Two-phase flow chokeling results and control in high-pressure gas wells producing water

-

摘要:

井筒气水两相管流节流前后动态特性分析与控制,对保障致密气等高压含水气井高效稳定安全开采和水合物防治具有重要意义。考虑等熵绝热、等压热容、等容热容、不同井深节流能量等因素,推导气水两相流体流经喷嘴的能量、动能和温度动态变化等热力学微分方程组,建立高压含水气井两相节流能量、节流系统热量、节流物质平衡和流体质量流量变化等井下节流场数学模型,提出一种气水两相井筒节流前后动态特性分析与控制方法,为优化井下节流器及其节流喷嘴的结构参数和保障气井流动安全提供理论依据。最后依据数值模拟手段及其判断结果,以鄂尔多斯盆地东缘大宁−吉县区块为例进行验证,以揭示高压含水气井喷嘴尺寸和深度、含水率、节流前压力和温度对节流前后动态特性的影响规律。结果表明:高压含水气井气水两相流体质量流量先是随节流压力比减小而呈指数级增大,并在压力比降至0.55阈值附近时达到最大值,增大喷嘴下入深度和含水率、同时降低节流前压力和温度,可提高节流后温度,有利于抑制水合物生成;且节流过程临界质量流量受喷嘴内径的影响最大,含水率和节流前压力次之,而节流前温度和喷嘴深度的影响最小,且增加含水率会提高临界质量流量,但产气量也随之下降;大宁–吉县区块现场工程实例分析表明,井下节流喷嘴内径由3.0 mm扩至5.0 mm和节流前压力由14 MPa增至18 MPa时,气水两相流体的临界质量流量提升幅度分别为179.3%和27.8%,而利用地层温度等将节流前温度由313 K升至333 K时,节流过程临界质量流量反而小幅下降且下降幅度仅为5.15%,为此,增大喷嘴内径及其下入深度和节流前压力同时降低节流前温度,有利于提高气水两相流体节流过程中临界质量流量,并提升高压含水气井的产气量。

Abstract:Prediction and control of two-phase flow chokeling in tight gas wellbores are essential for the normal operation and hydrate control of high-pressure gas wells producing water. The thermodynamic differential equations of energy, kinetic energy and temperature and models of chokeling field for two-phase energy, system heat, mass balance and flow were developed under the conditions of isentropic adiabatic, isobaric heat capacity, constant volume heat capacity, and chokeling energy. A methodology on predicting characteristics and control of two-phase flow before and after chokeling was proposed for gas-water two phase flow. It provided a theoretical basis for optimizing the structural parameters of downhole throttle and its nozzle and ensuring the flow safety. The dynamic variations of two-phase flow chokeling with nozzle size and its depth, water content, pressure and temperature were analyzed on numerical simulation and verification of Daning-Jixian oilfield in the eastern margin of Ordos Basin. The results show that the mass flow rate increases exponentially with the decreased pressure ratio, and it reaches the maximum while pressure ratio drops to the threshold of 0.55. The temperature will be enhanced after chokeling and the formation of hydrates will be inhibited while the nozzle depth and water content are increased and pressure and temperature are reduced before chokeling. The effects of nozzle inner diameter, water content, pressure, temperature and nozzle depth on the critical mass flow gradually decreases during chokeling. The increase of water content will enhance the critical mass flow rate and decrease gas production of high-pressure gas wells producing water. The well site analysis on Daning-Jixian oilfield shows that the mass flow rates increase 179.3% and 27.8%, respectively, while nozzle inner diameters enhance from 3.0 mm to 5.0 mm and pressures on chokeling process increase from 14 MPa to 18 MPa. The mass flow rate varies with a small drop of 5.15%. Increasing the nozzle inner diameter, its depth and the pressure while reducing the temperature is beneficial to improve the mass flow rate during the chokeling process of two-phase fluid and increase the gas production in high-pressure gas wellbores producing water.

-

井筒气水两相管流节流前后动态特性分析与控制,对保障致密气等含水气井高效稳定安全开采和解决因水合物淤积造成管阻问题具有重要意义[1-3]。由于气井井下节流喷嘴的降压作用,井口压力得到有效调节,井口设备与管道承压下降[4-6];此外,节流后的含水气流一般处于临界流动状态,井口设备的压力波动不会对井底压力产生影响,减少了压力波动和井底出砂。

对于气液两相流态节流过程,目前主要通过研究节流中流体质量、动量、能量与相态的变化,提出了经验和机理相结合的算法。Shao Huaishuang等[7]在Perkins和Al-safran模型基础上,提出一种节流阀多相流态和质量流量预测方法,该方法考虑了流体经喷嘴节流时的交替气液绝热条件和气液两相间的滑移现象,但模型中两相流为均相流,且仅适用于临界流与亚临界流。C. M. Carstensen等[8]在Gilbert和Ros模型基础上,修正非平衡系数并解释节流阀快速降压的中间状态,提出运用非平衡流动的概念预测冻结流动和绝热膨胀的节流过程,但却忽略了组分、温压、体积与流体温度等因素的影响。王振嘉等[9]综合产量对比分析法和油套环空压差预测法,并结合井下节流喷嘴尺寸、下井深度等参数,提出一种适用于“低渗透率、低孔隙率、低丰度、强非均质性”特征储层井下节流气井的积液量预测方法,其适用范围受限。安永生等[10]建立了井下节流气井渗流、喷嘴气流数学模型,并依此推导数值求解源汇项方程,完成气井渗流和喷嘴气流的耦合处理,仅适用于遵守达西定律的单相气体流动,且假设节流前后为等温过程。曾焱等[11]建立了节流气井储层和井筒耦合生产动态模型,拟合试井解释或生产动态数据,并依此预测节流气井的流量和压力变化情况,但仅适用于单相气体流动工况。

S. Naseri等[12]在GA-RBF模型基础上,提出一种亚音速气流经喷嘴和孔板式节流阀时人工智能预测流量系数方法,该方法采用径向基函数神经网络结合遗传算法,并考虑了雷诺数以及节流喷嘴直径与管径比值等因素。王荧光等[13]模拟井下节流过程压力和温度变化情况,依据NETOPT网络模型优化节流喷嘴内径等结构参数。这些研究可归纳为网络优化模型,但由于算法的实际应用效果欠佳,目前工程上还没有得到普遍应用。

目前,大部分研究成果不适用于高压含水气井或存在工程上应用受限等问题,笔者综合等熵绝热膨胀、焓与动能非平衡转化等过程,提出一种适用于致密气、湿气井等高压含水气井开采工况下的井筒气水两相管流节流前后动态特性分析与控制方法,并通过数值模拟和在鄂尔多斯盆地东缘大宁−吉县区块井场验证,分析高压含水气井节流过程随喷嘴尺寸、含水率以及节流前压力和温度动态变化状况等,以期达到保证高压含水气井高效稳定开采和防治水合物的目的。

1 气水两相井下节流热力学模型

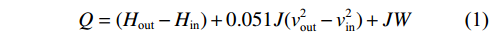

气水两相流经节流喷嘴时,井下节流过程的能量变化基本方程[14-15]为:

$$ Q = ({H_{{\text{out}}}} - {H_{{\text{in}}}}) + 0.051J(v_{{\text{out}}}^{\text{2}} - v_{{\text{in}}}^2) + JW $$ (1) 气水两相流体流经节流喷嘴的时间较短,节流前后气水两相流体几乎不与井筒及其近井围岩发生热功和机械功的交换,则节流过程气水两相流体的能量组成为:

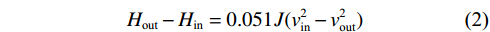

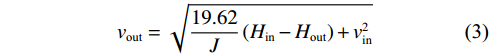

$$ {H_{{\text{out}}}} - {H_{{\text{in}}}} = 0.051J(v_{{\text{in}}}^2 - v_{{\text{out}}}^{\text{2}}) $$ (2) 由此推导出喷嘴出口处两相流的速度为:

$$ {v_{{\text{out}}}} = \sqrt {\frac{{19.62}}{J}\left( {{H_{{\text{in}}}} - {H_{{\text{out}}}}} \right) + v_{{\text{in}}}^2} $$ (3) 井下节流前后,流经喷嘴的气水两相流体的焓转化为动能,节流后两相流速得以提升,等熵绝热过程中,节流后的两相流体压力下降,而比热容增大;与此同时,节流后两相流体的熵不变,但两相流体的温度下降。

2 气水两相井下节流场数学模型

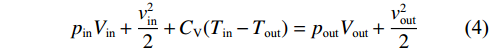

不考虑井下节流过程的位能差、系统与外界的热交换,且节流喷嘴内部流体处于等熵绝热状态,依据节流过程能量守恒方程[16-18],气水两相管流井下节流过程的能量变化(图1)为:

$$ {p}_{\text{in}}{V}_{\text{in}}+\frac{{v}_{\text{in}}^{2}}{2}+{C}_{\mathrm{V}}({T}_{\text{in}}-{T}_{\text{out}})={p}_{\text{out}}{V}_{\text{out}}+\frac{{v}_{\text{out}}^{2}}{2} $$ (4) 单位质量气水两相流体的能量组成为:

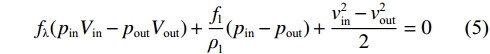

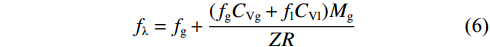

$$ f_{\text{λ}} ({p_{{\text{in}}}}{V_{{\text{in}}}} - {p_{{\text{out}}}}{V_{{\text{out}}}}) + \frac{{{f_{{{\mathrm{l}}}}}}}{{{\rho _{{{\mathrm{l}}}}}}}({p_{{\text{in}}}} - {p_{{\text{out}}}}) + \frac{{v_{{\text{in}}}^{\text{2}} - v_{{\text{out}}}^{\text{2}}}}{2} = 0 $$ (5) $$ f_{\text{λ}} ={f}_{\mathrm{g}}+\frac{({f}_{\mathrm{g}}{C}_{\mathrm{V}\mathrm{g}}+{f}_{{{\mathrm{l}}}}{C}_{\mathrm{Vl}{}}){M}_{\mathrm{g}}}{ZR} $$ (6) 节流过程中系统热量Q保持不变,则有:

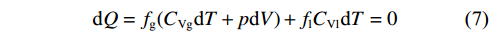

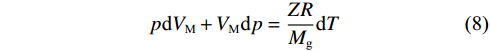

$$ {\text{d}}Q = {f_{\text{g}}}({C_{{\mathrm{V}}{{{\mathrm{g}}}}}}{\text{d}}T + p{\text{d}}V) + {f_{{{\mathrm{l}}}}}{C_{{\mathrm{V}}{{{\mathrm{l}}}}}}{\text{d}}T = 0 $$ (7) 基于熵的流体热力学微分方程为:

$$ p{\text{d}}{V_{\text{M}}} + {V_{\text{M}}}{\text{d}}p = \frac{{ZR}}{{{M_{\text{g}}}}}{\text{d}}T $$ (8) 由此推导出节流过程系统热量微分方程为:

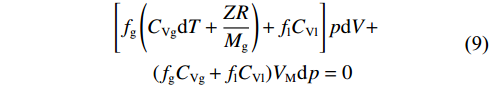

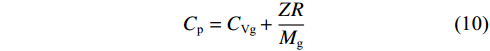

$$\begin{aligned} &\left[{f}_{{\mathrm{g}}}\left({C}_{\mathrm{V}\mathrm{g}}{\mathrm{d}}T+\frac{ZR}{{M}_{\mathrm{g}}}\right)+{f}_{{\mathrm{l}}}{C}_{{\mathrm{Vl}}}\right]p{\mathrm{d}}V+\\ &\qquad ({f}_{\mathrm{g}}{C}_{\mathrm{V}\mathrm{g}}+{f}_{\mathrm{l}}{C}_{\mathrm{V}\mathrm{l}}){V}_{\mathrm{M}}{\mathrm{d}}p=0\end{aligned}$$ (9) 井下节流过程中,气相等压热容(Cp)[19-20]与气相等容热容(CVg)之间的关系式为:

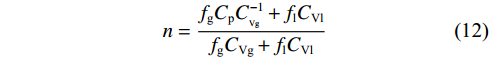

$$ {C_{\text{p}}} = {C_{{\text{Vg}}}} + \frac{{ZR}}{{{M_{\text{g}}}}} $$ (10) 考虑等压热容、等容热容等因素后的节流系统热量为:

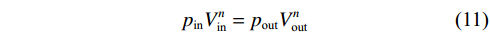

$$ {p_{{\text{in}}}}V_{{\text{in}}}^n = {p_{{\text{out}}}}V_{{\text{out}}}^n $$ (11) 其中,

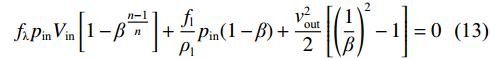

$$ n = \frac{{{f_{\text{g}}}{C_{\text{p}}}C_{_{{\text{Vg}}}}^{ - 1} + {f_{\text{l}}}{C_{{\text{Vl}}}}}}{{{f_{\text{g}}}{C_{{\text{Vg}}}} + {f_{\text{l}}}{C_{{\text{Vl}}}}}} $$ (12) 引入节流后出口与节流前入口的压力比β,减小压力比β,节流过程气水两相流体质量流量有增大的趋势,且节流后出口压力降至一定程度后,流体速度存在音速界限并保持不变,即两相流体达到音速的临界流动状态[21-24],临界流动状态单位质量两相流体能量为:

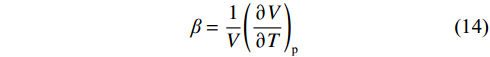

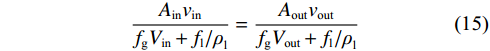

$$ f_{\text{λ}} {p_{{\text{in}}}}{V_{{\text{in}}}}\left[1 - {\beta ^{\tfrac{{n - 1}}{n}}}\right] + \frac{{{f_{\text{l}}}}}{{{\rho _{\text{l}}}}}{p_{{\text{in}}}}(1 - \beta ) + \frac{{v_{{\text{out}}}^{\text{2}}}}{2}\left[ {{{\left( {\frac{1}{\beta }} \right)}^2} - 1} \right] = 0 $$ (13) $$ \beta = \frac{1}{V}{\left( {\frac{{\partial V}}{{\partial T}}} \right)_{\text{p}}} $$ (14) $$ \frac{{{A_{{\text{in}}}}{v_{{\text{in}}}}}}{{{f_{\text{g}}}{V_{{\text{in}}}} + {f_{\text{l}}}/{\rho _{\text{l}}}}} = \frac{{{A_{{\text{out}}}}{v_{{\text{out}}}}}}{{{f_{\text{g}}}{V_{{\text{out}}}} + {f_{\text{l}}}/{\rho _{\text{l}}}}} $$ (15) 井下节流过程流体的质量流量为:

$$ w = \frac{{Av}}{{{f_{\text{g}}}{V_{{\text{out}}}} + {f_{\text{l}}}/{\rho _{\text{l}}}}} $$ (16) 井下节流入口压力与出口压力之间的压力比低于临界压力比[29-31]时,气水两相流体处于临界流动状态,质量流量达到最大并保持不变,即:

$$ \frac{{\text{d}}}{{{\text{d}}\beta }}{\left( {\frac{w}{{{A_{{\text{out}}}}\sqrt {{p_{{\text{in}}}}/{V_{{\text{in}}}}} }}} \right)^2} = 0 $$ (17) 3 高压含水气井节流特性实例分析

3.1 基本参数

选取鄂尔多斯盆地东缘大宁−吉县区块致密气高压含水气井开展井筒气水两相流态井下节流前后动态特性分析。依据井下技术作业公司的检测报告,大宁−吉县区块井场测试的井筒各部分物性参数与生产参数为:节流前压力14、15、16、17、18 MPa,节流前温度313、318、323、328、333 K,气体密度0.68 kg/m3,含水率0、0.1、0.2、0.3、0.4 mol/mol,喷嘴内径3.0、3.5、4.0、4.5、5.0 mm,油管内径63 mm,油套内径139.7 mm。

3.2 节流前后两相流动态特性

高压含水气井节流前后两相流的动态特性会受到喷嘴尺寸等结构参数的影响。节流前压力18 MPa、温度333 K和含水率0.1 mol/mol时,气水两相流体节流过程质量流量随喷嘴内径和压力比的动态变化关系如图2所示。减小压力比β,节流过程两相流体质量流量先是呈指数级增大而后基本保持恒定,压力比的阈值为0.55左右。

喷嘴内径等结构参数对高压含水气井两相流节流过程质量流量的影响相对较大,且给定压力比β时,节流过程质量流量随喷嘴内径的不断增大而显著提升,这与安永生等[10]所得出的“井下节流喷嘴直径越大,气井产量越高”的结论一致。图2a中,喷嘴内径由3.0 mm扩至5.0 mm时,气水两相流体的临界质量流量由1.45×104 kg/d增至4.05×104 kg/d,临界质量流量提升幅度达到179.3%。图2b给出不同压力比β工况节流后温度变化情况,当β=1时,节流后温度等于节流前温度;而后随压力比不断减小,节流后温度呈现类“抛物线”式下降的趋势。其主要原因在于节流前入口压力一定的情况下,节流后出口压力的下降会造成压力比β的减小,节流过程气水两相流体质量流量有增大的趋势,综合等压热容、等容热容等因素作用,节流之后出现两相流体温度降低的现象。此外,节流前入口压力一定时,喷嘴结构参数设计不合理易使得节流后出口压力发生“低压”工况(图2b中压力比小于0.1),由此会造成节流之后的两相流体温度降至零度以下;而当节流后出口压力一定时,不断增加典型“高压”含水气井的节流前入口压力(14~18 MPa),也易出现节流后两相流体温度降至零度以下的现象。

图2c中,给定压力比β时,喷嘴下入深度越深,节流后温度越高,这与曾焱等[11]所得出的“井下节流温度随喷嘴深度的不断增大而逐渐提升”的结论一致。此外,图2c中气水两相流体节流后温度随喷嘴下入深度和压力比的不断减小而呈现类“抛物线”式逐渐下降的趋势;且喷嘴下入深度较浅且压力较小时,节流之后的两相流体温度可降至−293 K~−333 K而出现低温工况,其主要原因在于高压含水气井节流前后两相流动态特性分析充分考虑了等熵绝热、等压热容、等容热容、不同井深节流能量等因素的综合作用,而且低温高压工况的出现易导致水相态发生变化并伴随水合物生成的情况,从而不利于水合物生成的防治;图2c中喷嘴下入深度400 m且压力比0.01的工况下,气水两相流体的节流后温度最低可降至−325.7 K。为此,需合理设计高压含水气井喷嘴的下入深度,避免出现井深超1.6 km而节流作业中喷嘴下入深度不足1.0 km的情况;并且需合理制定节流前后的压力等生产制度,防止发生因压力比过小而造成节流后温度过低等问题;同时,充分利用地层温度对两相流体进行升温,以保证气水两相流体节流过程中的温度和节流后的温度高于水合物的临界生成温度。

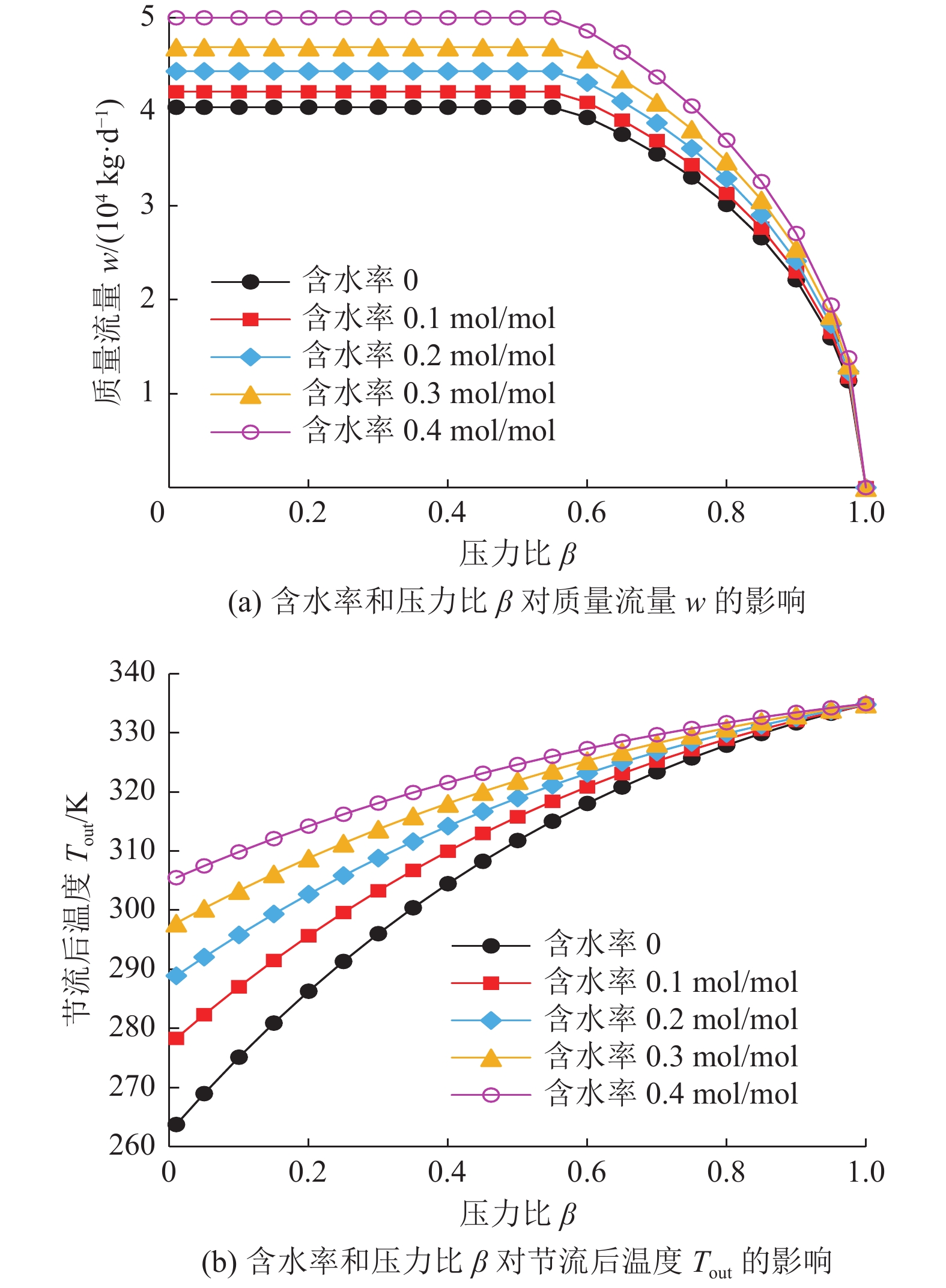

高压含水气井节流前后的动态特性也受到压力等生产参数的影响,喷嘴内径5.0 mm、节流前温度333 K和含水率0.1 mol/mol工况下,气水两相流体节流过程质量流量以及节流后温度随节流前压力和压力比的动态变化关系如图3所示。

高压含水气井气水两相流体节流过程质量流量随节流前压力的增大而缓慢提升,且较喷嘴内径的影响较低,图3a中,节流前压力由14 MPa增至18 MPa时,气水两相流体的临界质量流量由3.17×104 kg/d升至4.05×104 kg/d,临界质量流量提升的幅度仅为27.8%。图3b中,节流过程给定压力比β时,节流前压力越高,节流后温度越低,且其影响程度随压力比下降而显著增大。

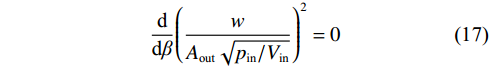

高压含水气井节流前后的动态特性还受到温度等生产参数的影响,喷嘴内径5.0 mm、节流前压力18 MPa和含水率0.1 mol/mol工况下,气水两相流体节流过程质量流量以及节流温差随节流前温度和压力比的动态变化关系如图4所示。

节流前温度等生产参数对高压含水气井气水两相流体节流过程质量流量以及节流温差的影响均较小,节流过程质量流量随节流前温度的升高而略有降低,图4a中,节流前温度由313 K升至333 K时,气水两相流体的临界质量流量由4.27×104 kg/d降至4.05×104 kg/d,下降幅度仅为5.15%。图4b中,节流过程给定压力比β时,节流前温度越高,节流温差ΔT=Tout−Tin越低,且其影响程度随压力比下降而显著增大。

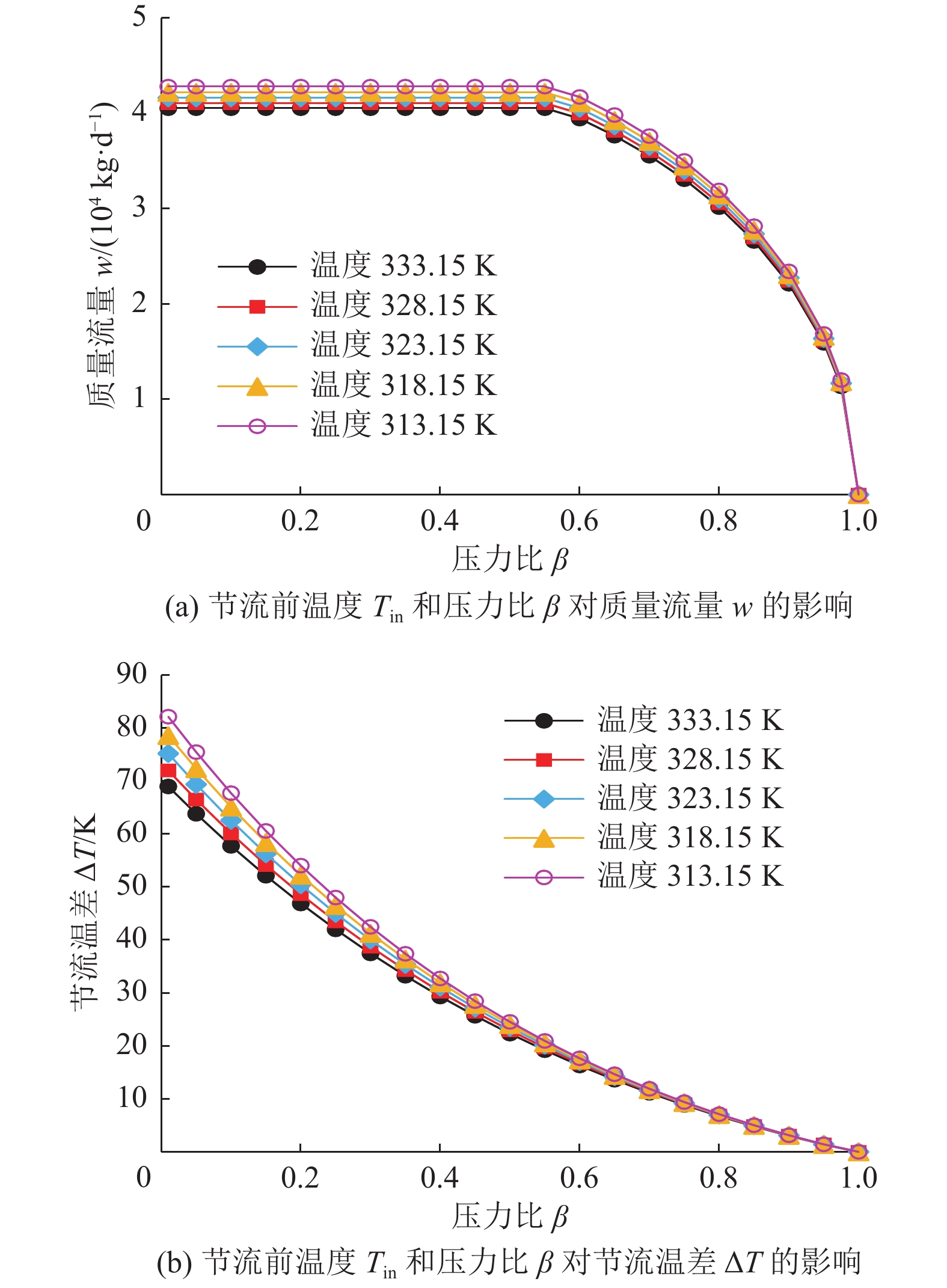

高压含水气井节流前后的动态特性同时会受到含水率等物性参数的影响,喷嘴内径5.0 mm、节流前压力18 MPa和温度333 K工况下,气水两相流体节流过程质量流量以及节流后温度随含水率和压力比的动态变化关系如图5所示。

含水率等物性参数对高压含水气井气水两相流体节流过程质量流量的影响相对较小,与节流前压力的影响接近,图5a中,含水率由0增至0.4 mol/mol时,气水两相流体的临界质量流量由4.04×104 kg/d升至5.01×104 kg/d,增幅为23.76%。图5b中,节流过程给定压力比时,含水率越高,节流后温度也越高。

3.3 节流判断结果对比

气水两相流体井筒运移节流过程临界质量流量受喷嘴内径的影响最大,这与安永生等[10]所提出的“定气嘴尺寸生产”的概念一致,含水率和节流前压力的影响次之,而节流前温度和喷嘴下入深度的影响最小。

相较于安永生、曾焱等前人研究[9-11],一方面笔者团队综合等熵绝热膨胀、焓与动能非平衡转化等过程,提出了一种适用于致密气等高压含水气井开采工况和气水两相流体节流前后动态特性分析方法,而不是仅适用于单相气体流动工况、特定特征储层节流积液量预测或假设节流前后为等温过程;另一方面,本文不仅量化分析了喷嘴内径等结构参数对节流过程动态特性的影响,而且揭示出含水率和喷嘴深度等物性参数以及压力和温度等生产参数对高压含水气井节流特性的具体影响程度,初步解决了现有算法实际应用效果欠佳和工程上应用受限的问题,并为优化井下节流器及其节流喷嘴的结构参数和保障气井流动安全提供了理论依据。

4 结 论

a. 综合等熵绝热、等压热容、等容热容、不同井深节流能量等因素,推导出气水两相流体经喷嘴的能量、动能和温度动态变化等热力学微分方程组,提出了一种高压气水两相节流动态特性分析与节流控制方法,为优化井下节流器及其节流喷嘴的结构参数和保障气井流动安全提供了理论依据,并可避免致密气等高压含水气井因水合物淤积而引起的管阻问题。

b. 增大喷嘴内径及其下入深度和节流前压力同时降低节流前温度,有利于提高两相流体节流过程中临界质量流量,并提升高压含水气井的产气量;而增加含水率虽然会小幅增加临界质量流量,但产气量也随之下降;且节流临界质量流量受喷嘴内径的影响最大,含水率和节流前压力次之,而节流前温度和喷嘴深度的影响最小。

c. 在高压含水气井的实际生产中,应合理设计喷嘴下入深度和节流前后压力,并控制含水率和节流温度,同时充分利用地层温度对两相流体进行升温,达到保障高压含水气井高效稳定开采和防治水合物的目的。

d. 致密气、湿气井等高压含水气井开采工况受多因素影响,且高压气水两相流体节流前后流场及运移规律复杂,本次研究成果仅用于高压含水气井节流前后两相流动态特性分析,后续可继续开展高压含水气井不同开采工况喷嘴动态节流场仿真分析和节流喷嘴优化设计工作。

符号注释:

A为连接节流器的油管流道横截面积,m2;Ain、Aout分别为节流前喷嘴入口处和节流后喷嘴出口处的节流器流道横截面积,m2;CV为流体的等容热容,J/(mol∙K);Cp、CVg、CVl分别为气相等压热容、等容热容和水相等容热容,J/(mol∙K);fg、fl分别为气相与水相的滞留率;fλ为滞留率;Hin、Hout分别为喷嘴入口和出口处流体焓,J/kg;J为热功当量,J/kg;Mg为气相的相对分子质量,J/(kg∙K);n为节流系统热量系数;p为流体压力,MPa;pin、pout分别为节流前后流体压力,MPa;Q为总交换热,J/kg;R为气体通用常数,J/(mol∙K);T为流体温度,K;Tin、Tout分别为节流前后流体温度,K;v为节流过程中流体速度,m/s;vin、vout分别为喷嘴入口和出口处流体的速度,m/s;V为流体的摩尔体积,L/mol;VM为井筒壁面流体的摩尔体积,L/mol;Vin、Vout分别为节流前后流体的摩尔体积,L/mol;w为节流过程流体的质量流量,kg/d;W为总交换功,J/kg;Z为压缩因子;ρl为水相密度,kg/m3。

-

-

[1] 周慧,朱建鲁,李玉星,等. 纯氢与掺氢天然气节流特性及节流系数预测新方法[J]. 天然气工业,2022,42(4):139−148. ZHOU Hui,ZHU Jianlu,LI Yuxing,et al. Throttling characteristics and throttling coefficient prediction of pure hydrogen and hydrogen–blended natural gas[J]. Natural Gas Industry,2022,42(4):139−148.

[2] LIU Xinfu,LIU Chunhua,WU Jianjun. A modern approach to analyzing the flowing pressures of a two–phase CBM and water column in producing wellbores[J]. Geofluids,2019,2019(5):3093707.

[3] 周劲辉,张云,熊至宜,等. 煤层气井底节流阀节流效应数值模拟[J]. 中国石油大学学报(自然科学版),2021,45(6):144−151. ZHOU Jinhui,ZHANG Yun,XIONG Zhiyi,et al. Numerical simulation of throttling effect on throttle valve at well bottom hole[J]. Journal of China University of Petroleum (Edition of Natural Science),2021,45(6):144−151.

[4] SABERI A,ALAMDARI A,RASOOLZADEH A,et al. Insights into kinetic inhibition effects of MEG,PVP,and L–tyrosine aqueous solutions on natural gas hydrate formation[J]. Petroleum Science,2021,18(2):495−508. DOI: 10.1007/s12182-020-00515-0

[5] DONG Lin,LI Yanlong,LIU Changling,et al. Mechanical properties of methane hydrate–bearing interlayered sediments[J]. Journal of Ocean University of China,2019,18(6):1344−1350. DOI: 10.1007/s11802-019-3929-z

[6] 贺登辉,陈森林,白博峰. V锥节流装置内气液分层流动特性数值模拟[J]. 中国石油大学学报(自然科学版),2019,43(3):151−158. HE Denghui,CHEN Senlin,BAI Bofeng. Numerical simulation of stratified gas–liquid flow inside V–cone throttle device[J]. Journal of China University of Petroleum (Edition of Natural Science),2019,43(3):151−158.

[7] SHAO Huaishuang,JIANG Lei,LIU Lei,et al. Modeling of multiphase flow through chokes[J]. Flow Measurement and Instrumentation,2018,60(4):44−50.

[8] CARSTENSEN C M,ONESUBSEA S K K. Multiphase flow through chokes:An evaluation of frozen,equilibrium,and nonequilibrium flow models[J]. Journal of Petroleum Science & Engineering,2022,215(8):110402.

[9] 王振嘉,郑海亮,刘永建,等. 苏里格气田井下节流气井积液量预测方法及应用[J]. 天然气勘探与开发,2019,42(4):115−120. WANG Zhenjia,ZHENG Hailiang,LIU Yongjian,et al. Methods to predict liquid loading in gas wells with downhole choke and its application to Sulige gasfield[J]. Natural Gas Exploration and Development,2019,42(4):115−120.

[10] 安永生,曹孟京,兰义飞,等. 井下节流气井的生产动态模拟新方法[J]. 天然气工业,2016,36(4):55−59. AN Yongsheng,CAO Mengjing,LAN Yifei,et al. A new production behavior simulation method for gas wells equipped with a downhole throttling device[J]. Natural Gas Industry,2016,36(4):55−59.

[11] 曾焱,陈伟,段永刚,等. 井下节流气井的生产动态预测[J]. 西南石油大学学报(自然科学版),2009,31(6):110−112. ZENG Yan,CHEN Wei,DUAN Yonggang,et al. Production performance prediction of downhole throttling gas well[J]. Journal of Southwest Petroleum University (Science & Technology Edition),2009,31(6):110−112.

[12] NASERI S,TATAR A,SHOKROLLAHI A. Development of an accurate method to prognosticate choke flow coefficients for natural gas flow through nozzle and orifice type chokes[J]. Flow Measurement and Instrumentation,2016,48(4):1−7.

[13] 王荧光,裴红,刘文伟,等. 苏里格气田井下节流综合预测[J]. 天然气工业,2010,30(2):97−101. WANG Yingguang,PEI Hong,LIU Wenwei,et al. An integrated forecast for downhole throttling at the Sulige gas field[J]. Natural Gas Industry,2010,30(2):97−101.

[14] 赵金洲,彭瑀,李勇明,等. 基于双层非稳态导热过程的井筒温度场半解析模型[J]. 天然气工业,2016,36(1):68−75. ZHAO Jinzhou,PENG Yu,LI Yongming,et al. A semi–analytic model of wellbore temperature field based on double–layer unsteady heat conducting process[J]. Natural Gas Industry,2016,36(1):68−75.

[15] 王雪瑞,孙宝江,刘书杰,等. 基于水化反应动力学的深水固井井筒温度与压力耦合预测模型[J]. 石油勘探与开发,2020,47(4):809−818. WANG Xuerui,SUN Baojiang,LIU Shujie,et al. A coupled model of temperature and pressure based on hydration kinetics during well cementing in deep water[J]. Petroleum Exploration and Development,2020,47(4):809−818.

[16] 吴栋梁. 低温节流特性可视化实验系统研制及液氮节流参数化研究[D]. 上海:上海交通大学,2020. WU Dongliang. Development of visual system for cryogenic throttling experiment and parametric study of liquid nitrogen throttling[D]. Shanghai:Shanghai Jiao Tong University,2020.

[17] SEIDI S,SAYAHI T. A new correlation for prediction of sub–critical two–phase flow pressure drop through large–sized wellhead chokes[J]. Journal of Natural Gas Science & Engineering,2015,26(9):264−278.

[18] LEPORINI M,TERENZI A,MARCHETTI B. Improvement of a multiphase flow model for wellhead chokes under critical and subcritical conditions using field data[J]. Journal of Petroleum Exploration & Production Technology,2021,11(3):1487−1503.

[19] PERKINS T K. Critical and subcritical flow of multiphase mixtures through chokes[J]. SPE Drilling & Completion,1993,8(4):271−276.

[20] NASRIANI H R,KALANTARIASL A. Choke performance in high–rate gas condensate wells under subcritical flow condition[J]. Energy Sources,2015,37(2):192−199. DOI: 10.1080/15567036.2011.582607

[21] LEE S Y,SCHROCK V E. Critical two–phase flow in pipes for subcooled stagnation states with a cavity flooding incipient flashing model[J]. Journal of Heat Transfer,1990,112(4):1032−1040. DOI: 10.1115/1.2910475

[22] BOGDANOVIC–JOVANOVIC J B,STAMENKOVIC Z M. Experimental and CFD analysis of MHD flow around smooth sphere and sphere with dimples in subcritical and critical regimes[J]. Thermal Science,2021,25(3):1781−1794.

[23] 张新宾,宋党育,李云波,等. 超临界态甲烷密度研究[J]. 煤田地质与勘探,2021,49(1):137−142. ZHANG Xinbin,SONG Dangyu,LI Yunbo,et al. Study on density of the supercritical methane[J]. Coal Geology & Exploration,2021,49(1):137−142.

[24] 蒋代君,陈次昌,钟孚勋,等. 天然气井下节流临界状态的判别方法[J]. 天然气工业,2006,26(9):115−117. JIANG Daijun,CHEN Cichang,ZHONG Fuxun,et al. Discriminance of the flow state in downhole choke of natural gas wells[J]. Natural Gas Industry,2006,26(9):115−117.

[25] 顾浩,郑松青,张冬丽,等. 超深油藏物质平衡方程修正及应用[J]. 石油学报,2022,43(11):1623−1631. GU Hao,ZHENG Songqing,ZHANG Dongli,et al. Modification and application of material balance equation for ultra–deep reservoirs[J]. Acta Petrolei Sinica,2022,43(11):1623−1631.

[26] 周海,王晓冬,吴明涛. 页岩气水两相物质平衡方程及其生产预测[J]. 辽宁工程技术大学学报(自然科学版),2020,39(1):18−23. ZHOU Hai,WANG Xiaodong,WU Mingtao. Shale gas and water two–phase material balance equation and its production prediction[J]. Journal of Liaoning Technical University (Natural Science),2020,39(1):18−23.

[27] 武男,石石,郑世琪,等. 基于物质平衡反演法的致密砂岩气藏地层压力计算[J]. 煤田地质与勘探,2022,50(9):115−121. WU Nan,SHI Shi,ZHENG Shiqi,et al. Formation pressure calculation of tight sandstone gas reservoir based on material balance inversion method[J]. Coal Geology & Exploration,2022,50(9):115−121.

[28] 胡素明,李相方,胡小虎,等. 考虑煤层气藏地解压差的物质平衡储量计算方法[J]. 煤田地质与勘探,2012,40(1):14−19. HU Suming,LI Xiangfang,HU Xiaohu,et al. Reserves calculation method with a material balance equation considering the difference between initial coal seam pressure and critical desorption pressure[J]. Coal Geology & Exploration,2012,40(1):14−19.

[29] 张士宏,徐文灿. 测定气动元件的有效截面积( S值和 A值)确定临界压力比( b值)的方法研究[J]. 液压气动与密封,2013,33(3):63−65. ZHANG Shihong,XU Wencan. Study on critical pressure ratio ( b) by determinations of effective area ( S and A)[J]. Hydraulics Pneumatics & Seals,2013,33(3):63−65.

[30] 司冀,王永盛,史维祥. 关于气动阀临界压力比 b及其流量公式的探讨[J]. 液压气动与密封,2011,31(2):47−51. SI Ji,WANG Yongsheng,SHI Weixiang. An approach to critical pressure ratio b and its flow–rate formulas for pneumatic valve[J]. Hydraulics Pneumatics & Seals,2011,31(2):47−51.

[31] 周国发,李鸣,屈娅嘉. 由喷管临界压力比确定安全阀临界压力比的计算公式[J]. 南昌大学学报(工科版),2000,22(2):72−76. ZHOU Guofa,LI Ming,QU Yajia. The formula of the critical pressure ratio for safety valve by the critical pressure ratio for nozzle[J]. Journal of Nanchang University (Engineering & Technology),2000,22(2):72−76.

-

期刊类型引用(2)

1. 郑刚,刘新福,刘广胜,魏韦,邓泽鲲,刘春花. 井口简易防喷器密封胶芯形变及其密封特性分析. 机床与液压. 2025(01): 140-145 .  百度学术

百度学术

2. 程清扬,张胜利,宋一昂,王丽娜,高仁安. 耐二氧化碳井下节流器投捞工艺延长凝析气井经济开采期. 石油钻采工艺. 2024(05): 618-634 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: