Resistivity detection and its application in underground coal mine directional boreholes

-

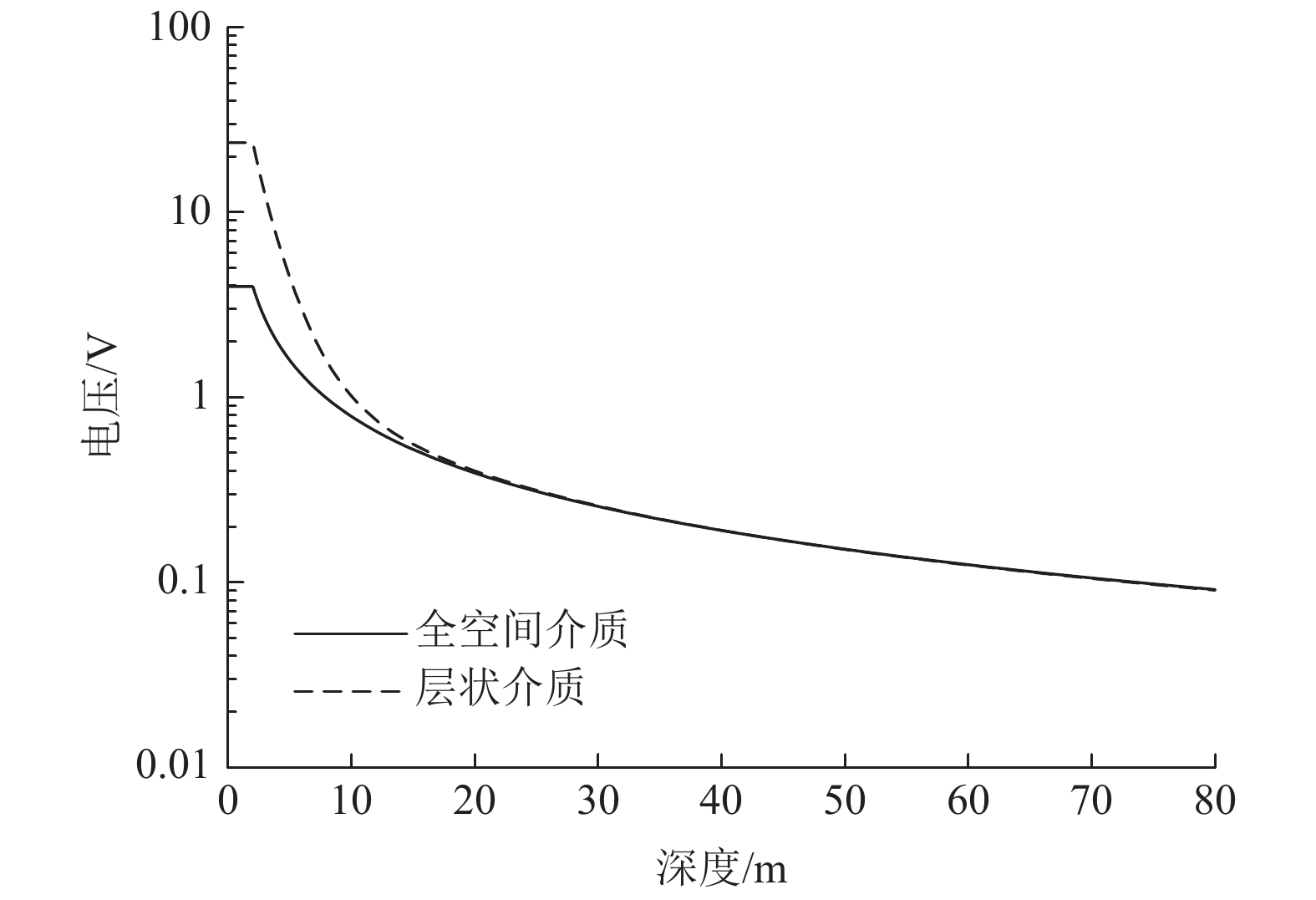

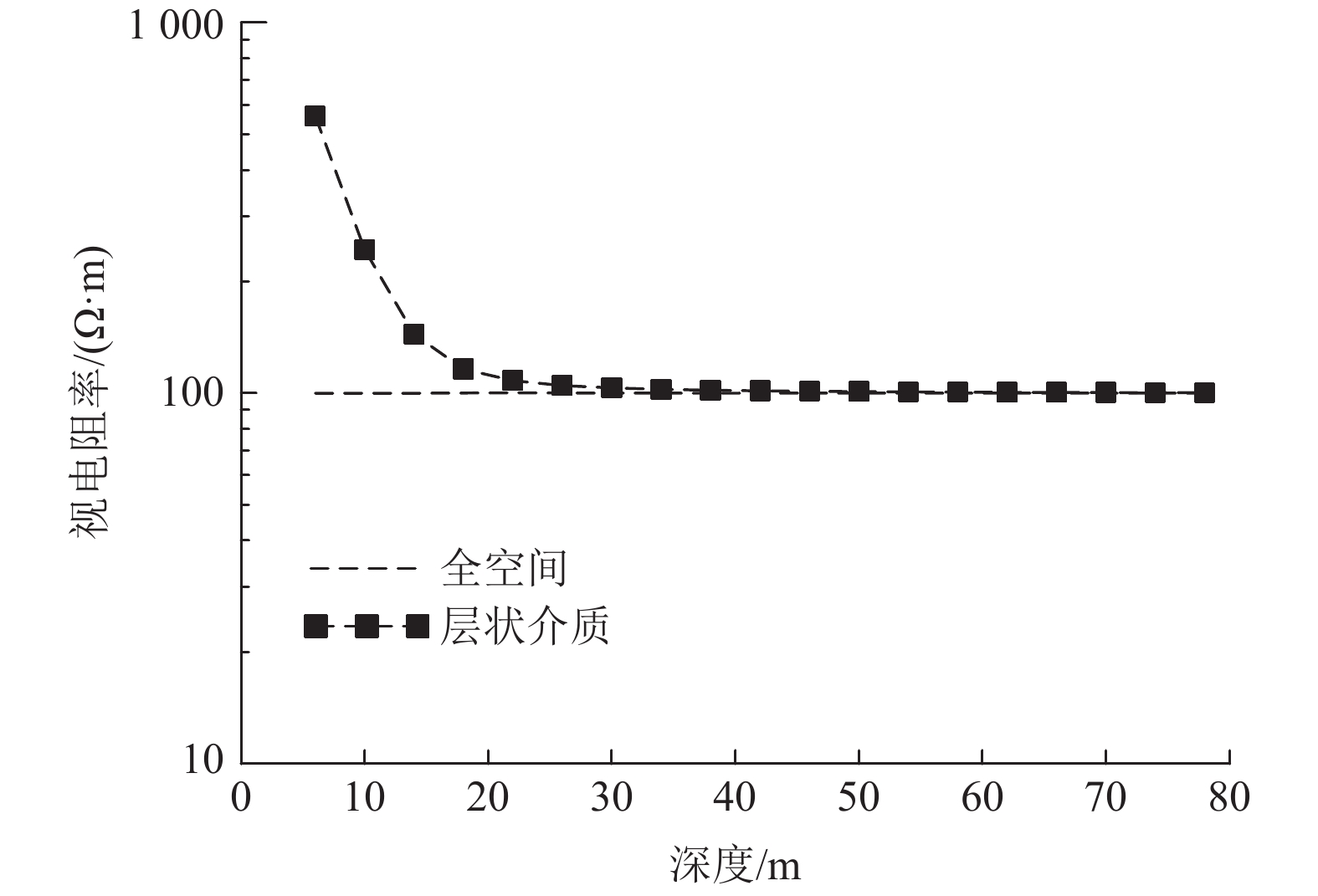

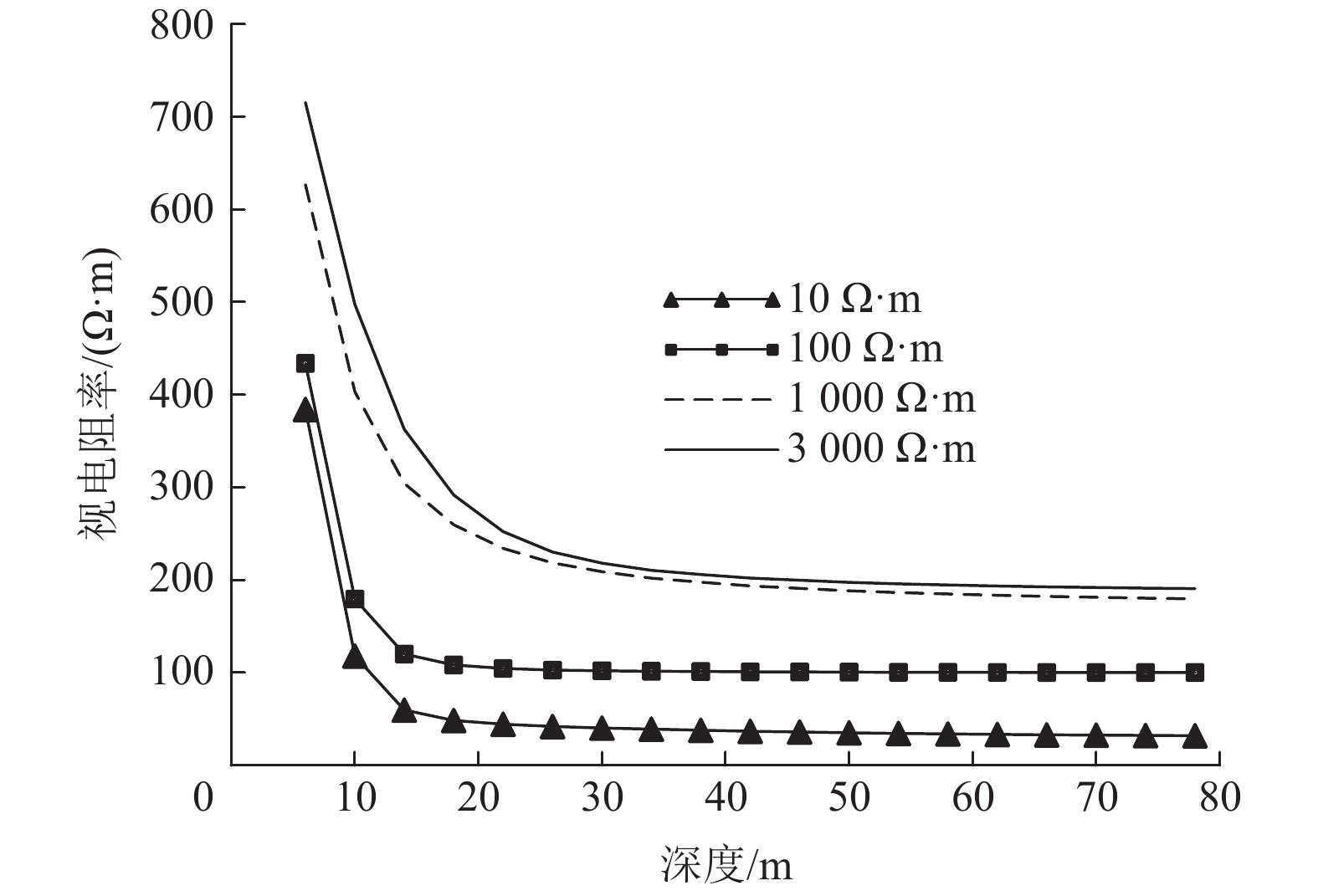

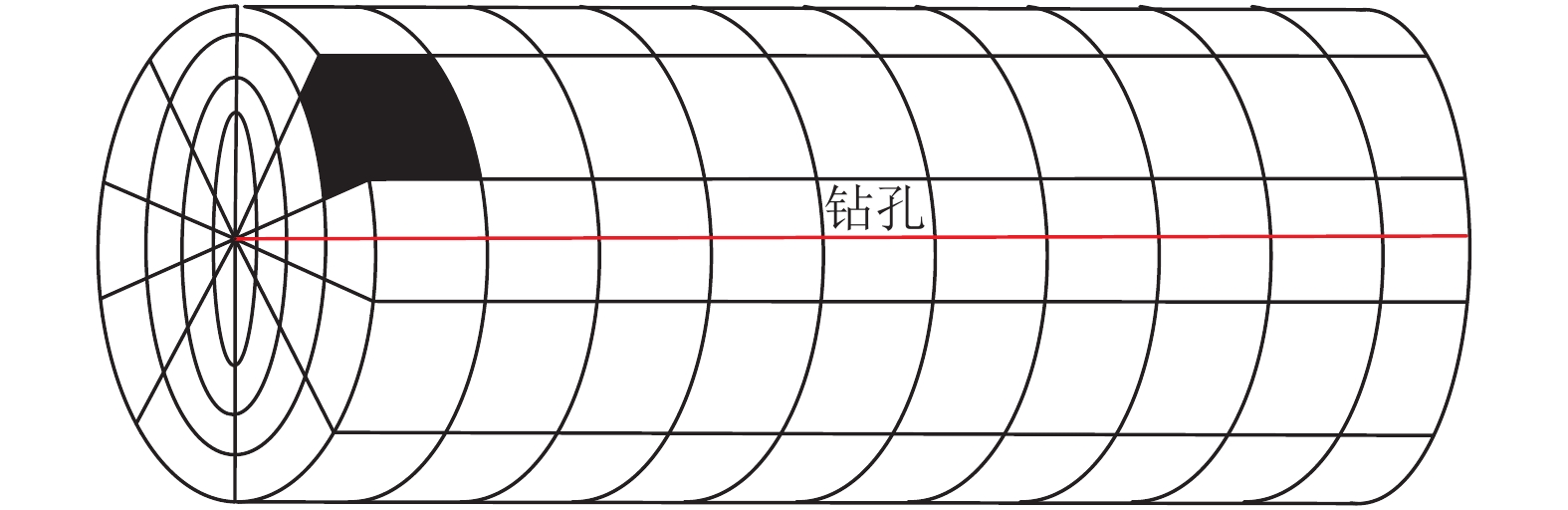

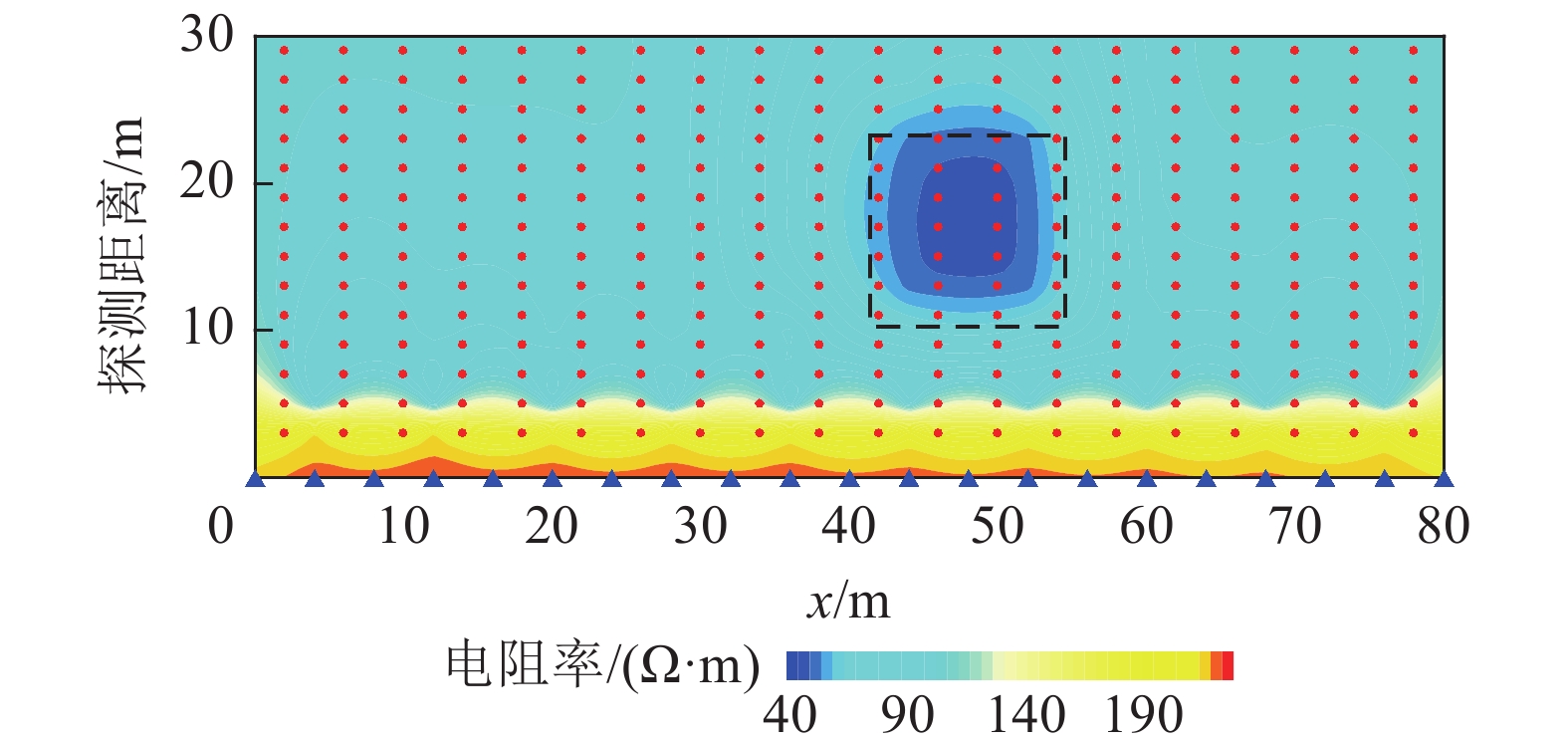

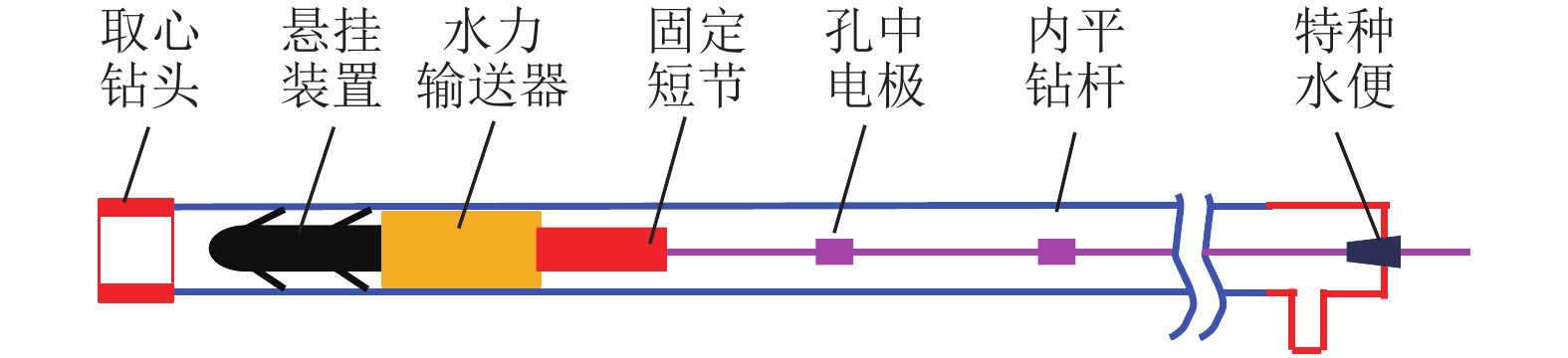

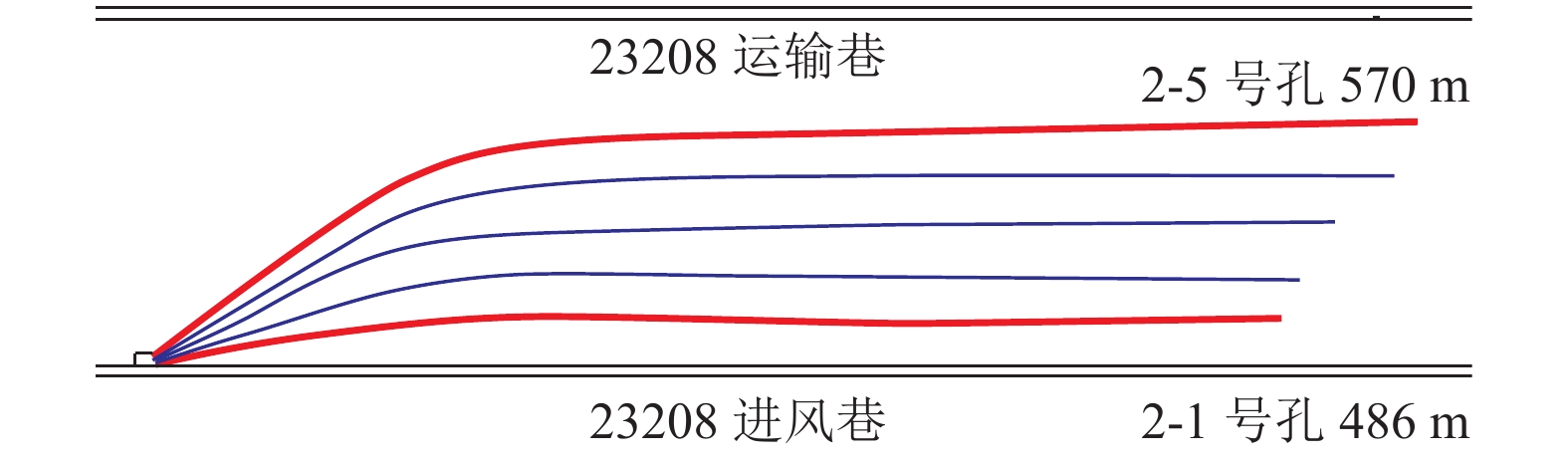

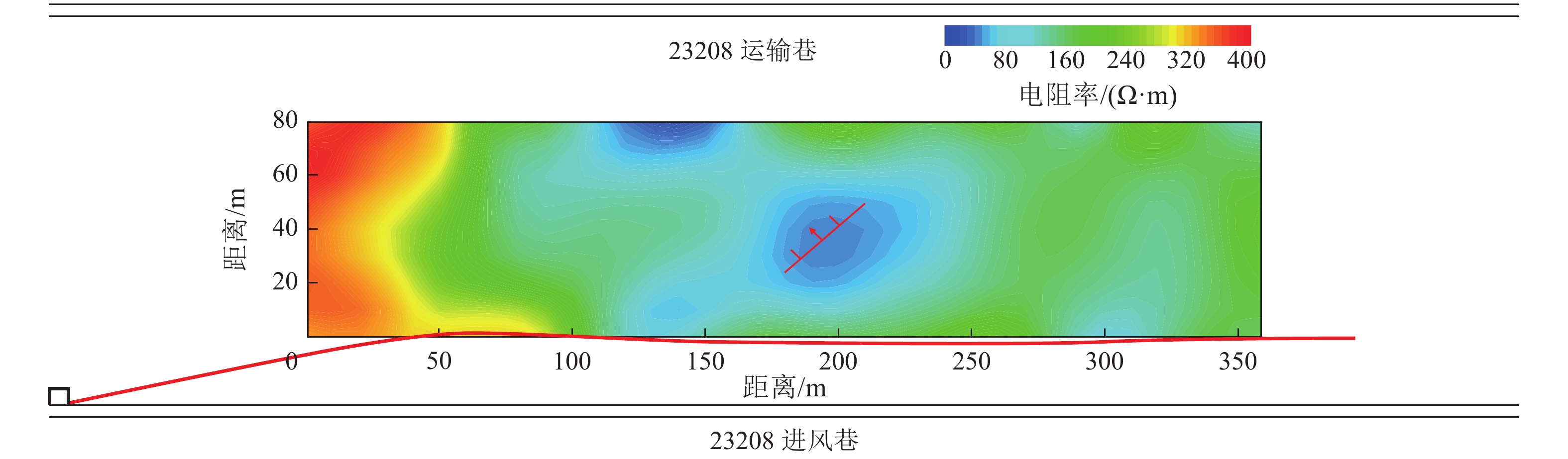

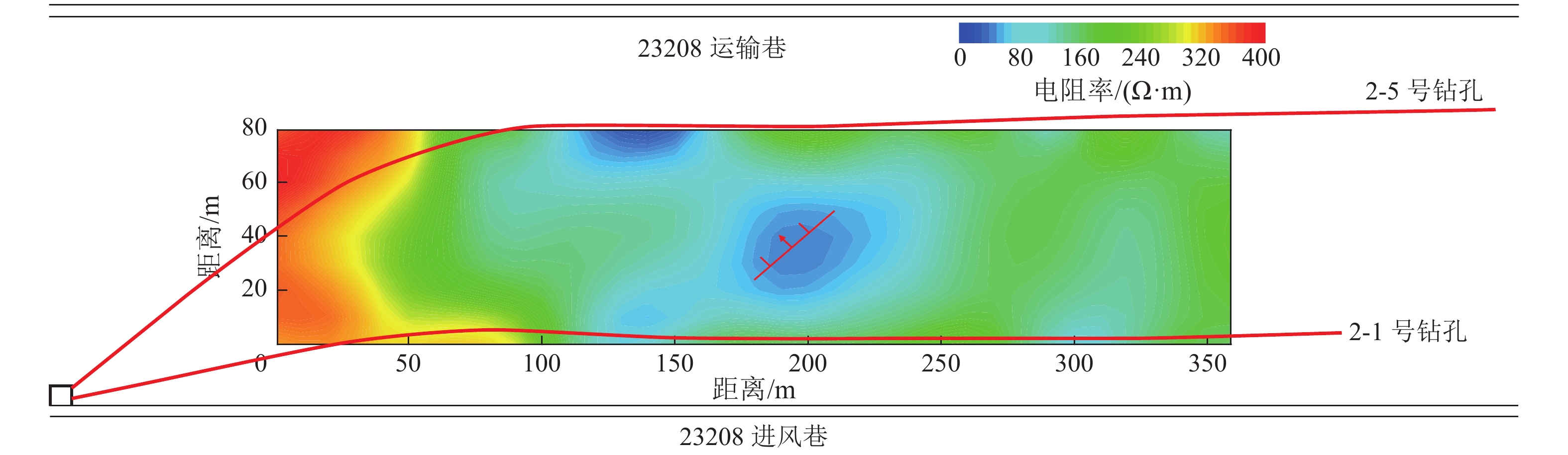

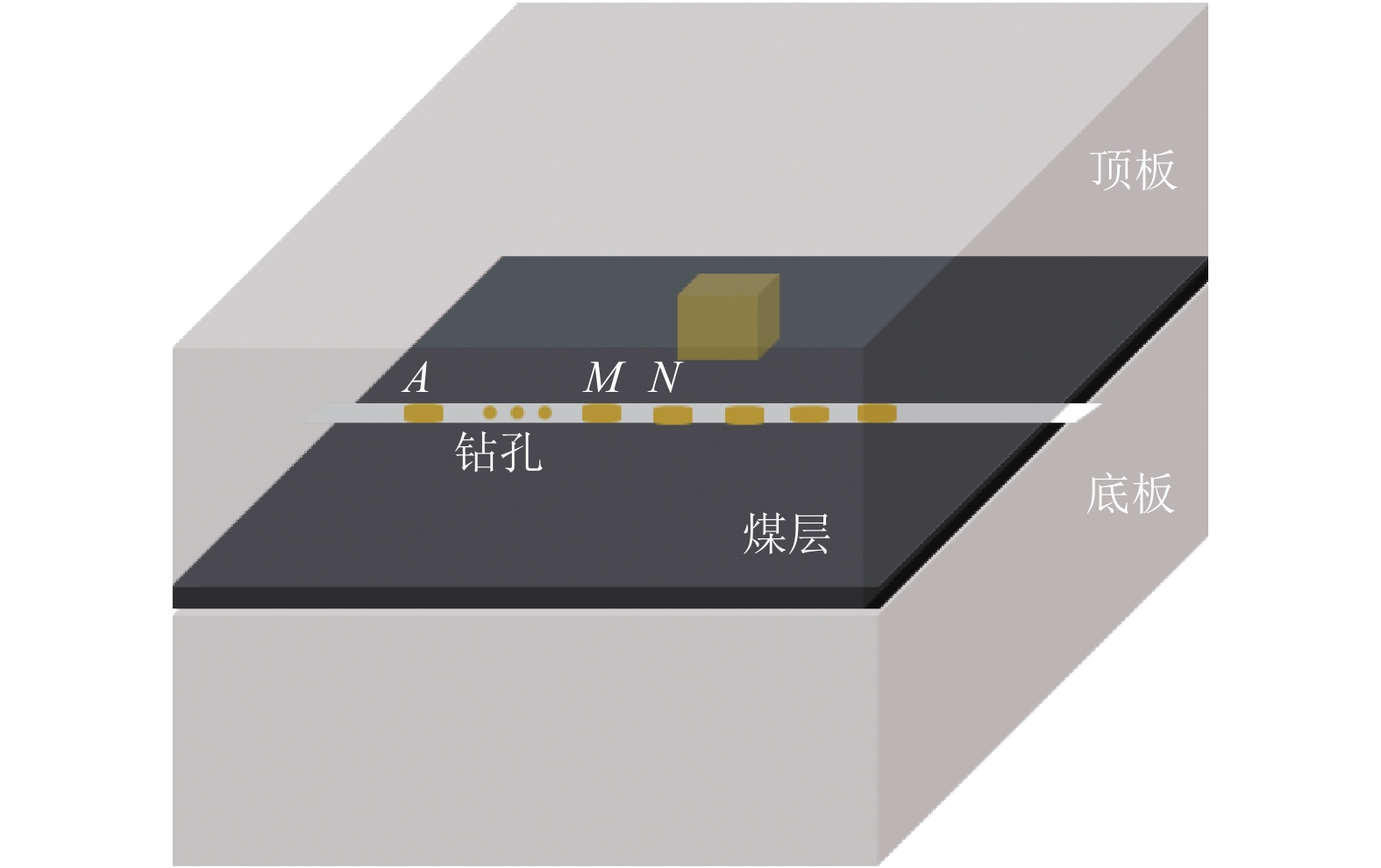

摘要: 受高瓦斯/承压奥灰水威胁的工作面开采前,一般采取定向钻进技术在工作面底板开展压裂或注浆工程保障开采安全。利用底板定向钻孔开展孔中探测工作,可更加精细揭露工作面内隐伏构造,还可实现“一孔多用”。为解决定向钻孔内的探测问题,提出一种在水平定向钻孔中进行直流电阻率法探查的方法。定向钻孔施工完毕后,退出定向钻孔施工的通缆钻杆,送入内平钻杆,将孔中高密度电缆通过钻杆尾端特制水便送入钻孔,使孔中电缆平铺于钻孔中,在定向钻孔水平段,进行孔内直流电阻率法径向探测。在理论上通过数值模拟研究层状介质下单孔测量工作模式的接收信号衰减规律、视电阻率曲线变化特征、顶底板岩性对测量结果的影响等,并采用单孔测量数据对孔旁异常范围进行反演定位。数值模拟研究表明,孔中电阻率探测方法对隐伏的异常体有良好的探测效果。通过在陕西韩城某矿井下实际煤层底板探测试验,对研究区2个定向抽采钻孔孔中探测数据进行处理,反演结果异常区与工作面内隐伏小断层位置吻合,验证了定向钻孔中电缆布置的可行性和定向钻孔内通过孔内径向和孔间透视探测隐伏构造的可靠性。Abstract: The working face threatened by high gas or Ordovician limestone water pressure generally adopts directional drilling technology to carry out fracturing or grouting works at the bottom of the working face before mining to ensure the safety of mining. In-hole probing in directional boreholes in the bottom plate can reveal the hidden structures in the working face in a more detailed way, and can also realize “one hole for multiple uses”. In order to solve the detection problem in the directional drilling, a method of DC resistivity detection in the horizontal directional drilling is proposed. To solve the problem of detection in directional hole, a method of direct current detection in horizontal directional drilling is proposed. After the completion of directional drilling, exit the cable drill pipe of directional drilling and send it into the inner flat drill pipe. Sent the high-density cable of the hole into the drill hole through the special water supply device at the end of the drill pipe, so that the cable in the hole is laid flat in the drill hole. Through numerical simulation, the attenuation law of the received signal, the variation characteristics of the apparent resistivity curve, and the influence of roof and floor lithology on the measurement results of the working mode of single-hole measurement in layered media are studied, and the anomaly range near the hole is inverted by using the single-hole measurement data. In the horizontal section of the directional drilling, radial detection by direct current method in the hole is carried out. Numerical simulation results show that the resistivity detection method is effective in detecting concealed abnormal bodies. Through the actual coal seam floor detection test in a mine in Hancheng, Shaanxi Province, the data processing results of two directional extraction boreholes in the study area show that the anomaly area of inversion is consistent with the location of hidden small faults in the working face; the feasibility of cable arrangement in directional borehole and the reliability of radial/perspective detection of concealed structure in directional borehole are verified.

-

-

-

[1] 吴荣新,张平松,刘盛东,等. 矿井工作面无线电波透视“一发双收”探测与应用[J]. 煤炭学报,2010,35(增刊1):170−174. WU Rongxin,ZHANG Pingsong,LIU Shengdong,et al. Radio wave penetration by the device of one−transmitter and two−receivers for coal face and its application[J]. Journal of China Coal Society,2010,35(Sup.1):170−174.

[2] 姬广忠,程建远,胡继武,等. 槽波衰减系数成像方法及其应用[J]. 煤炭学报,2014,39(增刊2):471−475. JI Guangzhong,CHENG Jianyuan,HU Jiwu,et al. In−seam wave imaging using attenuation coefficient:Method and application[J]. Journal of China Coal Society,2014,39(Sup.2):471−475.

[3] 高致宏,王彦红,陈青峰. 工作面富水区探测与矿井电法: 音频电透视在工作面富水区探测中的应用效果[J]. 煤田地质与勘探,2002,30(4):51−54. DOI: 10.3969/j.issn.1001-1986.2002.04.019 GAO Zhihong,WANG Yanhong,CHEN Qingfeng. Surveying the water–full situation in work face and mine electric method:An application example using electric audio−clarivoyant method[J]. Coal Geology & Exploration,2002,30(4):51−54. DOI: 10.3969/j.issn.1001-1986.2002.04.019

[4] 韩德品,李丹,程九龙,等. 超前探测灾害性含导水地质构造的直流电法[J]. 煤炭学报,2010,35(4):635−639. HAN Depin,LI Dan,CHENG Jiulong,et al. DC method of advanced detecting disastrous water conducting or water bearing geological structures along same layer[J]. Journal of China Coal Society,2010,35(4):635−639.

[5] 李术才,苏茂鑫,薛翊国,等. 城市地铁跨孔电阻率CT超前地质预报方法研究[J]. 岩石力学与工程学报,2014,33(5):913−920. LI Shucai,SU Maoxin,XUE Yiguo,et al. Study on computed tomography of cross–hole resistivity in urban subway geological prediction[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(5):913−920.

[6] 刘征宇,李术才,刘斌,等. 用于地铁盾构区间孤石探测的三维电阻率跨孔CT方法研究及物理模型试验[J]. 岩石力学与工程学报,2015,34(12):2519−2530. LIU Zhengyu,LI Shucai,LIU Bin,et al. Boulder detection method based on 3D resistivity cross–hole tomography in metro shield zones and its physical model experimental study[J]. Chinese Journal of Rock Mechanics and Engineering,2015,34(12):2519−2530.

[7] 张平松,刘盛东,吴荣新,等. 采煤面覆岩变形与破坏立体电法动态测试[J]. 岩石力学与工程学报,2009,28(9):1870−1875. DOI: 10.3321/j.issn:1000-6915.2009.09.019 ZHANG Pingsong,LIU Shengdong,WU Rongxin,et al. Dynamic detection of overburden deformation and failure in mining workface by 3D resistivity method[J]. Chinese Journal of Rock Mechanics and Engineering,2009,28(9):1870−1875. DOI: 10.3321/j.issn:1000-6915.2009.09.019

[8] 张群,葛春贵,李伟,等. 碎软低渗煤层顶板水平井分段压裂煤层气高效抽采模式[J]. 煤炭学报,2018,43(1):150−159. ZHANG Qun,GE Chungui,LI Wei,et al. A new model and application of coalbed methane high efficiency production from broken soft and low permeable coal seam by roof strata in horizontal well and staged hydraulic fracture[J]. Journal of China Coal Society,2018,43(1):150−159.

[9] 李彬刚. 芦岭煤矿碎软低渗煤层高效抽采技术[J]. 煤田地质与勘探,2017,45(4):81−84. DOI: 10.3969/j.issn.1001-1986.2017.04.014 LI Bingang. Technology of CBM extraction in the crushed and soft coal seam in Luling coal mine[J]. Coal Geology & Exploration,2017,45(4):81−84. DOI: 10.3969/j.issn.1001-1986.2017.04.014

[10] 赵庆彪. 奥灰岩溶水害区域超前治理技术研究及应用[J]. 煤炭学报,2014,39(6):1112−1117. ZHAO Qingbiao. Ordovician limestone karst water disaster regional advanced governance technology study and application[J]. Journal of China Coal Society,2014,39(6):1112−1117.

[11] 赵兵文,关永强. 大采深矿井高承压奥灰岩溶水综合治理技术[J]. 煤炭科学技术,2013,41(9):75−78. ZHAO Bingwen,GUAN Yongqiang. Comprehensive treatment technology of high pressure–bearing Ordovician limestone karst water in large mining depth mine[J]. Coal Science and Technology,2013,41(9):75−78.

[12] 阮百尧,熊彬. 电导率连续变化的三维电阻率测深有限元模拟[J]. 地球物理学报,2002,45(1):131−138. DOI: 10.3321/j.issn:0001-5733.2002.01.016 RUAN Baiyao,XIONG Bin. A finite element modeling of three−dimensional resistivity sounding with continuous conductivity[J]. Chinese Journal of Geophysics,2002,45(1):131−138. DOI: 10.3321/j.issn:0001-5733.2002.01.016

[13] 黄俊革,王家林,阮百尧. 坑道直流电阻率法超前探测研究[J]. 地球物理学报,2006,49(5):1529−1538. DOI: 10.3321/j.issn:0001-5733.2006.05.035 HUANG Junge,WANG Jialin,RUAN Baiyao. A study on advanced detection using DC resistivity method in tunnel[J]. Chinese Journal of Geophysics,2006,49(5):1529−1538. DOI: 10.3321/j.issn:0001-5733.2006.05.035

[14] 黄俊革,阮百尧,王家林. 坑道直流电阻率法超前探测的快速反演[J]. 地球物理学报,2007,50(2):619−624. DOI: 10.3321/j.issn:0001-5733.2007.02.037 HUANG Junge,RUAN Baiyao,WANG Jialin. The fast inversion for advanced detection using DC resistivity in tunnel[J]. Chinese Journal of Geophysics,2007,50(2):619−624. DOI: 10.3321/j.issn:0001-5733.2007.02.037

[15] 曹权,项伟,贾海梁,等. 跨孔超高密度电阻率法在球状风化花岗岩体探测中的应用[J]. 工程地质学报,2013,21(5):730−735. DOI: 10.3969/j.issn.1004-9665.2013.05.009 CAO Quan,XIANG Wei,JIA Hailiang,et al. Application of cross−hole ultra−density resistivity method to detection of spherically weathered granite[J]. Journal of Engineering Geology,2013,21(5):730−735. DOI: 10.3969/j.issn.1004-9665.2013.05.009

[16] 王刚,周启友,吴世艳,等. 二维孔间电阻率成像中钻孔效应[J]. 地球物理学进展,2011,26(1):311−319. DOI: 10.3969/j.issn.1004-2903.2011.01.037 WANG Gang,ZHOU Qiyou,WU Shiyan,et al. Borehole effects of two dimensional cross−borehole ERT[J]. Progress in Geophysics,2011,26(1):311−319. DOI: 10.3969/j.issn.1004-2903.2011.01.037

-

期刊类型引用(2)

1. 文国军,黄子恒,王玉丹,史垚城,姜宇昊. 基于仿真数据驱动的激光钻进气体喷嘴结构优化. 钻探工程. 2024(03): 69-75 .  百度学术

百度学术

2. 刘旭堂,黄梦婕,王伟. 机械式激光窗口结构设计与防尘罩抗风载能力研究. 四川轻化工大学学报(自然科学版). 2022(01): 59-66 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: