Architecture of intelligent service platform for drilling based on digital twin

-

摘要:

针对地质钻进过程中钻遇对象未知且复杂多变、钻进事故频发的现状,采用数字孪生技术,构建了基于时序数据驱动的地质钻探数字孪生模型体系,用以满足随钻探测、工况识别、钻速优化等实际需求。将监测到的地表设备、随钻测量、钻进工艺等数据按照时间序列分解为事前数据、实时数据、延时数据和迟到数据,利用物联网技术将这些多源异构数据进行处理,采用时序数据进行特征分析,基于事前数据建立典型工况,实时数据进行随钻预测和钻进过程工况识别,延时数据和迟到数据演进融合进行钻后优化,建立了数字孪生智能钻进周期服务平台,平台设计了设备物理层、虚拟模型层、数据处理层及钻探服务层4层交互系统,实现钻前、钻中、钻后全数据的全过程集成融合,达到了钻进系统参数最优化配置和安全高效钻探的目的。基于上述平台,利用Unity3D软件开发了数字孪生智能钻进原型系统,实现了钻前设备的数字化设计、钻进过程孔内三维可视化和钻进过程参数实时监测与控制的功能。结果表明,基于时序数据构建的数字孪生模型可有效提高钻进过程的效率和可靠性。研究结果为智能钻探优化提供了全新的路径和方法,有望在煤炭、石油、天然气、页岩气等钻探领域实现工程应用。

Abstract:In view of the situation of unknown, complex and variable drilling objects and frequent drilling accidents during the geological drilling, a digital twin model system of geological drilling based on time series data was built with the digital twin technology, so as to meet the actual requirements of prediction while drilling, condition identification, drilling rate optimization and others. The monitored data of ground equipment, measurement-while-drilling and drilling process were decomposed into prior data, real-time data, delayed data and late data according to the time series. On this basis, these multi-source heterogeneous data were processed by the Internet of Things, characteristic analysis was carried out with the time series data, the typical operating conditions were established based on the prior data, the conditions of prediction while drilling and that during the drilling were identified based on real-time data, and the time series evolution was integrated with the delayed and late data for post-drilling optimization. Then, the digital twin based intelligent drilling full-cycle service platform was established, this platform has been designed with a four interactive systems of equipment physical layer, virtual model layer, data processing layer and drilling service layer, which realizes the full-process integration of the prior data, real-time data, and delayed data. Thus, the purposes of optimal configuration of the drilling system parameters and drilling with high safety and efficiency have been achieved. Based on the above platform, the digital twin based intelligent drilling prototype system was developed using the Unity3D software, which realized the functions of digital design of pre-drilling equipment, 3D visualization of the drilling process and real-time monitoring and controlling of drilling parameters. The results show that the digital twin model based on time series data could effectively improve the efficiency and reliability of the drilling process. Besides, the research results could provide a new path and method for intelligent drilling optimization under the complex geological conditions, which is expected to be applied in coal, oil, natural gas, shale gas drilling and other fields.

-

习近平总书记在全国科技大会上指出“向地球深部进军是必须解决的战略科技问题”,把深地资源科技创新提升到关系国家发展大局的战略高度[1]。钻探是隐蔽的地下空间工程,钻进过程中经常会遇到地应力集中、地层压力异常、地层破碎、地层蠕变缩径、高矿化度(高密度)等复杂地质条件[2],钻进机具在这样一个复杂且高度狭窄、环境变量多变的隐蔽空间中工况异常恶劣,导致整个钻进过程效率低,钻进成本高,钻进质量低,钻进事故频发。

以往地质钻探过程状态监测多采用总线技术将钻进监测设备连接起来,并将采集的监测数据集中在显示屏上形成局域网络控制,导致钻进信息来源多样,数据类型不统一,数据利用效率低,钻进过程状态实时获取困难等问题。随着新一代信息技术,包括云计算、混合现实、物联网和信息物理系统等技术的迅速发展,在地质钻探和石油工程领域,许多国内外学者和公司都开展了钻进过程状态监测技术研究,部分研究结果已得到了工程应用。

目前钻进过程状态监测技术的研究热点主要围绕3个方面:(1)钻进地层的智能可钻性预判研究。地层的可钻性是表征地层被钻难易程度的综合指标,是预判钻探过程的核心参数。根据分析数据的来源和方法,可钻性的预判可划分为试验分析法[3]、统计分析法[4]和机器学习分析法[5]。其中,基于机器学习的可钻性预判已成为当前研究热点,国内外研究人员在采用各种机器学习优化算法建立预测模型并获得预测分析结果方面取得了一定成果,但如何提高地层可钻性预测的适应性和准确性,将其有机地融入钻进过程监测与控制中仍是地层预测的下一步研究方向。(2)数据驱动的钻进过程工况识别方法研究。通过随钻收集的测量参数进行数据处理及定性分析,诊断可能发生的事故类型并进行参数优化决策。目前比较常用的数据驱动工况识别方法主要有基于机器学习的方法[6-8],多传感器信息融合方法[9],多Agent方法[10]及多元统计分析方法[11],其中机器学习的方法最常用,国内外研究人员在基于机器学习算法进行事故预判及参数优化方面取得了不错的研究进展,但在钻进过程中根据实时钻进数据进行钻进过程工况的识别和预测方面仍具有较大研究空间。(3)钻速的智能预测与优化控制研究。建立钻速预测模型是实现钻进过程控制科学化、智能化的重要前提,已然成为国内外钻进过程控制的研究重点。钻速预测模型的建立方法也主要划分为机理分析法[12]与机器学习法[13-14]。当前研究主要围绕将常用优化算法应用到参数拟合过程中对传统模型进行优化,但在如何提高钻进优化控制的准确性和实时性等方面,仍有待进一步研究。上述研究虽然各自进步较快但较为独立和分离,如何将其有效整合,利用钻进过程中采集的数据,进行钻进工况识别,从而提高钻进效率,使整个钻进过程具有自主分析、决策和执行能力,是智能钻探技术有待解决的难题。

数字孪生[14-16]作为信息物理系统融合领域的新技术,是一种集成多模型、大数据、跨学科的数据驱动技术,目前已经在产品设计制造[17-18]、车间运行[19-20]、航空航天[21-22]、煤炭数字化综采[23-25]、石油化工[26]等领域得到应用。笔者通过对基于数字孪生的智能钻探服务平台架构、运行模式与平台实现进行研究,利用钻进过程不同时段获取的时序监测数据驱动在虚拟空间中构建钻进过程数字孪生模型,实现信息空间中钻进全过程模拟。钻探数字孪生模型对钻进过程、地层环境和钻机设备等参数进行实时采集,采用虚拟仿真技术和孪生数据驱动技术,实现钻进过程工况动态仿真及钻进事故预测分析及决策,并通过智能钻进控制系统对钻进过程参数进行实时控制,更有效、快速地对钻进过程事故进行预测、分析及决策,以期提高钻进过程的效率和可靠性。

1 钻探时序数据特征与驱动方法

1.1 数据特征

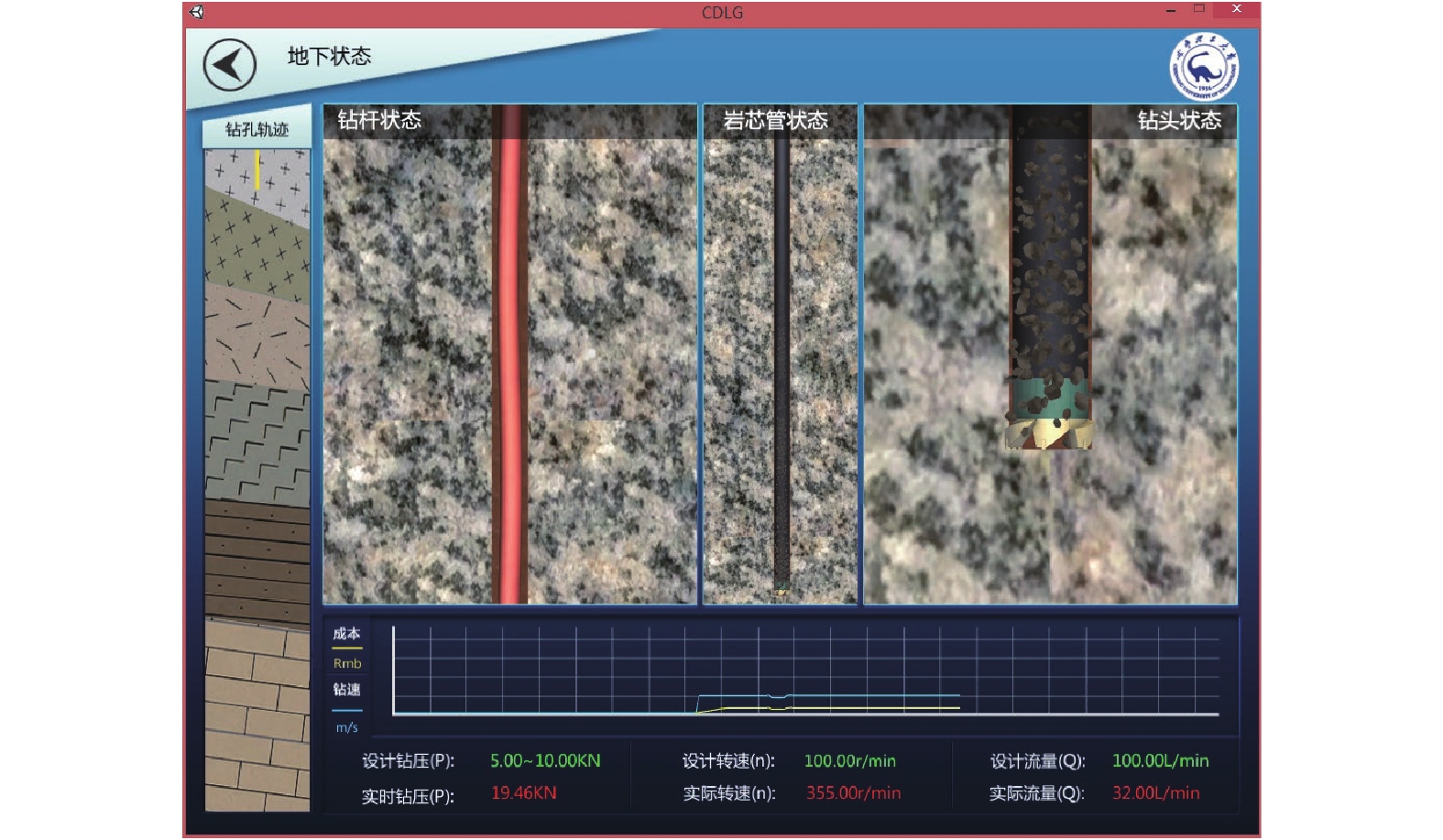

随着实时监测技术的高速发展,当前地质钻探施工过程中可以采集大量的数据,包括地表设备数据、随钻测量数据、钻进工艺数据等,但受数据产生位置深埋地下、数据传输速度等因素的影响,除地表设备之外的数据都无法实时采集,致使其时序特征极其明显。按照数据产生的时间序列将数据分为事前数据、实时数据、延时数据、迟到数据4类,如图1所示。

其中,事前数据主要由历史经验数据和钻进机具工艺参数组成。事前数据是建立钻探数字孪生模型的基础数据,在孔底破碎前就已收集完成。另外3类数据是在钻进过程中产生的,实时数据主要指地表设备的实时监测数据,这些数据在孔底破碎的时刻t0发生,响应时间极短,在t1时刻即可获得。延时数据主要指通过随钻测量装置传输的部分孔内随钻测量数据,随钻传输速度不稳定使得部分数据出现延时,这些数据在孔底破碎的时刻t0发生,响应时间较长,在t2时刻获得。迟到数据主要指部分由岩屑提供的数据,这些数据需要跟随岩屑由钻井液携带至地表,受岩屑与钻井液组成的多相流流态不稳定及岩屑在钻井液中相对运动的影响,数据必然存在偏差,这些数据在孔底破碎的时刻t0发生,响应时间长,在t3时刻获得。最后将t0时刻采集的实物岩心提至地表,岩心数据应为标定数据,以实物岩心采集的数据作为标尺,对延时数据和迟到数据进行关联。4类数据都进入钻探数据融合平台,驱动数字孪生模型,并实现相关应用。4类数据包含的具体参数类型,见表1。

表 1 参数信息Table 1. Drilling parameters数据类型 参数名称 事前数据 井眼位置、深度、井径 实时数据 转速、钻压、泵压、泵量、提升力、钻时 延时数据 钻速、扭矩、钻柱振动、钻井液入口温度、

钻井液出口温度迟到数据 岩性、岩屑粒径、钻头内排磨损分级、

钻头外排磨损分级1.2 数据采集与传输

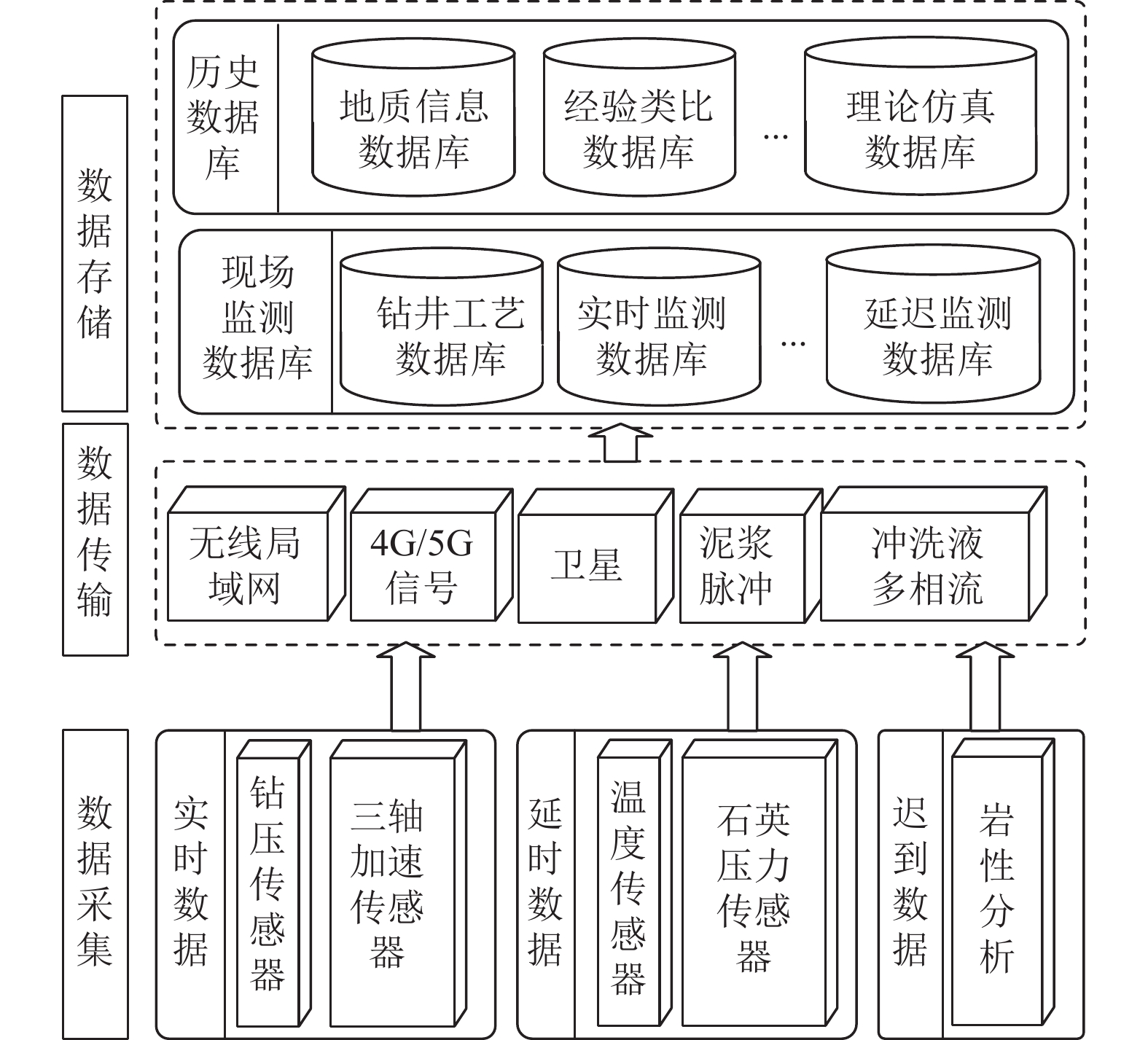

在现场实际数据采集中,监测数据来自不同厂家的多种传感器,数据结构的明显差异,在汇总前呈现为多源异构特征。本研究在厂家提供的数据字典基础上,确定各类传感器传输数据的具体结构,建立不同数据有效信息的对应关系。在此基础上,对采集的元数据进行统一规范化处理,实现采集数据的初步清洗过程,并根据数据类型将其存放在不同的数据库中。

延时数据和迟到数据通过钻杆、泥浆脉冲、冲洗液多相流等传输方式传递到地表,地表设备监测采用无线连接,远程接收装置采用DSP构建远程主控单元,利用DSP信号处理能力,对接收到的信号进行阵列处理以有效地提高远程接收系统的处理增益,将处理结果通过ZigBee协议发送至场地接收机。场地接收机只需添加RS232通信模块和ZigBee协议模块即可。远程接收装置可将远程的传感器阵列接受的微弱电磁信号传输至场地接收机,完成远程信息的采集、接收和处理功能。在按照时序数据特征标定后,数据从采集、传输到存储至数据库整体流程如图2所示。

1.3 钻进时序数据关联与融合方法

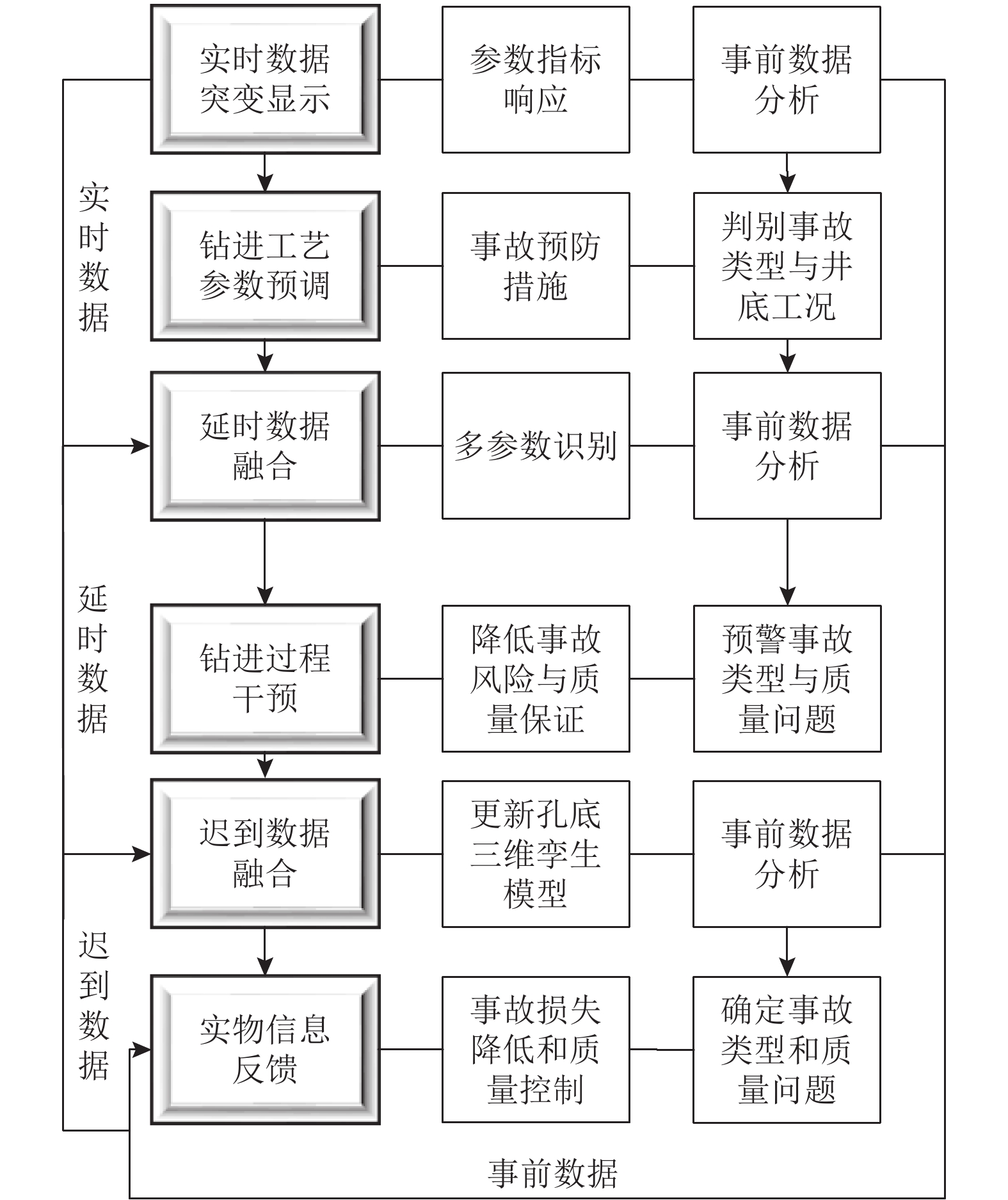

根据当前的钻进施工事前数据,总结事故出现时地表数据的实时响应,但是由于传感器、地层环境、传输条件过于复杂等原因,导致漏报、误报等问题的出现,所以必须依靠延迟数据和迟到数据,并利用相关方法对各类数据进行关联与融合,实现精确分析钻进工况,对可能出现的钻进事故进行合理决策,如图3所示。

1) 基于事前数据的典型工况时序数据特征分析

地质钻探是一项具有高度风险的隐蔽性工程,钻具在狭小、对象复杂、环境多变的隐蔽空间中完成钻进,无法避免孔内问题的发生,孔内问题主要包括钻进事故和钻进质量不足两类。钻进事故是指在施工过程中,发生孔内故障而中断正常钻进的情况,典型事故如钻具变形、断钻具、卡钻、埋钻和烧钻等。钻进质量不足指地质钻探施工未达到相应的技术要求,典型指标如取心率未达到要求、钻进速度慢无法满足工期和经济要求等。根据当前的钻进施工事前数据,总结与典型工况相关的各类数据及变化趋势,典型钻进问题的时序特征见表2。

表 2 典型钻进工况的时序数据及特征变化趋势Table 2. Time series data and characteristic change trend of typical drilling conditions典型工况 实时数据特征 延时数据特征 迟到数据特征 钻进事故 断钻 钻压突变

泵压下降

转速快扭矩突降 岩性变硬 钻具变形 钻压降低

钻时增大钻柱振动增大 岩屑粒径减小

钻头磨损增大卡钻 泵压增大

提升力增大钻柱振动减弱 岩屑比例降低 埋钻 提升力下降

泵压增大钻柱振动减弱 岩屑粒径变大 烧钻 泵压增大

泵量增大钻井液升温

振动减弱岩性变软

钻头磨损率高钻进质量不足 取心率不足 钻时增大 钻柱振动增大 岩屑减少 钻进速度慢 转速降低

钻压增大钻速降低 钻头磨损率增大 2) 基于神经网络的钻进实时数据异常预测

通过已有事前数据分析建立的典型工况,需要判断实时采集数据的异常。由于地质钻探状态与时序数据特征关系明显,实时数据会呈现突变、缓变、波动等特征,对于突变和缓变的异常数据的判别,可以采取不同时间间隔的办法对数据进行处理,短时间间隔内的数据处理可以较好地体现钻进参数的突变特性,长时间间隔可以较好地体现钻进参数的缓变特性,由此综合描述数据的波动特征,在此基础上再利用神经网络算法进行识别。假设钻进过程的数据采样周期为

$ \Delta T $ ,短时间间隔定义为${T}_{{\rm{s}}}$ ,长时间间隔定义为${T}_{{\rm{L}}}$ ,长时间间隔${T}_{{\rm{L}}}=n{T}_{{\rm{s}}i}$ ,即把${T}_{{\rm{L}}}$ 等分为n个短间隔${T}_{{\rm{s}}i}:{T}_{{\rm{L}}}=\left\{{T}_{{\rm{s}}n}, {T}_{{\rm{s}}(n-1)},\cdots ,{T}_{{\rm{s}}1}\right\}$ 。长时数据的时间顺序为:${T}_{{\rm{s}}n}\to T_{{\rm{s}}{(n-1)}} \to \cdots \to T_{1}$ 。再把短时间间隔分为m个实时间隔$ \Delta T $ :${T}_{{\rm{s}}}=\left\{{\Delta T}_{m},{\Delta T}_{m-1},\cdots ,{\Delta T}_{1}\right\}$ ,短时数据的时间顺序为:${\Delta T}_{m}{\to \Delta T}_{m-1}\to \cdots \to \Delta T_{1}$ 。长时间间隔TL内采集的数据可以分析实时钻进参数的缓变状态,而短时间间隔可以分析实时钻进参数的突变动态特征。根据系统要求和现场条件对$ \Delta T $ 、${T}_{{\rm{s}}}、{T}_{{\rm{L}}}$ 进行取值。每一口地质钻井通过钻进监测系统记录的数据,数据量可能达到上万甚至十几万条,结合典型的实时数据类型6个输入参数(x1—x6)预测钻进事故和钻进质量是一个多变量非线性拟合问题。神经网络在求解类似问题时具有极高的精度,因此选择广泛使用的神经网络算法对钻进事故和钻进质量不足进行预测,神经网络包括3层,分别为输入层、隐含层和输出层,每一层都包含几个神经元,相邻层的神经元相互连接,但不在同一层。输入层和输出层的神经元数量分别等于输入变量和输出变量的数量,图4为所建立的神经网络预测模型拓扑结构示意图,图中的x1—x6为神经网络预测模型的输入层神经元,由实时数据中的6个参数组成,这些神经元不需要进行任何计算,只传递数据。h5—h10为预测模型的隐含层神经元,隐含层神经元不与外界直接连接,而是通过前面的输入层和后面的输出层与外界间接相连,图中只有一层隐含层共6个神经元,在实际建模过程中可以设置多个隐含层,也可根据情况调整隐含层神经元的个数。在隐含层中需要执行计算,将输入层传入的数据经过权值加和,并将加和结果通过隐含层中的激活函数进一步计算最终传到输出层。y1—y4为输出层神经元,即神经网络模型的最终预测结果,由隐含层计算结果进一步权值加和计算得到。

3)基于时序演进融合的钻进延时数据和迟到数据分析

需要进行时序演进融合的延时数据和迟到数据,主要包括随钻测量数据、钻井液监测数据、岩屑分析数据3类。随钻测量主要分为有线传输和无线传输,无线传输主要依靠泥浆连续波,而泥浆密度和固相含量决定了数据的传输速度。钻井液上返运动规律受自身流动特性控制,通过理论迟到时间公式[27]计算。与钻井液一起上返的岩屑,受孔底重复破碎和多相流中固体颗粒不断下沉作用的影响,导致迟到时间增加。其中下沉速度受岩屑的尺寸和形状影响,重复破碎的程度受钻压、钻头切削具磨损程度和钻井液的流速影响,相关指标可通过岩石机械破碎模型和多相环状流动模型获取。将钻进延时数据和迟到数据与实时数据进行比较,检测多参数异常,确定孔内地层、钻具和循环介质的工作状态,并将其作为钻孔可靠度判据,识别孔底出现非正常钻进的情况,及时预警可能出现的事故类型,并通过钻进可调整施工参数,在钻进过程中进行延时干预。岩心需要提钻采取,其信息在时间序列上是离散的,属于迟到数据,但是其提供的深度、地质信息和施工特征是确切的,将其作为延迟信息的时间端点和参照物,校准延时数据的时间序列,实现数据的演进融合。

2 基于数字孪生的智能钻探服务平台架构

数字孪生的智能钻探服务平台架构,基于信息技术和虚拟现实技术,在虚拟环境中真实还原实际钻探工作过程,通过实际钻进过程和虚拟仿真平台的双向映射、动态响应和时序数据交互,实现钻探过程的钻进参数优化、钻孔轨迹控制以及孔内事故预测处理等服务,从而实现智能钻进。

2.1 系统架构

在数字孪生五维结构的基础上[28],构建了基于数字孪生的智能钻探服务平台,如图5所示。平台可划分为设备物理层、虚拟模型层、数据处理层及钻探服务层。源于设备物理层的随钻测量数据通过数据处理层对数据进行统一处理得到时序数据,时序数据持续更新并聚合驱动虚拟模型层进行仿真和钻探服务层优化设计,所得的虚拟数据、仿真数据与随钻测量数据由神经网络算法进行融合,优化后的数据再次驱动各层平台运行并交互反馈,形成自适应循环,不断演进数字孪生模型,实现虚拟信息空间中钻进全过程模拟。

设备物理层:钻探过程涉及的物理主体,包括钻机、钻具、钻井液、钻进人员、钻进控制系统、钻进导向系统等,以及钻进过程所有活动集合,还包括能够进行时序数据采集和传输的井下有线测量传输装置、随钻测量无线传感器、泥浆脉冲发生器、射频识别读写器等功能部件。

虚拟模型层:主要指钻进过程虚拟仿真平台搭建,包括三维虚拟钻进过程模型构建以及力学模型构建。虚拟模型层构建的三维虚拟钻进过程模型是对实际孔内钻进过程全周期实现真实完整映射。力学模型包括钻孔周边围岩的THM(温度−渗流−应力)耦合演化模型[29],岩石−机械回转切削破碎模型[30],钻具组合动力模型[31],多相流异径环空流动模型[32]和孔壁泥皮时间固结模型[27]。

数据处理层:包括了钻进过程实时采集的动态数据及实际钻进与虚拟模型之间实时的交换数据以及各种算法模型。通过设备物理层采集的动态数据对虚拟模型进行修正,通过虚拟模型层模拟仿真实际运行情况并进行分析和优化,将优化数据反馈给物理实体层,使其对钻进参数、钻孔轨迹进行调节与修正。

钻探服务层:包括为钻进过程提供钻前钻进设计与风险评估、钻进场地虚拟布置、钻具组合选择等服务,钻中钻进参数优化、钻孔结构可视化、孔内事故监测、事故决策、钻探设备健康管理等服务,以及钻后案例分析及存储服务,从钻前、钻中、钻后整个钻进全周期实现复杂地层钻进智能服务。

2.2 运行流程

钻前阶段通过设备物理层和钻探服务层的交互实现钻井施工设计。当钻探服务平台接到一个设计任务(设计参数及相关地层条件等)时,钻探功能服务层中的钻进施工设计模块在对应的历史数据及其他关联数据的驱动下,进行井身结构、钻具及设备选择、钻井液设计及工艺参数等初始施工方案设计,从而指导设备物理层进行施工。而设备物理层将设备布设的实时数据发送到钻探功能服务层中继续进行虚拟机具装配,虚拟钻头选择,虚拟场地布设,并指导设备物理层进行相应修正,反复迭代后,获得最优的钻进设计方案。

钻中阶段是设备物理层、虚拟模型层与数据处理层的交互优化和迭代,包括以下3个部分。

1) 设备物理层与虚拟模型层交互实现全周期演化

钻孔在向地层深部延伸过程中,实体对象存在演化现象,主要表现为:(1)钻井液在上返过程中,伴随着孔深不断增大,孔内液柱压力增加,致使钻井液出现渗透−失水现象,在孔壁形成连续的泥皮结构。(2)孔底钻头上切削具的磨损,会导致钻孔的直径出现减小的情况,增加底部粗径钻具(岩心管)的磨损。(3)在地表钻机和钻杆自重的作用下,高速旋转的细长钻杆柱会在孔内呈现螺旋弯曲的状态,增大钻杆的磨损。基于设备物理层实时采集的钻进动态数据,赋予虚拟模型对应的演化状态,从而实现更高精度、高仿真度的虚拟模型构建。

2) 设备物理层与数据处理层交互实现全工况智能预测及事故预警

通过数据处理层的理论分析模型计算结果与设备物理层实测的数据进行比较,利用模式识别确定孔底钻进工况,分析动力输出与破碎过程的匹配程度,从钻孔倾斜、钻井液携带能力、孔内压力波动、钻具消耗等方面,进行钻孔事故的全工况智能预测及事故预警。

3) 虚拟模型层与设备物理层交互实现全参数优化控制

在虚拟模型层中进行钻进参数的调整与优化,尽量减少和避免孔内事故的发生,并将经过虚拟模型层优化的参数输入设备物理层中的钻进设备实现钻进过程的控制与修正。钻进参数分为实时调整参数和周期调整参数,实时调整参数主要是地表设备能够调节的输入参数,如地表钻压、主动钻杆转速、泵量等,而周期调整参数,如钻头磨损率等,以非实时可调整参数为主,这类参数无法通过地表设备进行实时调控,但可以实现孔内事故综合预测评判及钻进质量评价。

钻后阶段是虚拟模型层与钻探服务层的交互优化迭代,通过已采集钻进数据,精确分析不同井段、不同作业状态工作效率、反映作业整体状况、现场操作水平以及井下状况,提供后续钻进事故施工设计参考。通过相同井况条件下的参数对比分析,优化得到最佳的钻进施工方案,为区域其他钻进作业的优化提供依据。

基于数字孪生的复杂地层钻进智能服务平台运行流程如图6所示。

3 钻探数字孪生原型系统示例

在实验室条件下,利用Unity3D初步实现了数字孪生钻进设计原型系统,可以分别完成虚拟钻孔数字化设计、钻进过程孔内三维仿真和钻进参数实时虚拟监测与控制等功能。

3.1 钻孔数字虚拟化设计

根据地质条件(矿产种类、岩性、可钻性、松散性、漏失、膨胀性能等),施工环境要素(高程、水电条件、季节、风力等)及钻孔质量要求(取心率、钻孔倾斜、水文等),形成虚拟场景,设计钻孔结构,选取钻进方法,确定钻进设备,选取钻井液类型,套管下放深度和直径。根据数字化钻孔设计成果,选取钻机、泥浆泵、动力机和其他附属设备和钻塔,并实现地表钻进场地虚拟布置,包括虚拟搭设钻塔,布置钻场和各类机具,实现钻进设备交互性设备操作,如图7所示。

3.2 钻进过程孔底三维可视化

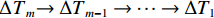

根据地层条件,再现钻孔的三维地质环境,对地质钻进实时数据监测情况,建立数字孪生模型,实现钻孔的三维可视化,并通过数据驱动实现实时地层钻进和虚拟地层钻进的一一对应,包括地层信息、钻孔轨迹、钻杆动力形态、孔底破碎过程及钻进速度的模拟仿真,钻机参数交互界面如图8所示,包含钻孔结构及钻进实时剖面结构。

3.3 钻进过程参数虚拟监测及控制

以钻进过程中钻杆发生屈曲导致岩心扰动明显过程为例,数字孪生模型根据实时数据动态还原虚拟孔底破碎过程,随着钻杆上部压力增大,钻杆柱呈现螺旋屈曲状态,加剧了钻具与孔壁之间的接触,岩心管在孔内出现不对称破碎情况下产生偏倒,孔底钻压降低,致使切削具无法有效刻入岩体产生体积破碎,破碎后的岩屑颗粒逐渐减小,钻进速度明显降低,钻进时间增长,进而导致岩心扰动明显,影响钻进质量,如图9所示为地下状态界面,涉及钻杆、岩心管及钻头状态,并实时显示设计与实际的钻压、转速及流量。

再通过钻进参数设计系统,对现有钻进过程参数进行调整,具体包括钻压、钻速和泵量,通过提供系统优化设计参数和常规经验设计参数2种模式对钻进参数进行控制优化。在系统优化设计参数模式下,系统根据当前井眼的地层对钻进参数进行优化设计,常规设计参数则直接根据相关规范进行计算,钻进参数设计系统界面如图10所示,涉及井身结构分段和钻进参数计算。

4 结 论

a. 采用数字孪生技术,提出了基于时序数据驱动的地质钻探数字孪生模型体系构建方法,构建了数字孪生智能钻探全周期服务平台。

b. 开发了数字孪生智能钻进原型系统,实现了钻前设备的数字化设计、钻进过程孔内三维可视化和钻进过程参数实时监测与控制的功能。

c. 数字孪生智能钻进技术为复杂地质条件下智能化钻进、无人值守钻进的早日实现提供了全新的路径和方法,加强其在我国多种复杂地质条件下煤炭、石油、天然气、页岩气等钻探领域的工程现场应用及进一步验证服务平台可靠性将是下一步工作的主要研究方向。

-

表 1 参数信息

Table 1 Drilling parameters

数据类型 参数名称 事前数据 井眼位置、深度、井径 实时数据 转速、钻压、泵压、泵量、提升力、钻时 延时数据 钻速、扭矩、钻柱振动、钻井液入口温度、

钻井液出口温度迟到数据 岩性、岩屑粒径、钻头内排磨损分级、

钻头外排磨损分级表 2 典型钻进工况的时序数据及特征变化趋势

Table 2 Time series data and characteristic change trend of typical drilling conditions

典型工况 实时数据特征 延时数据特征 迟到数据特征 钻进事故 断钻 钻压突变

泵压下降

转速快扭矩突降 岩性变硬 钻具变形 钻压降低

钻时增大钻柱振动增大 岩屑粒径减小

钻头磨损增大卡钻 泵压增大

提升力增大钻柱振动减弱 岩屑比例降低 埋钻 提升力下降

泵压增大钻柱振动减弱 岩屑粒径变大 烧钻 泵压增大

泵量增大钻井液升温

振动减弱岩性变软

钻头磨损率高钻进质量不足 取心率不足 钻时增大 钻柱振动增大 岩屑减少 钻进速度慢 转速降低

钻压增大钻速降低 钻头磨损率增大 -

[1] 习近平. 为建设世界科技强国而奋斗[EB/OL]. (2016-05-31) [2023-07-04]. http://www.xinhuanet.com/politics/2016–05/31/c_11189651.htm. [2] 姚宁平,王毅,姚亚峰,等. 我国煤矿井下复杂地质条件下钻探技术与装备进展[J]. 煤田地质与勘探,2020,48(2):1−7. DOI: 10.3969/j.issn.1001-1986.2020.02.001 YAO Ningping,WANG Yi,YAO Yafeng,et al. Progress of drilling technologies and equipment for complicated geological conditions in underground coal mines in China[J]. Coal Geology & Exploration,2020,48(2):1−7. DOI: 10.3969/j.issn.1001-1986.2020.02.001

[3] 邓理,李黔,高自力. 岩石可钻性评价方法研究新进展[J]. 钻采工艺,2007,30(6):27−29. DOI: 10.3969/j.issn.1006-768X.2007.06.011 DENG Li,LI Qian,GAO Zili. New evaluation method of rock drillability[J]. Drilling & Production Technology,2007,30(6):27−29. DOI: 10.3969/j.issn.1006-768X.2007.06.011

[4] 李士斌,闫铁,李玮. 地层岩石可钻性的分形表示方法[J]. 石油学报,2006,27(1):124−127. DOI: 10.3321/j.issn:0253-2697.2006.01.027 LI Shibin,YAN Tie,LI Wei. Fractal representation of rock drillability[J]. Acta Petrolei Sinica,2006,27(1):124−127. DOI: 10.3321/j.issn:0253-2697.2006.01.027

[5] 林海飞,刘时豪,周捷,等. 基于STL-EEMD-GA-SVR的采煤工作面瓦斯涌出量预测方法及应用[J]. 煤田地质与勘探,2022,50(12):131−141. DOI: 10.12363/issn.1001-1986.22.04.0218 LIN Haifei,LIU Shihao,ZHOU Jie,et al. Prediction method and application of gas emission from mining workface based on STL-EEMD-GA-SVR[J]. Coal Geology & Exploration,2022,50(12):131−141. DOI: 10.12363/issn.1001-1986.22.04.0218

[6] 范海鹏,吴敏,曹卫华,等. 基于钻进状态监测的智能工况识别[J]. 探矿工程(岩土钻掘工程),2020,47(4):106−113. FAN Haipeng,WU Min,CAO Weihua,et al. Intelligent drilling mode identification based on drilling state monitoring while drilling[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2020,47(4):106−113.

[7] HEGDE C,GRAY K. Evaluation of coupled machine learning models for drilling optimization[J]. Journal of Natural Gas Science and Engineering,2018,56:397−407. DOI: 10.1016/j.jngse.2018.06.006

[8] GAN Chao,CAO Weihua,WU Min,et al. Two–level intelligent modeling method for the rate of penetration in complex geological drilling process[J]. Applied Soft Computing,2019,80:592−602. DOI: 10.1016/j.asoc.2019.04.020

[9] 崔凤新,廖明燕. 基于数据融合技术的钻井过程故障诊断[J]. 石油矿场机械,2008,37(12):7−11. DOI: 10.3969/j.issn.1001-3482.2008.12.003 CUI Fengxin,LIAO Mingyan. Drilling fault diagnosis based on data fusion technology[J]. Oil Field Equipment,2008,37(12):7−11. DOI: 10.3969/j.issn.1001-3482.2008.12.003

[10] 刘若君,张幼振,姚克. 基于T-S模糊故障树的煤矿坑道钻机液压动力系统故障诊断研究[J]. 煤田地质与勘探,2022,50(12):194−202. DOI: 10.12363/issn.1001-1986.22.06.0478 LIU Ruojun,ZHANG Youzhen,YAO Ke. Fault diagnosis of hydraulic power system for coal mine tunnel drilling rig based on T-S fuzzy fault tree[J]. Coal Geology & Exploration,2022,50(12):194−202. DOI: 10.12363/issn.1001-1986.22.06.0478

[11] WILLERSRUD A,BLANKE M,IMSLAND L,et al. Fault diagnosis of downhole drilling incidents using adaptive observers and statistical change detection[J]. Journal of Process Control,2015,30:90−103. DOI: 10.1016/j.jprocont.2014.12.010

[12] KOR K,ERTEKIN S,YAMANLAR S,et al. Penetration rate prediction in heterogeneous formations:A geomechanical approach through machine learning[J]. Journal of Petroleum Science & Engineering,2021,207:109138.

[13] GAN Chao,CAO Weihua,WU Min,et al. Prediction of drilling rate of penetration (ROP) using hybrid support vector regression:A case study on the Shennongjia Area,central China[J]. Journal of Petroleum Science and Engineering,2019,181:106200. DOI: 10.1016/j.petrol.2019.106200

[14] LI Yupeng,CAO Weihua,HU Wenkai,et al. Diagnosis of downhole incidents for geological drilling processes using multi–time scale feature extraction and probabilistic neural networks[J]. Process Safety and Environmental Protection,2020,137:106−115. DOI: 10.1016/j.psep.2020.02.014

[15] 李鹏,程建远. 基于微服务的地质保障系统架构与应用[J]. 煤田地质与勘探,2022,50(1):118−127. DOI: 10.12363/issn.1001-1986.21.11.0632 LI Peng,CHENG Jianyuan. Design and implementation of the geological guarantee system architecture based on microservices[J]. Coal Geology & Exploration,2022,50(1):118−127. DOI: 10.12363/issn.1001-1986.21.11.0632

[16] TAO Fei,QI Qinglin. Make more digital twins[J]. Nature,2019,573(7775):490−491. DOI: 10.1038/d41586-019-02849-1

[17] 方鹏,姚克,王龙鹏,等. ZDY25000LDK智能化定向钻进装备关键技术研究[J]. 煤田地质与勘探,2022,50(1):72−79. DOI: 10.12363/issn.1001-1986.21.10.0597 FANG Peng,YAO Ke,WANG Longpeng,et al. Research on key technologies of the ZDY25000LDK intelligent directional drilling equipment[J]. Coal Geology & Exploration,2022,50(1):72−79. DOI: 10.12363/issn.1001-1986.21.10.0597

[18] 向峰,黄圆圆,张智,等. 基于数字孪生的产品生命周期绿色制造新模式[J]. 计算机集成制造系统,2019,25(6):1505−1514. DOI: 10.13196/j.cims.2019.06.018 XIANG Feng,HUANG Yuanyuan,ZHANG Zhi,et al. New paradigm of green manufacturing for product life cycle based on digital twin[J]. Computer Integrated Manufacturing Systems,2019,25(6):1505−1514. DOI: 10.13196/j.cims.2019.06.018

[19] 孙惠斌,潘军林,张纪铎,等. 面向切削过程的刀具数字孪生模型[J]. 计算机集成制造系统,2019,25(6):1474−1480. DOI: 10.13196/j.cims.2019.06.015 SUN Huibin,PAN Junlin,ZHANG Jiduo,et al. Digital twin model for cutting tools in machining process[J]. Computer Integrated Manufacturing Systems,2019,25(6):1474−1480. DOI: 10.13196/j.cims.2019.06.015

[20] 王天龙,马斌,董洪波. 煤矿用自动化钻机远程监测系统研制[J]. 煤田地质与勘探,2022,50(1):80−85. DOI: 10.12363/issn.1001-1986.21.12.0723 WANG Tianlong,MA Bin,DONG Hongbo. Development of a remote monitoring system for coal mine automatic drilling rigs[J]. Coal Geology & Exploration,2022,50(1):80−85. DOI: 10.12363/issn.1001-1986.21.12.0723

[21] 张连超,刘蔚然,程江峰,等. 卫星总装数字孪生车间物料准时配送方法[J]. 计算机集成制造系统,2020,26(11):2897−2914. DOI: 10.13196/j.cims.2020.11.001 ZHANG Lianchao,LIU Weiran,CHENG Jiangfeng,et al. Just–in–time material distribution method for satellite assembly digital twin shop–floor[J]. Computer Integrated Manufacturing Systems,2020,26(11):2897−2914. DOI: 10.13196/j.cims.2020.11.001

[22] 王建军,向永清,何正文. 基于数字孪生的航天器系统工程模型与实现[J]. 计算机集成制造系统,2019,25(6):1348−1360. DOI: 10.13196/j.cims.2019.06.004 WANG Jianjun,XIANG Yongqing,HE Zhengwen. Models and implementation of digital twin based spacecraft system engineering[J]. Computer Integrated Manufacturing Systems,2019,25(6):1348−1360. DOI: 10.13196/j.cims.2019.06.004

[23] 金杰,夏超,肖士利,等. 基于数字孪生的火箭起飞安全系统设计[J]. 计算机集成制造系统,2019,25(6):1337−1347. DOI: 10.13196/j.cims.2019.06.003 JIN Jie,XIA Chao,XIAO Shili,et al. Rocket launch safety system design scheme based on digital twins[J]. Computer Integrated Manufacturing Systems,2019,25(6):1337−1347. DOI: 10.13196/j.cims.2019.06.003

[24] 王国法,张建中,薛国华,等. 煤矿回采工作面智能地质保障技术进展与思考[J]. 煤田地质与勘探,2023,51(2):12−26. DOI: 10.12363/issn.1001-1986.23.02.0062 WANG Guofa,ZHANG Jianzhong,XUE Guohua,et al. Progress and reflection of intelligent geological guarantee technology in coal mining face[J]. Coal Geology & amp; Exploration,2023,51(2):12−26. DOI: 10.12363/issn.1001-1986.23.02.0062

[25] 葛世荣,张帆,王世博,等. 数字孪生智采工作面技术架构研究[J]. 煤炭学报,2020,45(6):1925−1936. DOI: 10.13225/j.cnki.jccs.ZN20.0327 GE Shirong,ZHANG Fan,WANG Shibo,et al. Digital twin for smart coal mining workface:Technological frame and construction[J]. Journal of China Coal Society,2020,45(6):1925−1936. DOI: 10.13225/j.cnki.jccs.ZN20.0327

[26] 龚晓燕,雷可凡,吴群英,等. 数字孪生驱动的掘进工作面出风口风流智能调控系统[J]. 煤炭学报,2021,46(4):1331−1340. DOI: 10.13225/j.cnki.jccs.2020.0963 GONG Xiaoyan,LEI Kefan,WU Qunying,et al. Digital twin driven airflow intelligent control system for the air outlet of heading face[J]. Journal of China Coal Society,2021,46(4):1331−1340. DOI: 10.13225/j.cnki.jccs.2020.0963

[27] 鄢泰宁, 胡郁乐, 张涛. 检测技术及钻井仪表[M]. 武汉: 中国地质大学出版社, 2009. [28] 余斌,朱伟佳. 石化行业数字孪生技术的应用探索[J]. 化工进展,2019,38(增刊1):278−282. DOI: 10.16085/j.issn.1000-6613.2019-1205 YU Bin,ZHU Weijia. Application exploration of digital twin technology in petrochemical industry[J]. Chemical Industry and Engineering Progress,2019,38(Sup.1):278−282. DOI: 10.16085/j.issn.1000-6613.2019-1205

[29] 唐江涛,邓兆俊,覃羡安,等. 基于地质模型快速构建的边坡三维稳定性分析[J]. 地质与勘探,2021,57(1):175−183. DOI: 10.12134/j.dzykt.2021.01.016 TANG Jiangtao,DENG Zhaojun,QIN Xian’an,et al. Three-dimensional slope stability analysis based on rapid construction of geological model[J]. Geology and Exploration,2021,57(1):175−183. DOI: 10.12134/j.dzykt.2021.01.016

[30] 于永平, 孙友宏. 数值与解析逼近方法在钻柱系统稳定性分析中的应用[M]. 北京: 科学出版社, 2017. [31] 豆旭谦,姚宁平,李秀山,等. 基于单柱齿破岩过程的高压液动冲击回转钻进试验研究[J]. 煤田地质与勘探,2022,50(12):170−176. DOI: 10.12363/issn.1001-1986.22.03.0165 DOU Xuqian,YAO Ningping,LI Xiushan,et al. Experimental study on high-pressure hydraulic percussive rotary drilling based on single-tooth rock-breaking process[J]. Coal Geology & Exploration,2022,50(12):170−176. DOI: 10.12363/issn.1001-1986.22.03.0165

[32] 汤凤林, A. T. 加里宁, 段隆臣. 岩心钻探学[M]. 武汉: 中国地质大学出版社, 2009. -

期刊类型引用(6)

1. 赵贵征,张凤喜,成艳. 浅谈AIGC在油气勘探开发中的应用. 中国石油和化工标准与质量. 2025(01): 102-104 .  百度学术

百度学术

2. 王清峰,刘洋,陈航,史书翰,崔小超. 煤矿井下钻进工况参数智能控制技术发展与展望. 矿业安全与环保. 2025(01): 20-29 .  百度学术

百度学术

3. 胥知画,姜杰,周长春,李谦,任军. 基于粒子群优化的融合特征选择钻速预测模型研究. 钻探工程. 2025(02): 134-143 .  百度学术

百度学术

4. 张媛. 基于数字孪生技术的钻井工程智能作业支持系统的设计. 信息系统工程. 2024(04): 4-7 .  百度学术

百度学术

5. 林伯韬,朱海涛,金衍,张家豪,韩雪银. 油气钻采数字孪生模型构建方法及应用案例. 石油科学通报. 2024(02): 282-296 .  百度学术

百度学术

6. 王钧泽,李黔,尹虎. 基于数字孪生技术的钻井复杂风险智能预警系统架构. 石油钻探技术. 2024(05): 154-162 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: