Seepage evolution patterns and self-sealing characterization of mining-induced overburden fractures in ecologically vulnerable mining areas

-

摘要:目的

我国西部生态脆弱区受煤矿开采影响巨大,在开采扰动下采空区上覆含水岩层遭到破坏,易导致水资源流失、土地荒漠化等问题,为此人工引导裂隙自修复进而保护或恢复地下水位至关重要。

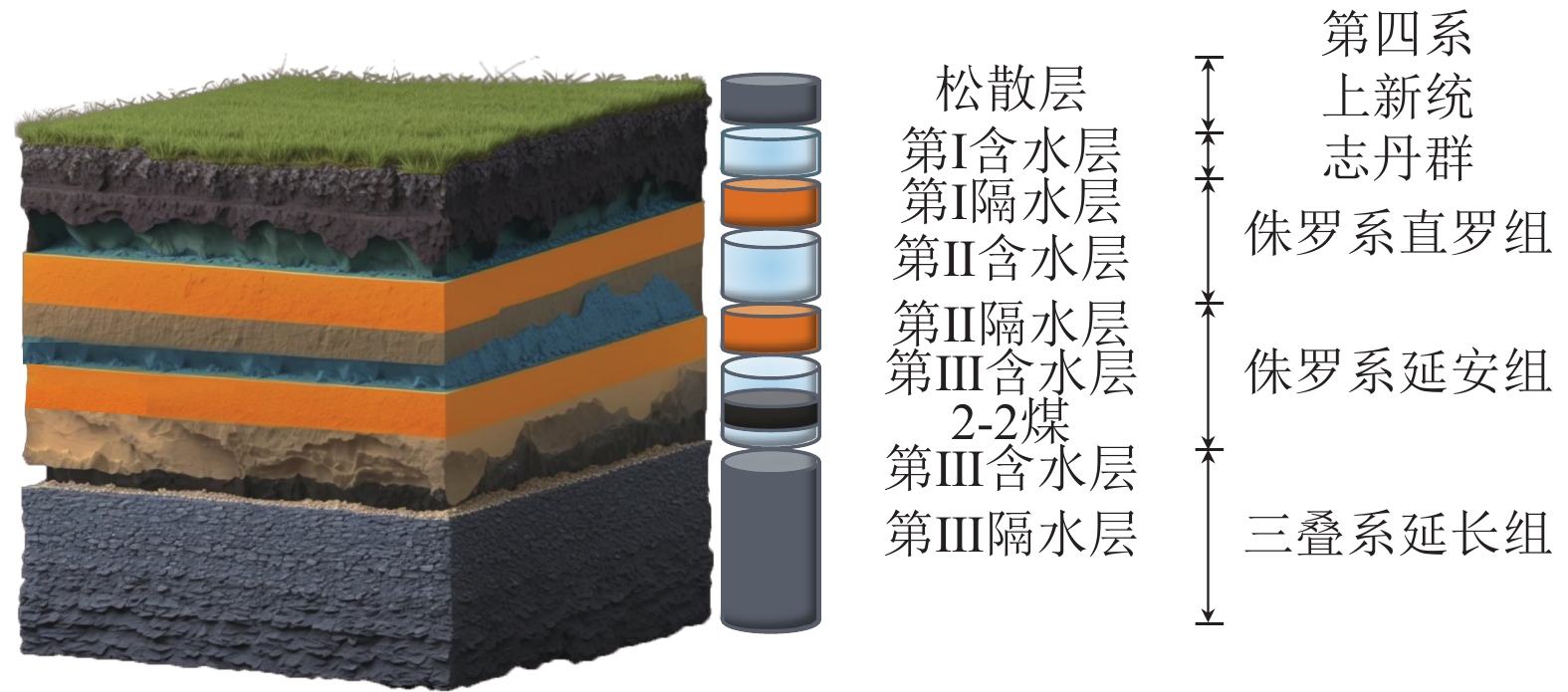

方法以内蒙古布尔台煤矿22108工作面为工程背景,采用物理相似试验、数值计算与理论分析等方法,深入研究开采扰动和裂隙水渗流耦合作用下生态脆弱矿区煤层覆岩裂隙渗流演化规律,并对覆岩裂隙自修复效果进行表征分析。

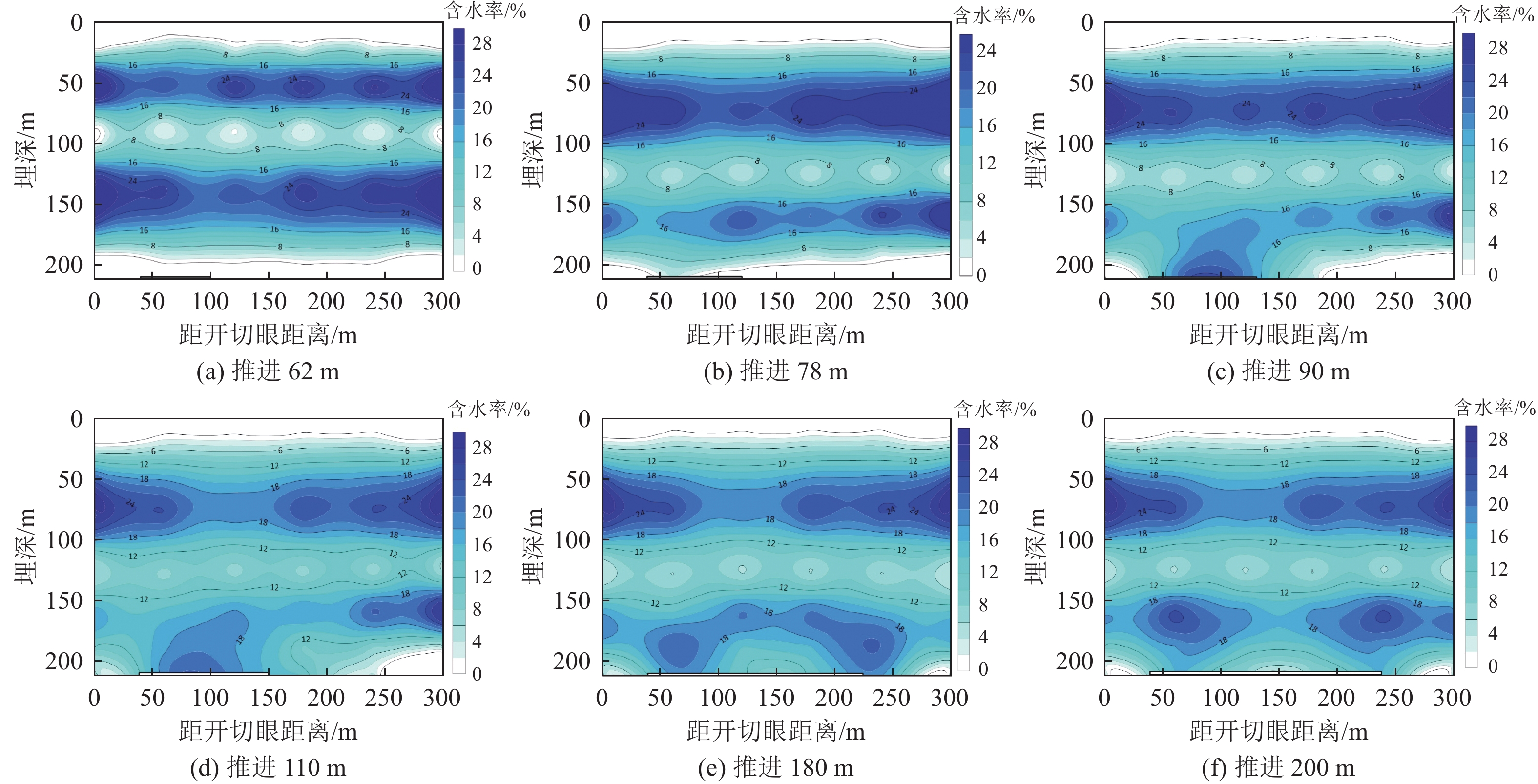

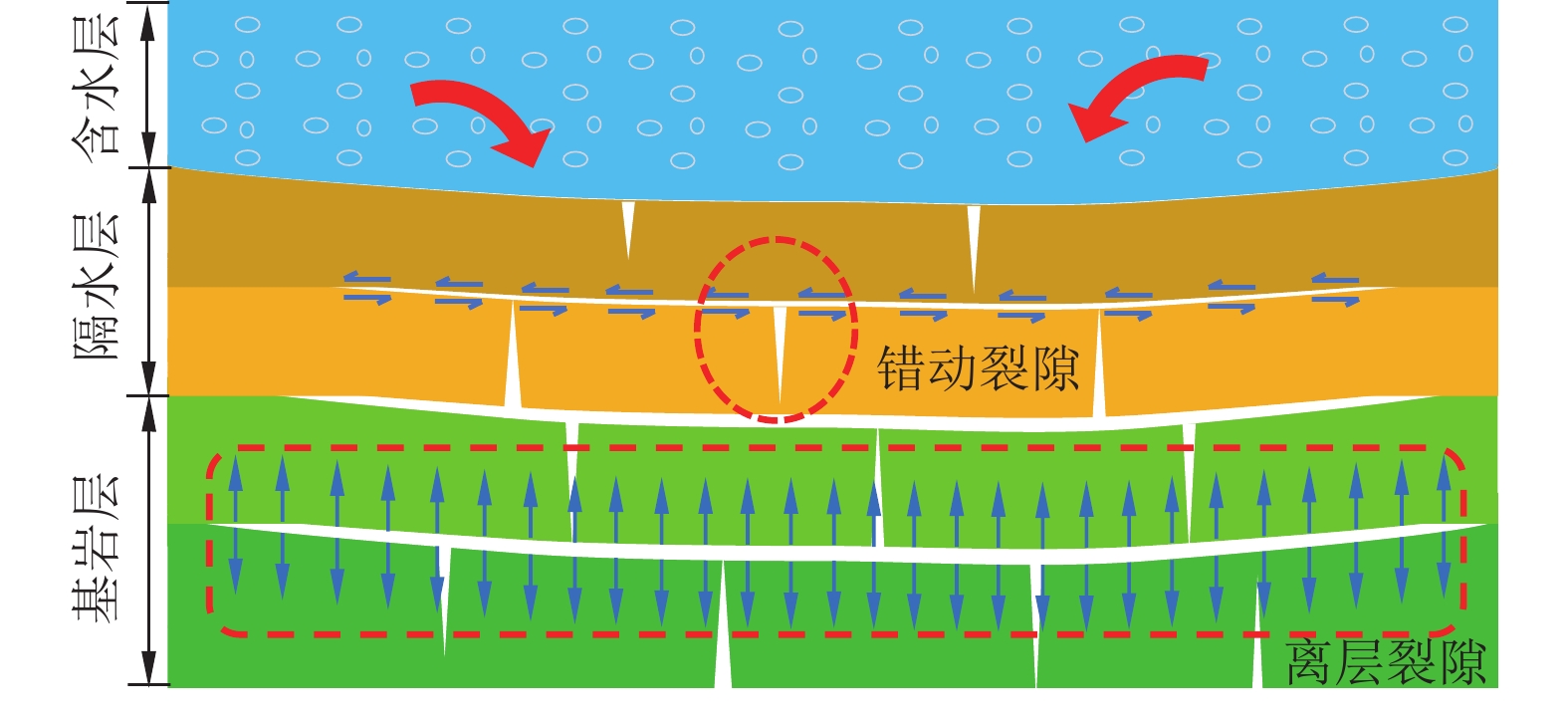

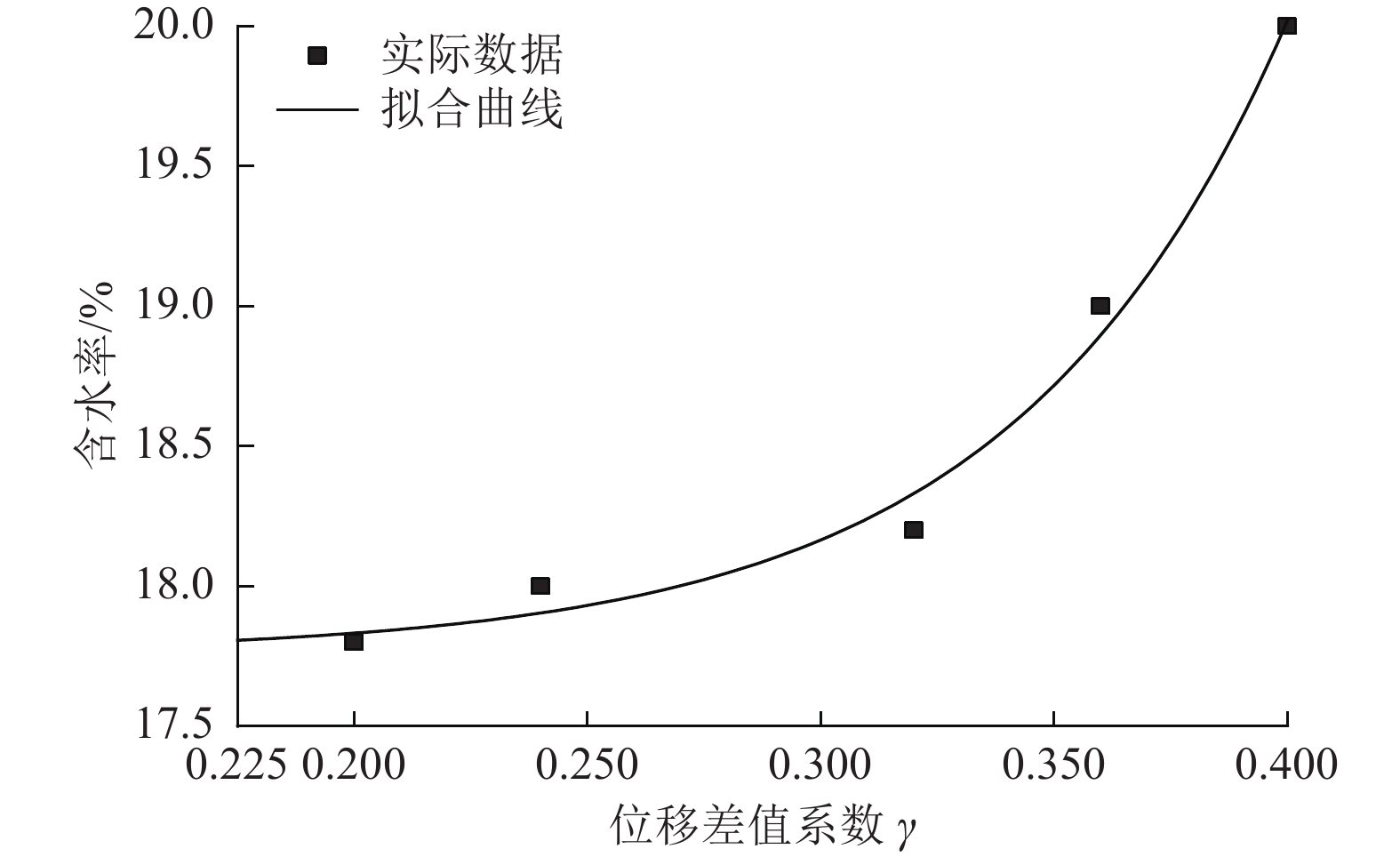

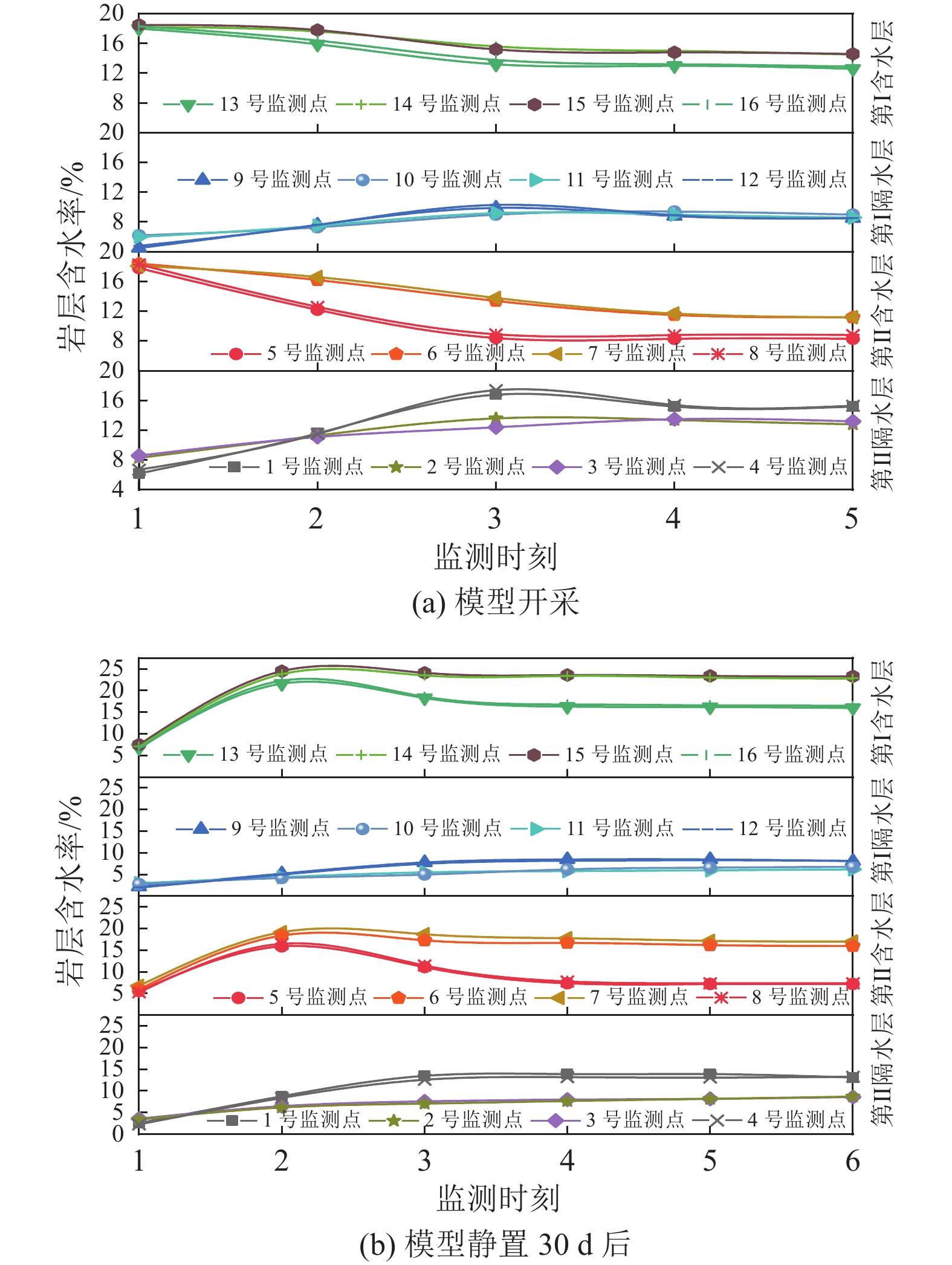

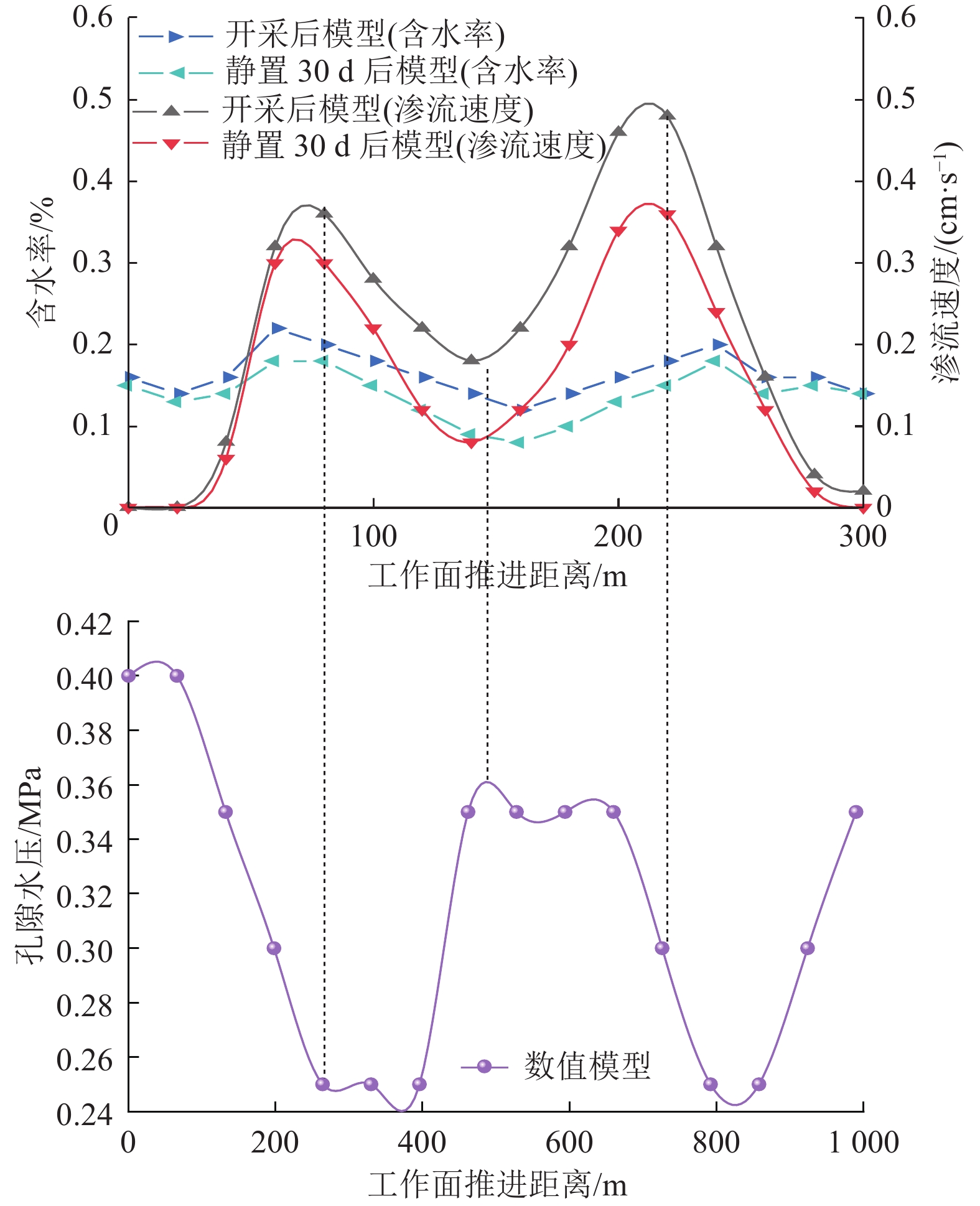

结果与结论结果显示:(1)基于位移差值系数,裂隙发育总体表现为采空区两侧高度发育、中部压实的“双峰”状分布。(2)工作面推进78 m时,导水裂隙已发育至第Ⅱ含水层,此时位移差值系数为0.25,并出现突变现象,渗流演化分布与覆岩裂隙发育开始呈现强相关性,位移差值系数由0.25增大至0.40时,覆岩隔水层含水率平均增加2.0%,且开采边界附近裂隙导流能力大于其采空区中部覆岩裂隙导流能力。(3)开采结束后,第Ⅱ含水层水位较开采前有所下降,平均水位下移13 m,由于采空区压实及覆岩采动裂隙闭合形成新的含水层,地下水流场实现自身演替。(4)经长期残余沉降、应力压实等多因素耦合影响,覆岩裂隙岩体表现出隔水层降渗的自修复现象,根据模拟开采完毕8.3 a后自修复结果显示,基于导水裂隙渗流速度求得采空区中部覆岩区域自修复率为45.5%~55.6%,开采边界区域自修复率为6.3%~25.0%;基于覆岩含水率求得采空区中部区域自修复率为33.3%~35.7%,开采边界区域自修复率为10.0%~18.2%。研究成果为揭示西部生态脆弱矿区覆岩裂隙渗流演化规律及其自修复特性的定量表征提供了理论依据。

Abstract:ObjectiveThe ecologically vulnerable areas (EVAs) in West China have been significantly affected by coal mining. In these areas, aquifers overlying goaves have been damaged under mining disturbance, being prone to cause water resource loss and desertification. Hence, it is crucial to guide the self-sealing of fractures artificially to preserve and further restore the groundwater level.

MethodsThis study investigated mining face 22108 in the Buertai coal mine in the Inner Mongolia Autonomous Region. Based on the physical simulation experiments using similar materials, numerical calculations, and theoretical analysis, this study delved into the seepage evolution patterns of fractures in the overburden of coal seam 2-2 in the ecologically vulnerable mining area under the coupling effect of mining disturbance and fracture water seepage. Moreover, this study characterized and analyzed the self-sealing effect of overburden fractures.

Results and ConclusionsThe results indicate that the overall fracture development, derived using displacement difference coefficients, exhibited a bimodal distribution characterized by highly-developed fractures on both sides of the goaf and compaction in its central part. As the mining face advanced for 78 m, hydraulically conductive fractures propagated to the No.Ⅱ aquifer, corresponding to a displacement difference coefficient of 0.25 and an abrupt change in moisture content. In this case, the evolution and distribution of seepage began to correlate passively with the development of overburden fractures. As the displacement difference coefficient increased from 0.25 to 0.40, the average moisture content of aquicludes in the overburden increased by 2.0%. Concurrently, fractures near the mining boundary exhibited higher conductivity than overburden fractures in the central part of the goaf. After coal mining, the groundwater level in the No.Ⅱ aquifer declined by 13 m on average, and new aquifers were formed by the compaction of the goaf and the closure of mining-induced overburden fractures, suggesting the succession of the groundwater flow field. Under the long-term influence of multiple factors like residual subsidence and stress-induced compaction, the fractured rock masses in the overburden showed a self-sealing phenomenon as evidenced by seepage reduction in aquicludes. According to the simulation results of self-sealing 8.3 years after coal mining, the fracture self-sealing rates, calculated using the seepage velocity of hydraulically conductive fractures, ranged from 45.5% to 55.6% in the central part of the goaf and from 6.3% to 25.0% in the mining boundary areas. In contrast, the self-sealing rates calculated based on the moisture content of the overburden ranged from 33.3% to 35.7% in the central part of the goaf and from 10.0% to 18.2% in the mining boundary area. The results of this study provide a theoretical basis for revealing the evolution patterns of seepage in overburden fractures in ecologically vulnerable mining areas in West China and quantitatively characterizing the self-sealing capacity of fractures.

-

-

图 15 同一时刻工作面不同推进距离下物理相似模型渗流速度、含水率与数值模型孔隙水压演化特征曲线

Fig. 15 Curves showing the evolutionary characteristics of seepage velocity and moisture content (derived using the physical simulation experiment model using similar materials) and pore water pressure (derived using the numerical model) under varying advancing distances of the mining face at the same time

表 1 22108工作面顶底板情况

Table 1 Roofs and floors of mining face 22108

顶底板名称 岩石名称 厚度/m 抗压强度/

MPa抗拉强度/

MPa岩性特征 基本顶 粉砂岩 3~21/10 27.37 7.8 浅灰色,巨厚层状,含云母碎片,局部含煤屑及夹细粒砂岩薄层,半坚硬 直接顶 砂质泥岩 3~18/11 25.38 5.3 深灰色,半坚硬,参差状断口,泥质结构,含不完整植物化石 直接底 砂质泥岩 2~20/7 25.90 5.3 灰色,半坚硬,参差状断口,泥质结构,局部夹薄层粉砂岩,含植物化石及煤线 基本底 砂质泥岩 2~18/5 25.10 5.3 灰白色,含少量云母,炭屑,平坦状断口 注:3~21/10表示最小~最大值/均值,其他同。 表 2 材料配比及分层质量

Table 2 Ratios of materials and layer mass

序号 含/隔水层设置 岩性 原岩厚度/m 模型厚度/cm 配比号 分层质量/kg 砂子质量/kg 碳酸钙/膨润土/kg 石膏质量/kg 1 黄土风积沙 12.00 6.00 873 21.60 19.20 1.68 0.72 2 含砾砂岩 10.00 5.00 373 18.00 18.00 2.84 1.22 3 粗砂岩 10.00 5.00 637 18.00 18.00 0.70 1.62 4 砂质泥岩 13.00 6.50 737 24.12 24.12 0.81 1.91 5 细砂岩 21.20 10.60 555 34.20 34.20 2.57 2.57 6 砂质泥岩 15.00 7.50 737 27.00 27.00 0.90 2.13 7 第Ⅰ含水层 中砂岩 20.00 10.00 637 37.80 37.80 1.47 3.39 8 第Ⅰ隔水层 砂质泥岩 12.80 6.40 755 22.86 22.86 1.29 1.29 9 粉砂岩 13.20 6.60 537 23.76 23.76 1.07 2.49 10 砂质泥岩 16.00 8.00 755 28.80 28.80 1.62 1.62 11 第Ⅱ含水层 细砂岩 34.80 17.40 555 62.64 62.64 4.43 10.31 12 第Ⅱ隔水层 砂质泥岩 23.20 11.60 755 41.76 41.76 2.36 2.36 13 泥岩 11.80 5.90 473 21.24 21.24 2.67 1.15 14 粉砂岩 9.80 4.90 637 17.64 17.64 1.72 4.02 15 砂质泥岩 10.00 5.00 555 18.00 18.00 1.35 1.35 16 煤层 2-2煤 3.80 1.90 773 6.66 6.66 0.52 0.22 表 3 数值模型煤岩层物理力学参数

Table 3 Physical and mechanical parameters of the coal seam and rock layers in the numerical model

岩层编号 岩性 厚度/m 剪切模量G/MPa 体积模量KV/MPa 黏聚力C/MPa 抗拉强度/MPa 内摩擦角φ/(°) 1 表土 16.00 2 含砾粗砂岩 12.00 2100 6000 3.80 12.2 20 3 粗砂岩 10.00 2540 5500 3.00 7.8 30 4 砂质泥岩 10.00 1600 2400 1.20 5.3 28 5 细砂岩 13.00 2200 4500 2.30 10.3 29 6 砂质泥岩 21.20 1430 2400 0.80 5.3 25 7 中砂岩 15.00 2 000 4800 2.60 11.1 32 8 砂质泥岩 20.00 1600 2400 1.20 5.3 28 9 粉砂岩 12.80 2100 2600 1.00 5.3 28 10 砂质泥岩 13.20 1600 2400 1.20 5.3 28 11 粗砂岩 16.00 2540 5500 3.00 7.8 30 12 细砂岩 34.80 2200 4500 2.30 10.3 29 13 砂质泥岩 23.20 1600 2400 1.20 5.3 28 14 泥岩 11.80 2 000 5800 3.60 9.1 35 15 粉砂岩 9.80 2540 5500 3.00 7.8 30 16 砂质泥岩 10.00 1600 2400 1.20 5.3 28 17 2-2煤 3.80 1 960 3200 0.64 1.2 20 18 砂质泥岩 5.00 1600 2400 1.20 5.3 28 -

[1] 王双明,刘浪,朱梦博,等. “双碳”目标下煤炭绿色低碳发展新思路[J]. 煤炭学报,2024,49(1):152−171. WANG Shuangming,LIU Lang,ZHU Mengbo,et al. New way for green and low–carbon development of coal industry under the target of “dual–carbon”[J]. Journal of China Coal Society,2024,49(1):152−171.

[2] 彭苏萍,毕银丽. 西部干旱半干旱煤矿区生态环境损伤特征及修复机制[J]. 煤炭学报,2024,49(1):57−64. PENG Suping,BI Yinli. Properties of ecological environment damage and their mechanism of restoration in arid and semi–arid coal mining area of western China[J]. Journal of China Coal Society,2024,49(1):57−64.

[3] 王双明,孙强,耿济世,等. 西部矿区采动损害及减损开采的地质保障技术框架体系[J]. 煤田地质与勘探,2024,52(9):1−13. WANG Shuangming,SUN Qiang,GENG Jishi,et al. Geological support technology framework system for mining induced hazards and damage reduction mining of geological conditions in western mining area[J]. Coal Geology & Exploration,2024,52(9):1−13.

[4] 姚强岭,于利强,陈胜焱,等. 西部生态脆弱矿区采动水资源与生态环境效应[J/OL]. 煤炭学报,2024:1–22 [2025-02-19]. https://doi.org/10.13225/j.cnki.jccs.2023.1695 YAO Qiangling,YU Liqiang,CHEN Shengyan,et al. Mining–affected water resources and ecological effects in ecologically fragile mining areas of western China[J/OL]. Journal of China Coal Society,2024:1–22 [2025-02-19]. https://doi.org/10.13225/j.cnki.jccs.2023.1695.

[5] 申艳军,杨博涵,王双明,等. 黄河几字弯区煤炭基地地质灾害与生态环境典型特征[J]. 煤田地质与勘探,2022,50(6):104−117. SHEN Yanjun,YANG Bohan,WANG Shuangming,et al. Typical characteristics of geological hazards and ecological environment of coal base in the bends area of the Yellow River[J]. Coal Geology & Exploration,2022,50(6):104−117.

[6] 何柯璐,汤伏全,李振洪. 基于地形特征的采煤沉陷盆地构建与水平移动信息智能提取方法[J]. 武汉大学学报(信息科学版),2023,48(5):717−729. HE Kelu,TANG Fuquan,LI Zhenhong. Coal mining subsidence basin construction and horizontal movement intelligent extraction based on topographic features[J]. Geomatics and Information Science of Wuhan University,2023,48(5):717−729.

[7] 王震宇,刘晓民,刘廷玺,等. 煤炭资源富集区煤–水协调共采影响因素研究[J/OL]. 煤炭科学技术,2024:1–14 [2025-02-19]. http://kns.cnki.net/kcms/detail/11.2402.td.20240521.1632.003.html. WANG Zhenyu,LIU Xiaomin,LIU Tingxi,et al. Study on influencing factors of coal–water coordinated co–mining in coal resource rich area[J/OL]. Coal Science and Technology,2024:1–14 [2025-02-19]. http://kns.cnki.net/kcms/detail/11.2402.td.20240521.1632.003.html.

[8] 李全生,李晓斌,许家林,等. 岩层采动裂隙演化规律与生态治理技术研究进展[J]. 煤炭科学技术,2022,50(1):28−47. LI Quansheng,LI Xiaobin,XU Jialin,et al. Research advances in mining fractures evolution law of rock strata and ecological treatment technology[J]. Coal Science and Technology,2022,50(1):28−47.

[9] 隋旺华. 基于结构水文地质学的采掘诱发高势能突水溃砂主动防控[J]. 工程地质学报,2022,30(1):101−109. SUI Wanghua. Active prevention and control of water–sand mixture inrush with high potential energy due to mining based on structural hydrogeology[J]. Journal of Engineering Geology,2022,30(1):101−109.

[10] LI Xiaobin,JI Dongliang,HAN Penghua,et al. Study of water–conducting fractured zone development law and assessment method in longwall mining of shallow coal seam[J]. Scientific Reports,2022,12(1):7994. DOI: 10.1038/s41598-022-12023-9

[11] DONG Fangying,YIN Huiyong,REN Hongxu,et al. Trapezoidal failure behavior and fracture evolution mechanism of overburden in extra–thick coal mining in weakly cemented strata[J]. Rock Mechanics and Rock Engineering,2024,57(12):11239−11260. DOI: 10.1007/s00603-024-04147-3

[12] ZHANG Ze,WANG Shuhong,HAN Bowen,et al. Influence of normal stress–induced three–dimensional rough fracture aperture heterogeneity on nonlinear seepage–heat transfer coupling processes[J]. International Journal for Numerical and Analytical Methods in Geomechanics,2024,48(4):974−1000. DOI: 10.1002/nag.3672

[13] YU Beichen,ZHANG Dongming,LI Shujian,et al. Biot’s coefficient and permeability evolution of damaged anisotropic coal subjected to true triaxial stress[J]. Rock Mechanics and Rock Engineering,2023,56(1):237−260. DOI: 10.1007/s00603-022-03085-2

[14] 李全生,鞠金峰,许家林,等. 神东矿区采动裂隙岩体自修复特征研究[J]. 煤炭科学技术,2023,51(8):12−22. LI Quansheng,JU Jinfeng,XU Jialin,et al. Self–healing law of mining fractured rock mass in Shendong Coalfield[J]. Coal Science and Technology,2023,51(8):12−22.

[15] 李全生,鞠金峰,许家林,等. 导水裂隙的自修复:地下水混流沉淀的影响[J]. 煤炭学报,2023,48(6):2540−2549. LI Quansheng,JU Jinfeng,XU Jialin,et al. Self–healing mechanisms of water–conducting fractures:The influence of chemical precipitation induced by the mixing of different groundwater[J]. Journal of China Coal Society,2023,48(6):2540−2549.

[16] JU Jinfeng,LI Quansheng,XU Jialin,et al. Self–healing effect of water–conducting fractures due to water–rock interactions in undermined rock strata and its mechanisms[J]. Bulletin of Engineering Geology and the Environment,2020,79(1):287−297. DOI: 10.1007/s10064-019-01550-x

[17] 鞠金峰,李全生,许家林,等. 采动含水层生态功能修复研究进展[J]. 煤炭科学技术,2020,48(9):102−108. JU Jinfeng,LI Quansheng,XU Jialin,et al. Progress of ecological remediation technology of mining–damaged aquifer[J]. Coal Science and Technology,2020,48(9):102−108.

[18] JIANG Chuanyin,DELPHINE R,LEI Qinghua,et al. Anomalous transport and upscaling in critically–connected fracture networks under stress conditions[J]. Journal of Hydrology,2024,630:130661. DOI: 10.1016/j.jhydrol.2024.130661

[19] LUKAS R,MARIA R L,LIU Quan,et al. Hybrid discrete fracture network inversion of hydraulic tomography data from a fractured–porous field site[J]. Water Resources Research,2024,60(1):e2023WR036035. DOI: 10.1029/2023WR036035

[20] 张世忠,范钢伟,张东升,等. 应力–损伤–渗流耦合下采动弱胶结覆岩渗透性演化规律[J]. 采矿与安全工程学报,2024,41(6):1230−1240. ZHANG Shizhong,FAN Gangwei,ZHANG Dongsheng,et al. Mining–induced permeability evolution in weakly cemented strata under stress–damage–seepage coupling[J]. Journal of Mining & Safety Engineering,2024,41(6):1230−1240.

[21] HE Xiang,ZHANG Cun,YANG Ke,et al. Cooperative failure of overburden–surface and its control measures in longwall mining[J]. Geotechnical and Geological Engineering,2023,41(6):3587−3604. DOI: 10.1007/s10706-023-02475-9

[22] 李聪聪,王佟,赵欣,等. 高原高寒矿区生态修复中的煤炭资源保护技术[J]. 煤田地质与勘探,2024,52(11):1−11. LI Congcong,WANG Tong,ZHAO Xin,et al. Techniques for coal resource conservation during the ecological restoration of alpine mining areas on plateaus[J]. Coal Geology & Exploration,2024,52(11):1−11.

[23] 刘成勇,宋伟,盛奉天,等. 强含水层下特厚煤层综放开采导水裂隙带发育高度[J]. 采矿与岩层控制工程学报,2024,6(2):023524. LIU Chengyong,SONG Wei,SHENG Fengtian,et al. Development height of water–conducting fracture zone in fully–mechanized caving of extra–thick coal seam under strong aquifer[J]. Journal of Mining and Strata Control Engineering,2024,6(2):023524.

[24] 李全生,鞠金峰,曹志国,等. 采后10 a垮裂岩体自修复特征的钻孔探测研究:以神东矿区万利一矿为例[J]. 煤炭学报,2021,46(5):1428−1438. LI Quansheng,JU Jinfeng,CAO Zhiguo,et al. Detection of the self–healing characteristics of mining fractured rock mass after 10 years of underground coal mining:A case study of Wanli Coal Mine Shendong mining area[J]. Journal of China Coal Society,2021,46(5):1428−1438.

[25] 陈卫忠,雷江,于洪丹,等. 温度–渗流–应力耦合条件下黏土岩裂隙自闭合特性研究现状与思考[J]. 岩石力学与工程学报,2019,38(9):1729−1746. CHEN Weizhong,LEI Jiang,YU Hongdan,et al. A review of self–sealing characteristics of clay rocks under coupled thermo–hydro–mechanical conditions[J]. Chinese Journal of Rock Mechanics and Engineering,2019,38(9):1729−1746.

[26] 张玉军,张维庆. 裂隙贯通率对双重孔隙介质热–水–应力耦合现象影响的有限元分析[J]. 岩土力学,2011,32(12):3743−3750. DOI: 10.3969/j.issn.1000-7598.2011.12.034 ZHANG Yujun,ZHANG Weiqing. Finite element analyses of effects of fracture continuity rate on thermo–hydro–mechanical coupling in dual–porosity medium[J]. Rock and Soil Mechanics,2011,32(12):3743−3750. DOI: 10.3969/j.issn.1000-7598.2011.12.034

[27] 来兴平,张旭东,单鹏飞,等. 厚松散层下三软煤层开采覆岩导水裂隙发育规律[J]. 岩石力学与工程学报,2021,40(9):1739−1750. LAI Xingping,ZHANG Xudong,SHAN Pengfei,et al. Study on development law of water–conducting fractures in overlying strata of three soft coal seam mining under thick loose layers[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(9):1739−1750.

[28] 黄庆享,韩金博. 浅埋近距离煤层开采裂隙演化机理研究[J]. 采矿与安全工程学报,2019,36(4):706−711. HUANG Qingxiang,HAN Jinbo. Study on fracture evolution mechanism of shallow–buried close coal seam mining[J]. Journal of Mining & Safety Engineering,2019,36(4):706−711.

[29] 李建伟,刘长友,卜庆为. 浅埋厚煤层开采覆岩采动裂缝时空演化规律[J]. 采矿与安全工程学报,2020,37(2):238−246 LI Jianwei,LIU Changyou,BU Qingwei. Spatio–temporal evolution of overburden fissures in shallow thick coal seam mining[J]. Journal of Mining & Safety Engineering,2020,37(2):238−246.

[30] 余伊河,马立强,张东升,等. 长壁工作面采动覆岩层理开裂机理及侧向裂隙发育规律[J]. 煤炭学报,2023,48(增刊2):527−541. YU Yihe,MA Liqiang,ZHANG Dongsheng,et al. Mechanism of bedding cracking and development laws of lateral fracture in overlying strata induced by longwall mining[J]. Journal of China Coal Society,2023,48(Sup.2):527−541.

[31] 徐超,王凯,郭琳,等. 采动覆岩裂隙与渗流分形演化规律及工程应用[J]. 岩石力学与工程学报,2022,41(12):2389−2403. XU Chao,WANG Kai,GUO Lin,et al. Fractal evolution law of overlying rock fracture and seepage caused by mining and its engineering application[J]. Chinese Journal of Rock Mechanics and Engineering,2022,41(12):2389−2403.

下载:

下载: