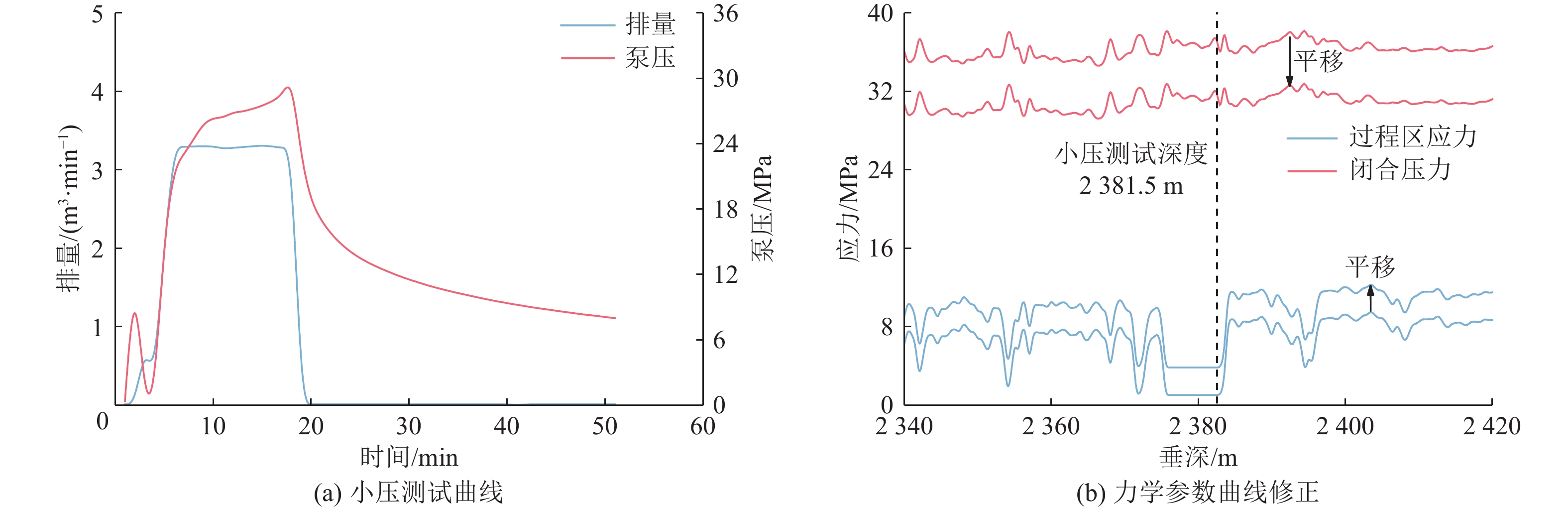

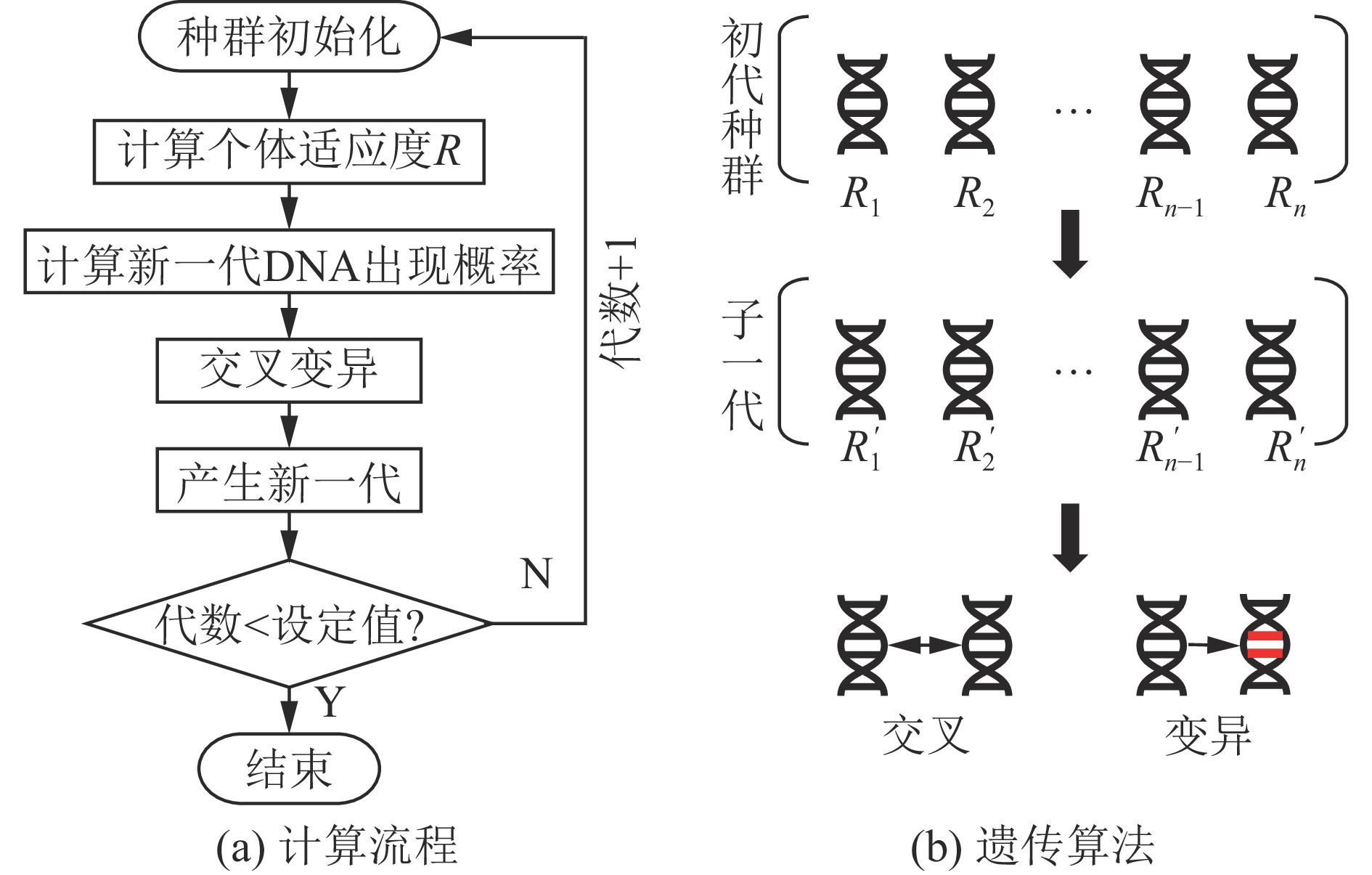

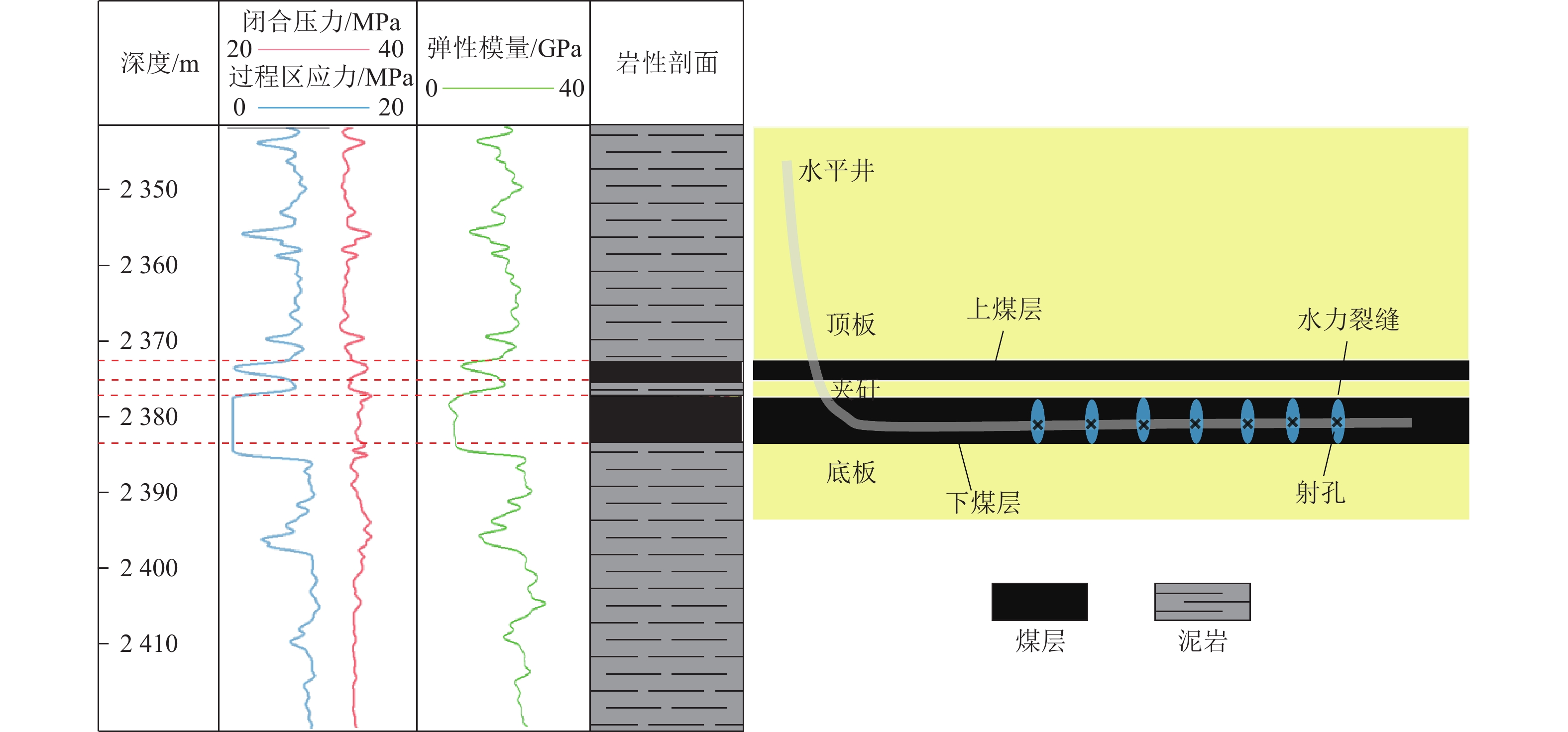

方法以准噶尔盆地白家海地区深层煤系气储层为对象,建立了顶底板−夹矸−煤复合地质构造的水平井多簇射孔分段压裂模型,模型考虑煤的层理、割理对裂缝扩展和储层滤失的影响,利用小压测试数据对储层关键参数进行修正,综合表征深层煤系气储层的物理力学特性。建立了多目标条件下最优泵注参数组合设计方法,获微地震监测数据验证。

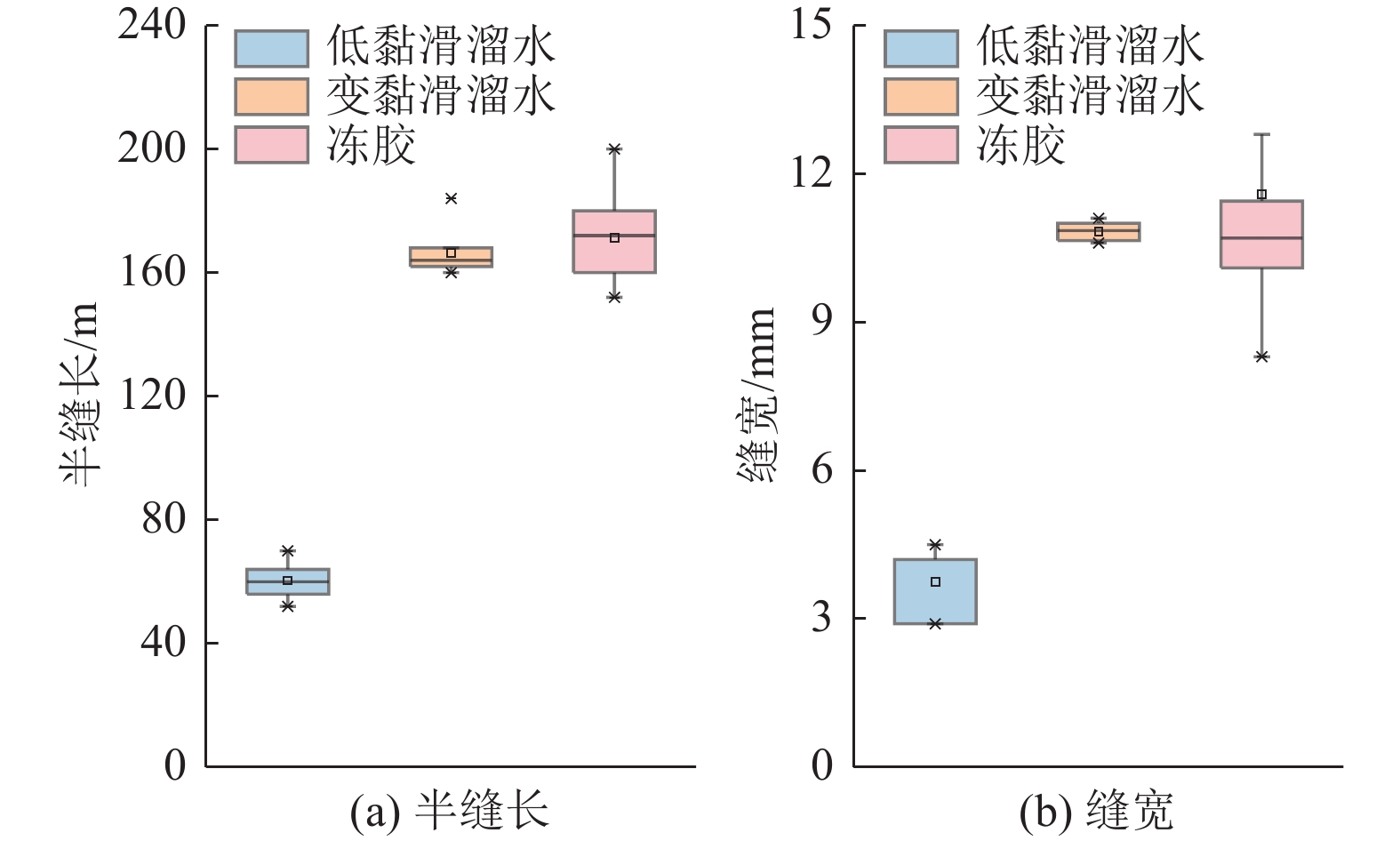

结果和结论结果表明,变黏滑溜水体系相较低黏滑溜水体系、冻胶体系更适合深层煤系气压裂,兼具缝长、缝宽和裂缝均衡性的优势;获得目标区块压裂最优参数组合:3簇+簇间距19 m+每米加砂量2.8 m3+排量16 m3/min。试验井微地震监测结果表明,优化后裂缝半长和改造体积分别增加了57.2%和12.3%。对隔层遮挡严重的深层煤系储层,裂缝在缝高方向通常难以突破,因此,需要提高缝长和缝宽。增大砂量和排量可以显著提高缝长和缝宽,是提升改造效果的关键。

Abstract:ObjectiveThe multistage horizontal well fracturing based on multi-cluster perforation has emerged as an effective approach for the efficient production of deep coal-measure gas (CMG). However, deep coals feature unique rock mechanical properties, fluid loss characteristics of reservoirs, and microfracture developmental characteristics, which differ significantly from those of unconventional shales, tight sandstones, and shallow coals. As a result, existing fracturing experience cannot be directly applied, highlighting the investigation of fracturing parameter optimization tailored for deep CMG production.

MethodsFocusing on deep CMG reservoirs in the Baijiahai area within the Junggar Basin, this study constructed a model of multistage horizontal well fracturing based on multi-cluster perforation for a composite geological structure composed of a roof, a floor, gangue, and coals. This model considered the effects of bedding and cleats in coals on fracture propagation and the fluid loss of reservoirs. Furthermore, critical reservoir parameters in the model were corrected using data derived from mini-fracture tests. These contributed to an elevated accuracy of the model, which, therefore, allowed for the comprehensive characterization of the physical and mechanical properties of deep CMG reservoirs. The optimal fracturing fluid system for deep CMG reservoirs was selected through numerical simulation, and a method for designing the optimal pumping parameter combination under multiple objectives was developed. Finally, the simulation results were verified using microseismic data.

Results and ConclusionsThe results indicate that compared to the low-viscosity slickwater and gelled systems, the variable-viscosity slickwater system was more suitable for the fracturing of deep CMG reservoirs while also enjoying advantages in terms of fracture length, fracture width, and fracture equilibrium. The optimal parameter combination for fracturing in the target block was determined to include three clusters per stage, a cluster spacing of 19 m, a proppant volume of 2.8 m3 per meter, and an injection rate of fracturing fluids of 16 m3/min. The microseismic monitoring results of test wells demonstrate that after parameter optimization, the fracture half-length and stimulated reservoir volume (SRV) increased by 57.2 % and 12.3 %, respectively. A comparison of fracture geometries under varying fracturing parameter combinations reveals that in deep CMG reservoirs subjected to severe blocking by barriers, fractures typically cannot propagate in their height directions, necessitating increasing their lengths and widths. Increasing the proppant volume and the injection rate of fracturing fluids can significantly increase fracture lengths and widths, playing a key role in improving reservoir fracturing performance.

-

-

表 1 压裂模拟泵注程序

Table 1 Pumping schemes for hydraulic fracturing simulation

压裂液体系 泵注阶段 压裂液类型 排量/(m3·min−1) 液量/m3 支撑剂类型 砂质量分数/(kg·m−3) 低黏滑溜水 前置液 低黏滑溜水 12 240 70/140石英砂 100 携砂液 600 40/70、20/40 200 顶替液 60 — — 变黏滑溜水 前置液 高黏转低黏 240 70/140石英砂 100 携砂液 高黏滑溜水 600 40/70、20/40 200 顶替液 低黏滑溜水 60 — — 冻胶 前置液 冻胶 240 70/140石英砂 100 携砂液 600 40/70、20/40 200 顶替液 60 — — 注:70/140、40/70、20/40表示石英砂目数,对应的粒径分别为0.212 mm/0.106 mm、0.425 mm/0.212 mm、0.850 mm/0.425 mm。顶替液阶段不加砂,用“—”表示。 表 2 多簇射孔压裂模拟参数组合

Table 2 Parameter combinations for fracturing simulation based on multi-cluster perforation

簇数 簇间距/m 每米加砂量/m3 排量/(m3·min−1) 3 15 1.84 12 4 20 2.30 14 5 25 2.80 16 表 3 各目标参数所占权重

Table 3 Weights of various target parameters

权重类型 裂缝均衡性 平均半缝长 缝宽 客观 0.70 0.21 0.09 主观 0.16 0.54 0.30 组合 0.40 0.40 0.20 表 4 各组合类型参数取值

Table 4 Parameter values for each combination type

组合类型 簇数 簇间距/m 每米加砂量/m3 排量/(m3·min−1) 1 5 19 2.80 16 2 3 25 2.80 16 3 3 19 1.84 16 4 3 19 2.80 12 5 3 19 2.80 16 表 5 X区块A、B井优化前后对比

Table 5 Comparison of wells A and B in block X before and after parameter optimization

类型

(井号)平均半

缝长/m裂缝

均衡系数单段微地震

事件数总改造体积/

106m3优化前(A井) 138 0.88 62 9.79 优化后(B井) 217 0.89 87 10.99 -

[1] 李斌,杨帆,张红杰,等. 神府区块深部煤层气高效开发技术研究[J]. 煤田地质与勘探,2024,52(8):57−68. DOI: 10.12363/issn.1001-1986.24.01.0082 LI Bin,YANG Fan,ZHANG Hongjie,et al. Technology for efficient production of deep coalbed methane in the Shenfu Block[J]. Coal Geology & Exploration,2024,52(8):57−68. DOI: 10.12363/issn.1001-1986.24.01.0082

[2] 王鹏,李斌,王昆剑,等. 神府区块深部煤层气钻完井关键技术及应用[J]. 煤田地质与勘探,2024,52(8):44−56. WANG Peng,LI Bin,WANG Kunjian,et al. Critical drilling and completion techniques for deep coalbed methane in the Shenfu Block and their applications[J]. Coal Geology & Exploration,2024,52(8):44−56.

[3] 夏玉磊,屈海清,端木晓亮,等. 山西吉县–大宁区域煤层气压裂浅析[J]. 中国石油和化工标准与质量,2013,33(17):139. [4] 刘川庆,朱卫平,夏飞,等. 鄂尔多斯盆地大宁–吉县区块煤层气水平井分段压裂实践[J]. 天然气工业,2018,38(增刊1):112−117. [5] 徐凤银,聂志宏,孙伟,等. 大宁–吉县区块深部煤层气高效开发理论技术体系[J/OL]. 煤炭学报,2023:1–17 [2023-11-22]. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=MTXB20231120003&;dbname=CJFD&dbcode=CJFQ. XU Fengyin,NIE Zhihong,SUN Wei,et al. Theoretical and technological system for highly efficient development of deep coalbed methane in Daning–Jixian Block[J/OL]. Journal of China Coal Society,2023:1–17 [2023-11-22]. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=MTXB20231120003&;dbname=CJFD&dbcode=CJFQ.

[6] 杨帆,李斌,王昆剑,等. 深部煤层气水平井大规模极限体积压裂技术:以鄂尔多斯盆地东缘临兴区块为例[J]. 石油勘探与开发,2024,51(2):389−398. DOI: 10.11698/PED.20230513 YANG Fan,LI Bin,WANG Kunjian,et al. Extreme massive hydraulic fracturing in deep coalbed methane horizontal wells:A case study of the Linxing Block,eastern Ordos Basin,NW China[J]. Petroleum Exploration and Development,2024,51(2):389−398. DOI: 10.11698/PED.20230513

[7] 张聪,李梦溪,胡秋嘉,等. 沁水盆地南部中深部煤层气储层特征及开发技术对策[J]. 煤田地质与勘探,2024,52(2):122−133. ZHANG Cong,LI Mengxi,HU Qiujia,et al. Moderately deep coalbed methane reservoirs in the southern Qinshui Basin:Characteristics and technical strategies for exploitation[J]. Coal Geology & Exploration,2024,52(2):122−133.

[8] 薛海飞,朱光辉,王伟,等. 沁水盆地柿庄区块煤层气井压裂增产效果关键影响因素分析与实践[J]. 煤田地质与勘探,2019,47(4):76−81. XUE Haifei,ZHU Guanghui,WANG Wei,et al. Analysis and application of key influencing factors of CBM well fracturing effects in Shizhuang area,Qinshui Basin[J]. Coal Geology & Exploration,2019,47(4):76−81.

[9] 李德旗,陈钊,邹清腾,等. 四川盆地渝西大安区块龙潭组深层煤岩气压裂技术探索[J]. 天然气工业,2024,44(10):150−158. LI Deqi,CHEN Zhao,ZOU Qingteng,et al. Fracturing technologies for Longtan Formation deep coal–rock gas in Da’an Block of western Chongqing,Sichuan Basin[J]. Natural Gas Industry,2024,44(10):150−158.

[10] 彭文利,薛冽,马效杰. 准噶尔盆地白家海地区深部煤储层测井解释参数构建[C]//2020年全国煤层气学术研讨会论文集. 北京,2020. [11] 张涛,王晓惠,毛新军,等. 白家海地区西山窑组煤层储层压裂改造难点和对策[J]. 新疆石油天然气,2014,10(2):65−67. DOI: 10.3969/j.issn.1673-2677.2014.02.014 ZHANG Tao,WANG Xiaohui,MAO Xinjun,et al. Difficulties and countermeasures of propped fracturing in the coalbed of Xishanyao Formation in Baijiahai[J]. Xinjiang Oil & Gas,2014,10(2):65−67. DOI: 10.3969/j.issn.1673-2677.2014.02.014

[12] 倪方杰. 白家海凸起深层煤层气压裂试气实践与认识[J]. 江汉石油职工大学学报,2019,32(5):36−38. NI Fangjie. Practice and understanding of deep CBM fracturing gas testing in Baijiahai uplift[J]. Journal of Jianghan Petroleum University of Staff and Workers,2019,32(5):36−38.

[13] 徐亚军,朱书仪,王渊,等. 基于地面微地震监测下深层煤层气改造认识[C]//2022油气田勘探与开发国际会议集I. 西安,2022. [14] 兰浩,杨兆彪,仇鹏,等. 新疆准噶尔盆地白家海凸起深部煤层气勘探开发进展及启示[J]. 煤田地质与勘探,2024,52(2):13−22. LAN Hao,YANG Zhaobiao,QIU Peng,et al. Exploration and exploitation of deep coalbed methane in the Baijiahai uplift,Junggar Basin:Progress and its implications[J]. Coal Geology & Exploration,2024,52(2):13−22.

[15] 李雪彬,金力新,陈超峰,等. 深层煤岩气水平井压裂关键技术:以准噶尔盆地白家海地区侏罗系为例[J]. 油气藏评价与开发,2024,14(4):629−637. LI Xuebin,JIN Lixin,CHEN Chaofeng,et al. Key technologies of horizontal well fracturing for deep coal–rock gas:A case study of Jurassic in Baijiahai area,Junggar Basin[J]. Petroleum Reservoir Evaluation and Development,2024,14(4):629−637.

[16] 李国欣,张水昌,何海清,等. 煤岩气:概念、内涵与分类标准[J]. 石油勘探与开发,2024,51(4):783−795. LI Guoxin,ZHANG Shuichang,HE Haiqing,et al. Coal–rock gas:Concept,connotation and classification criteria[J]. Petroleum Exploration and Development,2024,51(4):783−795.

[17] 闫霞,熊先钺,李曙光,等. 深层煤岩气水平井各段产出贡献及其主控因素:以鄂尔多斯盆地东缘大宁–吉县区块为例[J]. 天然气工业,2024,44(10):80−92. YAN Xia,XIONG Xianyue,LI Shuguang,et al. Production contributions of deep CBM horizontal well sections and their controlling factors:A case study of Daning–Jixian area,eastern Ordos Basin[J]. Natural Gas Industry,2024,44(10):80−92.

[18] BARREE R D. A practical numerical simulator for three–dimensional fracture propagation in heterogeneous media[C]//SPE Reservoir Simulation Symposium. San Francisco:Society of Petroleum Engineers,1983.

[19] 冯利娟,郭大立,曾晓慧,等. 煤层应力敏感性及其对压裂液滤失的影响[J]. 煤田地质与勘探,2010,38(2):14−17. FENG Lijuan,GUO Dali,ZENG Xiaohui,et al. Experimental study on the stress sensitivity of coal and its impact on the filtration of the fracturing fluid[J]. Coal Geology & Exploration,2010,38(2):14−17.

[20] BAŽANT Z P,PLANAS J. Fracture and size effect in concrete and other Quasibrittle materials[M]. Boca Raton:CRC Press,1998.

[21] LI Yang. Theoretical and numerical analysis of stress shadow effect between echelon fractures in hydraulic fracturing of double vertical wells[J]. Engineering Fracture Mechanics,2023,284:109238. DOI: 10.1016/j.engfracmech.2023.109238

[22] NAGEL N,ZHANG F,SANCHEZ–NAGEL M,et al. Stress shadow evaluations for completion design in unconventional plays[C]//SPE Unconventional Resources Conference Canada. Calgary:SPE,2013.

[23] LI Minghui,LYU Wenjing,LIU Jinjun,et al. Effect of perforation friction on 3D in–stage multiple fracture propagation:A numerical study[J]. Engineering Fracture Mechanics,2022,267:108415. DOI: 10.1016/j.engfracmech.2022.108415

[24] 向文鑫,桑树勋,吴章利,等. 贵州省煤层气规划区块煤储层特征与有利区优选[J]. 煤田地质与勘探,2022,50(3):156−164. DOI: 10.12363/issn.1001-1986.21.12.0731 XIANG Wenxin,SANG Shuxun,WU Zhangli,et al. Characteristics of coal reservoirs and favorable areas classification and optimization of CBM planning blocks in Guizhou Province[J]. Coal Geology & Exploration,2022,50(3):156−164. DOI: 10.12363/issn.1001-1986.21.12.0731

[25] 赵耀,刘闯,刘振翼,等. 基于事故树–层次分析法的原油储罐泄漏风险识别[J]. 新疆石油天然气,2023,19(3):80−85. ZHAO Yao,LIU Chuang,LIU Zhenyi,et al. Indentification for leakage risks of crude oil tanks based on fault tree–analytic hierarchy process[J]. Xinjiang Oil & Gas,2023,19(3):80−85.

[26] HUDEBINE D,VERSTRAETE J J. Reconstruction of petroleum feedstocks by entropy maximization:Application to FCC gasolines[J]. Oil & Gas Science and Technology–Revue D’IFP Energies Nouvelles,2011,66(3):437−460.

[27] JAYNES E T. On the rationale of maximum–entropy methods[J]. Proceedings of the IEEE,1982,70(9):939−952. DOI: 10.1109/PROC.1982.12425

[28] MANNOR S,PELEG D,RUBINSTEIN R. The cross entropy method for classification[C]//The 22nd International Conference on Machine Learning. Bonn:ACM,2005.

[29] WRIGHT A H. Genetic algorithms for real parameter optimization[J]. Foundations of Genetic Algorithms,1991,1:205−218.

-

期刊类型引用(11)

1. 侯恩科,吴家镁,杨帆,张池. 基于鲸鱼优化算法-支持向量机判别模型的风化基岩富水性评价:以神府煤田张家峁煤矿为例. 科学技术与工程. 2025(01): 119-127 .  百度学术

百度学术

2. 王海. 隐伏火烧区烧变岩含水层水害治理技术研究. 煤田地质与勘探. 2024(05): 88-97 .  本站查看

本站查看

3. 詹林,潘剑伟,高健,张成丽,杨晨,钱伦,槐玉鹿. 基于局部加密的非结构化网格SNMR方法二维Occam反演研究. 地球物理学进展. 2024(03): 1089-1101 .  百度学术

百度学术

4. 薛建坤. 新疆阿艾矿区烧变岩水害特征及防治技术. 煤炭工程. 2024(11): 90-95 .  百度学术

百度学术

5. 侯恩科,杨斯亮,苗彦平,车晓阳,杨磊,路波,谢晓深,王慧德,党冰. 基于Bayes判别分析模型的风化基岩富水性预测. 煤矿安全. 2023(01): 180-187 .  百度学术

百度学术

6. 杨月堂. 煤矿顶部隔水性能多尺度评价. 能源与环保. 2023(02): 268-274 .  百度学术

百度学术

7. 郭飞,侯克鹏,钟晓勇,陈俊彬,汪云川. 核磁共振技术在露天矿山地下水勘查中的应用. 中国矿业. 2023(05): 146-152+159 .  百度学术

百度学术

8. 黄忠正,赵宝峰. 复合砂岩含水层下掘进巷道顶板富水异常区探查技术. 煤炭技术. 2023(07): 108-111 .  百度学术

百度学术

9. 郭源. 地空电磁—核磁共振联测方法在地层富水性探测中的应用与研究. 山西煤炭. 2023(02): 89-95 .  百度学术

百度学术

10. 吕振猛,孟凡贞,吕文茂,李梁宁. 改进的富水性预测评价方法. 煤炭技术. 2023(09): 152-155 .  百度学术

百度学术

11. 赵宝峰,黄忠正,宗伟琴. 宁东煤田鸳鸯湖矿区煤层顶板水害防控技术与应用宁东煤田鸳鸯湖矿区煤层顶板水害防控技术与应用. 中国煤炭. 2022(03): 23-29 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: