-

摘要:目的

深部煤层气产出与浅部存在较大差异,维持储层渗透性或尽可能减小渗透率损失、提高煤层气(CH4)解吸效率及准确预测扩散规律是深部煤层气产出面临的重要挑战,亟需通过技术创新和理论研究攻关突破。

方法对国内外煤储层渗透性、煤层气解吸、扩散等基础研究进展进行系统分析,结合深部煤储层排采阶段划分和不同阶段煤层气运移主要形式,总结深部煤层气产出机制及其影响因素。

结果和结论结果表明:(1) 深部煤层气产出划分为快速上产、相对稳产、缓慢递减和低产4个阶段。(2) 快速上产和相对稳产阶段,储层压力高,气源以游离气为主,甲烷运移以渗流为主导,其主要影响因素包括煤体结构、孔裂隙发育程度、储层温度、原位地应力、有效应力等。该阶段应尽可能地减少渗透率损失,避免直接压开碎粒煤、糜棱煤占比较大的储层;相对稳产阶段之后储层温度的增渗作用会随着滑脱效应的增强逐渐增大;控压降、慢排采有助于减缓储层渗透率衰减。尽管在低产气阶段原生裂隙及人工裂隙渗透率损失率均接近100%,但不可逆渗透率损失率却远远低于浅部煤储层,昭示着储层二次改造增产的可行性。(3) 快速上产至相对稳产阶段,吸附气开始缓慢解吸,扩大解吸范围、保证渗流通道,提高煤层气井产量是重中之重。深部煤储层中吸附气解吸较浅部所需时间长,临界解吸压力难以准确判断,解吸气体运移通道易压缩闭合,解吸范围受限。实验研究时应选用逐级降压解吸方式,可精准预估煤层气开采率;排采过程控制储层压力缓慢降低,可有效提升微孔中吸附气的解吸率。(4) 低产气阶段,产气以远井区域解吸气供给为主,甲烷扩散决定煤层气井产量,扩散系数的准确测试和动态模型构建是关键。扩散系数各向异性特征显著,目前CH4扩散模型对煤体结构的各向异性特征很少涉及;构建CH4时变扩散模型,需考虑煤体多尺度孔隙−显微裂隙中扩散模式;结合煤中多尺度孔裂隙精细表征实验与高温高压核磁成像分析技术,可表征不同孔径间CH4密度变化。本次系统的总结和认识,将理论与生产实践相结合,进一步完善深部煤层气开发理论基础。

Abstract:ObjectiveThe production characteristics of coalbed methane (CBM) from deep reservoirs differ significantly from those of CBM from shallow reservoirs. Key challenges in deep CBM production include maintaining reservoir permeability or minimizing permeability loss, enhancing CBM (CH4) desorption efficiency, and accurately predicting the laws of CH4 diffusion. There is an urgent need to overcome these challenges through technological innovation and theoretical research.

MethodsThis study systematically analyzed the advances in domestic and international research on coal reservoir permeability, CBM desorption, and CBM diffusion. By integrating the classification of production stages of deep coal reservoirs with the dominant CBM migration mechanisms of varying stages, this study summarized the mechanisms and influential factors of deep CBM production.

Results and ConclusionsThe results indicate that deep CBM production can be divided into four stages: rapid production increase, relatively stable production, gradual production decrease, and low production. During the former two stages, reservoir pressure remains high, free gas serves as a primary gas source, and methane migration is dominated by seepage flow. Key influential factors of both stages include coal structure, developmental degrees of pores and fractures, reservoir temperature, in situ stress, and effective stress. At these stages, minimizing permeability loss is crucial, and direct fracturing should be avoided in reservoirs with a high proportion of granulated and mylonite coals. After the relatively stable production phase, an increase in the reservoir permeability caused by reservoir temperature will gradually increase with an enhancement in the slip effect. Controlling pressure drop and slow production can help to slow down the decline of reservoir permeability. In the low-production stage, the permeability loss rate caused by both primary and artificially induced fractures approaches 100%. However, the irreversible permeability loss rate remains significantly lower than that of shallow coal reservoirs, suggesting the feasibility of secondary reservoir stimulation for increased production. From the rapid production increase stage to the relatively stable production stage, the adsorbed gas begins to undergo gradual desorption. In this case, the primary objectives are to expand the desorption range, ensure the opening of seepage channels, and enhance the productivity of CBM wells. Compared to shallow reservoirs, the desorption of adsorbed gas in deep coal reservoirs occurs over a prolonged period, with the critical desorption pressure being challenging to determine accurately. Furthermore, the pathways for gas migration are prone to be compressed and close, leading to a limited desorption range. To achieve precise estimations of CBM recovery rates, it is necessary to adopt a stepwise depressurization desorption method in experimental research. Specifically, achieving a gradual decrease in the reservoir pressure using control measures during CBM production can effectively enhance the desorption rate of adsorbed gas in micropores. In the low-production stage, gas production primarily originates from desorbed gas in remote well areas. In this stage, the production of CBM wells is determined by methane diffusion, with the accurate measurement of the diffusion coefficient and the development of dynamic diffusion models playing a crucial role. Notably, the diffusion coefficient exhibits significant anisotropy, yet current CH4 diffusion models seldom account for the anisotropic characteristics of coal structure. It is necessary to develop a time-varying CH4 diffusion model while considering the CH4 diffusion patterns across multi-scale pores and microfractures in coals. Experiments on the fine-scale characterization of multi-scale pores and fractures, combined with high-temperature with high-pressure nuclear magnetic resonance imaging, allow for the characterization of variations in CH4 density across different pore sizes. This systematic review integrates theories and practice, further laying a theoretical foundation for deep CBM recovery.

-

Keywords:

- coalbed methane (CBM) /

- permeability /

- desorption /

- diffusion /

- deep coal reservoir

-

深部煤层气是我国煤层气产业规模化发展的资源保障,是下一步天然气增储上产的重要接替领域。煤层气资源开发的“深部”不仅指埋藏深度,更是一种由地应力场、温度场、动力场和化学场共同控制的地层状态[1]。与浅部相比,深部煤层处在相对封闭的水文地质环境中[2],具有高地应力、高储层压力、高地层温度特点(“三高”),煤体表现出更强的工程力学强度[3]。前期煤储层物性研究表明:(1) 煤吸附甲烷体积随压力增大呈现出低压阶段的快速增长和较高压力下的缓慢增长[4],储层条件下的吸附气也随埋深增大呈现相同变化[5]。(2) 煤储层渗透率、储层条件下的试井渗透率随有效应力增大呈现出先急后缓的下降趋势[6]。(3) 煤孔隙随有效应力增大呈现出低应力条件下的急剧下降和较高应力条件下缓下降,甚至不变特点[7]。(4) 煤体极限强度(轴向破坏应力)、弹性模量等均随围压增大呈现出低围压条件下的变化快和较高围压下的变化慢特征[8]。以上昭示着深部煤层气的开发与浅部存在较大差异,亟需开展针对性的理论与技术攻关。

深部煤层气资源赋存状态复杂,可分为欠饱和湿煤系统、饱和—近饱和湿煤系统及过饱和干煤系统[9]。欠饱和湿煤系统开发过程需长期排水降压方能产气,产气阶段划分与中浅部煤层相似[10-12];饱和—近饱和湿煤系统储层能量高、气液比高,短期排水后见气投产;过饱和干煤系统与饱和—近饱和湿煤系统类似,但是储层不需排水降压,投产即高产,开发过程不产水或产水量低。在不考虑水的影响下,过饱和干煤系统与饱和—近饱和湿煤系统开采阶段可简化为:Ⅰ 快速上产阶段,游离气大量产出,甲烷运移以渗流为主导;Ⅱ 相对稳产阶段,游离气产量下降,吸附气开始解吸,补充气源;Ⅲ 缓慢递减阶段,游离气进一步产出,煤储层的压力进一步下降,吸附气解吸程度高,甲烷运移形式为扩散与渗流结合;Ⅳ 低产气阶段,储层有效应力大,裂隙通道闭合,产气量下降,但产气时间长,解吸气运移以扩散为主[13]。综上,深部煤层气的产出过程存在游离气渗流—吸附气解吸—解吸气扩散3个重要方面,面临的挑战则有:(1) 游离气产出阶段渗透率保持;(2) 游离气与吸附气解吸高效转换;(3) 解吸气扩散规律精准预测。

深部复杂的地质环境,“三高”条件耦合作用下煤储层物性特征随着排采的进行发生着阶段性动态演化,并深刻影响着煤层气的产出机制。笔者在前人研究的基础上,以深部过饱和干煤系统排采甲烷产出特点为例,围绕深部煤层气的产出的影响因素进行讨论,以夯实煤层CH4开发理论基础,为煤层气的开发工程提供理论指导。

1 CH4产出渗透率影响因素

在深部煤储层排采快速上产阶段及相对稳产阶段,储层压力高,大量的游离气及少量解吸气以渗流形式在相互连通的大孔和裂隙网络中运移,该阶段需尽可能地减少渗透率损失。储层渗透率的内在影响因素包括煤体结构、裂隙和孔隙等;外在影响因素包括储层温度、原位地应力、有效应力等;工程因素则主要为压降机制。

1.1 不同煤体结构对渗透率的影响

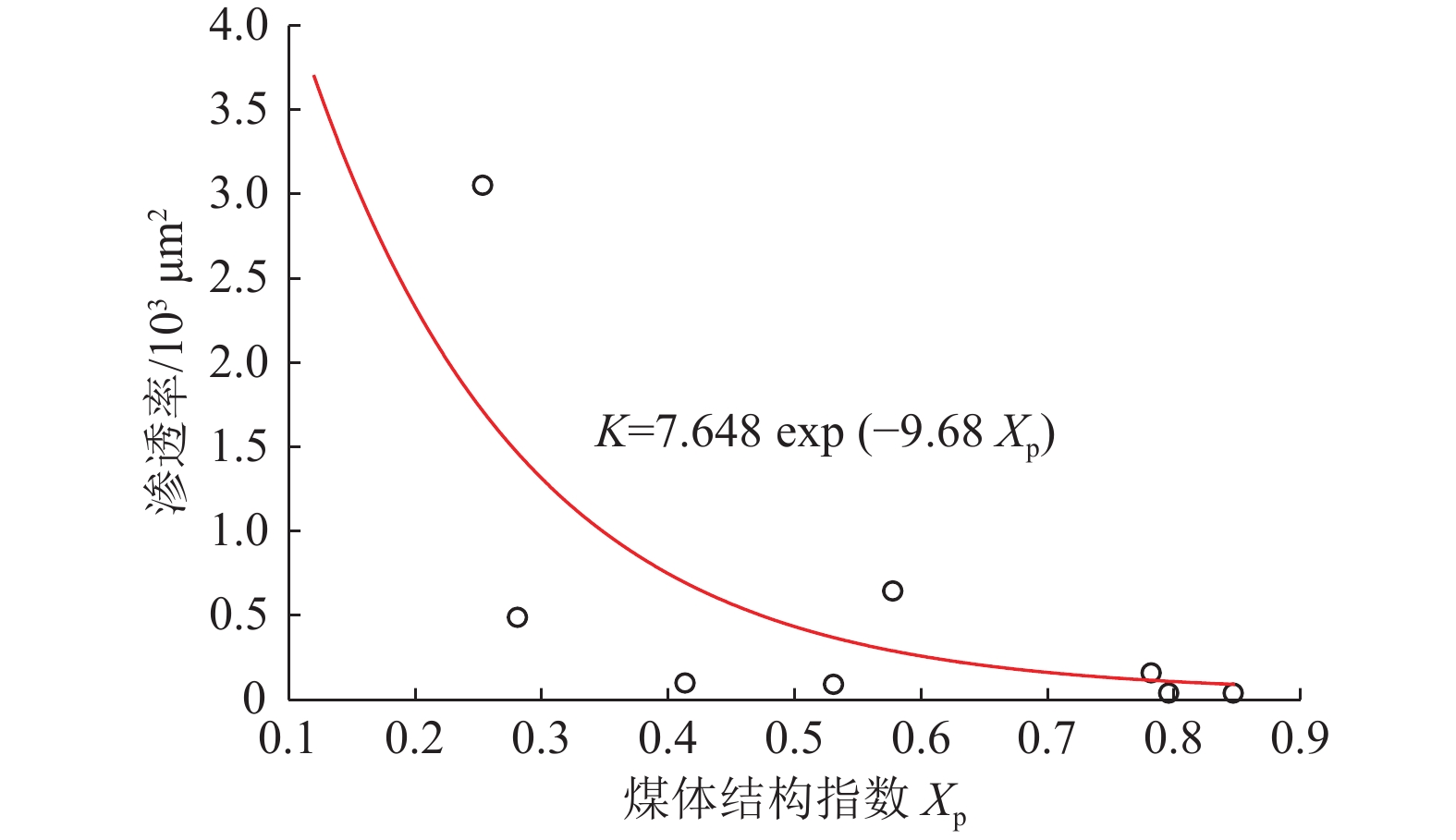

依据GB/T 30050—2013《煤体结构分类》,煤体结构可划分为原生结构煤、构造煤(碎裂煤、碎粒煤及糜棱煤)。实验测试表明,相同有效应力条件下,原生结构煤比构造煤的渗透率小两个数量级,但现场资料或井下瓦斯抽采数据中构造煤比原生结构煤渗透率小两个数量级[14]。构造变形强度对孔隙率、连通性、裂隙发育密度和开度的影响,整体呈现非线性变化,这是影响储层渗透率的关键因素。原生结构煤基质致密,适当的构造应力促进煤体脆性破碎,对微裂隙的改造表现为先延展裂隙长度,后扩展其开度,利于储层压裂改造[15]。强烈构造应力导致煤体结构严重破坏,糜棱煤、碎粒煤力学性质弱化、松软易碎[16],煤粉堵塞孔隙数量明显增加,裂隙趋于闭合;在开采过程中的急速卸压易导致煤层失稳破坏,不利于压裂改造[17]。因此,不同煤体结构储层渗透率符合糜棱煤<碎粒煤<原生结构煤<碎裂煤[18]。基于不同煤体结构的渗透率预测模型多为参数量化表征煤体结构变化,后根据实验测试或试井渗透率建立经验模型。如,郭红玉等[19]引入地质强度指标(GSI)表征煤体结构,当煤体的GSI指标接近52.7,渗透率急剧增长;远离52.7,无论增大或是减小,渗透率均急剧降低。吕闰生等[18]使用煤的坚固性系数f作为煤体结构分类的指标,建立了渗透率k与f的定量函数表达式。Fu Xuehai等[20]则依据淮南淮北煤田测试数据,建立了煤储层渗透率与煤体结构Xp之间的拟合函数模型(图1)。Xp为煤储层中碎粒煤和糜棱煤厚度之和占比。当Xp<20%时,储层渗透率较大,Xp>50%的储层渗透率则下降一个数量级。

我国构造煤普遍发育区域煤层气仍未实现规模化地面开采,深部煤层气开采难度更大,应避免直接压开碎粒煤、糜棱煤占比较大的储层。

1.2 裂隙发育特征对渗透率的影响

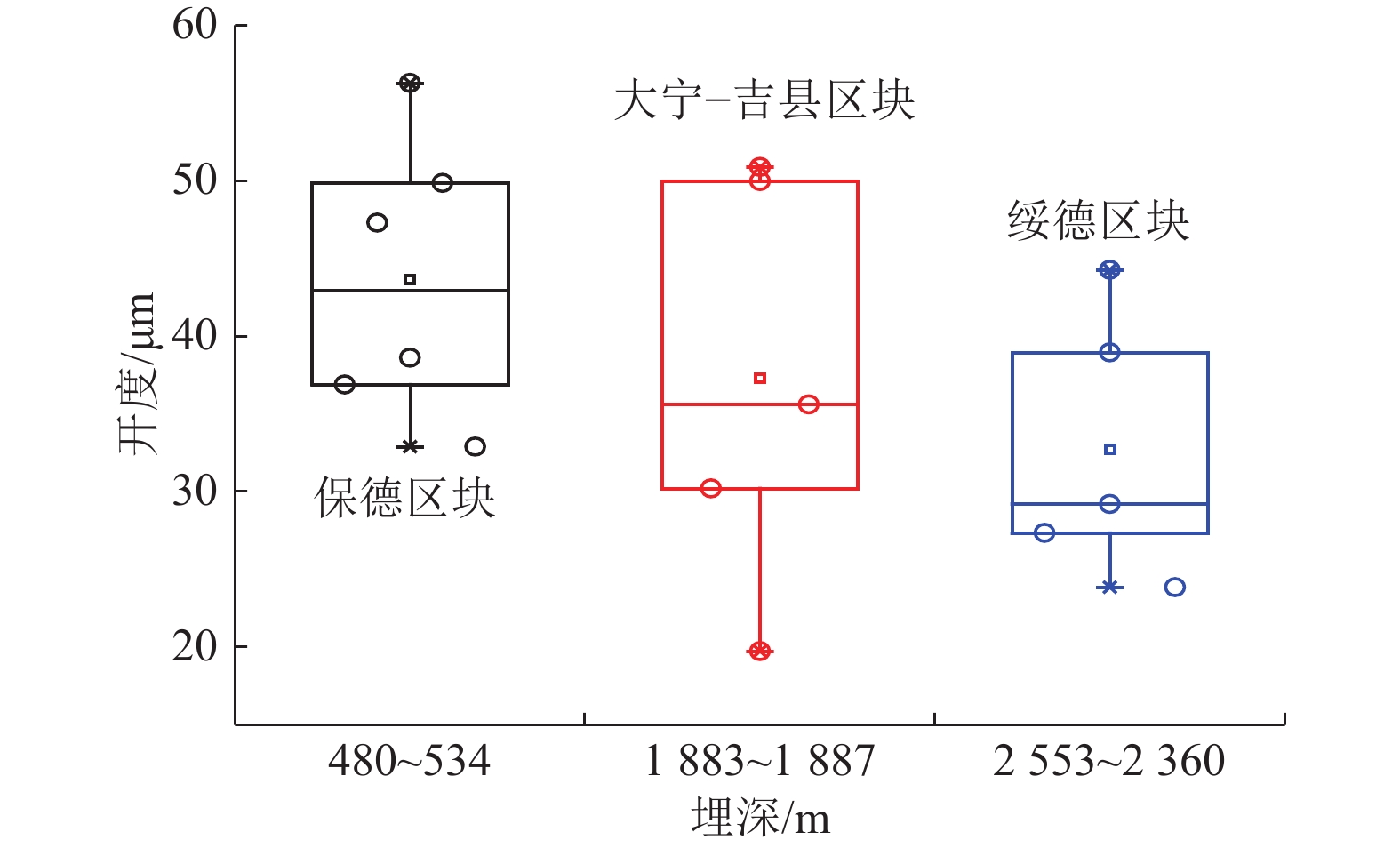

原位状态下深部煤储层裂隙的精确表征目前仍是难题,但其对掌握储层渗透率的变化至关重要。煤储层裂隙按照成因分类可分为内生裂隙(割理)及外生裂隙。目前对外生裂隙几何参数定量研究难以找到明显规律。对割理研究表明,渗透率随着割理的开度增加呈立方形式增加,在连通性不好的样品中,渗透率随割理长度的增加而增大;但割理的长度越长,其密度则越小,亦对渗透率起负面效应[21]。煤中割理开度较大时,在煤层气开采过程产水量同样会达到顶峰,如San Juan盆地煤中割理开度在3~40 μm时最有利于煤层气的开采[22]。笔者对新疆阜康矿区样品的近1.5万条割理进行统计分析表明,矿区西部煤矿样品中10~50 μm的割理数量占比平均21.81%,50~100 μm割理数量占比平均高达平均57.16%,大于100 μm割理数量平均占比20.68%;而矿区东部10~50 μm的割理数量占比平均高达68.46%,50~100 μm割理数量占比平均28.21%,大于100 μm割理数量平均占比3.65%[23]。在生产中,在矿区西部的CS井大部分井产水量高于产气量,而在东部的CSD井产气量则远远高于产水量[24]。鄂尔多斯盆地大宁−吉县区块、绥德区块部分深部煤裂隙开度较浅部明显减小[25](图2),但此方面对煤层气产出的影响仍需辩证看待。值得一提的是,浅部样品中裂隙面粗糙度与开度呈线性增长关系,粗糙度越大对渗透性的负面影响越大[26]。由此可知,在深部煤储层中割理面粗糙度也会随开度的减小而减小,从而对渗透影响减弱。

煤储层渗透率在不同方向上存在着很大的差异,尤其在平行层理方向和垂直层理方向上更为明显,二者渗透率比值可高达17∶1,造成差异的主要原因是裂隙的各向异性[27]。研究表明沁水盆地南部及鄂尔多斯盆地东缘的浅部煤储层裂隙各向异性演化特征随着煤级的增大呈先增大后减小现象[25];新疆阜康矿区煤储层平行层理与垂直层理方向的裂隙开度、裂隙密度以及裂隙连通性比值分别可达1.31∶1、1.61∶1和1.26∶1[23],面割理与端割理开度的比值最大可达5∶1[28],渗透率损失率垂直层理方向>平行层理方向,裂隙应力敏感性在平行层理方向>垂直层理方向。另外,煤的吸附/解吸诱导膨胀/收缩变形也同样表现出各向异性特征,具体表现为垂直层理方向>平行面割理方向>平行端割理方向,垂直层理方向膨胀量要比平行层理方向大30%~70%[29]。这种各向异性特征依赖于煤中的镜煤、亮煤及暗煤条带在垂直层理方向交错叠置的分布方式。不含条带煤膨胀各向异性弱,更符合各向同性膨胀[30]。目前,深部煤储层渗透率的各向异性特征鲜见报道,就已有资料可以看出最大、最小水平主应力随着埋深变化快慢存在显著差异,煤储层渗透率是否因“三高”环境而变化亟需探索。

1.3 储层温度对渗透率的影响

煤储层埋深的增加带来储层温度增高及有效应力增大两个直接结果。煤层渗透率随温度增加的变化关系存在降低[31]、升高[32]、先升高后减小[33]争议。影响渗透率变化的原因主要包括:(1) 升温煤基质热膨胀,减小渗流通道,导致渗透率降低[34];(2) 高温下甲烷气体黏度降低,分子运动加剧,自由程缩短,有效流动半径增加,导致气体吸附量减小,渗透率升高[35]。二者耦合导致在有效应力较低情况下,温度升高造成渗透率降低;有效应力升高,渗透率损失率受高温影响增长幅度降低[36](图3a),尤其是当有效应力增长到滑脱效应可明显影响渗透率时,滑脱因子随温度升高而增加,渗透率增幅更加明显。温度与孔隙压力耦合对CH4渗透率的影响由孔隙压力主导,增大压力会降低温度对渗透率的影响[37](图3b)。仅从这一方面很难体现温度对高压力储层渗透率的补偿效应。结合深部煤储层裂隙发育情况,可以认为在排采前2个阶段,储层压力较高,温度对储层渗透率影响较弱;从排采的第 Ⅲ 阶段开始,温度对渗透率的影响随着滑脱效应的增强逐渐增强。

1.4 应力对渗透率的影响

现今应力场中,水平地应力直接作用于割理,导致煤储层渗透率与最大、最小水平主应力均呈现较好的幂指数负相关关系。若最大水平主应力方向与煤储层优势裂隙(通常为面割理)发育方向垂直时,渗透率随着水平主应力差的增大急剧减小,相反则对渗透率有益,如我国沁水盆地中南部高渗透煤储层即是如此[38]。储层渗透率与垂直应力的相关性不明显,但与侧压系数关系密切。由浅及深,随着侧压系数的减小,渗透率可能下降超过2个数量级[39]。不同煤级煤的渗透率随储层有效应力的增大呈“急速下降−缓慢下降−趋于零”式非线性减小,低煤级煤急与缓的拐点在5 MPa,中高煤级煤拐点在9 MPa后[40]。笔者针对大宁−吉县(埋深

1888 ~1891 m)及绥德区块深部(埋深2194 ~2281 m)原生结构煤做了多组渗透率应力演化实验(图4a)。结果表明在有效应力为2~8 MPa深部煤渗透率均急速下降,当有效应力超过8 MPa时渗透率下降速度减缓,超过20 MPa条件下渗透率趋近于零(图4b)。煤层气排采过程,由于游离气、水的排出,导致储层压力降低,排采的快慢直接影响有效应力增大速度,进而作用于储层渗透率演化。在20世纪90年代,我国参照美国采用快速降压排采模式,在大成中煤级煤发育区的大参1号井进行了试采,结果初期产气较高,后产气量快速衰减。此后,国内煤层气行业研究者开始提出慢速降压排采的理念,并发展深化了“五段三压四点法”排采控制方法[41]。按照这一排采管控方法,在沁水盆地樊庄区块取得了较好的效果。李金平等[42]依据累计产水量和井底流压的关系,将排采曲线划分为渗透率稳定型、改善型和敏感型,并依据曲线动态调整排采制度,在四川盆地沐爱、山西郑庄等地取得了一定的效果。基于中浅部煤层气生产实践的经验,结合深部复杂的地质条件,学者们认为降压速率控制不当主要会出现6个方面问题:(1) 深部煤储层渗透率差,压降漏斗延伸阻力大,排采过快导致泄压面积小[43];(2) 排采快,大量煤粉产出易导致卡泵,停排后又对人工裂缝、水平井段、储层造成伤害[44];(3) 高地应力条件下,储层压力降低过快,有效应力增大,裂隙面受到挤压作用,裂隙空间减小,渗透率损失严重[45];(4) 支撑剂嵌入、破碎及运移,不利于保持裂隙的导流能力;(5) 后期排驱压力较小,煤基质孔裂隙内聚集的解吸气产生的气泡无法排出,堵塞孔隙喉道;(6) 深部储层煤层气临界解吸压力和储层压力差值较大,排采慢则生产成本增加[46]。在原煤及人工裂隙煤渗透率应力演化实验中(图4a),笔者发现渗透率衰减速度小应力加载<大应力加载(图4b、图4c);无论应力加载幅度大小,原煤渗透率损失率在23 MPa接近100%,且在16 MPa条件下出现转折点,即此时储层加快卸压并不影响原煤渗透率(图4d)。以2、3 MPa加载有效应力过程中,人工裂隙煤渗透率损失率呈线性增大,但在24 MPa时渗透率损失率约90%;以6、9 MPa加载有效应力至在14 MPa时渗透率损失率即达80%(图4e)。储层压力下降过快,地应力增长至一定阈值,裂隙空间急剧下降,煤体可以视为内部充满复杂孔隙结构的基质块体,渗透率损失严重。在此阶段慢速排气、排水降压可有效减缓自然裂隙渗透率损失,维持压裂裂隙渗透率,使更多吸附气解吸并产出。以2 MPa及3 MPa卸载有效应力,人工裂隙渗透率不可逆损失率小于5%,原生裂隙渗透率不可逆损失率约25%,这一点远远低于浅部煤储层[23,47-48](图4f)。其原因可归结为以下两点:(1) 深部储层高应力环境促使煤大分子结构由无序向有序转化、有序畴和定向性增大,煤大分子结构更加紧密[49];(2) 高应力环境导致煤层压实致密,部分大孔及割理闭合。二者导致煤体刚度及延展性提高、抗压强度及弹性模量增加,使渗透率不可逆损失率减少[50]。该发现预示着在低产气阶段向储层多次充能可有效恢复渗透率。

2 煤中CH4差异解吸研究

深部煤层吸附气解吸是一个多阶段发展、多因素影响的过程,需要综合考虑地质条件、煤层特性以及工程技术等多方面因素。熊先钺等[51]认为深部煤层气排采过程的4个阶段中吸附气解吸可划分为低效解吸、缓慢解吸、规模解吸及敏感解吸4种类型。自缓慢解吸开始,扩大解吸范围、保证渗流通道,提高深部煤层气井产量是重中之重。煤层气为物理吸附,吸附亲和力取决于气体分子与煤分子之间的作用力,与气体的沸点、吸附势等参数有关。理论上解吸是吸附的逆过程,其影响因素可参照吸附来分析,即外在因素、内在因素及其他因素(表1)。

表 1 煤吸附影响因素Table 1. Factors affecting gas adsorption in coals影响因素 预测 参考文献 外在因素 温度 随温度增加而降低 [52] 压力 随压力增高而升高 [53] 气体组成 随气体组成成分变化受分压及(或)竞争吸附的影响而变化 [54] 水分 水分含量增加减少了气体吸附点位,吸附量减少 [55] 内在因素 变质程度 随变质程度呈现U形变化 [56] 变形程度 随变形程度增强而增大,煤粒径越小吸附量越大 [57] 孔隙 微孔是主要的吸附场所,随孔隙比表面积增大而增大 [58] 显微组分 随镜质组含量增高吸附量增大,随惰质组含量增高吸附量减小 [59] 煤岩成分 镜煤>亮煤>暗煤 [60] 煤质 随灰分含量增长而降低,随挥发分含量增长而降低,随固定碳含量增长而增长 [51] 其他因素 吸附时间 是煤的微观结构对气体解吸、扩散、渗流等过程影响的直观表现,

吸附饱和前,吸附体积与吸附时间有着正相关的关系[61] 2.1 解吸的影响因素

我国浅部煤层甲烷的解吸率普遍低于60 %,解吸率大小受煤中孔隙孔容、比表面积的分布与孔隙封闭性影响,随煤级的升高呈现倒U形趋势[62];解吸量则随煤变质、变形程度的增加而增加,随吸附压力的增大而增大[53]。原生结构煤中,高煤级煤微孔(<2 nm)含量高,比表面积大,影响压差在煤储层内的传递,进而降低气体解吸效率[61],导致解吸率小于低、中煤级煤;中煤级煤中大孔、裂隙的发育情况决定了解吸甲烷是否可以及时逸出,扩大储层内压力传导,增加解吸范围。煤中水分含量增加,甲烷解吸初速度及最大解吸量减少[63]。依据常压下解吸实验和煤层气参数井的实测数据:浅部储层解吸率主要受煤层的埋深和煤级的影响,最佳解吸深度一般在400~600 m,临界解吸压力在0.50~6.51 MPa[64]。深部煤储层的“三高”条件,温度对于吸附的负效应超过压力的正效应;高温高压条件下煤有机大分子碳结构石墨化,芳香层片距有规律减小,吸附点位减少[65],以上造成深部煤层游离气比例增大。综上,深部煤储层排采过程吸附气解吸有3方面问题:(1) 较高的储层压力导致临储比的减小,吸附气解吸相较浅部所需时间长,解吸困难;(2) 排采见气(游离气)时储层压力是否是临界解吸压力难以准确判断;(3) 煤中大孔、裂隙易受应力压缩闭合,解吸气体运移通道易受阻,解吸范围受限[51]。

2.2 常压与逐级降压解吸实验方法的选择

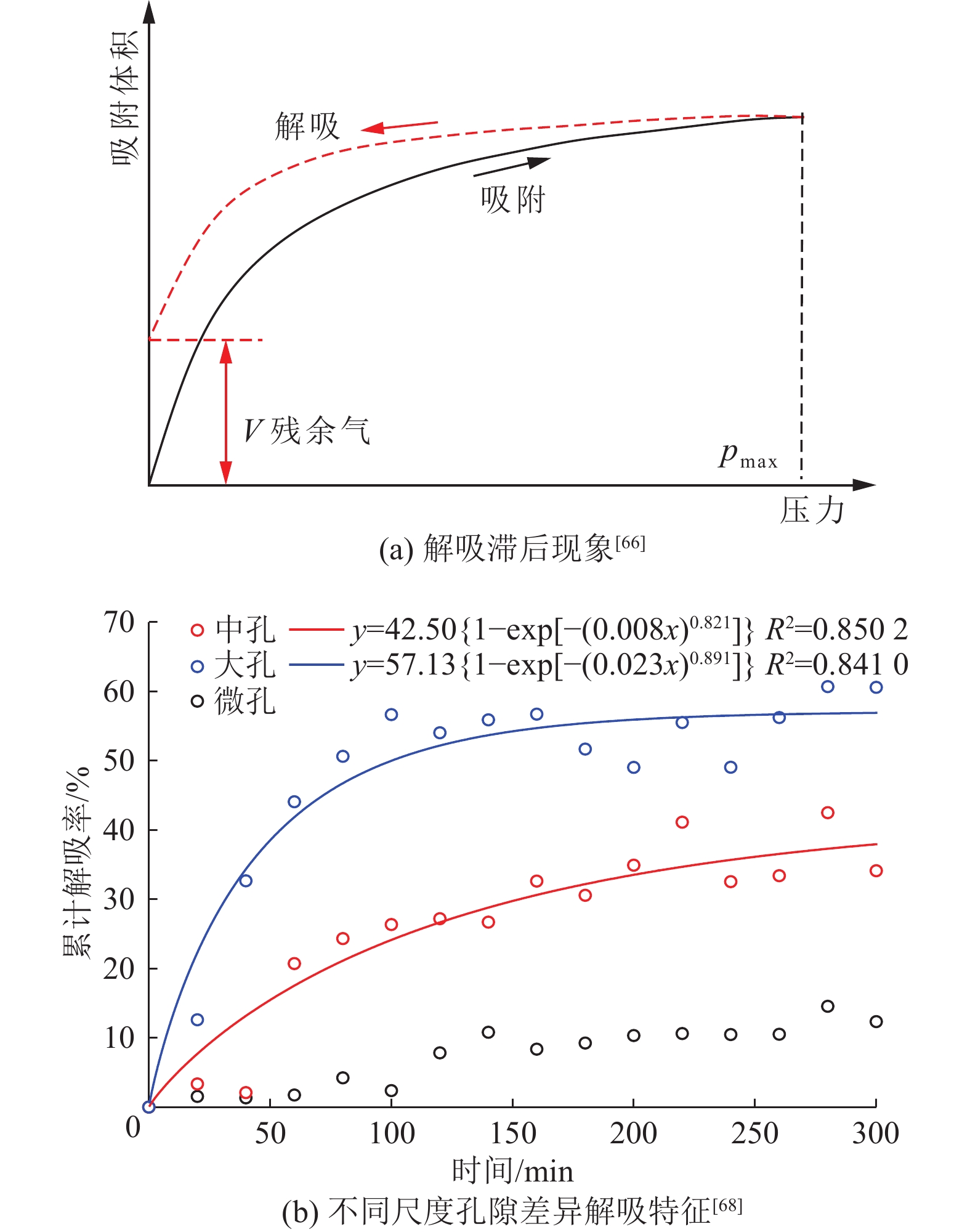

室内常压解吸测试(直接降压至0.1 MPa)表明煤的吸附−解吸过程具有滞后性,匮乏压力条件下煤体内存在残余气可高达50%[66](图5a)。煤体内部结构缺乏协调性和恢复能力,微孔和中孔富集且连通性差,发育大量的封闭和半封闭孔隙,孔隙喉道−显微裂隙易受压降影响闭合,表现出强烈的非均质性、应力敏感性[67]。笔者前期进行的CH4解吸实验表明(实验吸附压力5 MPa,围压10 MPa,吸附420 min后以2 MPa恒定压力解吸),解吸平衡后微孔CH4仅解吸10%左右,且不同尺度孔隙内CH4解吸不同步(图5b),压差越大,微孔CH4越难解吸[68]。原因包括:(1) 毛细凝结现象和液化[69];(2) 有效应力的增大导致被吸附压力强行打开的微孔、裂隙系统关闭,使部分气体在煤中无法逸出[67]。在实际工程中,无论是煤层瓦斯向采煤工作面涌出的过程,还是地面抽采过程,煤层绝大部分区域瓦斯压力的下降都是一个缓慢的过程。相应的,煤解吸实验直接将吸附压力降为大气压将会导致气锁现象,大大低估了煤层气开采率[70]。

国内外关于模拟排采过程的逐级降压解吸研究成果表明:常压解吸模式CH4解吸速率大于逐级降压解吸模式,解吸终止时间远超前于逐级降压解吸[71];解吸末期,常压解吸速度减小并最终趋近于零,逐级降压解吸则呈现波动形式变化;逐级降压累计解吸量约是常压解吸1.5倍(图6a),在0.1 MPa条件下解吸率仍可超过10%(图6b),这与实际煤层气开发工程中低压阶段煤层气产出情况吻合[72]。笔者对陕西绥德深部煤进行CH4逐级降压解吸测试,吸附时长48 h,围压30 MPa,气压20 MPa,解吸每24 h压力降低2 MPa,最终微孔吸附气解吸达50%左右(图6c)。煤解吸气体势必会诱导基质收缩响应。逐级降压解吸煤体累计收缩应变大于常压解吸,不同压力点下收缩速率无明显差异;吸附−解吸实验后煤体存在残余膨胀变形(常压解吸>逐级降压解吸),其既是煤层气未完全解吸的结果,又是煤层气扩散的影响因素[71]。

2.3 解吸基质收缩特征及应变速率计算模型

煤中甲烷解吸诱导煤基质收缩变形,但受储层围压影响,收缩只能沿裂隙发生局部侧向应变,致使裂隙开度增加,储层渗透率增大。煤解吸气体诱导的基质收缩随煤级的升高变化存在两种观点:(1) 随煤级增高,煤体力学性质增大,弹性模量增高,解吸诱导基质收缩减小[73];(2) 随煤级增高,煤中微孔体积增大,含气量增加,因收缩应变与解吸气体体积呈线性或者非线性正相关系,解吸诱导基质收缩增大[74]。笔者前期工作发现:从不同煤级煤中孔裂隙发育状态考虑,解吸收缩应变呈现倒U形状态,对于渗透率增长率表现为高煤级煤>低煤级煤>中煤级煤,增长值表现为中煤级煤>低煤级煤>高煤级煤[75]。另外,煤基质解吸收缩随储层温度的增高而增大,随煤中水分的增加而减小[63]。吸附−解吸后煤体存在残余变形,原因包括:(1) 煤中基本结构单元堆砌度和延展度在吸附解吸后减小,晶格条纹间距值增大,微晶结构呈现不连续性[76];(2) 受压力变化导致的煤体不可逆损伤;(3) 煤体内部仍有残余气存在[61]。相较浅部,深部煤储层目前仍缺乏解吸收缩的定量研究,其对深部煤储层渗透率的影响亟需探究。

煤层内的煤−气数值描述是研究煤层气解吸收缩应变机理的重点。动力学中气体解吸诱导应变对时间的依赖性(收缩应变速率)可基于两种模型描述:(1) 基于Fick第二定律球对称模型;(2) 基于双孔隙结构的煤双吸附模型[77]。因浅部煤中微孔、中孔随煤级变化趋势迥异,高煤级煤的吸附/扩散采用单孔模型更加贴切,双孔模型更加符合低、中煤级煤吸附动力学。深部煤储层中割理、大孔因有效应力增大闭合,微孔较浅部更为发育,对于收缩应变动力学模型的选择需要进一步探索。

Busch方程将煤定义为具有2种不同孔隙体系的双吸附/扩散模型,大孔隙中包含着许多微孔的团簇,并假设宏观和微观的解吸收缩应变从开始即为等温线性;应变速率分为快、慢2个阶段,由2个一阶速率函数的线性组成[78]。然而,其受限之处即煤对CH4吸附明显具有典型的非线性特征。PSOE(the pseudo-second-order kinetic equation)方程为伪二级动力学方程,其更适合吸附速率较快的吸附气体研究,或者针对粉末和颗粒样品吸附研究,对于固体煤样研究方面表现较差[79]。Elovich方程是一个基于吸附量变化的动力学方程,常常应用于化学吸附,描述了由反应速率和扩散因子控制的非均相扩散过程,可用来描述吸附剂表面吸附位能量不均匀时的吸附/膨胀动力学[80],其在拟合煤对CH4和N2的吸附—解吸诱导应变实验中,初始吸附/解吸速率波动较大,无法准确描述煤基质收缩行为,计算出的收缩量趋近于无穷。SE(the stretched exponential)方程是一个全局动力学方程[81],其吸附/膨胀动力学方程可表示为:

$$ Y(t)=Y_{\mathrm{eq}}\left\{1-\exp \left[-(k t)^{b}\right]\right\} $$ (1) 拉伸参数b为煤的固有参数,不同煤样赋值不同,不随压力、温度条件大范围变化,已被确认在拟合二元混合气体诱导应变动力学方面可以反映吸附气体分压和选择性吸附效应[82],在深部煤储层解吸收缩应变动力学方面,可以进行尝试应用。

3 低产气阶段的CH4扩散研究

叶建平等[11]认为浅部储层在经典煤层气产出三阶段(单相流阶段—非饱和流动阶段—两相流阶段)之后,我国高煤级储层还存在单相气流产出阶段。该阶段煤层气井排采具有以下特点:储层压力低,不产水,气源为解吸气,运移以扩散为主,对煤层气井产能贡献大,如沁南潘庄、郑庄区块部分煤层气井第四阶段产气量占全周期产气量的60%以上[83]。深部煤储层的低产气阶段与之类似,产气以远井区域解吸气供给为主,扩散是决定煤层气井产量的关键[51]。

3.1 扩散系数测试方法及影响因素

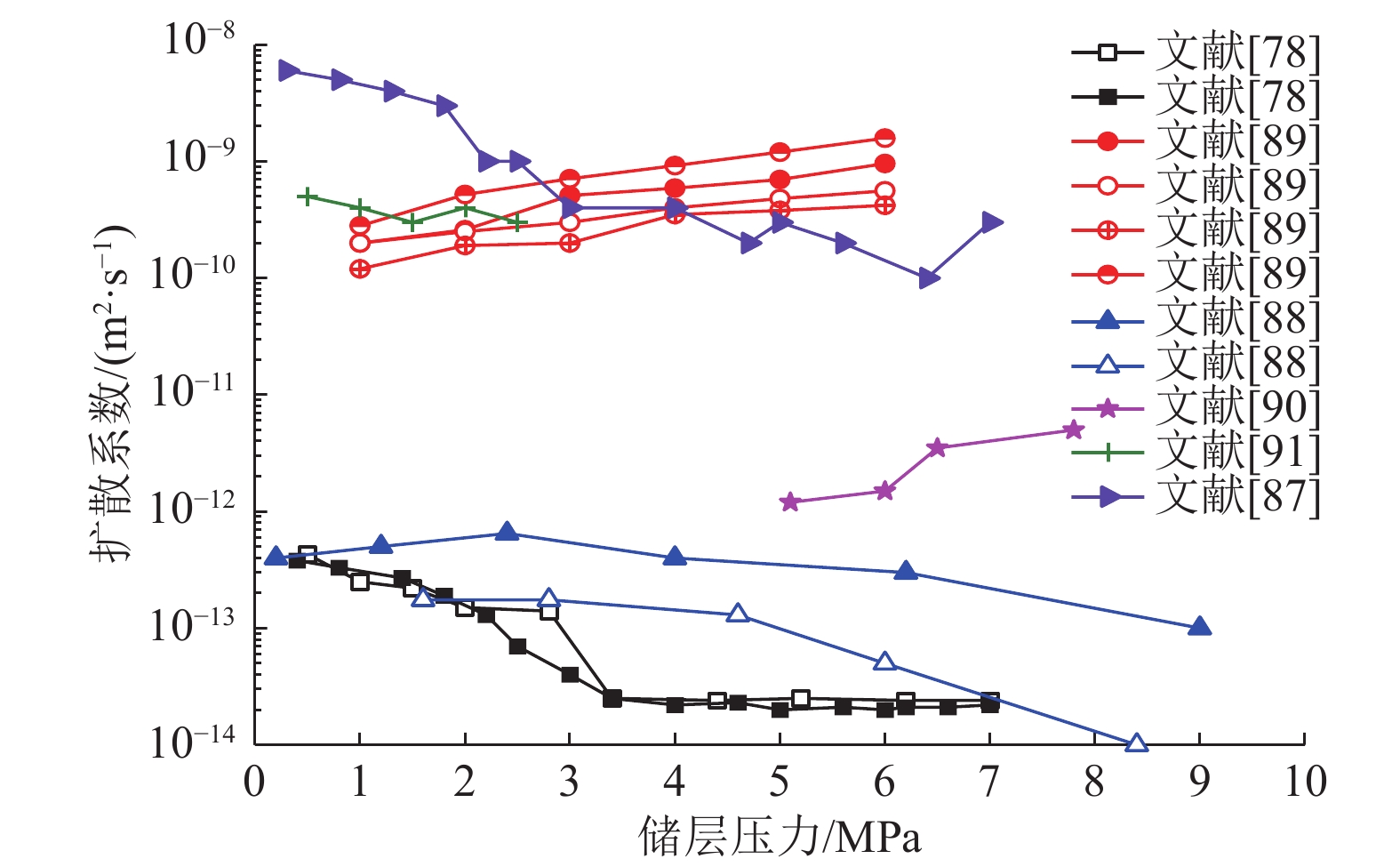

扩散的本质是在浓度差驱动下CH4分子的随机运动而形成的运移现象,可划分为表面扩散、晶体扩散(CH4压力需很高)及孔隙扩散。煤中孔隙扩散又可依据Knudsen数与孔径的关系分为过渡型扩散,Knudsen扩散和Fick型扩散。扩散系数的测试方法目前主要是颗粒煤常压解吸扩散法(小于3 mm颗粒)。然而,煤中CH4扩散动力学具有明显的尺度效应,扩散系数随着煤样尺寸的增加逐渐降低,采用煤颗粒测试预测煤层气产出不具有代表性[84]。无侧限煤心(柱状煤样)CH4常压解吸扩散测试,则无法避免煤中裂隙影响[85]。程远平团队通过“高应力煤体CH4扩散实验装置”测试高应力条件下(≥20 MPa)煤心的解吸扩散特征,避免了无侧限条件下裂隙的影响,并指出在1.0 MPa压差条件下,扩散系数与储层压力呈负相关[86]。煤心互扩散法是在煤心两端注入等压力的不同气体制造浓度差,这与煤层气成分主要为CH4相悖,其对反映储层条件的适用性仍需进一步验证。基于上述测试方法,学者们对不同影响因素下的CH4扩散规律进行了卓有成效的研究(表2)。随着储层压力的增大,气体分子运动加剧导致扩散系数升高,但也会造成气体吸附诱导煤基质膨胀变形降低扩散系数,因此,存在两种争议观点[78,87-91](图7)。

表 2 不同影响因素下CH4扩散规律Table 2. Laws of CH4 diffusion under varying influential factors3.2 考虑不同煤体结构的扩散模型

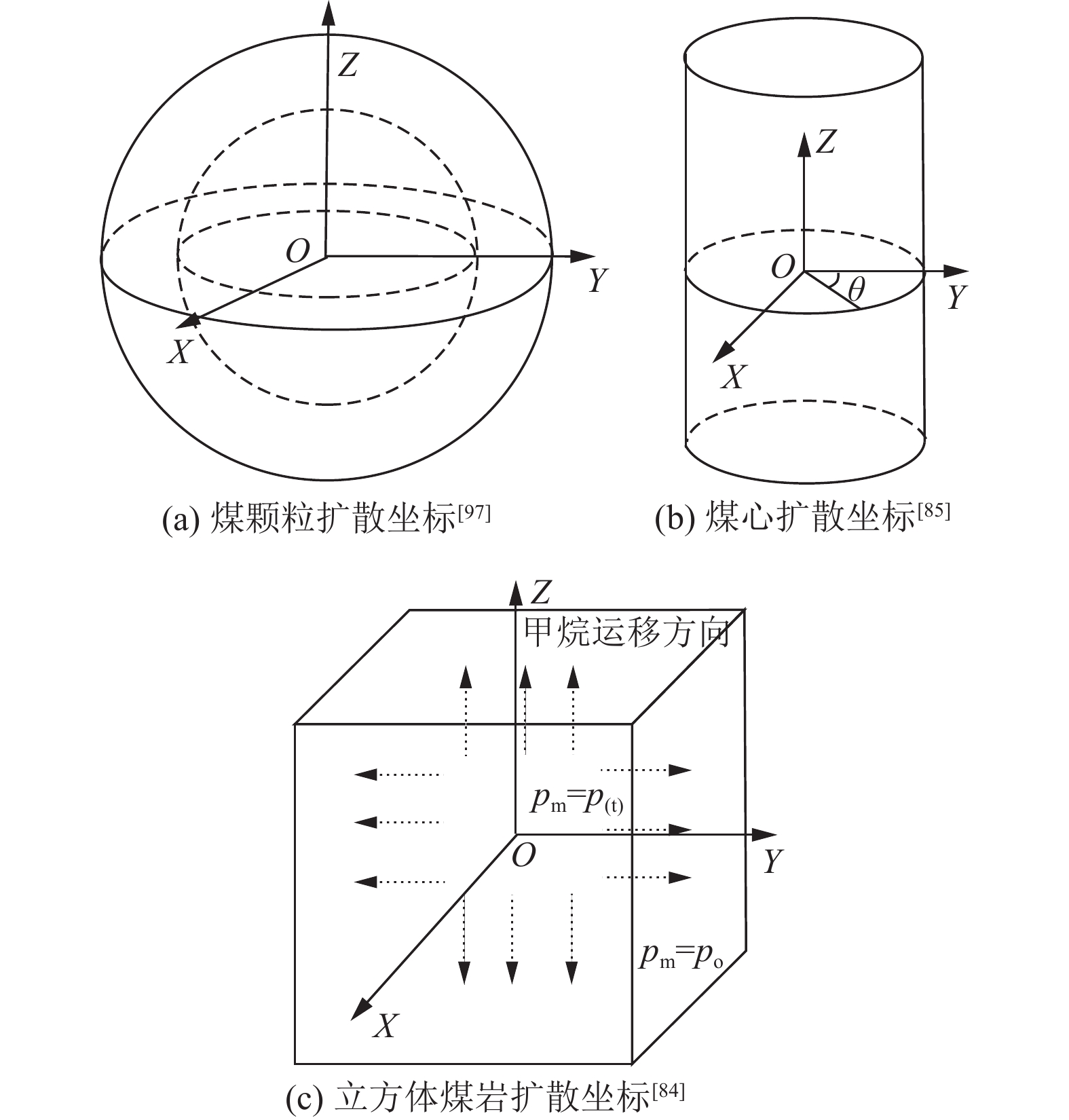

国内外学者基于Fick定律构建了许多经典模型获取扩散系数,主要有:单孔扩散模型、双孔扩散模型、多孔扩散模型[96]。颗粒煤常压解吸法假设煤基质均质球形(图8a)[97]。通过实践表明其拟合值与实验结果存在较大偏差,仅适合构造煤中瓦斯突出预测。煤心CH4扩散模型建立在单孔扩散模型的基础之上,假设煤基质为径向均质(图8b)[85],其与煤复杂的孔隙结构相差较大,并忽略了基质收缩造成的扩散模式的变化。立方体煤扩散模型进一步满足了多尺度样品CH4扩散数值模拟(图8c),模型考虑煤基质尺度效应、边界效应、时间效应、基质收缩效应[84],但同样假设煤体均质。

立方体煤He气孔隙率实验表明,煤中孔隙连通性在不同方向具有明显差异[98];并且,煤解吸收缩应变的各向异性随煤层气排采时间而增强,在低产气阶段最为突出[99]。因此,煤中CH4扩散系数同样具有各向异性,但目前仍难以与单一尺度孔隙参数建立联系[100]。笔者认为,扩散系数各向异性特征由多尺度孔隙—显微裂隙协同控制。然而,目前CH4扩散模型对煤体结构的各向异性特征涉及较少,该方面的研究对完善扩散动力学模型至关重要。

3.3 煤中CH4扩散时变模型

为了进一步描述全时段CH4解吸扩散过程,学者们将时间扩散因子与模型进行了结合,提出未来扩散模型发展需重视煤内部孔裂隙特征、原始储层条件、煤力学性质及扩散组合模式等参数[101]。扩散系数随时间增加而逐渐降低是孔隙结构多级分布造成的结果[84],不同尺度孔隙比表面积与扩散系数的演化历程有强相关关系[102],并可通过孔径分布、孔隙形态获得解吸曲线低压段扩散系数衰减规律[103]。刘大锰等[96]认为基于时间变化的扩散模型和非达西渗流模型联合表征虽然准确性仍有待考证,但也许更加适合解释我国低渗储层煤层气的运移过程。然而,S. A. Mathias等[104]指出扩散系数是否随时间变化,目前仍没有足够的证据。秦跃平等[97]则认为时间扩散因子违背了Fick模型扩散系数为常数的基本假设,进而基于煤基质为均质球形假设提出由游离CH4密度梯度驱动的扩散模型。综上可知,扩散系数的恒定假设与现实条件不符,现有扩散模型未考虑煤中孔隙多尺度、多类型分布特征影响。因此,亟需构建受煤体孔裂隙复杂结构影响的CH4时变扩散模型,其可从两方面考虑:(1) 基于Fick定律进一步深入探究,从煤体多尺度孔隙−显微裂隙中扩散模式的变化组合入手;(2) 基于游离态CH4密度梯度驱动扩散构建时变扩散模型。

3.4 煤中CH4密度梯度驱动扩散研究

CH4扩散机理一直存在争议。李相方[105]、徐风银[106]等指出煤储层内煤层气不存在浓度差,煤层气解吸从基质孔隙进入割理系统的过程属于压差驱动,原因包括:煤层基质孔隙中有气水两相,不满足单相条件;煤层气中CH4为主要成分,不存在浓度差;若考虑煤层气中的CO2、N2等,则需要该部分气体赋存于裂隙中,CH4赋存于基质孔隙中才能产生互扩散。如果煤基质孔隙与割理−裂隙系统压差不足,时间再长气体也不能进入割理−裂隙系统。秦跃平等[97]基于扩散系数随时间变化现象引入游离CH4密度梯度驱动扩散理论,在表征颗粒煤常压解吸扩散实验时,构建的密度差模型表现优于Fick模型,虽然其实验条件的特殊性导致该理论模型的普适性仍需进一步验证,但是该理论为扩散的研究提供了一个新的思路。

依据Gibbs理论,任何一个固−气吸附系统可以简化为:吸附剂、吸附相和游离相。吸附相的密度的计算方法有:(1) 通过将实验测得的过剩吸附量与气相密度作图,拟合高压下降段直线,获得吸附饱和时的吸附相密度[107];(2) 基于已有的吸附模型,结合Gibbs过剩吸附理论,将吸附相密度作为拟合参数之一进行计算[108];(3) 依据经验取定值,以常压沸点CH4密度0.423 g/cm3 或Van der Waals密度0.373 g/cm3替代吸附相密度[109];(4) 通过微孔填充和单分子层覆盖理论,计算得出不同尺度煤孔结构(0.38~1.49 nm)中吸附态CH4分子的分布[110]。另外,基于亥姆霍兹能量基本方程的经验状态方程,可计算出270~360 K、0~30 MPa温度与压力下储层游离态CH4密度[111]。目前对于不同尺度孔隙中CH4的密度研究较少。姚艳斌等[112]通过核磁T2谱值将对煤中CH4赋存(吸附态、游离态、自由态)、相应尺度孔隙(微孔、中孔、大孔)进行了有效划分。该种方法得到了广大学者的认可。目前,煤中多尺度孔裂隙精细表征实验已比较成熟,结合高温高压核磁成像分析技术,有望实现深部煤层低产气阶段不同尺度孔隙内CH4密度的表征。

4 结 论

(1) 深部煤层气产出由传统的排水降压转变为更为高效的排气(游离气)降压,排采过程可划分为4个阶段,存在“游离气产出阶段的渗透率保持”“游离气与吸附气解吸高效转换”及“解吸气扩散规律精准预测”3方面的挑战。

(2) 深部煤层气排采过程应控压降、慢排采,其优势有:① 可减缓前期储层原生裂隙渗透率衰减趋势,尽管在低产气阶段原生裂隙渗透率损失率接近100%,但人工裂隙还能维持一定的渗透性;② 可有效提高微孔中吸附气的解吸率,常压解吸实验中,微孔中吸附气解吸率仅10%左右,而逐级降压解吸的解吸率可达50%;③ 原生裂隙及人工裂隙不可逆渗透率损失率远低于浅部煤储层,分别约为25%和5%。

(3) 目前,应加快建立原位状态下煤中孔裂隙的精确表征方法体系,开展深部储层温度对渗透率补偿效应机理研究;解吸实验应坚持逐级降压解吸方式来提高煤层气采收率预测精度,亟需揭示排水降压与排气降压对煤层气解吸的影响差异;开展高温、高应力条件下不同尺度孔隙间煤层气运移差异研究,阐明不同尺度孔隙间CH4密度演化机制,构建煤中各向异性扩散时变模型。

符号注释:

b (0<b<1)为拉伸参数,反映吸附/解吸和诱导应变的弛豫时间;k为吸附/吸附膨胀应变速率,με/s;p0为标况下气体压力,MPa;pm为孔隙气体压力,MPa;p(t)为扩散过程中基质内部气体压力,MPa;Y为膨胀/收缩量,με;Yeq为平衡时的吸附/膨胀量,με。

-

表 1 煤吸附影响因素

Table 1 Factors affecting gas adsorption in coals

影响因素 预测 参考文献 外在因素 温度 随温度增加而降低 [52] 压力 随压力增高而升高 [53] 气体组成 随气体组成成分变化受分压及(或)竞争吸附的影响而变化 [54] 水分 水分含量增加减少了气体吸附点位,吸附量减少 [55] 内在因素 变质程度 随变质程度呈现U形变化 [56] 变形程度 随变形程度增强而增大,煤粒径越小吸附量越大 [57] 孔隙 微孔是主要的吸附场所,随孔隙比表面积增大而增大 [58] 显微组分 随镜质组含量增高吸附量增大,随惰质组含量增高吸附量减小 [59] 煤岩成分 镜煤>亮煤>暗煤 [60] 煤质 随灰分含量增长而降低,随挥发分含量增长而降低,随固定碳含量增长而增长 [51] 其他因素 吸附时间 是煤的微观结构对气体解吸、扩散、渗流等过程影响的直观表现,

吸附饱和前,吸附体积与吸附时间有着正相关的关系[61] 表 2 不同影响因素下CH4扩散规律

Table 2 Laws of CH4 diffusion under varying influential factors

-

[1] 申建,秦勇,傅雪海,等. 深部煤层气成藏条件特殊性及其临界深度探讨[J]. 天然气地球科学,2014,25(9):1470−1476. SHEN Jian,QIN Yong,FU Xuehai,et al. Properties of deep coalbed methane reservoir–forming conditions and critical depth discussion[J]. Natural Gas Geoscience,2014,25(9):1470−1476.

[2] WANG Haichao,FU Xuehai,ZHANG Xiaoyang,et al. Source,age,and evolution of coal measures water in central–south Qinshui Basin,China[J]. Energy & Fuels,2018,32(7):7358−7373.

[3] 谢和平,高峰,鞠杨. 深部岩体力学研究与探索[J]. 岩石力学与工程学报,2015,34(11):2161−2178. XIE Heping,GAO Feng,JU Yang. Research and development of rock mechanics in deep ground engineering[J]. Chinese Journal of Rock Mechanics and Engineering,2015,34(11):2161−2178.

[4] 傅雪海,秦勇,权彪,等. 中煤级煤吸附甲烷的物理模拟与数值模拟研究[J]. 地质学报,2008,82(10):1368−1371. DOI: 10.3321/j.issn:0001-5717.2008.10.009 FU Xuehai,QIN Yong,QUAN Biao,et al. Study of physical and numerical simulations of adsorption methane content on middle–rank coal[J]. Acta Geologica Sinica,2008,82(10):1368−1371. DOI: 10.3321/j.issn:0001-5717.2008.10.009

[5] 陈刚,李五忠. 鄂尔多斯盆地深部煤层气吸附能力的影响因素及规律[J]. 天然气工业,2011,31(10):47−49. DOI: 10.3787/j.issn.1000-0976.2011.10.010 CHEN Gang,LI Wuzhong. Influencing factors and patterns of CBM adsorption capacity in the deep Ordos Basin[J]. Natural Gas Industry,2011,31(10):47−49. DOI: 10.3787/j.issn.1000-0976.2011.10.010

[6] 李松,汤达祯,许浩,等. 深部煤层气储层地质研究进展[J]. 地学前缘,2016,23(3):10−16. LI Song,TANG Dazhen,XU Hao,et al. Progress in geological researches on the deep coalbed methane reservoirs[J]. Earth Science Frontiers,2016,23(3):10−16.

[7] MENG Zhaoping,ZHANG Jincai,WANG Rui. In–situ stress,pore pressure and stress–dependent permeability in the southern Qinshui Basin[J]. International Journal of Rock Mechanics and Mining Sciences,2011,48(1):122−131. DOI: 10.1016/j.ijrmms.2010.10.003

[8] 杨永杰,宋扬,陈绍杰,等. 煤岩强度离散性及三轴压缩试验研究[J]. 岩土力学,2006,27(10):1763−1766. DOI: 10.3969/j.issn.1000-7598.2006.10.024 YANG Yongjie,SONG Yang,CHEN Shaojie,et al. Experimental study on strength discreteness and triaxial compression of coal[J]. Rock and Soil Mechanics,2006,27(10):1763−1766. DOI: 10.3969/j.issn.1000-7598.2006.10.024

[9] 李勇,徐立富,张守仁,等. 深煤层含气系统差异及开发对策[J]. 煤炭学报,2023,48(2):900−917. LI Yong,XU Lifu,ZHANG Shouren,et al. Gas bearing system difference in deep coal seams and corresponded development strategy[J]. Journal of China Coal Society,2023,48(2):900−917.

[10] 李国富,侯泉林. 沁水盆地南部煤层气井排采动态过程与差异性[J]. 煤炭学报,2012,37(5):798−803. LI Guofu,HOU Quanlin. Dynamic process and difference of coalbed methane wells production in southern Qinshui Basin[J]. Journal of China Coal Society,2012,37(5):798−803.

[11] 叶建平,张健,王赞惟. 沁南潘河煤层气田生产特征及其控制因素[J]. 天然气工业,2011,31(5):28−30. DOI: 10.3787/j.issn.1000-0976.2011.05.007 YE Jianping,ZHANG Jian,WANG Zanwei. Production performance and its controlling factors in the Panhe CMB Gas Field,southern Qinshui Basin[J]. Natural Gas Industry,2011,31(5):28−30. DOI: 10.3787/j.issn.1000-0976.2011.05.007

[12] 徐凤银,聂志宏,孙伟,等. 鄂尔多斯盆地东缘深部煤层气高效开发理论技术体系[J]. 煤炭学报,2024,49(1):528−544. XU Fengyin,NIE Zhihong,SUN Wei,et al. Theoretical and technological system for highly efficient development of deep coalbed methane in the eastern edge of Erdos Basin[J]. Journal of China Coal Society,2024,49(1):528−544.

[13] 聂志宏,时小松,孙伟,等. 大宁–吉县区块深层煤层气生产特征与开发技术对策[J]. 煤田地质与勘探,2022,50(3):193−200. DOI: 10.12363/issn.1001-1986.21.12.0818 NIE Zhihong,SHI Xiaosong,SUN Wei,et al. Production characteristics of deep coalbed methane gas reservoirs in Daning–Jixian Block and its development technology countermeasures[J]. Coal Geology & Exploration,2022,50(3):193−200. DOI: 10.12363/issn.1001-1986.21.12.0818

[14] 程远平,雷杨. 构造煤和煤与瓦斯突出关系的研究[J]. 煤炭学报,2021,46(1):180−198. CHENG Yuanping,LEI Yang. Causality between tectonic coal and coal and gas outbursts[J]. Journal of China Coal Society,2021,46(1):180−198.

[15] 叶桢妮,侯恩科,段中会,等. 不同煤体结构煤的孔隙–裂隙分形特征及其对渗透性的影响[J]. 煤田地质与勘探,2019,47(5):70−78. DOI: 10.3969/j.issn.1001-1986.2019.05.010 YE Zhenni,HOU Enke,DUAN Zhonghui,et al. Fractal characteristics of pores and microfractures of coals with different structure and their effect on permeability[J]. Coal Geology & Exploration,2019,47(5):70−78. DOI: 10.3969/j.issn.1001-1986.2019.05.010

[16] 曹明亮,康永尚,邓泽,等. 煤阶和构造应力强度对煤岩力学性质的影响作用[J]. 煤炭科学技术,2019,47(12):45−55. CAO Mingliang,KANG Yongshang,DENG Ze,et al. Influence of coal rank and tectonic stress intensity on mechanical properties of coal rock[J]. Coal Science and Technology,2019,47(12):45−55.

[17] 蒋静宇,史孝宁,程远平,等. 急速卸压条件下构造煤体应力释放规律试验研究[J]. 采矿与安全工程学报,2024,41(3):634−644. JIANG Jingyu,SHI Xiaoning,CHENG Yuanping,et al. Study on stress release law of tectonic coal under rapid unloading confining pressure[J]. Journal of Mining and Safety Engineering,2024,41(3):634−644.

[18] 吕闰生,彭苏萍,徐延勇. 含瓦斯煤体渗透率与煤体结构关系的实验[J]. 重庆大学学报,2012,35(7):114−118. DOI: 10.11835/j.issn.1000-582X.2012.07.020 LYU Runsheng,PENG Suping,XU Yanyong. Experiments on the relationship between permeability of gas–bearing coal and coal body structure[J]. Journal of Chongqing University,2012,35(7):114−118. DOI: 10.11835/j.issn.1000-582X.2012.07.020

[19] 郭红玉,苏现波,夏大平,等. 煤储层渗透率与地质强度指标的关系研究及意义[J]. 煤炭学报,2010,35(8):1319−1322. GUO Hongyu,SU Xianbo,XIA Daping,et al. Relationship of the permeability and geological strength index (GSI) of coal reservoir and its significance[J]. Journal of China Coal Society,2010,35(8):1319−1322.

[20] FU Xuehai,QIN Yong,WANG G G X,et al. Evaluation of coal structure and permeability with the aid of geophysical logging technology[J]. Fuel,2009,88(11):2278−2285. DOI: 10.1016/j.fuel.2009.05.018

[21] BUSSE J,DE DREUZY J R,TORRES S G,et al. Image processing based characterization of coal cleat networks[J]. International Journal of Coal Geology,2017,169:1−21. DOI: 10.1016/j.coal.2016.11.010

[22] SCOTT A R. Hydrogeologic factors affecting gas content distribution in coal beds[J]. International Journal of Coal Geology,2002,50(1):363−387.

[23] WANG Zhenzhi,PAN Jienan,HOU Quanlin,et al. Changes in the anisotropic permeability of low–rank coal under varying effective stress in Fukang Mining Area,China[J]. Fuel,2018,234:1481−1497. DOI: 10.1016/j.fuel.2018.08.013

[24] KANG Junqiang,FU Xuehai,GAO Lin,et al. Production profile characteristics of large dip angle coal reservoir and its impact on coalbed methane production:A case study on the Fukang west block,southern Junggar Basin,China[J]. Journal of Petroleum Science and Engineering,2018,171:99−114. DOI: 10.1016/j.petrol.2018.07.044

[25] WANG Zhenzhi,FU Xuehai,PAN Jienan,et al. The fracture anisotropic evolution of different ranking coals in Shanxi Province,China[J]. Journal of Petroleum Science and Engineering,2019,182:106281. DOI: 10.1016/j.petrol.2019.106281

[26] WANG Zhenzhi,PAN Jienan,HOU Quanlin,et al. Anisotropic characteristics of low–rank coal fractures in the Fukang Mining Area,China[J]. Fuel,2018,211:182−193. DOI: 10.1016/j.fuel.2017.09.067

[27] KOENIG P A,STUBBS P B. Interference testing of a coalbed methane reservoir[C]//SPE Unconventional Gas Technology Symposium. Louisville,1986.

[28] WENIGER S,WENIGER P,LITTKE R. Characterizing coal cleats from optical measurements for CBM evaluation[J]. International Journal of Coal Geology,2016,154/155:176−192. DOI: 10.1016/j.coal.2015.12.005

[29] LIU Shimin,WANG Yi,HARPALANI S. Anisotropy characteristics of coal shrinkage/swelling and its impact on coal permeability evolution with CO2 injection[J]. Greenhouse Gases:Science and Technology,2016,6(5):615−632. DOI: 10.1002/ghg.1592

[30] ANGGARA F,SASAKI K,RODRIGUES S,et al. The effect of megascopic texture on swelling of a low rank coal in supercritical carbon dioxide[J]. International Journal of Coal Geology,2014,125:45−56. DOI: 10.1016/j.coal.2014.02.004

[31] 杨新乐,张永利. 气固耦合作用下温度对煤瓦斯渗透率影响规律的实验研究[J]. 地质力学学报,2008,14(4):374−380. DOI: 10.3969/j.issn.1006-6616.2008.04.007 YANG Xinle,ZHANG Yongli. Experimental study of effect of temperature on coal gas permeability under gas–solid coupling[J]. Journal of Geomechanics,2008,14(4):374−380. DOI: 10.3969/j.issn.1006-6616.2008.04.007

[32] 胡耀青,赵阳升,杨栋,等. 温度对褐煤渗透特性影响的试验研究[J]. 岩石力学与工程学报,2010,29(8):1585−1590. HU Yaoqing,ZHAO Yangsheng,YANG Dong,et al. Experimental study of effect of temperature on permeability characteristics of lignite[J]. Chinese Journal of Rock Mechanics and Engineering,2010,29(8):1585−1590.

[33] 谢建林,赵阳升. 随温度升高煤岩体渗透率减小或波动变化的细观机制[J]. 岩石力学与工程学报,2017,36(3):543−551. XIE Jianlin,ZHAO Yangsheng. Meso–mechanism of permeability decrease or fluctuation of coal and rock with the temperature increase[J]. Chinese Journal of Rock Mechanics and Engineering,2017,36(3):543−551.

[34] 夏同强,王有湃,周福宝,等. 煤岩体应力–渗流–温度多过程耦合试验系统[J]. 中国矿业大学学报,2021,50(2):205−213. XIA Tongqiang,WANG Youpai,ZHOU Fubao,et al. The stress–seepage–temperature multi–process coupling test system for coal and rock mass[J]. Journal of China University of Mining & Technology,2021,50(2):205−213.

[35] 李宝林,魏国营. 不同温度煤裂隙流动优势性的热流固耦合数值模拟[J]. 煤炭科学技术,2020,48(11):141−146. LI Baolin,WEI Guoying. Numerical simulation of thermal–fluid–solid coupling of the flow dominance of coal under different temperature conditions[J]. Coal Science and Technology,2020,48(11):141−146.

[36] 秦勇,申建,王宝文,等. 深部煤层气成藏效应及其耦合关系[J]. 石油学报,2012,33(1):48−54. DOI: 10.7623/syxb201201006 QIN Yong,SHEN Jian,WANG Baowen,et al. Accumulation effects and coupling relationship of deep coalbed methane[J]. Acta Petrolei Sinica,2012,33(1):48−54. DOI: 10.7623/syxb201201006

[37] 丁宝成,李佳芮,张秀平. 温度、应力对含瓦斯煤渗透特性影响的实验研究[J]. 世界科技研究与发展,2015,37(4):364−367. DING Baocheng,LI Jiarui,ZHANG Xiuping. Experimental study on permeability characteristics of coal containing gas influenced by temperature and stress[J]. World Sci–Tech R & D,2015,37(4):364−367.

[38] QIN Yong,MOORE T A,SHEN Jian,et al. Resources and geology of coalbed methane in China:A review[J]. International Geology Review,2018,60(5/6):777−812.

[39] 刘大锰,周三栋,蔡益栋,等. 地应力对煤储层渗透性影响及其控制机理研究[J]. 煤炭科学技术,2017,45(6):1−8. LIU Dameng,ZHOU Sandong,CAI Yidong,et al. Study on effect of geo–stress on coal permeability and its controlling mechanism[J]. Coal Science and Technology,2017,45(6):1−8.

[40] 周德华,陈刚,陈贞龙,等. 中国深层煤层气勘探开发进展、关键评价参数与前景展望[J]. 天然气工业,2022,42(6):43−51. DOI: 10.3787/j.issn.1000-0976.2022.06.004 ZHOU Dehua,CHEN Gang,CHEN Zhenlong,et al. Exploration and development progress,key evaluation parameters and prospect of deep CBM in China[J]. Natural Gas Industry,2022,42(6):43−51. DOI: 10.3787/j.issn.1000-0976.2022.06.004

[41] 段品佳,王芝银,翟雨阳,等. 煤层气排采初期阶段合理降压速率的研究[J]. 煤炭学报,2011,36(10):1689−1692. DUAN Pinjia,WANG Zhiyin,ZHAI Yuyang,et al. Research on reasonable depressurization rate in initial stage of exploitation to coal bed methane[J]. Journal of China Coal Society,2011,36(10):1689−1692.

[42] 李金平,潘军,李勇,等. 基于流动物质平衡理论的煤层气井定量化排采新方法[J]. 天然气工业,2023,43(6):87−95. DOI: 10.3787/j.issn.1000-0976.2023.06.008 LI Jinping,PAN Jun,LI Yong,et al. A new CBM well quantitative production method based on the flow material balance theory[J]. Natural Gas Industry,2023,43(6):87−95. DOI: 10.3787/j.issn.1000-0976.2023.06.008

[43] 伊永祥,唐书恒,张松航,等. 沁水盆地柿庄南区块煤层气井储层压降类型及排采控制分析[J]. 煤田地质与勘探,2019,47(5):118−126. DOI: 10.3969/j.issn.1001-1986.2019.05.016 YI Yongxiang,TANG Shuheng,ZHANG Songhang,et al. Analysis on the type of reservoir pressure drop and drainage control of coalbed methane well in the southern block of Shizhuang[J]. Coal Geology & Exploration,2019,47(5):118−126. DOI: 10.3969/j.issn.1001-1986.2019.05.016

[44] 张遂安,曹立虎,杜彩霞. 煤层气井产气机理及排采控压控粉研究[J]. 煤炭学报,2014,39(9):1927−1931. ZHANG Sui’an,CAO Lihu,DU Caixia. Study on CBM production mechanism and control theory of bottom–hole pressure and coal fines during CBM well production[J]. Journal of China Coal Society,2014,39(9):1927−1931.

[45] 吴建发,樊怀才,张鉴,等. 页岩人工裂缝应力敏感性实验研究:以川南地区龙马溪组页岩为例[J]. 天然气工业,2022,42(2):71−81. DOI: 10.3787/j.issn.1000-0976.2022.02.008 WU Jianfa,FAN Huaicai,ZHANG Jian,et al. An experimental study on stress sensitivity of hydraulic fractures in shale:A case study on Longmaxi Formation shale in the southern Sichuan Basin[J]. Natural Gas Industry,2022,42(2):71−81. DOI: 10.3787/j.issn.1000-0976.2022.02.008

[46] 韦涛,张争光,牛志刚,等. 深部与浅部煤层气储层物性及开发工程差异分析[J]. 煤炭技术,2018,37(2):58−60. WEI Tao,ZHANG Zhengguang,NIU Zhigang,et al. Analysis of physical properties and engineering difference between deep coal seam and shallow coal seam[J]. Coal Technology,2018,37(2):58−60.

[47] MENG Zhaoping,LI Guoqing. Experimental research on the permeability of high–rank coal under a varying stress and its influencing factors[J]. Engineering Geology,2013,162:108−117. DOI: 10.1016/j.enggeo.2013.04.013

[48] LI Yong,TANG Dazhen,XU Hao,et al. In–situ stress distribution and its implication on coalbed methane development in Liulin area,eastern Ordos Basin,China[J]. Journal of Petroleum Science and Engineering,2014,122:488−496. DOI: 10.1016/j.petrol.2014.08.010

[49] 宋昱,姜波,王猛,等. 煤缩合芳环应力响应:对无烟煤石墨化的启示[J]. 煤炭学报,2022,47(12):4336−4351. SONG Yu,JIANG Bo,WANG Meng,et al. Stress response of coal condensed aromatic ring:Inspiration for graphitization of anthracite[J]. Journal of China Coal Society,2022,47(12):4336−4351.

[50] 高向东,王延斌,倪小明,等. 临兴地区深部煤岩力学性质及其对煤储层压裂的影响[J]. 煤炭学报,2020,45(增刊2):912−921. GAO Xiangdong,WANG Yanbin,NI Xiaoming,et al. Mechanical properties of deep coal and rock in Linxing area and its influences on fracturing of deep coal reservoir[J]. Journal of China Coal Society,2020,45(Sup.2):912−921.

[51] 熊先钺,闫霞,徐凤银,等. 深部煤层气多要素耦合控制机理、解吸规律与开发效果剖析[J]. 石油学报,2023,44(11):1812−1826. DOI: 10.7623/syxb202311005 XIONG Xianyue,YAN Xia,XU Fengyin,et al. Analysis of multi–factor coupling control mechanism,desorption law and development effect of deep coalbed methane[J]. Acta Petrolei Sinica,2023,44(11):1812−1826. DOI: 10.7623/syxb202311005

[52] NIU Qinghe,CAO Liwen,SANG Shuxun,et al. Experimental study of permeability changes and its influencing factors with CO2 injection in coal[J]. Journal of Natural Gas Science and Engineering,2019,61:215−225. DOI: 10.1016/j.jngse.2018.09.024

[53] 康永尚,皇甫玉慧,张兵,等. 含煤盆地深层“超饱和”煤层气形成条件[J]. 石油学报,2019,40(12):1426−1438. DOI: 10.7623/syxb201912002 KANG Yongshang,HUANGFU Yuhui,ZHANG Bing,et al. Formation conditions for deep oversaturated coalbed methane in coal–bearing basins[J]. Acta Petrolei Sinica,2019,40(12):1426−1438. DOI: 10.7623/syxb201912002

[54] FAN Nan,WANG Jiren,DENG Cunbao,et al. Numerical study on enhancing coalbed methane recovery by injecting N2/CO2 mixtures and its geological significance[J]. Energy Science & Engineering,2020,8(4):1104−1119.

[55] 降文萍,崔永君,钟玲文,等. 煤中水分对煤吸附甲烷影响机理的理论研究[J]. 天然气地球科学,2007,18(4):576−579. DOI: 10.3969/j.issn.1672-1926.2007.04.019 JIANG Wenping,CUI Yongjun,ZHONG Lingwen,et al. Quantum chemical study on coal surface interacting with CH4 and H2O[J]. Natural Gas Geoscience,2007,18(4):576−579. DOI: 10.3969/j.issn.1672-1926.2007.04.019

[56] LIU Yu,ZHU Yanming,LIU Shimin,et al. Molecular structure controls on micropore evolution in coal vitrinite during coalification[J]. International Journal of Coal Geology,2018,199:19−30. DOI: 10.1016/j.coal.2018.09.012

[57] 潘结南,徐海飞. 河南省中–高煤阶构造变形煤甲烷吸附/解吸特征研究[J]. 煤炭科学技术,2015,43(2):29−32. PAN Jienan,XU Haifei. Study on characteristics of adsorption/desorption of medium and high rank tectonic deformation coals in Henan Province[J]. Coal Science and Technology,2015,43(2):29−32.

[58] CHENG Guoxi,JIANG Bo,LI Ming,et al. Effects of pore structure on methane adsorption behavior of ductile tectonically deformed coals:An inspiration to coalbed methane exploitation in structurally complex area[J]. Journal of Natural Gas Science and Engineering,2020,74:103083. DOI: 10.1016/j.jngse.2019.103083

[59] 王青青,孟艳军,闫涛滔,等. 不同煤阶煤储层吸附/解吸特征差异及其对产能的影响[J]. 煤田地质与勘探,2023,51(5):66−77. DOI: 10.12363/issn.1001-1986.22.10.0816 WANG Qingqing,MENG Yanjun,YAN Taotao,et al. Differences in the absorption/desorption characteristics of coal reservoirs with different coal ranks and their effects on the reservoir productivity[J]. Coal Geology & Exploration,2023,51(5):66−77. DOI: 10.12363/issn.1001-1986.22.10.0816

[60] 侯伟,徐凤银,张雷,等. 煤岩类型对煤储层吸附/解吸特征影响及实践意义:以保德区块为例[J]. 煤田地质与勘探,2022,50(3):110−118. DOI: 10.12363/issn.1001-1986.21.12.0864 HOU Wei,XU Fengyin,ZHANG Lei,et al. Influence of coal lithotypes on adsorption/desorption characteristics in coal reservoirs and its practical significance:A case study in Baode Block[J]. Coal Geology & Exploration,2022,50(3):110−118. DOI: 10.12363/issn.1001-1986.21.12.0864

[61] WANG Zhenzhi,FU Xuehai,HAO Ming,et al. Experimental insights into the adsorption–desorption of CH4/N2 and induced strain for medium–rank coals[J]. Journal of Petroleum Science and Engineering,2021,204:108705. DOI: 10.1016/j.petrol.2021.108705

[62] 傅雪海,秦勇,叶建平,等. 中国部分煤储层解吸特性及甲烷采收率[J]. 煤田地质与勘探,2000,28(2):19−22. DOI: 10.3969/j.issn.1001-1986.2000.02.006 FU Xuehai,QIN Yong,YE Jianping,et al. Desorption properties of some coal reservoirs and methane recovery rate in China[J]. Coal Geology & Exploration,2000,28(2):19−22. DOI: 10.3969/j.issn.1001-1986.2000.02.006

[63] 陈向军,程远平,王林. 外加水分对煤中瓦斯解吸抑制作用试验研究[J]. 采矿与安全工程学报,2013,30(2):296−301. CHEN Xiangjun,CHENG Yuanping,WANG Lin. Experimental study on the inhibition of injection water to the gas desorption of coal[J]. Journal of Mining & Safety Engineering,2013,30(2):296−301.

[64] 马金魁,陈勇. 变质程度对煤样瓦斯解吸特征参数V1值的影响实验研究[J]. 煤矿安全,2019,50(9):29−33. MA Jinkui,CHEN Yong. Experimental research on influence of metamorphic degree on V1 value of gas desorption characteristics of coal samples[J]. Safety in Coal Mines,2019,50(9):29−33.

[65] 李伍,杨文斌,战星羽,等. 煤有机大分子碳结构石墨化机制[J]. 煤炭学报,2023,48(2):855−868. LI Wu,YANG Wenbin,ZHAN Xingyu,et al. Graphitization mechanism of coal organic macromolecular carbon structure[J]. Journal of China Coal Society,2023,48(2):855−868.

[66] 张先敏,冯其红,张纪远,等. 考虑吸附滞后效应的煤层气藏物质平衡方程建立及应用[J]. 煤炭学报,2017,42(10):2662−2669. ZHANG Xianmin,FENG Qihong,ZHANG Jiyuan,et al. Establishment and application of material balance equations for coalbed methane reservoirs considering adsorption hysteresis effect[J]. Journal of China Coal Society,2017,42(10):2662−2669.

[67] FENG Zengchao,WANG Chen,DONG Dong,et al. Experimental study of the characteristic changes of coal resistivity during the gas adsorption/desorption process[J]. Advances in Materials Science and Engineering,2018,2018(1):1450187. DOI: 10.1155/2018/1450187

[68] 王振至. 不同煤级煤N2–ECBM过程中吸附/解吸诱导应变及渗透率研究[D]. 徐州:中国矿业大学,2021. WANG Zhenzhi. Investigation of the adsorption/desorption,induced strain and permeability in different rank coal N2–ECBM process[D]. Xuzhou:China University of Mining and Technology,2021.

[69] 田永东,武杰. 沁水盆地南部高煤阶煤储层敏感性[J]. 煤炭学报,2014,39(9):1835−1839. TIAN Yongdong,WU Jie. Sensitivity of high–rank coal–bed methane reservoir in the southern Qinshui Basin[J]. Journal of China Coal Society,2014,39(9):1835−1839.

[70] SAURABH S,HARPALANI S,SINGH V K. Implications of stress re–distribution and rock failure with continued gas depletion in coalbed methane reservoirs[J]. International Journal of Coal Geology,2016,162:183−192. DOI: 10.1016/j.coal.2016.06.006

[71] WANG Zhenzhi,DENG Ze,FU Xuehai,et al. Effects of methane saturation and nitrogen pressure on N2–enhanced coalbed methane desorption strain characteristics of medium–rank coal[J]. Natural Resources Research,2021,30:1527−1545. DOI: 10.1007/s11053-020-09783-4

[72] 傅雪海,张小东,韦重韬. 煤层含气量的测试、模拟与预测研究进展[J]. 中国矿业大学学报,2021,50(1):13−31. FU Xuehai,ZHANG Xiaodong,WEI Chongtao. Review of research on testing,simulation and prediction of coalbed methane content[J]. Journal of China University of Mining and Technology,2021,50(1):13−31.

[73] WANG Zhenzhi,FU Xuehai,PAN Jienan,et al. Effect of N2/CO2 injection and alternate injection on volume swelling/shrinkage strain of coal[J]. Energy,2023,275:127377. DOI: 10.1016/j.energy.2023.127377

[74] ZHANG Baoxin,FU Xuehai,DENG Ze,et al. A comparative study on the deformation of unconfined coal during the processes of methane desorption with successively decreasing outlet pressure and with constant outlet pressure[J]. Journal of Petroleum Science and Engineering,2020,195:107531. DOI: 10.1016/j.petrol.2020.107531

[75] WANG Zhenzhi,FU Xuehai,DENG Ze,et al. Investigation of adsorption–desorption,induced strains and permeability evolution during N2–ECBM recovery[J]. Natural Resources Research,2021,30(5):3717−3734. DOI: 10.1007/s11053-021-09884-8

[76] PAN Jienan,LYU Minmin,HOU Quanlin,et al. Coal microcrystalline structural changes related to methane adsorption/desorption[J]. Fuel,2019,239:13−23. DOI: 10.1016/j.fuel.2018.10.155

[77] MUKHERJEE M,MISRA S. A review of experimental research on enhanced coal bed methane (ECBM) recovery via CO2 sequestration[J]. Earth–Science Reviews,2018,179:392−410.

[78] PILLALAMARRY M,HARPALANI S,LIU Shimin. Gas diffusion behavior of coal and its impact on production from coalbed methane reservoirs[J]. International Journal of Coal Geology,2011,86(4):342−348. DOI: 10.1016/j.coal.2011.03.007

[79] PLAZINSKI W,DZIUBA J,RUDZINSKI W. Modeling of sorption kinetics:The pseudo–second order equation and the sorbate intraparticle diffusivity[J]. Adsorption,2013,19(5):1055−1064. DOI: 10.1007/s10450-013-9529-0

[80] WANG Zhenzhi,DENG Ze,FU Xuehai,et al. Dynamic monitoring of induced strain during N2–ECBM of coal with different gas contents[J]. Energy & Fuels,2021,35(4):3140−3149.

[81] STAIB G,SAKUROVS R,GRAY E M A. Dispersive diffusion of gases in coals. Part I:Model development[J]. Fuel,2015,143:612−619. DOI: 10.1016/j.fuel.2014.11.086

[82] STAIB G,SAKUROVS R,GRAY E M A. Kinetics of coal swelling in gases:Influence of gas pressure,gas type and coal type[J]. International Journal of Coal Geology,2014,132:117−122. DOI: 10.1016/j.coal.2014.08.005

[83] 李贵红,吴信波,刘钰辉,等. 沁水潘庄煤层气井全生命周期产气规律与效果[J]. 煤炭学报,2020,45(增刊2):894−903. LI Guihong,WU Xinbo,LIU Yuhui,et al. Full life–circle production and effect evaluation of Panzhuang coalbed methane wells in Qinshui Basin[J]. Journal of China Coal Society,2020,45(Sup.2):894−903.

[84] 刘厅. 深部裂隙煤体瓦斯抽采过程中的多场耦合机制及其工程响应[D]. 徐州:中国矿业大学,2019. LIU Ting. Multifield coupling processes during gas drainage in deep fractured coal seam and its engineering response[D]. Xuzhou:China University of Mining and Technology,2019.

[85] 李志强,成墙,刘彦伟,等. 柱状煤芯瓦斯扩散模型与扩散特征实验研究[J]. 中国矿业大学学报,2017,46(5):1033−1040. LI Zhiqiang,CHENG Qiang,LIU Yanwei,et al. Research on gas diffusion model and experimental diffusion characteristic of cylindrical coal[J]. Journal of China University of Mining & Technology,2017,46(5):1033−1040.

[86] 刘正东. 高应力煤体物理结构演化特性对瓦斯运移影响机制研究[D]. 徐州:中国矿业大学,2020. LIU Zhengdong. Research on physical structure evolution characteristic of coal mass under high stress condition and its influence on gas migration[D]. Xuzhou:China University of Mining and Technology,2020.

[87] CHARRIERE D,POKRYSZKA Z,BEHRA P. Effect of pressure and temperature on diffusion of CO2 and CH4 into coal from the Lorraine Basin (France)[J]. International Journal of Coal Geology,2010,81(4):373−380. DOI: 10.1016/j.coal.2009.03.007

[88] WANG Yi,LIU Shimin. Estimation of pressure–dependent diffusive permeability of coal using methane diffusion coefficient:Laboratory measurements and modeling[J]. Energy & Fuels,2016,30(11):8968−8976.

[89] XU Hao,TANG Dazhe,ZHAO Junlong,et al. A new laboratory method for accurate measurement of the methane diffusion coefficient and its influencing factors in the coal matrix[J]. Fuel,2015,158:239−247. DOI: 10.1016/j.fuel.2015.05.046

[90] YANG Bin,KANG Yili,YOU Lijun,et al. Measurement of the surface diffusion coefficient for adsorbed gas in the fine mesopores and micropores of shale organic matter[J]. Fuel,2016,181:793−804. DOI: 10.1016/j.fuel.2016.05.069

[91] YUAN Weina,PAN Zhejun,LI Xiao,et al. Experimental study and modelling of methane adsorption and diffusion in shale[J]. Fuel,2014,117:509−519. DOI: 10.1016/j.fuel.2013.09.046

[92] 李祥春,李忠备,张良,等. 不同煤阶煤样孔隙结构表征及其对瓦斯解吸扩散的影响[J]. 煤炭学报,2019,44(增刊1):142−156. LI Xiangchun,LI Zhongbei,ZHANG Liang,et al. Pore structure characterization of various rank coals and its effect on gas desorption and diffusion[J]. Journal of China Coal Society,2019,44(Sup.1):142−156.

[93] WANG Kai,ZANG Jie,FENG Yufeng,et al. Effects of moisture on diffusion kinetics in Chinese coals during methane desorption[J]. Journal of Natural Gas Science and Engineering,2014,21:1005−1014. DOI: 10.1016/j.jngse.2014.10.032

[94] KARACAN C Ö,MITCHELL G D. Behavior and effect of different coal microlithotypes during gas transport for carbon dioxide sequestration into coal seams[J]. International Journal of Coal Geology,2003,53(4):201−217. DOI: 10.1016/S0166-5162(03)00030-2

[95] 李阳. 构造煤多尺度孔隙结构与瓦斯扩散分形特征[D]. 焦作:河南理工大学,2019. LI Yang. Fractal characteristics of multi–scale pore structure and gas diffusion in tectonic coal[D]. Jiaozuo:Henan Polytechnic University,2019.

[96] 刘大锰,刘正帅,蔡益栋. 煤层气成藏机理及形成地质条件研究进展[J]. 煤炭科学技术,2020,48(10):1−16. LIU Dameng,LIU Zhengshuai,CAI Yidong. Research progress on accumulation mechanism and formation geological conditions of coalbed methane[J]. Coal Science and Technology,2020,48(10):1−16.

[97] 秦跃平,徐浩,毋凡,等. 密度梯度驱动的煤粒瓦斯解吸扩散模型及试验研究[J]. 煤炭科学技术,2022,50(1):169−176. DOI: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201016 QIN Yueping,XU Hao,WU Fan,et al. Gas desorption and diffusion model driven by density gradient in coal particle and its experimental study[J]. Coal Science and Technology,2022,50(1):169−176. DOI: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201016

[98] NIU Qinghe,CAO Liwen,SANG Shuxun,et al. Anisotropic adsorption swelling and permeability characteristics with injecting CO2 in coal[J]. Energy & Fuels,2017,32(2):1979−1991.

[99] SAURABH S,HARPALANI S. Anisotropy of coal at various scales and its variation with sorption[J]. International Journal of Coal Geology,2019,201:14−25. DOI: 10.1016/j.coal.2018.11.008

[100] TAN Yuling,PAN Zhejun,LIU Jishan,et al. Experimental study of impact of anisotropy and heterogeneity on gas flow in coal. Part I:Diffusion and adsorption[J]. Fuel,2018,232:444−453. DOI: 10.1016/j.fuel.2018.05.173

[101] ZHAO Wei,CHENG Yuanping,PAN Zhejun,et al. Gas diffusion in coal particles:A review of mathematical models and their applications[J]. Fuel,2019,252:77−100. DOI: 10.1016/j.fuel.2019.04.065

[102] 房祥龙,蔡益栋,刘大锰. 基于低场核磁共振法的甲烷扩散特征研究[J]. 中国煤炭地质,2021,33(10):31−38. DOI: 10.3969/j.issn.1674-1803.2021.10.05 FANG Xianglong,CAI Yidong,LIU Dameng. Study on methane diffusion features based on low–field nuclear magnetic resonance (LF–NMR) method[J]. Coal Geology of China,2021,33(10):31−38. DOI: 10.3969/j.issn.1674-1803.2021.10.05

[103] 王凯,赵伟. 煤孔隙空间几何特征对瓦斯解吸曲线形态的控制机制研究进展[J]. 中国科学基金,2021,35(6):917−923. WANG Kai,ZHAO Wei. Research progress on the control mechanism of coal pore space geometric characteristics on the shape of gas desorption curves[J]. Bulletin of National Natural Science Foundation of China,2021,35(6):917−923.

[104] MATHIAS S A,DENTZ M,LIU Qingquan. Gas diffusion in coal powders is a multi–rate process[J]. Transport in Porous Media,2020,131(3):1037−1051. DOI: 10.1007/s11242-019-01376-x

[105] 李相方,石军太,杜希瑶,等. 煤层气藏开发降压解吸气运移机理[J]. 石油勘探与开发,2012,39(2):203−213. LI Xiangfang,SHI Juntai,DU Xiyao,et al. Transport mechanism of desorbed gas in coalbed methane reservoirs[J]. Petroleum Exploration and Development,2012,39(2):203−213.

[106] 徐凤银,肖芝华,陈东,等. 我国煤层气开发技术现状与发展方向[J]. 煤炭科学技术,2019,47(10):205−215. XU Fengyin,XIAO Zhihua,CHEN Dong,et al. Current status and development direction of coalbed methane exploration technology in China[J]. Coal Science and Technology,2019,47(10):205−215.

[107] 刘操,张玉贵,贾天让,等. 气源岩吸附试验的机理及吸附特征新认识[J]. 煤炭学报,2019,44(11):3441−3452. LIU Cao,ZHANG Yugui,JIA Tianrang,et al. New interpretation of adsorption test mechanism and adsorption law for gas source rock[J]. Journal of China Coal Society,2019,44(11):3441−3452.

[108] 朱汉卿,贾爱林,位云生,等. 蜀南地区富有机质页岩孔隙结构及超临界甲烷吸附能力[J]. 石油学报,2018,39(4):391−401. DOI: 10.7623/syxb201804003 ZHU Hanqing,JIA Ailin,WEI Yunsheng,et al. Pore structure and supercritical methane sorption capacity of organic–rich shales in southern Sichuan Basin[J]. Acta Petrolei Sinica,2018,39(4):391−401. DOI: 10.7623/syxb201804003

[109] 董银涛,鞠斌山,刘楠楠. 页岩甲烷高压等温吸附模型评价与改进[J]. 煤炭学报,2020,45(9):3208−3218. DONG Yintao,JU Binshan,LIU Nannan. Evaluation and improvement of high–pressure isothermal adsorption model for methane in shale[J]. Journal of China Coal Society,2020,45(9):3208−3218.

[110] HU Biao,CHENG Yuanping,HE Xinxin,et al. New insights into the CH4 adsorption capacity of coal based on microscopic pore properties[J]. Fuel,2020,262:116675. DOI: 10.1016/j.fuel.2019.116675

[111] 张新宾,宋党育,李云波,等. 超临界态甲烷密度研究[J]. 煤田地质与勘探,2021,49(1):137−142. DOI: 10.3969/j.issn.1001-1986.2021.01.014 ZHANG Xinbin,SONG Dangyu,LI Yunbo,et al. Study on density of the supercritical methane[J]. Coal Geology & Exploration,2021,49(1):137−142. DOI: 10.3969/j.issn.1001-1986.2021.01.014

[112] YAO Yanbin,LIU Dameng,XIE Songbin. Quantitative characterization of methane adsorption on coal using a low–field NMR relaxation method[J]. International Journal of Coal Geology,2014,131:32−40. DOI: 10.1016/j.coal.2014.06.001

下载:

下载: