Downhole heaters for in-situ pyrolysis of tar-rich coals:A review and prospects

-

摘要:

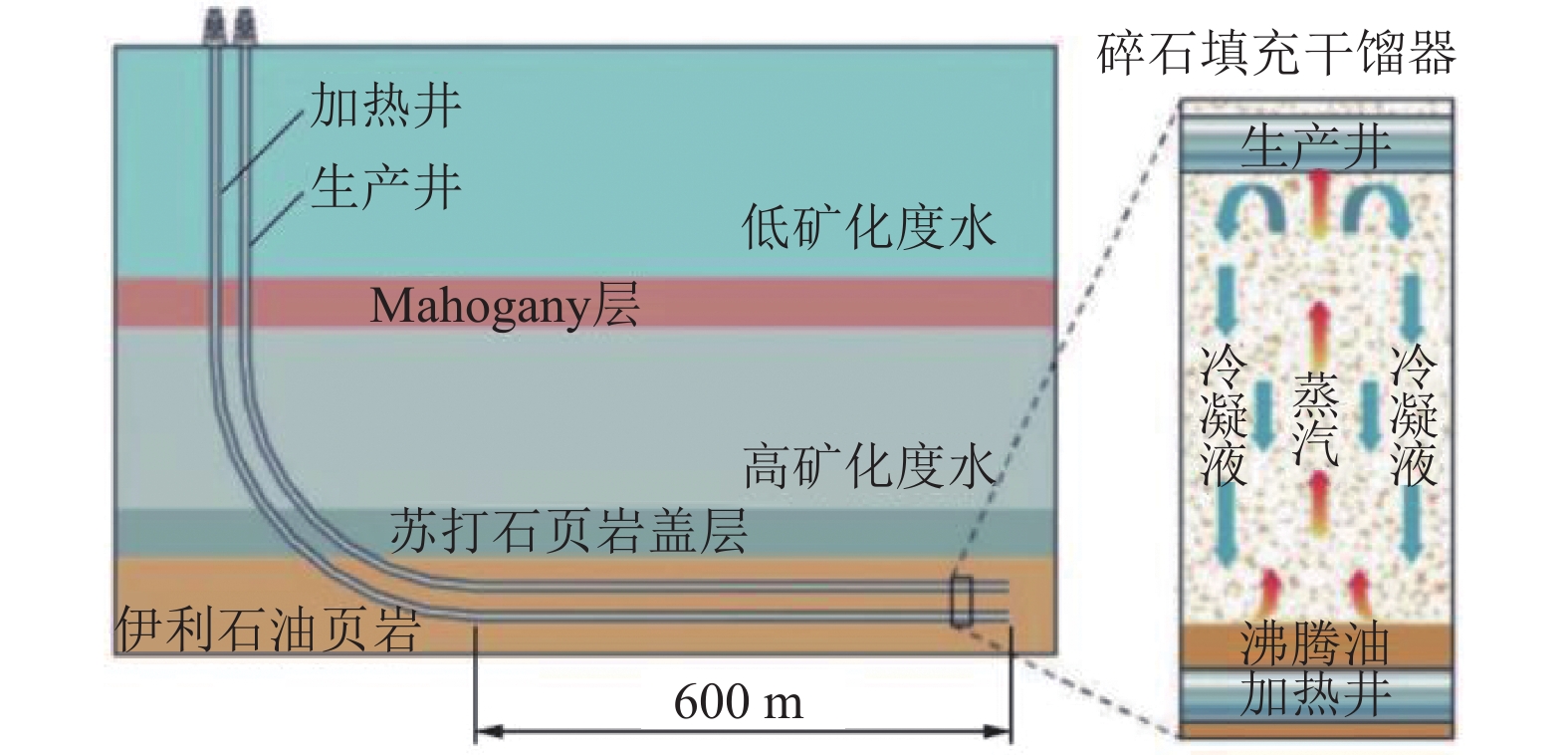

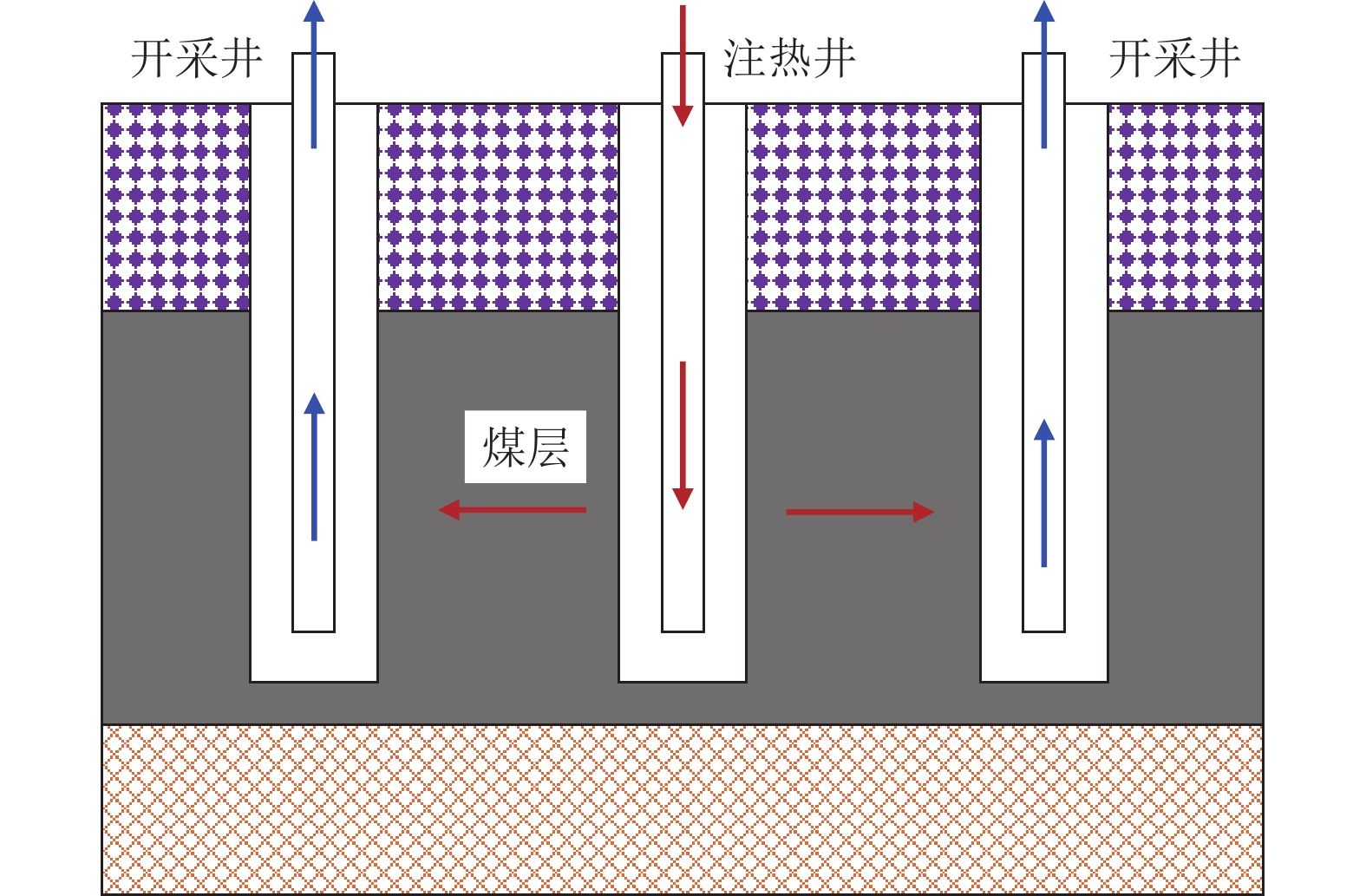

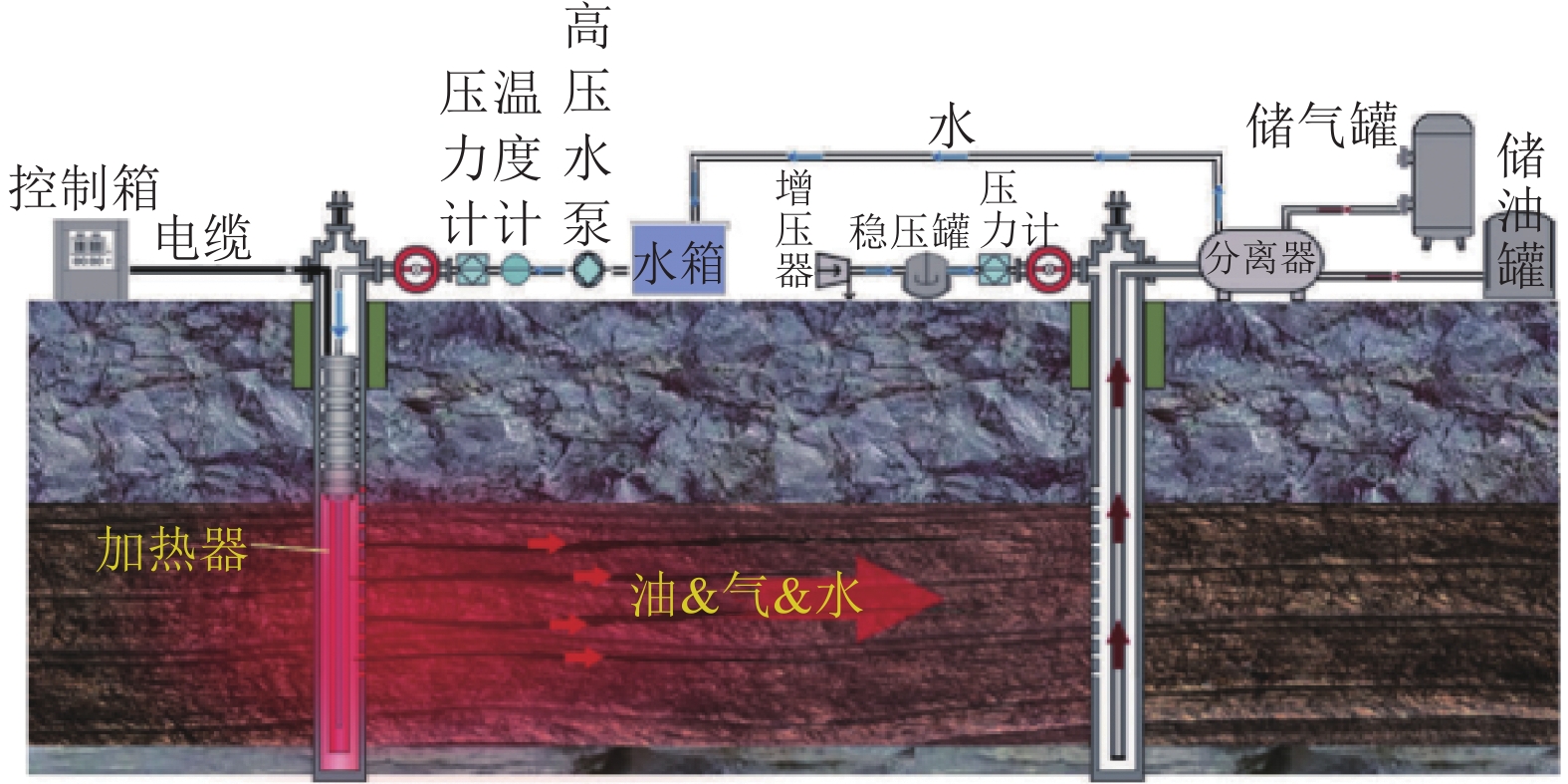

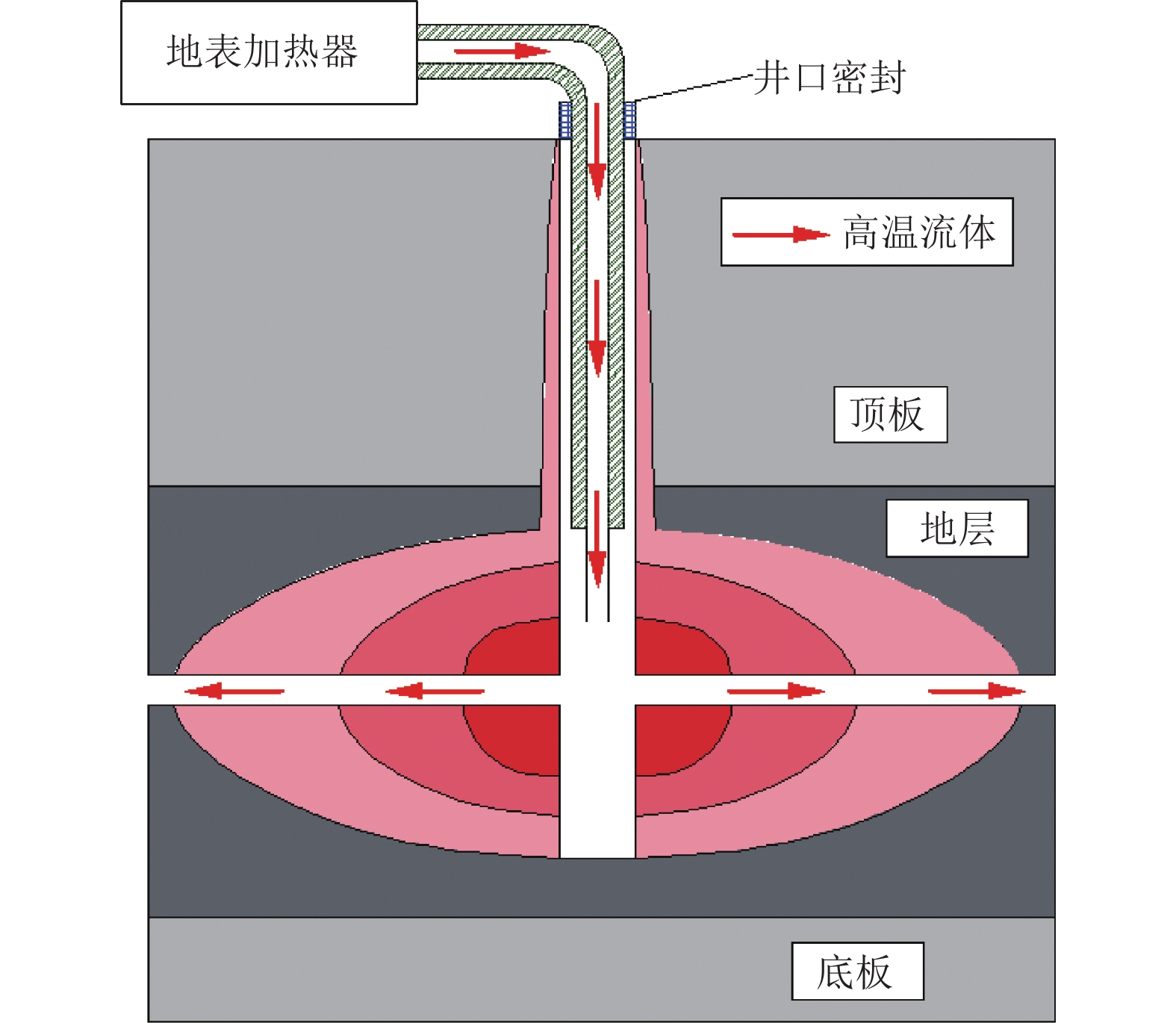

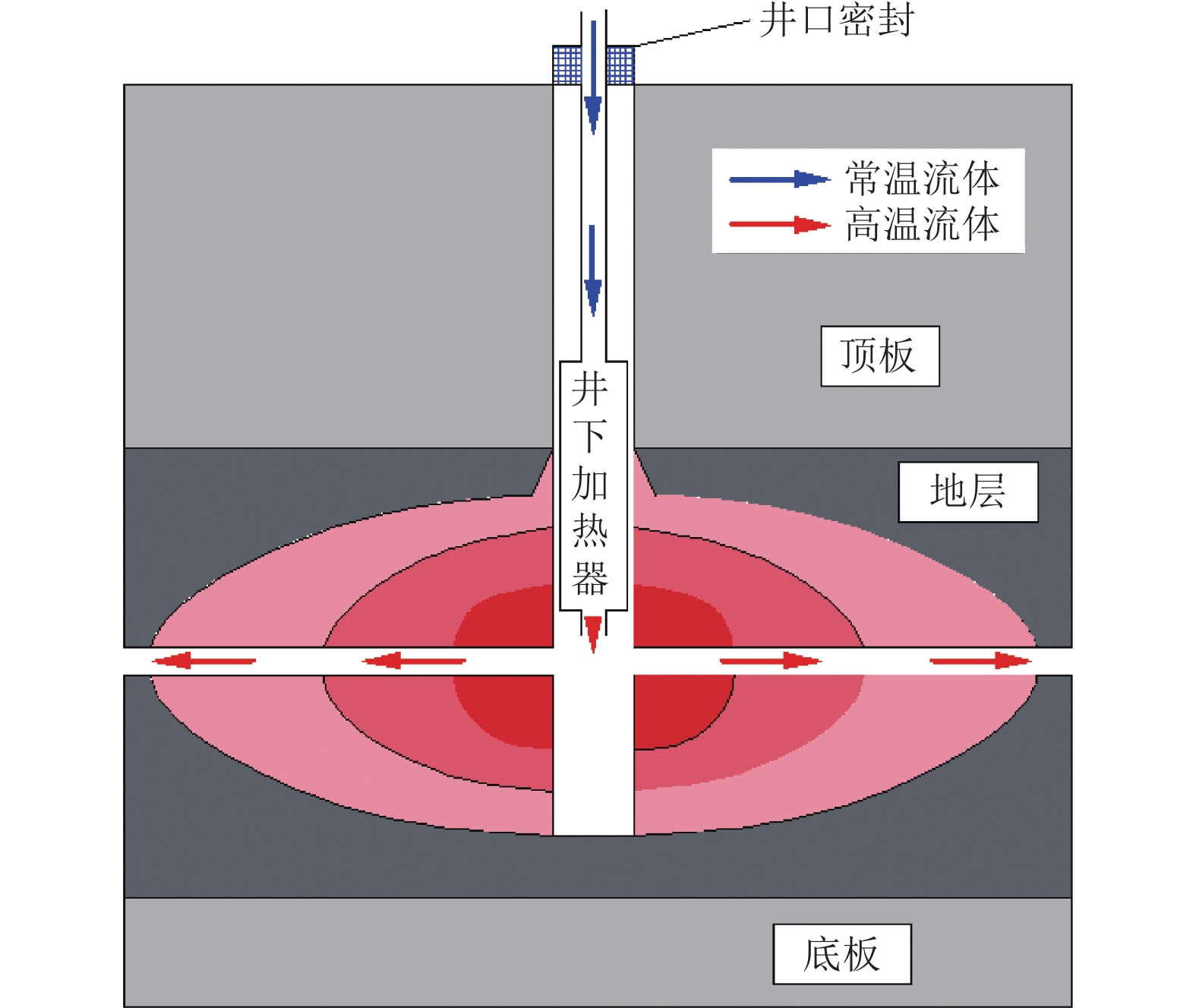

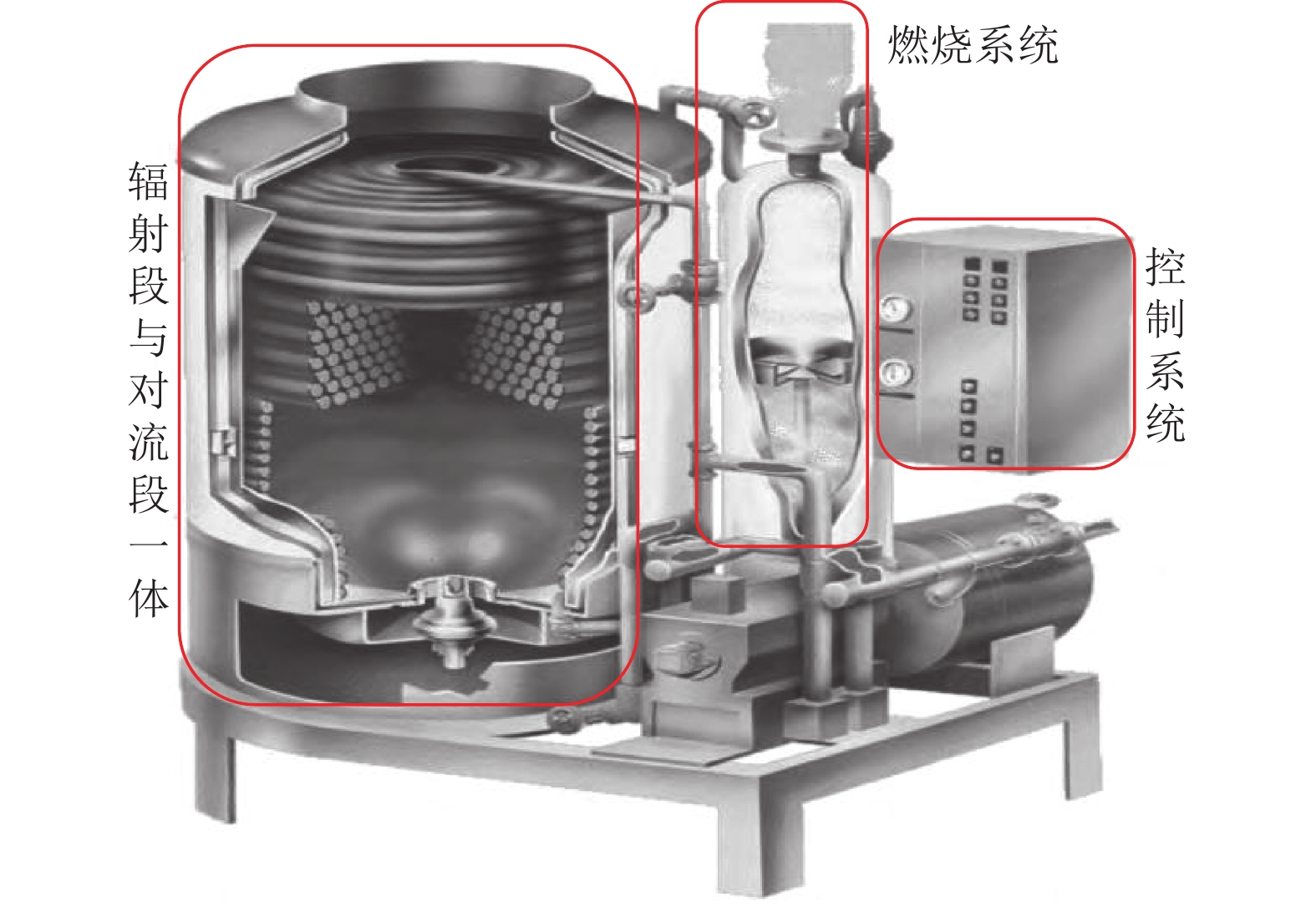

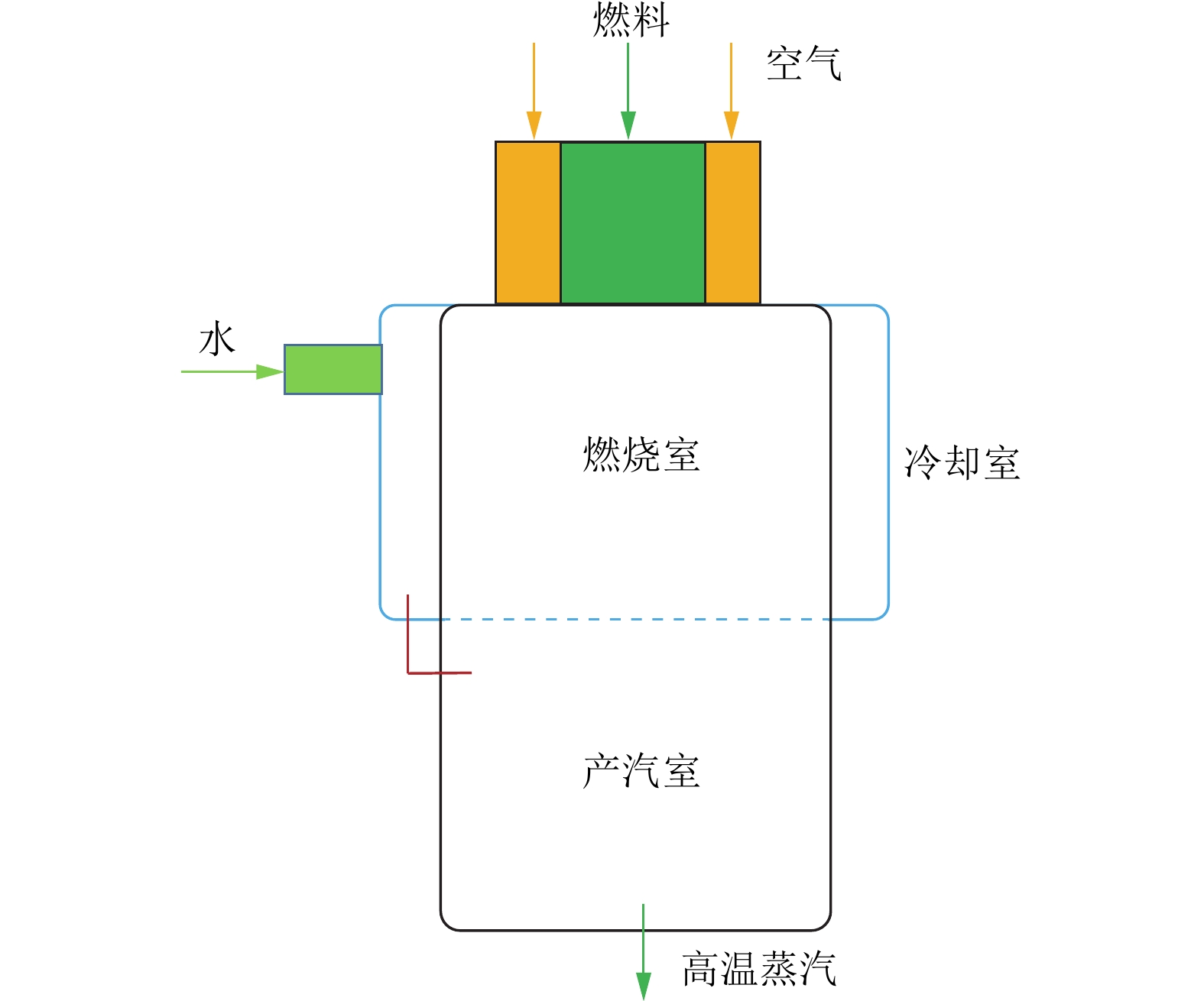

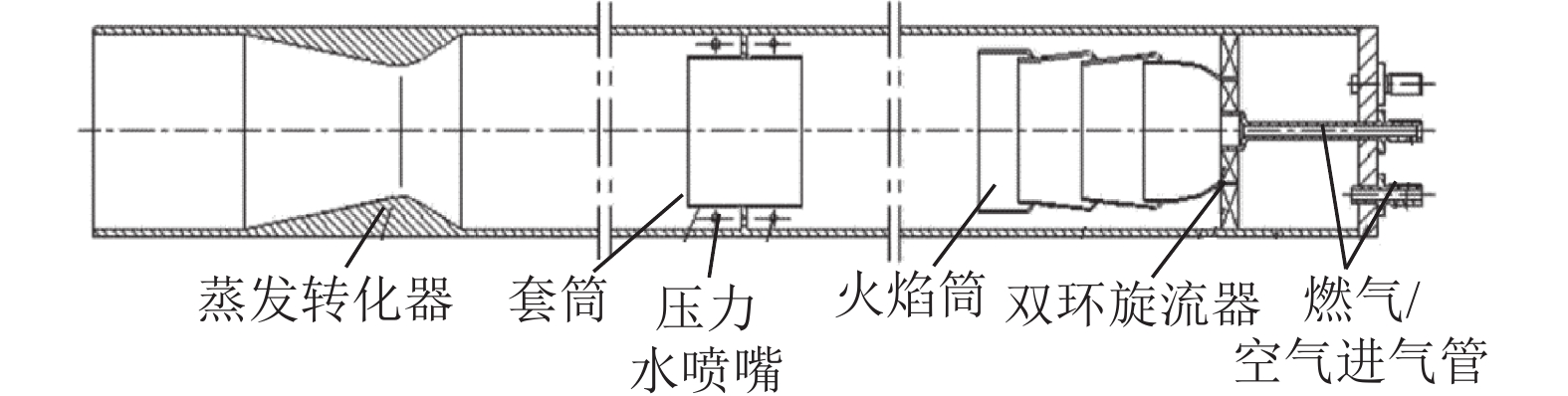

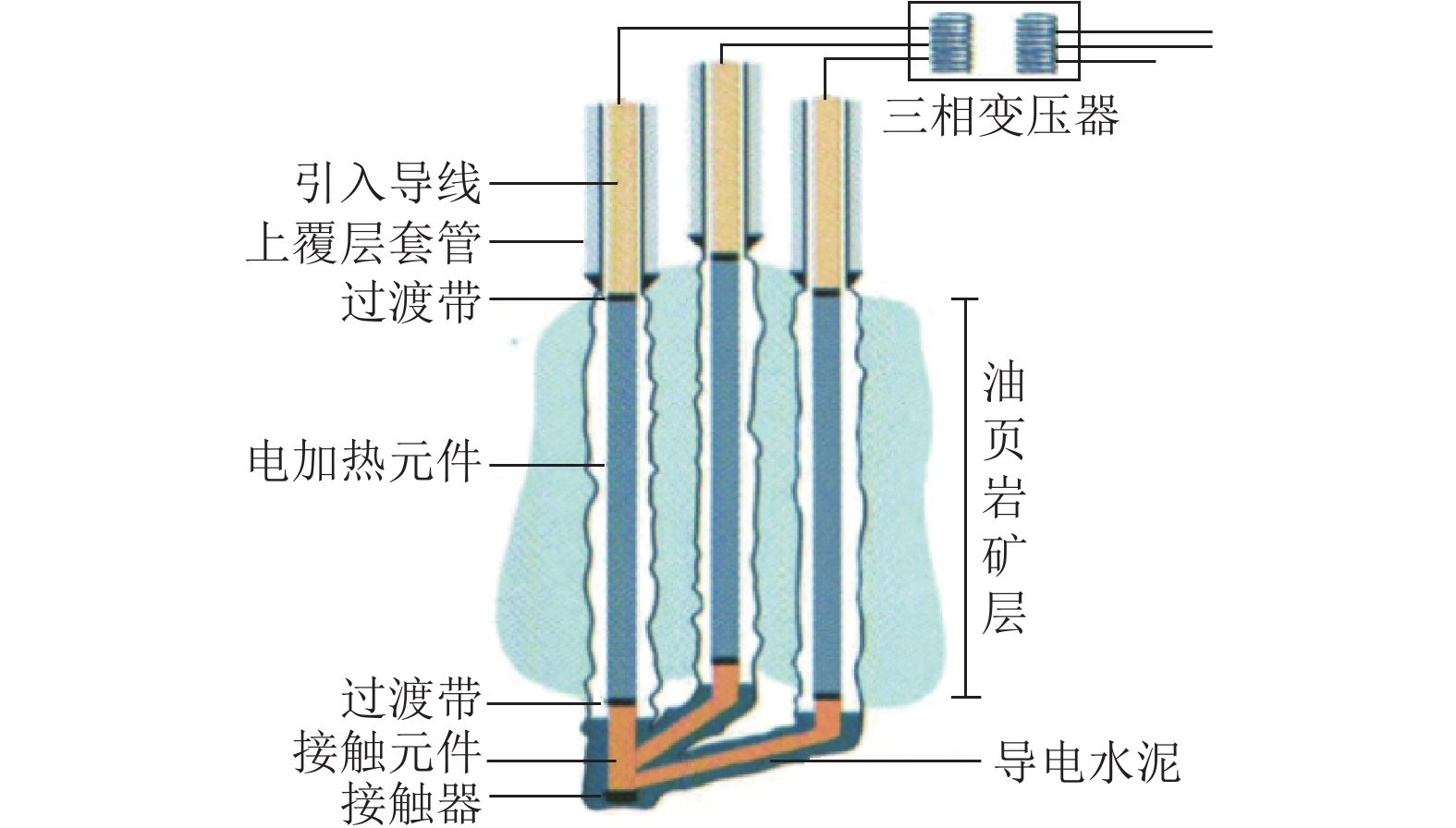

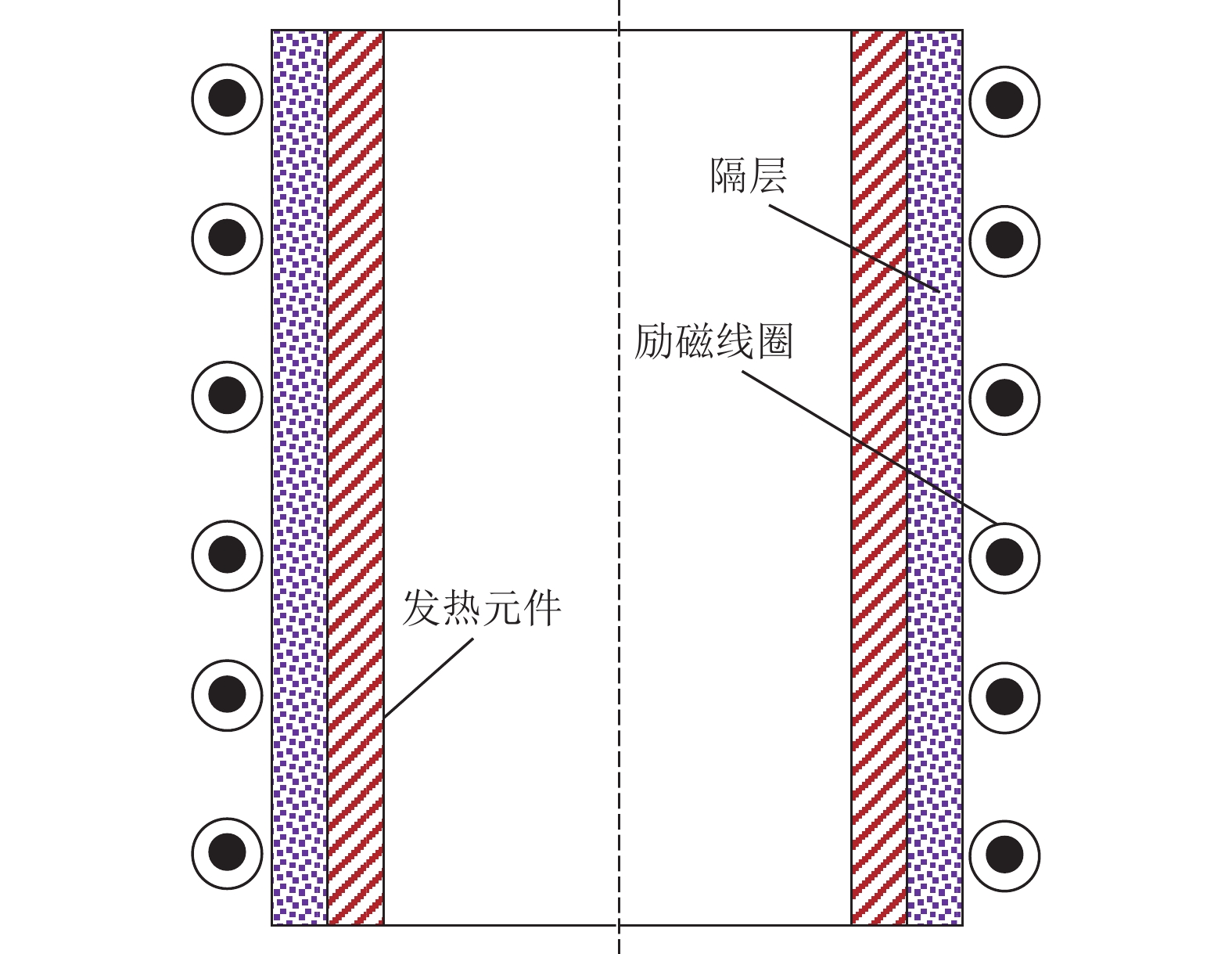

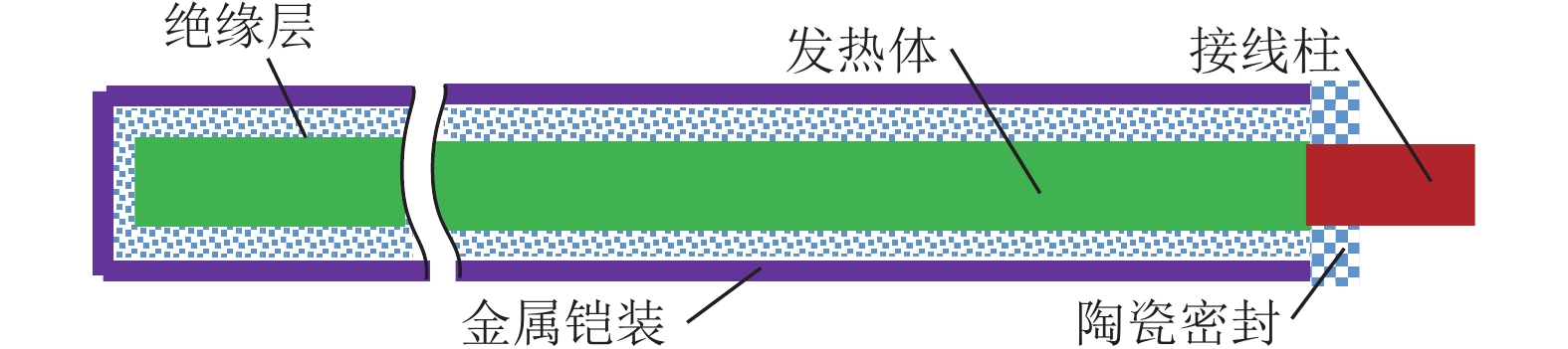

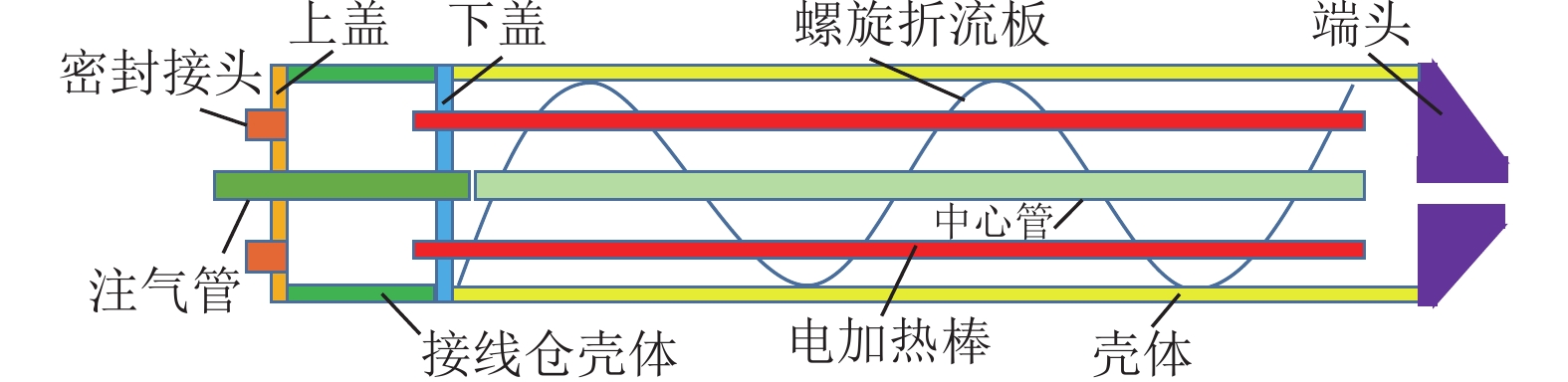

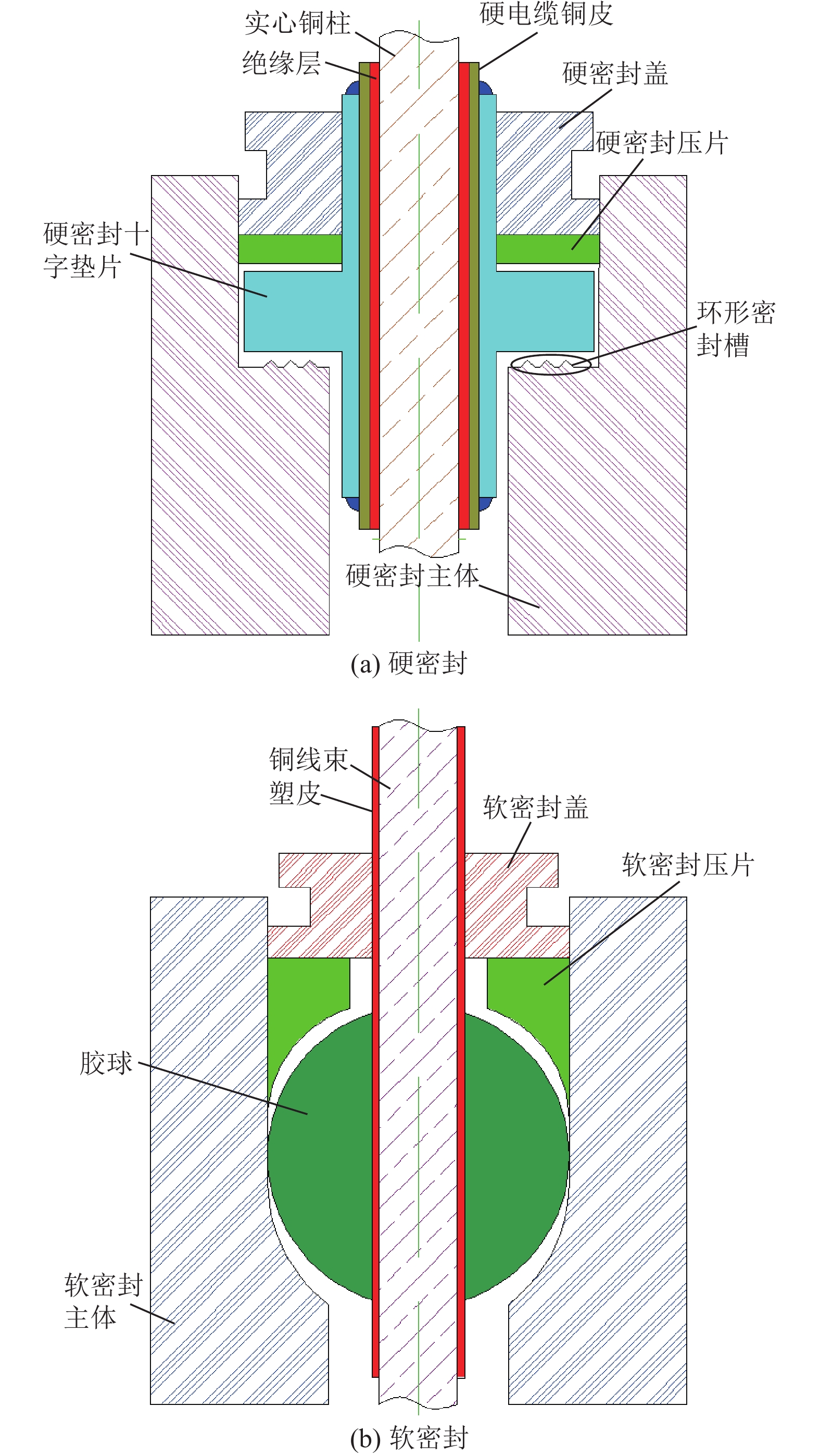

[意义]我国富油煤地质资源丰富,是保障能源安全的潜在煤基油气资源。富油煤地下原位热解“取氢留碳”是煤炭资源清洁低碳利用的发展趋势,而井下加热器是实现富油煤地下原位高效热解的关键设备之一。【进展】 在系统收集相关资料、数据和调研的基础上,简述了地下原位对流加热方法的现状,重点阐述了地下原位对流加热用加热器的研发现状,最后对井下电加热器的应用效果及后续的攻关方向分别进行了简述和展望。地表加热器的发展较为成熟,仅适用于埋深较浅和所需加热温度较低的地层(<350 ℃)。井下燃烧加热器还需有效解决极端工况下燃烧反应稳定性和二次点火可靠性的问题;井下电加热器通过将强化传热结构与电加热棒结合,不仅可缩小其尺寸,还可降低电加热棒的壁面温度,有效解决其加热效率低及寿命短的问题。此外,密封结构可有效提高井下电加热器在复杂工况下的适应性。采用自主研制的闭式双壳体井下电加热器,在陕北侏罗纪煤田榆神矿区大保当井田成功提取全球第一桶富油煤地下原位热解煤焦油。【展望】 为提高富油煤层的加热速度和加热效率,井下电加热器的后续研究可从高功率井下电加热器和复合加热两个方面着手。复合加热在介质输送过程中仍会产生一定量的热损失,随着加热井数量及煤层深度的增加,热损失问题会进一步凸显,故应重点攻关高功率井下电加热器,以期为我国富油煤地下原位热解工艺研发与工业化应用提供技术支撑。

Abstract:SignificanceChina boasts abundant tar-rich coal resources, which prove to be potential coal-based oil and gas resources capable of ensuring China's energy security. Extracting hydrogen while preserving carbon through the in-situ pyrolysis of tar-rich coals has developed into a trend in the clean and low-carbon utilization of coal resources. Downhole heaters serve as critical equipment for the efficient in-situ pyrolysis of tar-rich coals.

AdvancesBased on investigations and the systematic collection of relevant information and data, this study offers a brief introduction of the currently used methods for in-situ convection heating, focusing on the present situation of the research and development (R&D) of heaters for in-situ convection heating. Finally, this study briefly explores the application of downhole electric heaters, as well as providing future prospects for making breakthroughs. Relatively mature surface heaters are only suitable for shallow strata and strata requiring low heating temperatures (< 350 ℃). Downhole combustion heaters face challenges in effectively enhancing the stability of combustion reactions and the reliability of secondary ignition under extreme working conditions. Downhole electric heaters, which combine an enhanced heat transfer structure with electric heating rods, allow for reducing the surface temperatures of electric heating rods while decreasing the sizes of heaters, thereby effectively enhancing the heating efficiency and prolonging the service life. Additionally, employing seal structures can effectively improve the adaptability of downhole electric heaters to complex working conditions. Using a self-developed downhole electric heater with a closed double-shell structure, Shaanxi Coal Geology Group Co., Ltd. has successfully extracted the world's first barrel of coal tar from tar-rich coals through the in-situ pyrolysis in the Dabaodang mine field of the Yushen mining area in the Jurassic coalfield in northern Shaanxi.

ProspectsTo boost the heating rate and efficiency of tar-rich coal seams, subsequent research on downhole electric heaters can center around high-power downhole electric heaters and composite heating. However, composite heating suffers certain heat loss during medium transport, especially with an increase in heating well number and coal seam depth. Hence, it is recommended that high-power downhole electric heaters should be highlighted. This study is expected to provide technical support for the R&D and industrial application of the in-situ pyrolysis technology for tar-rich coals in China.

-

据不完全统计,我国华北型石炭–二叠纪煤田煤层受底板岩溶水害威胁的煤炭资源储量高达570亿t。煤层底板高承压含水层水害已经成为新时期我国煤炭资源安全高效开采的主要制约因素[1]。目前,采用注浆技术对底板隔水层加固和含水层改造是煤层底板水害防治的主要手段[2]。

以往煤层底板含水层注浆改造一直采用常规直孔注浆,但由于钻孔钻遇含水层孔段较短,需要布置较为密集的钻孔来达到改造目的[3-6],而且必须依托井巷工程实施[7]。同时,注浆工艺也面临注浆盲区大、目标位置不准确、注浆效果差等问题,使巷道掘进过程中水害难以高效探查与治理。2008年,董书宁等[8]首次提出利用水平定向钻孔进行煤层底板注浆加固的理念,发明煤层底板注浆加固水平定向钻孔的施工方法,大幅增加有效注浆孔段长度,提高钻孔揭露裂隙带、含水体面积,减小注浆盲区,提高注浆改造效率[9]。另外,利用水平定向钻注浆可扩大单孔探查或注浆面积,减少钻进机械搬运工程,降低钻探工程对矿井生产进度影响,对煤层底板进行超前探查和治理[10]。

2011年,中煤科工西安研究院(集团)有限公司(简称西安研究院)首次将水平定向钻技术引入到煤层底板水害超前注浆治理中,在河南能化集团赵固一矿11151工作面成功完成现场底板注浆加固试验。随后,超前区域治理理念在河北邯邢矿区、安徽淮北矿区煤层底板水害治理中大面积推广应用,并迅速发展到断层、陷落柱等导水构造治理,形成了集超前区域探查与面状治理于一体的煤层底板水害超前区域治理技术[11-12]。该技术先后在河北峰峰矿区九龙、陕西焦坪矿区桑树坪[13]、安徽淮北矿区朱庄等煤矿[14] 成功应用,并进一步推广至安徽皖北[15]和淮南[16]、山东黄河北[17]、河北邯邢[18]、河南焦作[19]等大水矿区,取得了良好的治理效果,使水平定向钻技术广泛应用于矿井水害防治工程[20]。但在工程实践中,普遍面临水平定向钻孔浆液运移规律不明、钻遇隐伏导水通道判识与治理难度高、注浆效果检验技术不可靠等问题,且井下定向钻机钻进能力无法满足高强度、高水压灰岩含水层钻进和安全需求。

因此,针对上述问题,笔者聚焦水平孔浆液运移规律、超前区域注浆改造模式和分类标准、灰岩地层水平定向钻高效钻进工艺、隐伏导水通道超前判识治理、底板水害超前治理关键参数控制工艺、注浆效果检验与评价等方面进行深入研究,形成煤层底板水害超前区域治理技术体系,以期为现场工程实践提供重要的理论和技术支撑。

1 煤矿底板水害超前区域治理理念与技术体系

针对华北型煤田煤层底板石炭–二叠系太原组薄层灰岩或奥陶系灰岩(简称奥灰)岩溶含水层突水威胁,突破常规井下直孔注浆的“被动式”局部工作面防治理念,采用水平定向钻从地面或井下对底板岩溶含水层进行超前区域(多个工作面)注浆改造,实现底板水害的“主动式”防治。该技术有效避免了井下施工位置限制和影响采掘作业等问题,通过多个工作面整体超前治理实现了水文地质条件的区域性改变,避免了井下局部单个工作面改造后的绕流现象。

煤层底板超前区域治理技术涉及采矿工程、水文地质、工程地质、钻探工程等专业学科,是一项复杂的系统工程,面临众多技术难题,包括注浆层位选择、灰岩地层水平孔高效钻进工艺、隐伏导水通道判识、关键注浆参数控制工艺、注浆效果评价技术等,必须进行超前区域注浆治理改造模式、水平孔倾斜裂隙浆液扩散规律、注浆效果评价方法等理论研究,开发相关关键技术,才能为煤层底板超前区域治理提供理论和技术支撑。西安研究院经过近10年的研究开发和工程实践,创建了煤层底板水害超前区域治理的理论框架和关键技术(图1)。具体包括煤层底板水害超前区域治理模式分类和选择准则,实现超前区域的精准治理;形成灰岩地层水平定向钻高效钻进工艺和隐伏导水通道超前判识治理技术,实现坚硬灰岩地层钻孔施工和隐伏通道的精准探查和治理;形成底板水害超前治理关键参数控制工艺,实现超前区域治理关键注浆参数的科学确定;提出多指标的注浆效果定性与定量相结合的检验与评价方法。

2 煤矿底板水害超前区域治理关键技术

2.1 治理模式分类和选择准则

2.1.1 模式分类

现阶段,我国煤层底板水害超前区域治理工程已经形成了定向钻进、常规钻进、径向射流结合的施工方式,及薄层太原组灰岩和厚层奥陶系灰岩的含水层治理模式,其具体定义为以底板水害防治与带压开采为目标,考虑基础水文地质条件、治理区地面施工条件、治理层位选择和钻孔钻进方式,从工程施工方案选择角度构建技术可靠、经济合理的注浆治理技术与方案的组合体系[21-22]。

1) 指 标

超前区域治理模式分类指标包括施工位置、层位选择、钻进方式。其中施工位置可选取地面钻孔施工结合地面浆液、井下钻孔施工结合地面浆液、井下钻孔施工结合井下浆液3种配置方案;改造层位包括太原组薄层灰岩含水层和奥陶系巨厚灰岩含水层;钻进方式包括定向钻进和径向射流2种钻进方式。

2) 模 式

采用交叉分类原则对各指标进行交叉组合分类,当3个指标连接形成闭合环路径时,可提炼形成治理模式,据此得到5种超前区域治理模式(表1)。

施工位置C 层位选取L 钻进方式D 治理模式M 地面施工C1 厚层灰岩L1 定向钻进D1 C1L1D1地面定向钻进厚层灰岩改造模式M1 井下施工C2 厚层灰岩L1 定向钻进D1 C2L1D1井下定向钻进厚层灰岩改造模式M2 地面施工C1 薄层灰岩L2 定向钻进D1 C1L2D1地面定向钻进薄层灰岩改造模式M3 井下施工C2 薄层灰岩L2 定向钻进D1 C2L2D1井下定向钻进薄层灰岩改造模式M4 地面施工C1 厚层灰岩L1 径向射流D2 C1L1D2地面径向射流厚层灰岩改造模式M5 3) 亚类模式

定向钻进过程中利用侧向分支孔可形成4种钻孔布设形态,包括扫帚状(S1)、鱼骨状(S2)、梳状(S3)、叉状(S4);径向射流在治理层位利用射流工艺可形成梅花状(S5)布孔形态。另外,根据钻孔探查情况采用不同注浆材料,常见超前区域注浆材料包括碎石骨料(G1)、河沙骨料(G2)、粉煤灰(G3)、水泥(G4)。根据超前区域探查改造模式结合施工设计中钻孔形态、注浆材料分类,可综合确定治理模式亚类(表2)。

表 2 超前区域治理注浆改造亚类模式[21]Table 2. Subgroup mode of grouting transformation in advanced regional control[21]治理模式(M) 钻孔形态(S) 注浆材料(G) 亚类分类 C1L1D1地面厚层灰岩定向钻孔改造模式 扫帚状(S1)

鱼骨状(S2)

梳状(S3)

叉状(S4)碎石骨料(G1)

河沙骨料(G2)

水泥−粉煤灰(G3)

纯水泥(G4)C1L1D1-(S1/S2/S3/S4)(G1/G2/G3)

C1L1D1-(S1/S2/S3/S4)(G1/G2/G4)

C1L1D1-(S1/S2/S3/S4)(G2/G3)

C1L1D1-(S1/S2/S3/S4)(G2/G4)

C1L1D1-(S1/S2/S3/S4)(G3)

C1L1D1-(S1/S2/S3/S4)(G4)C2L1D1井下厚层灰岩定向钻孔改造模式 扫帚状(S1)

鱼骨状(S2)

梳状(S3)

叉状(S4)水泥−粉煤灰(G3)

纯水泥(G4)C2L1D1-(S1/S2/S3/S4)(G3)

C2L1D1-(S1/S2/S3/S4)(G4)C1L2D1地面薄层灰岩定向钻孔改造模式 扫帚状(S1)

梳状(S3)

叉状(S4)碎石骨料(G1)

河沙骨料(G2)

水泥−粉煤灰(G3)

纯水泥(G4)C1L2D1-(S1/S3/S4)(G1/G2/G3)

C1L2D1-(S1/S3/S4)(G1/G2/G4)

C1L2D1-(S1/S3/S4)(G2/G3)

C1L2D1-(S1/S3/S4)(G2/G4)

C1L2D1-(S1/S3/S4)(G3)

C1L2D1-(S1/S3/S4)(G4)C2L2D1井下薄层灰岩定向钻孔改造模式 扫帚状(S1)

鱼骨状(S2)

梳状(S3)

叉状(S4)水泥−粉煤灰(G3)

纯水泥(G4)C2L2D1-(S1/S2/S3/S4)(G3)

C2L2D1-(S1/S2/S3/S4)(G4)C1L1D2地面厚层灰岩径向射流改造模式 梅花状(S5) 水泥−粉煤灰(G3)

纯水泥(G4)C1L1D2-S5(G3)

C1L1D2-S5(G3)2.1.2 模式选择准则

根据前文内容,可得到各判识指标选择标准:(1)地面有施工条件优先考虑地面施工;(2)煤层埋深大于800 m时地面施工钻探成本高,优先考虑井下施工;(3)煤层底板所承受水压大于6 MPa时,井下孔口装置难以保障施工安全,必须选用地面施工;(4)煤层埋深小于240 m时,地面定向钻孔施工难以实现造斜,优先考虑地面径向射流;(5)煤层底板有薄层灰岩地层结构,优先考虑改造薄层灰岩;(6)薄层、厚层灰岩顶部改造后需满足突水系数的要求。依据该选择准则体系,建立煤层底板灰岩含水层超前区域探查改造模式选择流程(图2)。

2.2 超前注浆定向钻孔高效钻进工艺

煤层底板超前注浆加固定向钻孔钻进时需要综合采用螺旋钻杆回转钻进、稳定组合钻具定向钻进和螺杆钻具随钻测量定向钻进等多种耦合工艺[23]。定向钻孔施工时按钻孔结构及施工工艺的不同可分为套管段施工、目的层位与套管之间层段施工、定向造斜段施工和透孔钻进施工等。钻进时,首先采用螺旋钻杆回转钻进工艺进行套管段施工,成功下入套管并试压合格;然后采用稳定组合钻具定向钻进工艺钻至目的层位,使钻孔倾角略为增加,以减少后期定向钻进倾角调整难度;再使用螺杆钻具随钻测量定向钻进完成定向造斜段和稳斜段施工,使钻孔按设计轨迹在目的岩层中延伸直至达到设计要求。

2.2.1 套管段

套管部位钻孔施工采用回转钻进成孔工艺,为确保套管顺利下入孔内,要求钻孔轨迹平直,孔内沉渣少,为此可采用螺旋钻进工艺配套稳定组合钻具和取心钻进工艺技术进行套管段施工。

2.2.2 回转钻进段

如果目的层位与套管之间岩层坚硬且较稳定,为缩短造斜段的距离,确保钻孔轨迹平滑可在回转钻进阶段利用稳定器组合钻具实施钻孔造斜;如果目的层位与套管之间岩层不稳定,钻进过程中需尽量缩短此段的钻孔长度,为此需对钻孔进行保直钻进。

2.2.3 定向钻进

井下硬岩层定向钻进过程中,造斜率是轨迹控制过程中衡量底部导向钻具组合造斜能力的重要指标,也是实施导向钻进工艺的重要依据。井下定向钻进普遍采用单弯螺杆马达,其配套的导向钻具长度较短、刚性较大、变形较小,可采用几何法计算煤矿井下导向钻具造斜率。

井下硬岩定向钻进轨迹控制宜采用复合定向钻进工艺。在钻进过程中钻杆柱“有滑有转”,以回转稳斜钻进为主、滑动造斜钻进为辅,典型轨迹控制方法如图3所示,当实钻轨迹与设计轨迹之间偏差达到一定值后,调整孔底螺杆马达造斜工具的指向(即工具面)、滑动给进,连续造斜改变钻孔前进方向,获得理想钻孔姿态参数后回转稳斜钻进,在水平面和垂直剖面内控制实钻轨迹围绕设计轨迹延伸。

2.3 隐伏导水通道超前判识治理技术

煤层底板隐伏导水通道是发生底板突水事故的主要因素之一,也是超前区域治理过程中的主要治理对象。综合采用钻进过程中岩屑录井、钻时录井、钻液漏失量、压水试验、随钻伽马、注浆参数等判识指标,能够验证地面物探疑似通道并在区域上探查隐伏导水通道发育情况,形成钻进过程中隐伏导水通道判识的主要指标、变化规律、通道类型等,科学判识通道导水性,为超前区域治理提供基础依据。

2.3.1 类型与特征

基于淮北、淮南、黄河北、邢台等华北型煤田矿区各矿井揭露的隐伏导水构造情况的分析和总结,得到矿井隐伏导水通道特征为:类型多样,且呈现隐伏断层、陷落柱及裂隙等构造类型组合出水事故特征;褶曲轴部裂隙相对发育,含水层富水性强,隔水层相对薄弱;多发育于煤层底板,发育层位低,位置不明,充填较松散、胶结差,导水性较好;隐蔽性好,可探测性差等。

华北型煤田开采主要受断层、陷落柱和岩溶裂隙构造的充水影响,根据岩溶含水层特征及钻探过程中所能探查的构造精度、种类和性质,可得到隐伏导水通道分类,即岩溶裂隙,包括封闭溶隙、弱连通溶隙、强连通溶隙;断层,包括隔水断层、弱导水断层、导水断层;陷落柱,包括全充水强导水型、边缘充水导水型、不导水(微弱导水)陷落柱。

2.3.2 判识指标

隐伏导水通道的存在是造成煤层底板突水事故的主要因素之一,是超前区域治理的主要对象。对我国多个矿区超前区域治理钻探、注浆成果进行统计,总结出岩屑录井、钻时录井、冲洗液消耗量、压水试验、注浆参数和随钻伽马6个隐伏导水通道的判识指标。其中,岩屑录井和钻时录井用于判识构造通道发育情况,冲洗液消耗量、压水试验和注浆参数用于判识通道的导水性,随钻伽马作为孔内地球物理探查方法,对所判识的隐伏导水通道进行验证和预判。

分析隐伏导水通道判识指标得到,定向钻进过程中,岩屑录井共有3种曲线类型,即岩屑渐变型(岩屑-Ⅰ型)、岩屑突变无岩爆型(岩屑-Ⅱ型)、岩屑突变有岩爆型(岩屑-Ⅲ型);钻时录井曲线共有3种曲线类型,即钻时渐变型(钻时-Ⅰ型)、钻时突变未放空型(钻时-Ⅱ型)、钻时突变放空型(钻时-Ⅲ型)。根据不同构造形态特征得到灰岩含水层中判识指标的多元组合(表3)。

表 3 多元信息通道判识组合Table 3. Combination of multiple information channel identification序号 岩屑录井形态 钻时录井形态 判识构造类型 1 岩屑渐变型(岩屑-Ⅰ型) 钻时渐变型(钻时-Ⅰ型) 穿层,非构造 2 无变化形态 钻时突变未放空型(钻时-Ⅱ型) 小型岩溶裂隙(隙宽<10 cm) 3 无变化形态 钻时突变放空型(钻时-Ⅲ型) 大型岩溶裂隙(隙宽>10 cm) 4 岩屑突变无岩爆型(岩屑-Ⅱ型) 钻时突变未放空型(钻时-Ⅱ型) 小型断层 5 岩屑突变无岩爆型(岩屑-Ⅱ型) 钻时突变放空型(钻时-Ⅲ型) 大中型断层 6 岩屑突变有岩爆型(岩屑-Ⅲ型) 钻时突变未放空型(钻时-Ⅱ型) 胶结良好陷落柱 7 岩屑突变有岩爆型(岩屑-Ⅲ型) 钻时突变放空型(钻时-Ⅲ型) 胶结较差陷落柱 2.3.3 判识方法

根据我国现阶段主要治理区钻孔施工揭露情况统计,确定“冲洗液消耗量中钻液漏失量大于30 m3/h,压水试验渗透率大于10 Lu,单位注浆量大于10 t/m”可作为地层通道导水性判识标准。基于多因素建立综合判识标准,对通道的导水性能进行分区,得出不同构造类型的导水性能类型。根据上述3因素进行通道导水性分区,可分为8个小区(图4)。

2.4 底板水害超前治理关键参数控制工艺

由于煤层底板岩溶裂隙含水层超前区域注浆具有隐蔽性特征,注浆实践中缺少对浆液扩散的有效控制,致使存在施工周期长、注浆量大、注浆效果不可靠等问题。基于超前区域注浆特点,关键注浆参数控制结合受注地层特征、注浆材料、浆液性能、浆液扩散规律[24]、底板注浆改造要求和工艺等因素,系统分析注浆材料及浆液选配和调控、注浆终结标准、钻孔布置间距和方向、注浆控制因素等[25]。

(1) 奥陶系灰岩顶部垂向渗透性存在明显差异,存在渗透性随深度增加而增大的变化趋势;细观空隙的总数量中以闭合裂隙和微张裂隙数量占比为主,两者开度均值分别稳定在120和420 μm,宽张裂隙和中张裂隙在总裂隙面积中占主要比例,具有较好的贯通性和延展性;在奥灰顶部超前区域注浆过程中可采用水泥−粉煤灰浆液或水泥−黏土浆液进行“垫底式”充填注浆,再采用颗粒较细小的水泥浆液对微小裂隙和闭合裂隙进行升压注浆和劈裂注浆[26-28]。

(2) 水泥浆液、水泥−粉煤灰浆液、水泥−黏土浆液的凝结时间主控因素为水玻璃掺量,黏度的主控因素分别为水玻璃掺量、水灰比、水灰比,结石率的主控因素分别为水灰比、水灰比、水玻璃掺量,强度的主控因素为水灰比;根据各因素极差大小进行排序,得到各因素对实验结果的敏感性,由大到小为:裂隙开度>裂隙倾角>水灰比>注浆压力,即裂隙开度对浆液扩散距离影响程度高于裂隙倾角,浆液水灰比高于注浆压力[29-31]。

(3) 关于注浆压力、稳压时间和钻孔间距确定,可通过分析不同条件下水平孔倾斜单裂隙浆液扩散距离特征曲线,得到不同浆液水灰比、受注地层条件和注浆压力下的浆液扩散距离,结合注浆设备额定工作能力约束,得到符合注浆设备工作能力的水平孔间距,同时也得到对应钻孔间距的注浆压力和稳压时间,通过与岩体起裂压力对比可得到合理的注浆终结压力,最后得到对应稳压时间和水平注浆孔间距的注浆终结压力标准,该标准能够满足注浆设备能力和水平注浆孔间距要求,也可有效保证注浆覆盖范围和注浆效果[32]。

(4) 水平分支孔布设方向可根据受注地层地应力方向尽量保持钻孔轨迹与最大主应力方向垂直、与最小主应力方向平行。注浆过程中浆液扩散可根据浆液性能和扩散距离敏感性特征通过调控浆液水灰比、注浆压力和注浆时间达到注浆终结压力和稳压时间标准。

综合上述控制因素和原则,结合底板超前区域注浆工艺和要求,形成煤层底板水害超前区域治理关键注浆参数控制技术(图5)[33]。

2.5 检验与评价

注浆效果评价为煤层底板超前区域治理技术的重要组成部分。准确地进行注浆效果评价,不但可以有效保证矿井采掘安全,还可为超前区域治理工程布设提供指导,进一步优化注浆孔布设及注浆工艺。

2.5.1 定性评价方法

灰色关联分析是灰色系统方法之一,已广泛应用于经济学、社会学和环境等各个领域。它的基本思想是根据2个数据序列几何形状的相似性来确定它们之间的关系度。根据几何形状建立了关系分析模型[34],断线之间的几何形状越近,关系度就越大。灰色关联分析可综合注浆量、钻井液漏失量、伽马值、水温、平均渗透率、注浆段长度等多种注浆因素,通过关联、分组、综合评分进行效果检验。具体注浆中分析和整理注浆点的注浆量、钻井液漏失量、伽马值、水温、平均渗透率、注浆段长度、奥灰含水层水压和隔水层厚度等数据,并灰色关联度计算,通过各个参数的灰色关联度确定其评价结果的权重。然后计算得到突水风险评估的综合权重系数、综合分数并完成突水风险评价图。

2.5.2 定量评价标准

注浆效果检查方法有钻探、物探和注浆特征分析法等,主要以定性评价方法为主。而以冲洗液消耗量、钻孔涌水量、渗透率和改造层厚度4个指标为研究对象,可建立超前区域治理技术的注浆效果定量评价分析方法[35]。

根据多个矿区注浆改造施工技术经验,当冲洗液消耗量为均匀消耗时,且消耗量不大于1 L/(min·m),表明注浆效果良好;根据多个矿区注浆改造施工技术经验,当井下检查孔为均匀出水且每钻进100 m段内涌水量小于5 m3/h时,表明注浆效果良好;当每个层段的渗透率均不大于1 Lu时,表明注浆效果良好。在地层结构预测准确的前提下,只要轨迹偏差、注浆结束标准均满足设计要求时,且在该注浆层段内,渗透率、钻孔涌水量、冲洗液消耗量均达到注浆良好标准时,表明改造层厚度达到设计要求。

2.5.3 孔中物探检验设备及配套工艺

电磁波在地下岩层中传播时,由于各种岩石、矿物电性参数(电阻率、介电常数等)不同,对电磁波能量的吸收有一定差异,电阻率较低的岩石、矿物具有较大的吸收作用。另外,伴随着断裂构造或空洞所出现的界面,能够对电磁波产生折射、反射等作用,也会造成电磁波能量的损耗。因此,可研究各种岩层及地质构造对电磁波传播的影响(包括吸收、反射、二次辐射等作用)所造成的各种异常进行地质解释,从而判识地质构造。基于上述原理,为实现注浆效果检验,制造了孔中无线电波透视装备,其工作原理如图6所示。

发射机是孔中电磁波透视仪的建场设备,供出稳定、具有较强功率且符合本安要求的电磁波信号是发射机的主要技术指标。接收机接收的信号范围为纳伏到微伏级,按探测设计要求可选择接收探测频率信号。接收机由模拟板、控制板、电源板和面板组成,接收机采用本安型防爆设计,孔中接收天线采用多级放大设计,使孔中接收信号通过天线放大处理,实现电磁波信号的高性能接收。具体检验钻孔可在工作面巷道底板施工定向钻,采取“一对二”施工方式,具体施工方式如图7所示。

2.5.4 综合检验技术

超前区域治理工程中可采用孔间电磁波透视仪对前一注浆序次进行效果检验并补充分支孔进行及时补充注浆。在治理完成后,综合单个钻孔漏失量、注浆量、水温、平均渗透率等指标,采用关联分析、综合评分定性评价整个治理区注浆效果。在孔间物探确定的浆液充填较差区、定性评价的注浆效果较差区施工井下注浆效果检查钻孔,评价注浆效果,并对效果较差区域进行补充注浆,由此形成了注浆效果检验综合评价装备技术体系(图8)。

3 工程应用

桑树坪煤矿位于陕西渭南,地表为山峁沟谷地貌,主采二叠系山西组3号煤和石炭系太原组11号煤,其中11号煤距底板奥陶系灰岩含水层近,受奥灰水害威胁极为严重(图9)。地面高程+430~+750 m,平均为+590 m;煤层埋深240~560 m,平均为400 m;奥灰顶界面高程+140~+210 m,平均为+175 m;奥灰含水层水位+380 m;底板与奥灰含水层间距16.5~21.5 m,承受最大水压为1.23 MPa,最大突水系数0.072 MPa/m。3105工作面实测底板破坏深度14.8 m,最小有效隔水层厚度仅有1.7 m。工作面回采面临极为严重的底板奥灰含水层突水威胁。

3.1 治理模式选取

由于煤层底板无薄层太原组灰岩,因此改造层位选择奥陶系灰岩顶部峰峰组风化充填带。由于3105工作面及周边对应地表为山峁沟谷地貌,沟壑纵横钻机进场施工难度高,且民事协调难度大,赔青费用高。因此,3105工作面区域治理不具备地面施工条件;另外,煤层底板所承受奥灰含水层最大水压为1.23 MPa,小于井下钻孔安全施工6 MPa的要求,确定区域治理钻孔施工采用井下定向钻进方式。综合分析,3105工作面采用C2S1D1井下厚层灰岩定向钻孔改造模式进行煤层底板含水层超前区域治理。

3.2 治理关键参数

基于工程成本和浆液性能考虑,注浆过程中主要采用水灰比相对较大的水泥浆液进行注浆,因此,在参数计算过程中采用牛顿型水泥浆液参数。在注浆过程中孔口注浆压力与受注地层裂隙注浆点处的有效压力存在中间流动过程的动力损失,计算公式见下式,因此,通过计算转换可得到有效注浆压力。

$$ {p_1} = p + {p_{\rm{s}}} - {p_\text{ξ}} $$ (1) 式中:p1为作用到灌浆段中点上的实际压力;p为孔口处压力表显示的压力;ps为浆液自重产生的压力;pξ为浆液在流经自压力表至灌浆段中点一段路程上的流动损失。

根据超前区域注浆改造范围将水平分支钻孔间距设置为40 m,基于水平孔倾斜单裂隙牛顿型流体扩散控制方程,计算得到桑树坪煤矿底板奥灰超前区域治理中注浆时间下限,其注浆改造试算参数见表4。

表 4 桑树坪煤矿超前区域注浆改造试算参数Table 4. Trial calculation parameters of grouting transformation in advanced regional control of Sangshuping Coal Mine浆液参数 孔口注浆压力/MPa 有效注浆压力/MPa 钻孔半径/m 静水压力/MPa 水灰比 黏度/(Pa·s) 相对密度/(kg·m−3) 1 0.1198 1424 3 4.30 0.048 2.05 2 0.0967 1248 4.14 3 0.0742 1160 4.06 经过计算得到6 000 s内不同水灰比下浆液扩散距离变化曲线(图10)。根据水平分支孔间距40 m,为保证注浆效果,水灰比为1∶1的浆液注浆时间不能低于3 800 s,水灰比为2∶1的浆液注浆时间不能低于3 200 s,水灰比为3∶1的浆液注浆时间不能低于2 600 s。

3.3 工程布设与应用效果

改造层位为进入奥灰层位后23~31 m,平均27 m;孔深660 m;三开裸孔段孔径96 mm。工作面回采前在井下巷道施工钻场,沿工作面走向布设定向钻孔14个,钻孔平面投影间距约40 m,垂直深度位于奥陶系灰岩顶面以下15~20 m,对于揭露的奥灰含水层出水位置采用下行式注浆方式,具体钻孔布设如图11所示。

工作面回采揭露表明,采用井下超前区域治理模式有效探查并改造了煤层底板含水层的富水位置,保障了工作面安全。

4 展 望

随着煤矿开采深度增加,煤炭开采面临底板高压岩溶含水层水害威胁愈发严重,为华北型煤田煤层底板超前区域治理工作提出了新的要求:

(1) 深部煤层底板岩溶含水层突水机理。煤层底板突水机理是指导底板超前区域治理层位和模式选择的依据。以往广泛应用的底板突水系数对于深部煤层底板突水评价适用性较差,目前其他突水机理研究成果尚未有效揭示深部煤层采动过程中底板应力、裂隙和水压等影响因素的耦合致灾机制,而采动过程中应力状态转换、水压损伤、裂隙通道起裂等变化存在相互影响和制约,如何揭示其内在关系是底板突水机理研究发展的重要方向。

(2) 煤矿底板导水通道超前精准探查。由于煤层底板灰岩岩溶裂隙分布的非均质性特征,利用水平定向钻实现导水通道精准探查是实现超前区域治理中“有的放矢、精准可控注浆”的基础。而导水通道精准探查需采用物探、钻探和化探等手段,综合判识。因此如何利用物探、钻探、化探相结合的技术手段,实现采前、采中分阶段全面精准探查,准确判识潜在导水通道的分布范围、充填结构、导水性能等,实现导水通道的智能化精准判识,将是底板导水通道超前精准探查研究的重要方向。

(3) 煤层底板超前区域治理。现阶段煤层底板超前区域治理技术相对成熟,但注浆材料、浆液配比、注浆压力、注浆时间、注浆量等关键注浆参数选取的智能化水平仍存在不足,如何实现注浆参数随受注地层空隙性、导水性、渗透性等特征而智能化调控是超前区域治理技术发展的方向。

5 结 论

a. 基于注浆改造过程中钻孔施工位置、注浆层位选择和钻进方式,建立了5种超前区域注浆改造主模式,确定了各类模式的确定方法和准则。结合注浆材料、钻孔布设形态,形成超前区域注浆改造亚类划分。

b. 形成了煤层底板超前注浆加固定向钻孔螺旋钻杆回转钻进、稳定组合钻具定向钻进和螺杆钻具随钻测量定向钻进等多种钻进方式耦合的钻进工艺。

c. 确定了冲洗液消耗量中钻液漏失量大于30 m3/h,压水试验渗透率大于10 Lu,单位注浆量大于10 t/m的地层通道导水性判识标准,得出了不同构造类型的导水性能类型,实现了通道导水性分区。

d. 分析了注浆材料及浆液选配和调控、注浆终结标准、钻孔布置间距和方向、注浆控制因素等,提出了基于受注地层特征、注浆材料、浆液性能、浆液扩散规律、底板注浆改造要求和工艺等因素的超前注浆浆液扩散控制工艺。

e. 提出了基于冲洗液消耗量、钻孔涌水量、渗透率和改造层厚度4个指标的超前区域注浆效果定量评价分析方法及基于灰色关联度分析的注浆效果检验定性评价方法,开发了井下水平定向钻孔的孔间电磁波透视仪,形成了底板灰岩超前注浆效果检验综合评价装备技术体系。

-

-

[1] 丁鹏,王迪. 我国油气资源进口安全问题及应对策略[J]. 中国能源,2023,45(5):56−63. DOI: 10.3969/j.issn.1003-2355.2023.05.007 DING Peng,WANG Di. Research on the security problems and countermeasures for China’s oil and gas resources import[J]. Energy of China,2023,45(5):56−63. DOI: 10.3969/j.issn.1003-2355.2023.05.007

[2] 张勇,李超. 国内油气对外依存度发展趋势[J]. 中国石油和化工标准与质量,2023,43(17):124−126. DOI: 10.3969/j.issn.1673-4076.2023.17.042 ZHANG Yong,LI Chao. Development trend of domestic oil and gas dependence on foreign countries[J]. China Petroleum and Chemical Standard and Quality,2023,43(17):124−126. DOI: 10.3969/j.issn.1673-4076.2023.17.042

[3] 李瑞忠,郗凤云,杨宁,等. 2010年世界能源供需分析:《BP世界能源统计2011》解读[J]. 当代石油石化,2011,19(7):30−37. DOI: 10.3969/j.issn.1009-6809.2011.07.008 LI Ruizhong,XI Fengyun,YANG Ning,et al. The analysis of world energy supply & demand in 2010:An explanation of BP statistical review of world energy 2011[J]. Petroleum & Petrochemical Today,2011,19(7):30−37. DOI: 10.3969/j.issn.1009-6809.2011.07.008

[4] 许勤华,李文琪. 全球碳中和背景下的中国能源安全方略[J]. 南通大学学报(社会科学版),2023,39(1):117−129. XU Qinhua,LI Wenqi. China’s energy security strategy in the context of global carbon neutrality[J]. Journal of Nantong University (Social Sciences Edition),2023,39(1):117−129.

[5] 纪玉山. 我国非常规油气资源的开发利用与能源安全的经济分析[J]. 社会科学家,2016(10):10−16. DOI: 10.3969/j.issn.1002-3240.2016.10.003 JI Yushan. Economic analysis on the development and utilization of unconventional oil and gas resources and energy security in China[J]. Social Scientist,2016(10):10−16. DOI: 10.3969/j.issn.1002-3240.2016.10.003

[6] 付德亮,段中会,杨甫,等. 富油煤钻井式地下原位热解提取煤基油气资源的几个关键问题[J]. 煤炭学报,2023,48(4):1759−1772. FU Deliang,DUAN Zhonghui,YANG Fu,et al. Key problems in in situ pyrolysis of tar-rich coal drilling for extraction of coal-based oil and gas resources[J]. Journal of China Coal Society,2023,48(4):1759−1772.

[7] 刘朝全,姜学峰. 2020年国内外油气行业发展报告[M]. 北京:石油工业出版社,2021. [8] 马丽,拓宝生. 陕西富油煤资源量居全国之首 榆林可“再造一个大庆油田”[J]. 陕西煤炭,2020,39(1):220−222. DOI: 10.3969/j.issn.1671-749X.2020.01.055 MA Li,TUO Baosheng. Shaanxi’s oil-rich coal resources rank first in China,and Yulin can “rebuild a Daqing oilfield”[J]. Shaanxi Coal,2020,39(1):220−222. DOI: 10.3969/j.issn.1671-749X.2020.01.055

[9] 马丽,王双明,段中会,等. 陕西省富油煤资源潜力及开发建议[J]. 煤田地质与勘探,2022,50(2):1−8. DOI: 10.12363/issn.1001-1986.21.10.0592 MA Li,WANG Shuangming,DUAN Zhonghui,et al. Potential of oil-rich coal resources in Shaanxi Province and its new development suggestion[J]. Coal Geology & Exploration,2022,50(2):1−8. DOI: 10.12363/issn.1001-1986.21.10.0592

[10] 汪友平,王益维,孟祥龙,等. 美国油页岩原位开采技术与启示[J]. 石油钻采工艺,2013,35(6):55−59. WANG Youping,WANG Yiwei,MENG Xianglong,et al. Enlightenment of American’s oil shale in situ retorting technology[J]. Oil Drilling & Production Technology,2013,35(6):55−59.

[11] JU Yang,ZHU Yan,ZHOU Hongwei,et al. Microwave pyrolysis and its applications to the in situ recovery and conversion of oil from tar-rich coal:An overview on fundamentals,methods,and challenges[J]. Energy Reports,2021,7:523−536. DOI: 10.1016/j.egyr.2021.01.021

[12] KANG Zhiqin,ZHAO Yangsheng,YANG Dong,et al. A pilot investigation of pyrolysis from oil and gas extraction from oil shale by in situ superheated steam injection[J]. Journal of Petroleum Science and Engineering,2020,186:106785. DOI: 10.1016/j.petrol.2019.106785

[13] JEREMY B. Oil shale:is now the time?[C]//Garfield County Energy Advisory Board Meeting. Colorado:2011.

[14] 高攀明. 鄂尔多斯盆地吴起地区长7页岩油烃源岩特征及生排烃潜力[J]. 非常规油气,2024,11(3):10−18. GAO Panming. Characteristics and hydrocarbon generation and expulsion potential of Chang7 shale oil source rocks in Wuqi Area,Ordos Basin[J]. Unconventional Oil & Gas,2024,11(3):10−18.

[15] 韩婧. 水氧协同作用对油页岩热解特性影响研究[D]. 长春:吉林大学,2019. HAN Jing. Study on the effect of synergy of water and oxygen on pyrolysis characteristics of oil shale[D]. Changchun:Jilin University,2019.

[16] 孙友宏,郭威,邓孙华. 油页岩地下原位转化与钻采技术现状及发展趋势[J]. 钻探工程,2021,48(1):57−67. DOI: 10.12143/j.ztgc.2021.01.008 SUN Youhong,GUO Wei,DENG Sunhua. The status and development trend of in situ conversion and drilling exploitation technology for oil shale[J]. Drilling Engineering,2021,48(1):57−67. DOI: 10.12143/j.ztgc.2021.01.008

[17] ALLIX P,BURNHAM A,FOWLER T,et al. Coaxing oil from shale[J]. Oilfield Review,2010,22(4):4−15.

[18] KANG Zhiqin,ZHAO Yangsheng,YANG Dong. Review of oil shale in situ conversion technology[J]. Applied Energy,2020,269:115121. DOI: 10.1016/j.apenergy.2020.115121

[19] 邓孙华. 近临界水对块状油页岩中有机质的提取研究[D]. 长春:吉林大学,2013. DENG Sunhua. Sub-cirtical water extraction of organic matter from oil shale lumps[D]. Changchun:Jilin University,2013.

[20] 王洪艳,邓孙华,李俊锋,等. 一种地下原位提取油页岩中烃类化合物的方法:CN101871339B[P]. 2013-03-27. [21] 王振东. 油页岩原位开采连续螺旋折流板式电加热器传热性能和加热效率研究[D]. 长春:吉林大学,2021. WANG Zhendong. Study on heat transfer performance and heating efficiency of electric heater with continuous helical baffles for oil shale in-situ conversion[D]. Changchun:Jilin University,2021.

[22] GUO Wei,WANG Zhendong,SUN Zhongjin,et al. Experimental investigation on performance of downhole electric heaters with continuous helical baffles used in oil shale in situ pyrolysis[J]. Applied Thermal Engineering,2019,147:1024−1035. DOI: 10.1016/j.applthermaleng.2018.11.013

[23] 刘争芬,彭杰,闫吉曾,等. 基于油气开发工程的深部煤炭地下气化关键技术[J]. 油气与新能源,2023,35(1):77−81. DOI: 10.3969/j.issn.2097-0021.2023.01.010 LIU Zhengfen,PENG Jie,YAN Jizeng,et al. Key deep underground coal gasification technology based on oil and gas development projects[J]. Petroleum and New Energy,2023,35(1):77−81. DOI: 10.3969/j.issn.2097-0021.2023.01.010

[24] 张杰,张轮亭,杨中成,等. 稠油热采用注汽锅炉现状及展望[J]. 工业加热,2016,45(3):61−63. DOI: 10.3969/j.issn.1002-1639.2016.03.019 ZHANG Jie,ZHANG Lunting,YANG Zhongcheng,et al. Status and development tendency of steam injection boiler to heavy oil thermal recovery[J]. Industrial Heating,2016,45(3):61−63. DOI: 10.3969/j.issn.1002-1639.2016.03.019

[25] 方兵. 稠油热采注汽锅炉清灰技术研究与应用[J]. 油气田环境保护,2014,24(5):21−22. DOI: 10.3969/j.issn.1005-3158.2014.05.007 FANG Bing. Research and application of soot cleaning technology of steam injection boiler for heavy oil thermal recovery[J]. Environmental Protection of Oil & Gas Fields,2014,24(5):21−22. DOI: 10.3969/j.issn.1005-3158.2014.05.007

[26] DONALDSON A B,HOKE D E,MULAC A J. Downhole steam generator with improved preheating/cooling features:US4411618[P]. 1983-10-25.

[27] MUIR J F,WEIRICK L J,PETTIT F S. Field test of two high-pressure,direct-contact downhole steam generators. Volume I. Air/diesel system[R]. United States:Sandia National Lab. (SNL-NM),Albuquerque,NM(U.S.),1983. doi:10.2172/6289352.

[28] 徐进良,陈听宽. 井下蒸汽发生器装置及燃烧特性的研究[J]. 动力工程,1992,12(2):9−14. XU Jinliang,CHEN Tingkuan. Uuder-ground steam ganarators and their combustion characteristics[J]. Power Engineering,1992,12(2):9−14.

[29] 徐进良,陈听宽. 井下蒸汽发生器燃烧室壁冷却传热特性的研究[J]. 动力工程,1993,13(4):6−10. XU Jinliang,CHEN Tingkuan. Research on combustion chamber’s wall cooling heat transfer characteristics of under-ground steam generators[J]. Power Engineering,1993,13(4):6−10.

[30] SCHICKS J,SPANGENBERG E,GIESE R,et al. A counter-current heat-exchange reactor for the thermal stimulation of hydrate-bearing sediments[J]. Energies,2013,6(6):3002−3016. DOI: 10.3390/en6063002

[31] FRIEDLE U,VESER G. A counter-current heat-exchange reactor for high temperature partial oxidation reactions I. Experiments[J]. Chemical Engineering Science,1999,54(10):1325−1332. DOI: 10.1016/S0009-2509(99)00061-5

[32] ALBERT H S. Engineering and economics of enhanced oil recovery in the Canadian oil sands[D]. Austin:University of Texas at Austin,2014.

[33] 赵帅,孙友宏,李强,等. 一种用于油页岩原位裂解的超燃加热器:CN208619096U[P]. 2019-03-19. [34] 刘鹏宇,康维国,刘黎,等. 用于石油稠油开采的蒸汽发生器:CN203547694U[P]. 2014-04-16. [35] 谢青,李宁,姚征,等. 黄陵矿区富油煤焦油产率特征及主控地质因素分析[J]. 中国煤炭,2020,46(11):83−90. DOI: 10.3969/j.issn.1006-530X.2020.11.013 XIE Qing,LI Ning,YAO Zheng,et al. Research on the tar yield characteristics and main control factors of tar-rich coal in Huangling mining area[J]. China Coal,2020,46(11):83−90. DOI: 10.3969/j.issn.1006-530X.2020.11.013

[36] SOEDER D J. The successful development of gas and oil resources from shales in North America[J]. Journal of Petroleum Science and Engineering,2018,163:399−420. DOI: 10.1016/j.petrol.2017.12.084

[37] 王盛鹏,刘德勋,王红岩,等. 原位开采油页岩电加热技术现状及发展方向[J]. 天然气工业,2011,31(2):114−118. DOI: 10.3787/j.issn.1000-0976.2011.02.029 WANG Shengpeng,LIU Dexun,WANG Hongyan,et al. Current situation and development potential of electric heating process of in situ oil shale conversion[J]. Natural Gas Industry,2011,31(2):114−118. DOI: 10.3787/j.issn.1000-0976.2011.02.029

[38] OJEDA S S,PARMAN D G. Use of electric downhole heaters to improve production and recovery of heavy,viscous oil in California and Venezuela[C]// SPE Kuwait Oil and Gas Show and Conference,Kuwait City,Kuwait,2013. DOI: 10.2118/167347-MS.

[39] YANG Hao,GAO Xiaoqiao,XIONG Fansheng,et al. Temperature distribution simulation and optimization design of electric heater for in situ oil shale heating[J]. Oil Shale,2014,31(2):105. DOI: 10.3176/oil.2014.2.02

[40] BYBEE K. Electrical downhole heaters for faja heavy-oil reservoirs[J]. Journal of Petroleum Technology,2009,61(3):77−79. DOI: 10.2118/0309-0077-JPT

[41] ZHU Zuojing,ZENG Fanhua,ZHAO Gong,et al. Evaluation of the hybrid process of electrical resistive heating and solvent injection through numerical simulations[J]. Fuel,2013,105:119−127. DOI: 10.1016/j.fuel.2012.07.019

[42] HASSANZADEH H,HARDING T. Analysis of conductive heat transfer during in-situ electrical heating of oil sands[J]. Fuel,2016,178:290−299. DOI: 10.1016/j.fuel.2016.03.070

[43] CASTROGIOVANNI A G,VOLAND R T,WARE C H,et al. Downhole steam generator and method of use:US9617840[P]. 2017-04-11.

[44] 匡韶华,王宝权,张建军,等. 井下电加热蒸汽发生器:CN203810358U[P]. 2014-09-03. [45] 董社霞,张海龙,张保康,等. 一种蒸汽热采稠油的设备及其方法:CN103114836A[P]. 2013-05-22. [46] 谢小辉. 井下电磁感应加热器理论分析及实验研究[D]. 成都:西南石油大学,2017. XIE Xiaohui. Theoretical analysis and experimental study of underground electromagnetic induction heater[D]. Chengdu:Southwest Petroleum University,2017.

[47] 郭威,王振东,孙友宏,等. 一种井下涡流加热器:CN108343415B[P]. 2023-09-22. [48] 郭威,王振东,孙友宏,等. 一种井下流体电加热器:CN108505971B[P]. 2023-09-22. [49] 郭威,王振东,孙友宏,等. 一种非常规能源用井下流体加热器:CN108301817B[P]. 2023-09-15. [50] 王振东,郭威,李强,等. 一种串联式变螺距井下流体电加热器:CN207093039U[P]. 2018-03-13. [51] 王振东,杨甫,付德亮,等. 一种井下电加热器:CN215718629U[P]. 2022-02-01. [52] 王振东,杨甫,付德亮,等. 一种双壳体井下电加热器:CN216305871U[P]. 2022-04-15. [53] GUO Wei,WANG Zhendong,SUN Youhong,et al. Effects of packer locations on downhole electric heater performance:Experimental test and economic analysis[J]. Energies,2020,13(2):377. DOI: 10.3390/en13020377

[54] WANG Zhendong,LÜ Xiaoshu,LI Qiang,et al. Downhole electric heater with high heating efficiency for oil shale exploitation based on a double-shell structure[J]. Energy,2020,211:118539. DOI: 10.1016/j.energy.2020.118539

[55] WANG Zhendong,YANG Fu,FU Deliang,et al. Economic and heating efficiency analysis of double-shell downhole electric heater for tar-rich coal in situ conversion[J]. Case Studies in Thermal Engineering,2023,41:102596. DOI: 10.1016/j.csite.2022.102596

[56] 郭威,王振东,李强,等. 一种油页岩用井下电缆高温高压密封接头:CN109861162B[P]. 2023-10-24. [57] 自然资源部煤炭资源勘查与综合利用重点实验室成功提取全球第一桶富油煤焦油. https://www.iziran.net/news.html?aid=5296081. [58] 郭威,刘召,孙友宏,等. 富油煤原位热解开发地下体系封闭方法探讨[J]. 煤田地质与勘探,2023,51(1):107−114. DOI: 10.12363/issn.1001-1986.22.12.0941 GUO Wei,LIU Zhao,SUN Youhong,et al. Discussion on underground system sealing methods in in-situ pyrolysis exploitation of tar-rich coal[J]. Coal Geology & Exploration,2023,51(1):107−114. DOI: 10.12363/issn.1001-1986.22.12.0941

-

期刊类型引用(1)

1. 吴晓丹,孙景耀,唐颖,董雪林. 富油煤原位转化感应加热和射频加热效果数值比选研究. 中国石油和化工标准与质量. 2024(24): 109-112 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: